Thiourea Dioxide Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433253 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Thiourea Dioxide Market Size

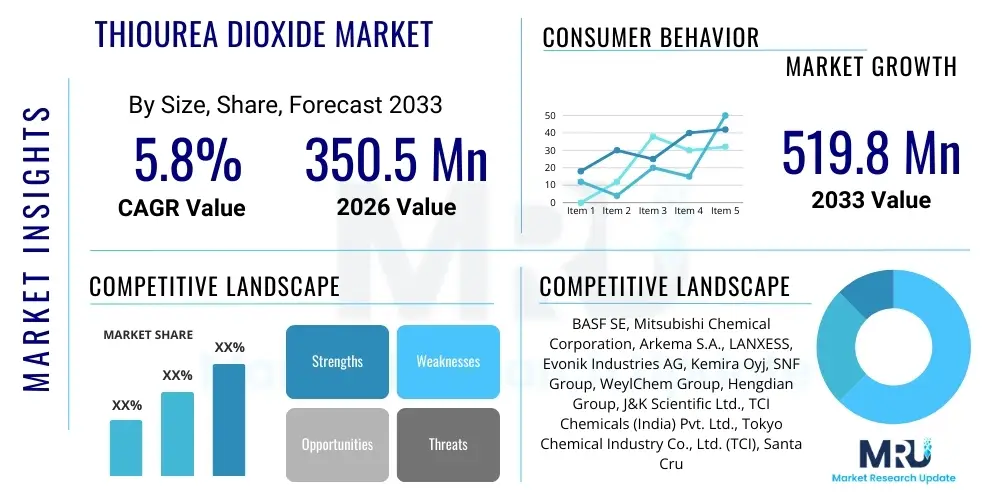

The Thiourea Dioxide Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 350.5 Million in 2026 and is projected to reach USD 519.8 Million by the end of the forecast period in 2033.

Thiourea Dioxide Market introduction

Thiourea Dioxide (TDO), also known as formamidinesulfinic acid (FAS), is a highly effective, non-toxic, and environmentally friendly reducing agent utilized across various industrial applications. As a significant replacement for traditional reducing agents like sodium dithionite, TDO offers superior thermal stability, excellent storage properties, and reduced pollutant generation, making it highly attractive in sectors prioritizing green chemistry principles. Its chemical structure grants it robust reducing power, which is activated under alkaline conditions, facilitating its widespread use in complex manufacturing processes where precise redox control is necessary. The compound is synthesized primarily through the reaction of thiourea with hydrogen peroxide, yielding a stable product critical for modern industrial chemical reactions.

The primary applications of TDO span several high-volume industries, most notably the textile sector where it serves as a powerful bleaching and stripping agent for cotton, wool, and synthetic fibers. Furthermore, the paper and pulp industry relies heavily on TDO for brightness enhancement and deinking processes, driving demand due to increasing global consumption of recycled paper products. In niche but growing sectors, TDO finds utility in leather processing as a reducing agent in dyeing and tanning, and increasingly in the pharmaceutical industry as a reagent or intermediate in complex organic synthesis. The inherent safety profile, being less corrosive and non-flammable compared to conventional alternatives, underpins its growing preference among manufacturers seeking compliance with stringent occupational health and safety regulations worldwide.

Key driving factors accelerating market expansion include the global shift towards sustainable manufacturing practices and the banning or phasing out of highly polluting conventional agents. Specifically, regulatory pressures concerning sulfur dioxide emissions, commonly associated with sodium dithionite use, position TDO as a crucial, clean alternative. Moreover, continuous innovation in textile dyeing technologies demanding high-quality, defect-free coloration processes, along with robust infrastructural development in emerging economies, particularly in Asia Pacific, further solidifies the demand trajectory for high-purity thiourea dioxide products across the forecast period.

Thiourea Dioxide Market Executive Summary

The Thiourea Dioxide market exhibits robust growth driven by accelerating adoption in the textile and paper industries, catalyzed by stringent environmental regulations mandating the replacement of hazardous chemicals. Business trends indicate significant capacity expansion and strategic alliances among leading manufacturers, primarily concentrated in Asia Pacific, aiming to secure raw material supply (thiourea and hydrogen peroxide) and optimize production efficiencies through continuous process improvement. Furthermore, a discernible trend toward developing liquid solution forms of TDO is emerging to enhance ease of handling, dosage accuracy, and integration into automated manufacturing lines, thus offering a competitive edge for companies catering to advanced industrial facilities. Demand volatility is mitigated by stable long-term contracts with large-scale industrial consumers, especially those focused on export-oriented textile production.

Regional trends highlight Asia Pacific, led by China and India, as the undisputed leader in both consumption and production capacity, benefiting from lower operating costs and a dense concentration of textile and paper mills. North America and Europe, while slower in volume growth, demonstrate high demand for premium, high-purity grades of TDO utilized in specialized chemical synthesis and pharmaceutical applications, adhering to rigorous quality standards such as REACH compliance. The market dynamics in Latin America and MEA are increasingly influenced by foreign investment in textile manufacturing, leading to a gradual but steady increase in TDO consumption, though supply chain maturity remains a limiting factor compared to established regions.

Segmentation trends reveal that the Application segment dominated by Textile Processing continues to hold the largest market share, though Paper & Pulp processing is exhibiting the fastest growth rate due to increased emphasis on sustainable recycling technologies. Regarding the Grade segment, Technical Grade TDO accounts for the bulk of consumption volume in industrial bleaching, while High Purity Grade is witnessing accelerated revenue growth driven by its non-traditional applications in sophisticated chemical reactions and pharmaceutical intermediaries. The shift from traditional powder forms towards granular or stable liquid solutions is a key segment trend reflecting user preference for enhanced safety and operational convenience.

AI Impact Analysis on Thiourea Dioxide Market

Common user questions regarding AI's impact on the Thiourea Dioxide market often revolve around efficiency optimization, quality control, and predictive supply chain management. Users frequently inquire about whether AI can predict fluctuations in raw material prices (thiourea), optimize complex synthesis reactions to maximize TDO yield, and integrate advanced sensor data for real-time quality assurance in textile dyeing processes. There are also significant concerns about the potential displacement of human labor in automated quality inspection tasks and the overall energy efficiency improvements AI might enable in high-temperature, high-pressure industrial production settings. Key themes emerging from user concerns center on minimizing batch variation, reducing waste (particularly wastewater discharge associated with textile processing), and enhancing process safety through intelligent monitoring systems that can detect anomalies before critical failures occur, thus positioning AI as a tool for sustainability and operational excellence rather than just cost reduction.

The integration of Artificial Intelligence, particularly Machine Learning (ML) algorithms, is poised to revolutionize the manufacturing processes of Thiourea Dioxide. ML models can analyze vast datasets concerning temperature profiles, reactant concentration ratios, stirring speeds, and reaction times during TDO synthesis. By identifying optimal parameter ranges that are often non-intuitive to human operators, AI ensures higher conversion rates, minimizes side product formation, and subsequently enhances the overall yield and purity of the technical and high-purity grades. This predictive maintenance capability extends to monitoring the lifespan of crucial reaction vessels and filtration equipment, drastically reducing unscheduled downtime and improving capital expenditure utilization rates, thereby lowering the cost of production.

In the downstream applications, especially in the textile and paper industries, AI-powered systems are crucial for optimizing the dosage of TDO. For instance, in continuous bleaching processes, computer vision and sophisticated spectrophotometric analysis, governed by AI, can instantaneously measure fabric whiteness or pulp brightness and adjust the TDO feed rate precisely, minimizing chemical overuse and ensuring color consistency across massive production batches. This precision driven by AI not only reduces chemical consumption—a significant cost driver—but also substantially minimizes the environmental footprint by decreasing chemical residue in effluent discharge, aligning directly with global sustainability mandates and bolstering the market adoption of TDO as a premium, efficiency-enabling chemical component.

- AI-driven optimization of TDO synthesis pathways to maximize conversion yield and minimize energy consumption.

- Machine learning models used for predictive maintenance of reactors and high-pressure pumps, ensuring zero unplanned downtime.

- Advanced sensor integration and AI analytics for real-time monitoring of TDO quality (purity and particle size distribution).

- Implementation of smart inventory systems predicting demand fluctuations and optimizing thiourea and hydrogen peroxide procurement strategies.

- AI-enabled dosage control systems in downstream textile and paper mills, ensuring precise TDO application and reducing chemical waste.

- Improved supply chain traceability using AI and blockchain integration to verify the source and sustainable production metrics of TDO.

- Automated quality control using computer vision in textile bleaching to detect color defects and adjust TDO concentration instantly.

DRO & Impact Forces Of Thiourea Dioxide Market

The Thiourea Dioxide market is significantly influenced by a complex interplay of Drivers, Restraints, and Opportunities, collectively determining the Impact Forces across the industry ecosystem. A major driver is the accelerating regulatory shift, particularly in Western economies and globally influential manufacturing hubs like China, away from highly polluting reducing agents such as sulfur-based compounds. This regulatory push provides a substantial competitive advantage to environmentally benign alternatives like TDO. Conversely, market restraints largely center on the high production costs associated with maintaining stringent purity standards, especially for pharmaceutical-grade applications, and the inherent volatility in the price of key raw materials, namely thiourea, which is linked to global ammonia and carbon disulfide supply chains. However, the immense opportunity lies in expanding TDO use beyond traditional textile and paper applications into advanced material synthesis, high-performance electronics, and specialized chemical manufacturing, capitalizing on its superior reducing capacity and thermal stability, thus paving the way for diversification and enhanced profit margins for market participants.

Key drivers include the technological advancements in textile dyeing processes that require stable and highly effective reducing agents to achieve deep, vibrant, and durable colors without compromising fiber integrity. Furthermore, the rising global consumption of recycled paper necessitates more efficient deinking and bleaching methods, where TDO provides superior performance compared to older technologies. On the restraint side, the primary impediment to market growth is the limited shelf life of TDO in certain unstable forms, requiring specific storage conditions and complicating logistical planning across long supply chains. Moreover, awareness about the full potential and handling requirements of TDO remains moderate in less industrialized regions, requiring substantial educational investment by manufacturers to unlock untapped markets and accelerate adoption among smaller-scale enterprises.

The overall impact forces are strongly positive, primarily driven by the sustainability imperative. The pressure from consumers, regulators, and corporate social responsibility goals compels industries to adopt cleaner chemical inputs, making TDO an essential component for environmentally conscious manufacturers. The substitution threat is relatively low in core applications due to TDO's unique combination of efficiency, stability, and ecological profile. Strategic opportunities are centered on vertical integration—securing thiourea supplies—and geographical expansion into high-growth areas of Southeast Asia and India, where manufacturing capacities are rapidly increasing. Addressing the technological challenge of producing highly stable, cost-effective liquid TDO formulations represents a significant opportunity that can bypass the handling and stability issues associated with powder formats, ensuring long-term market resilience and growth.

Segmentation Analysis

The Thiourea Dioxide market is comprehensively segmented based on its diverse applications across heavy and specialty chemical industries, the purity grade required for various end-uses, and the physical form in which the product is supplied. This segmentation is crucial for understanding specific demand drivers and targeting marketing efforts towards high-growth niches. The segmentation reveals that while industrial applications such as textiles dominate volume, high-purity grades required for pharmaceuticals and high-tech chemistry command premium pricing, driving revenue growth. Manufacturers are increasingly focused on customizing product formulations, particularly in terms of physical form (powder versus granular or liquid), to meet the precise handling and solubility requirements of different industrial consumers, which further refines market analysis and competitive positioning across the global value chain. The complexity of end-user needs, ranging from large-scale continuous processes in paper mills to highly controlled batch synthesis in laboratories, dictates the diversity within these key market segments.

- Application

- Textile Processing (Dyeing, Stripping, Bleaching)

- Paper & Pulp Industry (Deinking, Brightness Enhancement)

- Leather Industry (Dyeing, Tanning)

- Pharmaceutical Intermediates and Synthesis

- Chemical Synthesis and Polymerization

- Others (Photography, Metal Plating)

- Grade

- Technical Grade (Standard industrial use)

- High Purity Grade (Pharmaceutical, Specialized Chemical)

- Form

- Powder

- Granular

- Liquid Solution

- Region

- North America (U.S., Canada, Mexico)

- Europe (Germany, U.K., France, Italy, Spain, Rest of Europe)

- Asia Pacific (China, India, Japan, South Korea, Rest of APAC)

- Latin America (Brazil, Argentina, Rest of Latin America)

- Middle East & Africa (GCC Countries, South Africa, Rest of MEA)

Value Chain Analysis For Thiourea Dioxide Market

The value chain for Thiourea Dioxide commences with the upstream supply of fundamental chemical precursors. The primary raw materials are thiourea and hydrogen peroxide. Thiourea itself is typically synthesized from ammonia and carbon disulfide or calcium cyanamide derivatives, linking the TDO market's cost structure directly to global petrochemical and fertilizer market fluctuations. A stable, reliable, and cost-effective supply of high-quality thiourea is paramount, and many major TDO manufacturers pursue backward integration or long-term procurement contracts to mitigate price volatility and ensure feedstock purity, which is critical for the final TDO product quality. The manufacturing phase involves rigorous chemical processing, purification, and drying/granulation steps, requiring substantial capital investment in specialized reaction equipment and strict adherence to process safety standards due to the reactive nature of the intermediates.

Moving downstream, the distribution channel is highly diversified, reflecting the broad application base of TDO. Direct sales channels are frequently employed for large-volume customers, particularly major textile conglomerates, global paper manufacturers, and bulk chemical distributors, allowing for customized pricing, technical support, and logistical management. Smaller customers and geographically dispersed end-users, especially in the pharmaceutical and specialty chemical segments, rely heavily on indirect channels, involving regional chemical distributors and specialized agents who manage inventory, repackaging, and localized technical services. The selection of the distribution method—direct or indirect—is often dictated by the required grade purity, batch size, and the need for just-in-time inventory management at the customer site.

The terminal phase of the value chain involves the application and ultimate consumption of TDO by end-users. The downstream value creation is significant, as TDO enables improved product quality, such as brighter paper or consistently dyed textiles, which enhances the consumer appeal and market price of the final goods. Effective logistics, including packaging tailored for moisture sensitivity and adherence to international hazardous materials transport regulations, are vital to maintaining product integrity until the point of use. Continuous collaboration between TDO producers and downstream users, particularly concerning application method optimization and chemical handling best practices, helps solidify long-term partnerships and drives incremental market growth through innovation in TDO application technology.

Thiourea Dioxide Market Potential Customers

The primary consumers of Thiourea Dioxide are large-scale industrial entities whose operational success depends on efficient and reliable reducing agents for critical processes. The most significant customer segment belongs to the textile processing industry, encompassing integrated mills, independent dyeing and printing facilities, and specialized textile finishers, who utilize TDO extensively for vat dyeing, reductive clearing, stripping, and peroxide bleaching activation. These customers demand consistent quality, high thermal stability, and assurance of environmental compliance, favoring suppliers who can provide technical assistance in optimizing their chemical baths and wastewater treatment protocols. The high volumes consumed by this sector make it the cornerstone of the TDO market.

A rapidly expanding segment of potential customers includes the global paper and pulp industry, specifically paper recycling facilities and virgin pulp mills focused on high-quality printing and writing papers. These customers require TDO primarily for its effectiveness in deinking flotation processes and achieving high brightness levels in bleached chemical pulps. As regulatory pressure increases to maximize the use of recovered paper, the demand for efficient deinking chemicals like TDO grows proportionally. Customer procurement strategies in this segment emphasize supply chain robustness and the availability of cost-effective, bulk packaging solutions to support continuous, high-throughput operations.

Furthermore, specialty chemical manufacturers and pharmaceutical companies represent a high-value customer base for high-purity Thiourea Dioxide. In the pharmaceutical sector, TDO serves as a critical reducing agent in the synthesis of specific organic compounds, often requiring material purity exceeding 99.5% and adherence to strict cGMP (current Good Manufacturing Practice) standards. Customers in this highly regulated area prioritize supplier certifications, batch traceability, and comprehensive quality documentation over marginal cost savings, making these relationships long-term and highly specialized. Other niche buyers include manufacturers of photographic chemicals and providers of specialized metal plating and finishing services.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350.5 Million |

| Market Forecast in 2033 | USD 519.8 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BASF SE, Mitsubishi Chemical Corporation, Arkema S.A., LANXESS, Evonik Industries AG, Kemira Oyj, SNF Group, WeylChem Group, Hengdian Group, J&K Scientific Ltd., TCI Chemicals (India) Pvt. Ltd., Tokyo Chemical Industry Co., Ltd. (TCI), Santa Cruz Biotechnology Inc., Merck KGaA, Avantor Inc., Spectrum Chemical Mfg. Corp., Hefei TNJ Chemical Industry Co., Ltd., Nanjing Union Chemical Co., Ltd., Shandong Jidong Chemical Co., Ltd., Sichuan Nanbu Chemical Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Thiourea Dioxide Market Key Technology Landscape

The manufacturing process of Thiourea Dioxide fundamentally relies on the oxidation of thiourea using an appropriate oxidizing agent, typically hydrogen peroxide, under controlled conditions. The technological landscape is characterized by continuous efforts to optimize reactor design, improve product purification efficiency, and enhance the stability of the final product. Key technological advancements center on refining the crystallization and drying stages, which directly impact the final product's particle size distribution, bulk density, and subsequent ease of use in industrial applications. Modern facilities employ advanced continuous stirred-tank reactors (CSTRs) and sophisticated filtration and washing systems to ensure minimal residual impurities, meeting the increasingly stringent quality standards demanded by specialty consumers. Furthermore, process control technology, including precise temperature and pH regulation, is vital for managing the exothermic nature of the oxidation reaction and maximizing the conversion yield of the desired formamidinesulfinic acid product while minimizing undesirable side reactions and minimizing raw material waste.

A critical technological trend driving market differentiation is the development of stabilized Thiourea Dioxide formulations, particularly in granular and liquid forms. Traditional powdered TDO can be prone to caking and may pose handling challenges in terms of dust generation. Manufacturers are utilizing advanced granulation techniques, such as spray drying or fluidized bed granulation, to produce dust-free, free-flowing granules that offer superior stability, handling safety, and controlled dissolution rates. The most complex technological frontier involves creating highly concentrated, shelf-stable liquid TDO solutions. Achieving long-term stability in liquid form is challenging due to TDO's tendency to decompose in water; however, proprietary stabilizing additives and specialized blending technologies are being researched and patented to overcome this hurdle. Success in producing stable liquid TDO allows for automated dosing and easier integration into modern continuous processing lines, significantly reducing labor and potential errors at the customer end, providing a substantial technological advantage.

Beyond manufacturing, the technological landscape also encompasses application technologies, particularly sensor-based optimization systems in textile and paper mills. Spectrophotometers and chemical sensors are deployed to continuously monitor the concentration of TDO and its efficacy during bleaching or stripping operations. These systems are often integrated with advanced automation platforms, utilizing feedback control loops to adjust TDO input dynamically, leading to significant material savings and enhanced product consistency—a necessity in high-speed manufacturing environments. Furthermore, research and development efforts are directed towards finding cost-effective, sustainable alternative catalysts that might enhance the efficiency of the thiourea oxidation step or developing novel purification techniques, such as membrane separation, to further lower energy consumption and improve the environmental profile of the overall TDO production process, maintaining TDO's status as a leading 'green' chemical reagent.

Regional Highlights

The global Thiourea Dioxide market exhibits distinct regional dynamics shaped by industrial concentration, regulatory environment, and economic development levels. Asia Pacific (APAC) dominates the global market both in terms of production capacity and consumption volume, primarily fueled by the presence of the world's largest textile manufacturing and paper recycling industries, particularly in China and India. The region benefits from competitive production costs and high regional demand, though it also faces intense competition and margin pressures, leading manufacturers to constantly seek process efficiencies. The regulatory environment in major APAC economies, while historically lax, is rapidly tightening, compelling local industries to adopt cleaner chemical alternatives like TDO, thus ensuring sustained high-volume growth in the foreseeable future.

Europe represents a mature market characterized by stringent environmental regulations (such as REACH) that strongly favor TDO over traditional sulfur-based reducing agents. While consumption volumes are lower than in APAC, European demand is skewed towards high-purity and specialized grades, particularly for the synthesis of complex chemical intermediates and for high-end specialty textile finishing. Manufacturers targeting this region must adhere to meticulous quality control and provide extensive documentation regarding sustainability and safety profiles. The market growth here is driven less by volume expansion and more by the substitution of older, non-compliant chemicals and continuous innovation in application technologies aimed at minimizing effluent discharge.

North America maintains stable demand, driven by the paper and pulp industry and specialized chemical manufacturing. Although the textile industry footprint is relatively smaller than in APAC, the region's strong commitment to sustainability and safety ensures consistent demand for high-quality TDO products. Latin America and the Middle East & Africa (MEA) are emerging markets for TDO. Growth in these regions is heavily reliant on foreign investment into local manufacturing capabilities and the development of domestic infrastructure, particularly in countries like Brazil, Turkey, and South Africa, which are expanding their textile and packaging sectors. These emerging markets offer significant untapped potential, provided that effective distribution networks and localized technical support can be established by international suppliers.

- Asia Pacific (APAC): Market leader in volume and production, driven by massive textile and paper manufacturing industries in China and India; growth boosted by rapidly tightening environmental compliance standards.

- Europe: High-value market focused on high-purity grades; strict regulatory frameworks (REACH) drive substitution away from hazardous chemicals; growth is steady, emphasizing sustainability and quality.

- North America: Stable demand primarily from the paper & pulp sector and specialized chemical synthesis; high operational standards require premium, reliable TDO supply.

- Latin America: Emerging market with growing potential, influenced by expanding domestic textile production and increased imports of advanced chemical inputs.

- Middle East & Africa (MEA): Growth tied to regional industrialization projects and the expansion of domestic textile sectors; market penetration requires robust logistical strategies.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Thiourea Dioxide Market.- BASF SE

- Mitsubishi Chemical Corporation

- Arkema S.A.

- LANXESS

- Evonik Industries AG

- Kemira Oyj

- SNF Group

- WeylChem Group

- Hengdian Group

- J&K Scientific Ltd.

- TCI Chemicals (India) Pvt. Ltd.

- Tokyo Chemical Industry Co., Ltd. (TCI)

- Santa Cruz Biotechnology Inc.

- Merck KGaA

- Avantor Inc.

- Spectrum Chemical Mfg. Corp.

- Hefei TNJ Chemical Industry Co., Ltd.

- Nanjing Union Chemical Co., Ltd.

- Shandong Jidong Chemical Co., Ltd.

- Sichuan Nanbu Chemical Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Thiourea Dioxide market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Thiourea Dioxide (TDO) and why is it preferred over traditional reducing agents?

Thiourea Dioxide (TDO), or formamidinesulfinic acid (FAS), is a highly effective, non-toxic, and environmentally superior reducing agent. It is preferred primarily because it is non-flammable, has better stability, and, crucially, avoids the generation of sulfur dioxide and other toxic byproducts associated with conventional agents like sodium dithionite, aligning with modern green chemistry mandates.

Which industry applications drive the highest demand for Thiourea Dioxide?

The highest volume of demand for Thiourea Dioxide is driven by the Textile Processing industry, where it is extensively used for reductive clearing, stripping of dye residues, and as an activator for bleaching processes. Significant secondary demand originates from the Paper and Pulp sector, particularly for deinking and brightness enhancement in recycled paper production.

What are the primary challenges restraining the growth of the TDO market?

Key restraints include the fluctuating price and securing a stable supply of the primary raw material, thiourea, which impacts overall production costs. Additionally, the limited shelf life and stability issues of certain TDO forms, particularly in high humidity environments, necessitate specialized storage and distribution logistics, increasing operational complexity.

How does the High Purity Grade Thiourea Dioxide segment differ in market characteristics?

High Purity Grade TDO (often 99%+) is specifically designed for specialized applications, mainly pharmaceutical synthesis and high-end chemical reactions. This segment differs by demanding highly stringent quality controls, comprehensive batch traceability, and compliance with cGMP standards, commanding a significant price premium over the standard Technical Grade used in bulk industrial applications.

Which geographical region is forecasted to exhibit the fastest growth in the TDO market?

The Asia Pacific (APAC) region is forecasted to exhibit the fastest market growth, driven by rapid industrial expansion, particularly in the textile and paper manufacturing sectors in countries like China and India, coupled with increasing governmental enforcement of environmental regulations that favor the adoption of cleaner chemical alternatives like TDO.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager