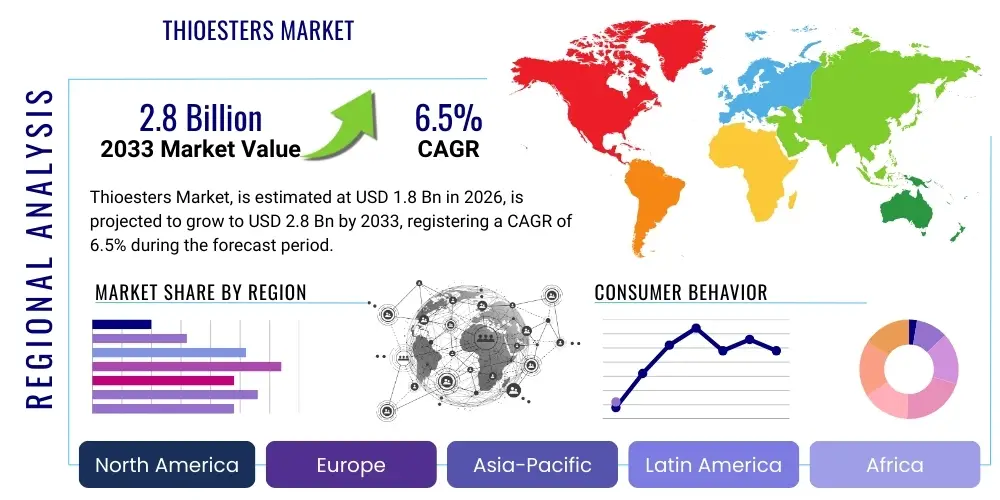

Thioesters Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436061 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Thioesters Market Size

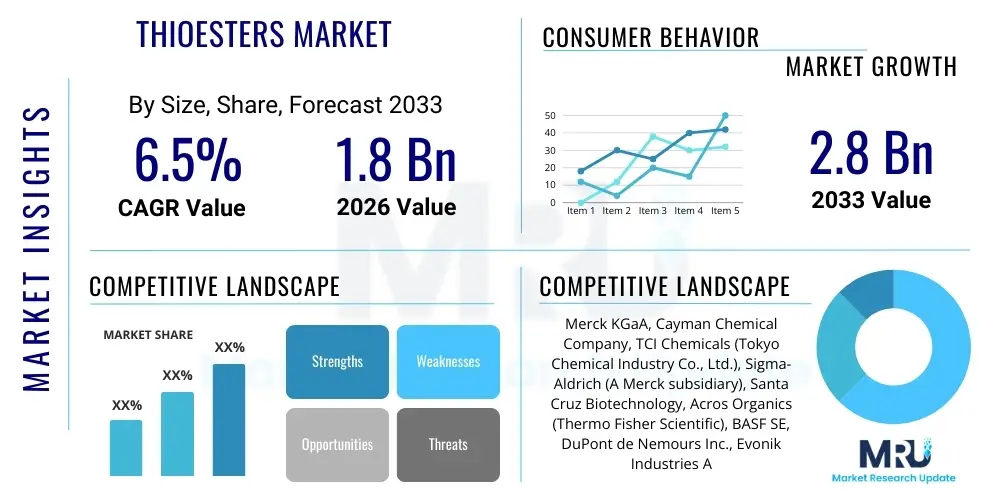

The Thioesters Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 1.8 Billion in 2026 and is projected to reach USD 2.8 Billion by the end of the forecast period in 2033.

Thioesters Market introduction

Thioesters are chemical compounds characterized by a functional group derived from an oxoacid by replacing the hydroxyl group with a thiol group. Structurally, they possess a sulfur atom bonded to a carbonyl group (R–CO–S–R'), making them high-energy compounds crucial for biological metabolism and sophisticated industrial chemical synthesis. In biochemistry, thioesters, particularly Acetyl-Coenzyme A (Acetyl-CoA), are fundamental intermediates in the citric acid cycle, fatty acid synthesis, and regulation of gene expression, highlighting their indispensable role in life processes. The synthetic application of thioesters spans across multiple high-value industries due to their high reactivity, acting as acylating agents in organic synthesis, including the production of peptides and pharmaceutical intermediates. This duality—biological importance and synthetic utility—positions thioesters as a critical segment within the specialty chemicals and biotechnology sectors.

The major applications of thioesters are diverse and reflect their chemical versatility. In the pharmaceutical sector, thioesters are utilized as key precursors for synthesizing various antibiotics, antiviral drugs, and complex organic molecules where mild, selective acylation is required. Furthermore, the agrochemical industry employs thioester derivatives in the formulation of specific herbicides and pesticides, capitalizing on their stability and targeted reactivity profiles. Beyond life sciences, thioesters contribute significantly to materials science, serving as essential monomers or stabilizers in the production of specialty polymers and high-performance plastics, improving material properties such as thermal stability and resistance to degradation. Their growing importance in the flavor and fragrance industry, where specific thioester compounds impart distinct savory or fruity notes, further diversifies the market landscape.

Driving factors for the Thioesters Market include the rapid expansion of the global pharmaceutical industry, particularly in emerging economies focused on advanced drug development and generic manufacturing. Increased R&D activities in synthetic biology and enzyme engineering, aiming to utilize thioesters in biocatalytic processes for sustainable chemical production, are also fueling demand. Moreover, the shift towards personalized medicine and complex peptide synthesis necessitates high-purity, specialized thioester building blocks. The inherent chemical benefits of thioesters, such as their high acyl transfer potential, ease of purification, and versatility in coupling reactions, solidify their status as preferred synthetic reagents across specialized manufacturing processes, ensuring sustained market growth throughout the forecast period.

Thioesters Market Executive Summary

The Thioesters Market is experiencing robust business trends driven by innovation in green chemistry and heightened regulatory scrutiny concerning chemical purity in end-use applications, particularly pharmaceuticals and food additives. Key business trends involve strategic collaborations between specialized chemical manufacturers and biotechnology firms focused on enzyme-catalyzed synthesis of high-value thioesters, moving away from traditional, harsher chemical routes. Furthermore, the market is characterized by a consolidation of specialized suppliers who can guarantee the high enantiomeric purity required for complex chiral drug synthesis. The increasing demand for sustainable manufacturing processes is pushing companies to invest in biocatalysis research, utilizing engineered enzymes to produce biologically relevant thioesters like Coenzyme A derivatives more efficiently and environmentally soundly, thereby streamlining production costs and reducing waste generation across the value chain. This strategic pivot towards sustainability is becoming a major competitive differentiator.

Regional trends indicate that Asia Pacific (APAC) is poised to exhibit the highest growth rate, primarily due to the rapid expansion of its chemical manufacturing base, the growing generics pharmaceutical market in India and China, and increasing investment in agrochemicals across Southeast Asia. North America and Europe remain mature markets, driven by stringent regulatory frameworks ensuring product quality and significant R&D spending in advanced biotechnology and specialty materials. These regions focus heavily on niche applications, such as high-performance polymers and advanced drug discovery programs, demanding bespoke thioester derivatives. The presence of major biotechnology hubs in the US and Western Europe ensures continuous innovation in both synthesis methods and application development, maintaining a steady, high-value segment growth rate, whereas APAC focuses on volume and expanding industrial application capacity.

Segment trends highlight the dominance of the Application segment by Pharmaceuticals, which accounts for the largest revenue share due to the continuous development of novel small-molecule drugs and increasing complexity in peptide synthesis protocols. Within the Type segment, synthetic thioesters, used primarily as robust acylating agents in industrial chemistry, are seeing substantial volumetric growth, driven by their utility in complex organic synthesis and material production. Conversely, biologically derived thioesters, such as specific Coenzyme A analogs, command a higher price point due to their biological specificity and application in diagnostic and therapeutic research. The ongoing trend across all segments is the increasing requirement for customization and high purity, driving specialized manufacturers to optimize their purification and quality control protocols to meet the stringent demands of high-end users, especially those in clinical research and high-tech material manufacturing.

AI Impact Analysis on Thioesters Market

User queries regarding AI's impact on the Thioesters Market primarily revolve around how machine learning can accelerate the discovery of novel thioester-containing molecules, optimize synthesis pathways, and improve the efficiency of biocatalytic production. Key concerns focus on AI's ability to predict the reactivity and stability of new thioester derivatives and whether computational chemistry can reduce the cost and time associated with experimental R&D in specialty chemicals. Users also express interest in AI-driven process optimization for large-scale industrial fermentation processes that produce biological thioesters, hoping for increased yields and reduced batch-to-batch variability. The underlying expectation is that AI will streamline the identification of optimal reaction conditions and reduce dependence on labor-intensive combinatorial chemistry, thereby accelerating the commercialization of new thioester-based products in pharmaceuticals and materials science.

The most immediate impact of Artificial Intelligence (AI) and Machine Learning (ML) is anticipated in the field of computational chemistry and retrosynthesis planning specific to thioester molecules. AI algorithms can rapidly screen vast databases of known reactions and predict the most efficient, cost-effective, and environmentally friendly synthetic route for target thioesters, potentially slashing R&D lead times from months to weeks. Furthermore, AI is crucial for high-throughput screening in drug discovery, where identifying active thioester scaffolds that inhibit specific enzyme targets is critical. By modeling molecular interactions and predicting bioavailability, AI minimizes the number of compounds that need to be physically synthesized and tested, drastically improving the productivity of research chemists focusing on novel therapeutics.

Beyond discovery, AI plays an accelerating role in optimizing the large-scale production of thioesters, particularly in bioprocesses. For biological thioesters produced via microbial fermentation, AI systems can analyze real-time bioreactor data (pH, temperature, nutrient consumption, metabolite concentration) to dynamically adjust parameters, maximizing yield and ensuring consistent product quality across different production batches. Predictive maintenance facilitated by AI also reduces downtime in specialized chemical plants. This convergence of computational prediction and process control, driven by AI, transforms the manufacturing paradigm for high-purity thioesters, making production more agile, efficient, and responsive to specialized customer requirements.

- AI accelerates the identification of novel thioester structures for drug discovery through virtual screening and predictive modeling.

- Machine Learning algorithms optimize reaction conditions (temperature, solvent, catalyst selection) for chemical synthesis of complex thioesters, improving yield and purity.

- Computational tools enhance retrosynthesis planning, identifying cost-effective and green routes for manufacturing industrial thioester derivatives.

- AI-driven bioprocess optimization maximizes the yield and quality of biologically derived thioesters (e.g., Acetyl-CoA) in large-scale fermentation.

- Predictive analytics minimizes batch variations and ensures stringent quality control compliance in pharmaceutical-grade thioester production.

DRO & Impact Forces Of Thioesters Market

The Thioesters Market is governed by a critical interplay of Drivers, Restraints, and Opportunities (DRO), which collectively dictate market trajectory and impact forces. A primary driver is the accelerating demand for advanced pharmaceuticals, particularly high-purity chiral molecules and complex peptides, where thioesters serve as essential, high-energy precursors facilitating difficult coupling reactions. Coupled with this is the robust growth in specialized materials science, where unique thioester functionalities are engineered into polymers to enhance performance characteristics like heat resistance and processability. However, the market faces significant restraints, chiefly the high manufacturing cost associated with the synthesis and purification of specific, biologically active thioester derivatives (like CoA analogs), often requiring sophisticated biocatalytic or multi-step chemical processes. Furthermore, the inherent instability of certain thioester compounds, which are susceptible to hydrolysis, presents challenges in long-term storage and formulation, necessitating specialized handling and packaging protocols, thereby increasing supply chain complexity and operational expenditure.

Opportunities within the market largely stem from the shift towards sustainable chemistry. The emergence of novel, enzymatic synthesis routes (biocatalysis) offers a green alternative to traditional chemical methods, reducing solvent use and minimizing hazardous waste generation, aligning with global environmental mandates. Furthermore, the burgeoning field of synthetic biology creates opportunities for developing tailored microbial strains capable of overproducing specific thioesters or their precursors, opening new avenues for cost-effective, large-scale production, especially for commodity applications. Regulatory clarity and standardization in the use of thioester-based polymers in medical devices and food contact materials also present a strong opportunity for market expansion in mature economies. The high acyl transfer potential of thioesters, a key impact force, ensures their continued relevance as a superior acylating agent compared to less reactive alternatives across multiple industrial applications.

The core impact forces shaping this market include stringent quality regulations, technological advancements in synthetic chemistry, and shifts in global manufacturing hubs. Regulatory standards, particularly those imposed by agencies like the FDA and EMA for pharmaceutical intermediates, compel manufacturers to invest heavily in advanced analytical techniques to certify the purity and chirality of thioester products. This force drives consolidation towards players capable of meeting these high standards. Simultaneously, continuous technological innovation in areas like flow chemistry and microreactor technology is making the synthesis of complex thioesters more efficient and safer, influencing production scalability. Finally, the geographic movement of chemical production capacities towards Asia Pacific influences pricing dynamics and regional consumption patterns, acting as a major external impact force affecting supply chain resilience and global trade flows of specialty thioesters.

Segmentation Analysis

The Thioesters Market is comprehensively segmented based on Type, Application, and End-Use Industry, allowing for granular analysis of demand drivers and growth pockets across the global landscape. Segmentation by Type distinguishes between biologically significant thioesters, primarily Acetyl-CoA and its derivatives crucial for metabolic research and diagnostics, and synthetic thioesters, which are broadly used as reagents, monomers, and intermediates in industrial chemical processes. The Application segmentation is crucial as it dictates the required purity levels and volumes, spanning high-value sectors such as pharmaceuticals and agrochemicals, through to high-volume industries like polymers and materials science. This framework enables market participants to tailor their product offerings and strategic investments based on the specific requirements, regulatory landscapes, and growth trajectories inherent to each defined segment.

Understanding the interplay between these segments is vital for strategic positioning. For instance, the high cost and low volume of Acetyl-CoA derivatives contrast sharply with the high volume and moderate pricing typical of thioester monomers used in polymer manufacturing. The End-Use segment, encompassing academic and research institutions, pharmaceutical companies, and specialty chemical manufacturers, provides insight into the consumer base and their specific purchasing criteria, such as batch size flexibility, certification requirements, and technical support needs. As the market matures, there is an observable trend of cross-segment integration, where pharmaceutical research utilizing synthetic thioesters often leads to the development of proprietary agrochemical compounds, broadening the commercial relevance of specific thioester chemistries. Accurate segmentation analysis is therefore foundational for forecasting future demand shifts.

- Type:

- Acetyl Coenzyme A (CoA) Derivatives

- Acyl Coenzyme A Derivatives

- Synthetic Thioesters (Including Thiol Esters of Carboxylic Acids)

- Application:

- Pharmaceutical Synthesis (Drug Intermediates, Peptide Synthesis)

- Agrochemicals (Herbicides, Fungicides)

- Polymers and Materials Science (Monomers, Initiators)

- Flavors and Fragrances

- Academic and Research Use

- Others (Diagnostics, Specialty Coatings)

- End-Use Industry:

- Pharmaceutical and Biotechnology Companies

- Specialty Chemical Manufacturers

- Polymer and Materials Industry

- Academic and Research Institutions

- Agrochemical Companies

Value Chain Analysis For Thioesters Market

The value chain for the Thioesters Market commences with upstream activities involving the sourcing and refinement of key raw materials, primarily thiols (sulfur-containing compounds), carboxylic acids, and specialized cofactors like coenzyme A precursors for biological synthesis. Upstream complexity is characterized by the need for high-purity starting materials to ensure the quality of the final thioester product, particularly for pharmaceutical applications. Suppliers of specialized thiols or advanced catalytic systems hold significant leverage at this stage. The core manufacturing stage involves complex organic synthesis, often requiring precise control over reaction conditions (e.g., coupling agents, temperature, pH) or highly optimized fermentation processes for biocatalytic routes. Differentiation at this stage relies heavily on intellectual property pertaining to novel, high-yield, and selective synthesis methods, particularly those that can achieve high enantiomeric purity without excessive purification steps.

Downstream analysis focuses on the distribution, formulation, and end-use application of the synthesized thioesters. Given the stability challenges and high-purity requirements, the distribution channel often involves specialized logistics providers capable of cold chain management and handling hazardous or temperature-sensitive chemicals. Direct distribution channels are highly prevalent for high-value segments, such as pharmaceutical intermediaries, where suppliers maintain direct relationships with key R&D labs and manufacturing sites to ensure specification compliance and technical support. Indirect distribution, leveraging chemical distributors, is more common for commodity-grade synthetic thioesters used in bulk polymer manufacturing or academic research supplies, where inventory management and regional availability are prioritized over direct technical engagement.

The profitability margins are typically higher in the specialized synthesis and direct distribution segments targeting pharmaceutical end-users due to the premium pricing associated with certified high-purity and unique molecular structures. Conversely, the mass production of generic synthetic thioesters utilizes indirect channels and competes primarily on cost and scale. The overall efficiency of the value chain is increasingly being optimized through digitization and rigorous quality management systems, particularly to mitigate risks associated with the stability and reactivity of these high-energy compounds. Understanding whether the product moves through a direct channel (manufacturer to pharma company R&D) or an indirect channel (manufacturer to distributor to bulk end-user) is crucial for assessing margin capture and market penetration strategies.

Thioesters Market Potential Customers

Potential customers for the Thioesters Market span a wide range of sophisticated industrial and research entities that require high-purity acylating agents, metabolic intermediates, or advanced monomers. The primary end-users are major Pharmaceutical and Biotechnology Companies, which utilize thioesters extensively in custom synthesis for drug candidates, specifically in peptide synthesis where thioesters facilitate robust ligation techniques, and as precursors for antibiotics and complex small molecules. These companies demand strict regulatory compliance, detailed documentation, and products with extremely high purity and specified stereochemistry. The growth in outsourced drug development further expands the customer base to include Contract Research Organizations (CROs) and Contract Manufacturing Organizations (CMOs) specialized in chemical synthesis.

Another significant customer base resides in the Specialty Chemical and Polymer Industry. These manufacturers use synthetic thioesters as monomers for creating specialized polymers with enhanced properties (e.g., polythioesters) or as high-performance stabilizers and polymerization initiators. Their buying criteria often focus on bulk availability, consistent quality, competitive pricing, and technical support for large-scale industrial processes. Furthermore, Agrochemical Manufacturers represent substantial buyers, utilizing specific thioester derivatives as active ingredients or intermediates in the production of high-efficacy herbicides and fungicides tailored for modern agricultural practices, demanding stability and environmental compliance documentation.

Finally, Academic and Governmental Research Institutions constitute a steady stream of specialized customers, requiring small, custom batches of unique thioester compounds, particularly Acetyl-CoA analogs and novel synthetic intermediates, for foundational research in metabolism, biochemistry, and synthetic chemistry. Although their purchase volumes are lower, their demand drives innovation and often requires the highest level of technical specification and purity. Serving these varied customers necessitates a versatile supply chain capable of handling everything from gram-scale custom orders to multi-ton industrial batches, underpinned by robust analytical and quality assurance protocols to meet diverse end-user specifications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.8 Billion |

| Market Forecast in 2033 | USD 2.8 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Merck KGaA, Cayman Chemical Company, TCI Chemicals (Tokyo Chemical Industry Co., Ltd.), Sigma-Aldrich (A Merck subsidiary), Santa Cruz Biotechnology, Acros Organics (Thermo Fisher Scientific), BASF SE, DuPont de Nemours Inc., Evonik Industries AG, Kanto Chemical Co., Inc., FUJIFILM Wako Pure Chemical Corporation, Creative Diagnostics, VWR International, Adooq Bioscience, LGC Standards, Alfa Aesar (Thermo Fisher Scientific), Advanced Synthesis Technologies, SynChem, Inc., Strem Chemicals, Inc., Angene International Limited. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Thioesters Market Key Technology Landscape

The technology landscape governing the Thioesters Market is rapidly evolving, driven by the need for enhanced selectivity, improved efficiency, and reduced environmental footprint. A cornerstone technology is the implementation of advanced catalytic methods, particularly transition metal-catalyzed coupling reactions and highly specific organocatalysis, which allow for the stereoselective synthesis of complex thioester architectures that are crucial for pharmaceutical applications. These methods minimize side reactions and maximize product purity, directly addressing the stringent requirements of high-value end-users. Additionally, continuous flow chemistry is gaining traction; this technology enables the synthesis of highly reactive thioesters in a safer, more controlled environment compared to traditional batch processing, facilitating better scalability and consistency, especially for unstable intermediates that require immediate downstream processing.

Biocatalysis represents a transformative technological advancement in this sector, utilizing isolated enzymes or engineered microbial systems to synthesize thioesters under mild conditions. This approach is particularly critical for producing biologically relevant molecules, such as CoA derivatives, which are often difficult and costly to synthesize chemically. Enzyme engineering technologies, including directed evolution, are continuously optimizing the performance and substrate specificity of acyltransferases and synthetases to increase the yield of desired thioesters. The focus on biocatalysis not only provides a cleaner manufacturing process but also helps in achieving the high enantiomeric purity often unattainable through conventional chemical means, positioning it as a key competitive technology for specialized thioester production.

Furthermore, analytical technologies play a crucial supporting role. High-Performance Liquid Chromatography (HPLC), Mass Spectrometry (MS), and advanced Nuclear Magnetic Resonance (NMR) techniques are essential for the rigorous characterization, quantification, and quality control of thioester products. Given the high reactivity and potential instability of many thioesters, sophisticated monitoring tools, often integrated with AI-driven analytics, ensure that products meet stringent specifications before packaging and distribution. The development of robust, real-time quality assurance protocols, often utilizing Process Analytical Technology (PAT), is a technological necessity for manufacturers aiming to serve regulated markets like pharmaceuticals, ensuring that every batch of thioester adheres to strict purity standards throughout the production lifecycle.

Regional Highlights

- Highlight key countries or regions and their market relevance

- North America: North America, particularly the United States, represents a mature yet highly innovative segment of the Thioesters Market. This region is characterized by substantial investment in biomedical research, advanced drug discovery, and a large biotechnology industry base. Demand is primarily driven by high-value, low-volume applications, including the synthesis of novel drug intermediates, complex peptide therapeutics, and advanced research in metabolic pathways utilizing specialized CoA derivatives. Stringent regulatory standards (FDA) necessitate premium-priced, high-purity products, positioning North America as a leader in technological adoption, particularly in flow chemistry and advanced biocatalysis. The presence of leading research universities and major pharmaceutical headquarters ensures continuous, high-level demand for specialized thioester chemistry.

- Europe: Europe holds a significant market share, fueled by a strong base in the specialty chemicals sector, robust agrochemical manufacturing capabilities, and a comprehensive pharmaceutical industry (Germany, Switzerland, UK). European demand is balanced between high-value pharmaceutical intermediates and higher-volume synthetic thioesters utilized in specialty polymer production and fine chemical synthesis. The region is highly influenced by sustainability initiatives, promoting the rapid adoption of green chemistry synthesis routes, including enzymatic methods, for thioester production. Regulatory frameworks like REACH also drive innovation towards safer and more environmentally friendly synthesis protocols, creating demand for novel, less toxic thioester precursors.

- Asia Pacific (APAC): APAC is the fastest-growing market, driven by expanding chemical manufacturing bases, burgeoning generic pharmaceutical industries in China and India, and rapid industrialization requiring specialty chemicals for infrastructure and materials. The market here is characterized by high volume consumption of synthetic thioesters for applications in plastics, coatings, and agricultural chemicals. While cost-competitiveness is a key factor, increasing regulatory awareness in countries like Japan and South Korea is pushing manufacturers towards adopting better quality control measures. Significant government investment in domestic R&D and pharmaceutical production ensures that APAC will continue to drive global volume growth for both basic and advanced thioester compounds.

- Latin America (LATAM): The LATAM market, while smaller in scale, shows promising growth, largely concentrated in Brazil and Mexico. Demand is tied predominantly to the growing agrochemical sector, requiring bulk synthetic thioesters for pesticide formulations, and expanding domestic pharmaceutical production focused on generics. Market growth is often dependent on foreign direct investment in chemical manufacturing infrastructure and technology transfer from global players. Price sensitivity is higher in this region, favoring bulk purchasing of well-established thioester types.

- Middle East and Africa (MEA): The MEA market for thioesters is nascent but expanding, primarily driven by investments in petrochemical derivatives and a slow but steady growth in pharmaceutical and specialty chemical manufacturing, particularly in Saudi Arabia and the UAE. Demand is currently focused on essential synthetic thioesters used as intermediates in polymer production or as stabilizers. Future growth potential hinges on diversification away from oil dependence and increased localized R&D expenditure to develop specialty downstream chemical industries, potentially utilizing thioester chemistry in novel materials applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Thioesters Market.- Merck KGaA

- Cayman Chemical Company

- TCI Chemicals (Tokyo Chemical Industry Co., Ltd.)

- Sigma-Aldrich (A Merck subsidiary)

- Santa Cruz Biotechnology

- Acros Organics (Thermo Fisher Scientific)

- BASF SE

- DuPont de Nemours Inc.

- Evonik Industries AG

- Kanto Chemical Co., Inc.

- FUJIFILM Wako Pure Chemical Corporation

- Creative Diagnostics

- VWR International

- Adooq Bioscience

- LGC Standards

- Alfa Aesar (Thermo Fisher Scientific)

- Advanced Synthesis Technologies

- SynChem, Inc.

- Strem Chemicals, Inc.

- Angene International Limited

Frequently Asked Questions

Analyze common user questions about the Thioesters market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary applications of synthetic thioesters in the industrial sector?

Synthetic thioesters are fundamentally used as powerful acylating agents in complex organic synthesis and, critically, as specialized monomers for the creation of high-performance polymers, plastics, and coatings, where they enhance thermal and chemical stability.

How is the stability challenge of thioesters being addressed in the market?

Manufacturers address the hydrolytic instability of thioesters through specialized packaging, strict cold chain distribution, formulation into more stable derivatives, and by utilizing advanced synthetic methods like flow chemistry to minimize storage time of reactive intermediates.

What role does Acetyl-CoA play in the Thioesters Market?

Acetyl-Coenzyme A (Acetyl-CoA) and its derivatives are crucial biological thioesters, driving demand in diagnostics, metabolic research, and therapeutic development. They represent the highest-value segment due to the complexity and necessity of their use in biochemical and biomedical studies.

Which technology is currently driving sustainable production in the thioesters market?

Biocatalysis, utilizing engineered enzymes and microbial strains, is the leading technology driving sustainable production, offering milder reaction conditions, reduced waste generation, and high stereoselectivity compared to traditional, energy-intensive chemical synthesis routes.

What is the main driver for market growth in the Asia Pacific region?

The primary driver in APAC is the rapid expansion of the generic pharmaceutical manufacturing industry and large-scale agrochemical production, leading to high volume demand for fundamental synthetic thioester intermediates and raw materials.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager