Tile Backer Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434044 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Tile Backer Market Size

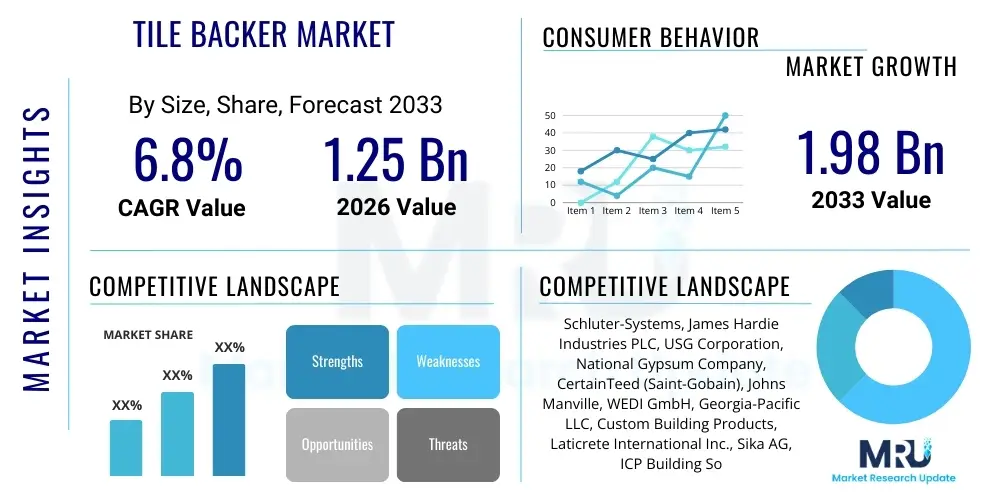

The Tile Backer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.25 billion in 2026 and is projected to reach USD 1.98 billion by the end of the forecast period in 2033.

Tile Backer Market introduction

The Tile Backer Market encompasses the sale and distribution of specialized construction boards used as a substrate behind ceramic, porcelain, or natural stone tiles. These boards, unlike traditional drywall, are engineered to provide superior water resistance, dimensional stability, and mold prevention, making them essential components in wet area applications such such as bathrooms, showers, and commercial kitchens. The primary function of a tile backer is to create a rigid, non-absorbent base that prevents substrate degradation, thus ensuring the longevity and structural integrity of the tiled surface and adhering to stringent building codes globally.

Major applications of tile backer materials include both new construction and renovation projects across the residential and commercial sectors. Benefits such as enhanced moisture management, ease of installation (particularly with lightweight foam core products), and improved thermal insulation properties are driving market adoption. Furthermore, the increasing consumer preference for large-format tiles and luxurious bathroom designs necessitates the use of high-performance backer materials capable of supporting greater weight and minimizing movement, thereby directly boosting demand for premium, specialized solutions like extruded polystyrene (XPS) foam boards.

Driving factors for sustained market growth include stringent environmental regulations promoting mold-resistant materials, rapid urbanization and infrastructure development in emerging economies, and the growing trend of DIY home improvement projects in developed regions. Additionally, continuous innovation in material science, leading to the development of cement boards that incorporate advanced waterproofing additives and lightweight alternatives, further stimulates market expansion by offering solutions that address labor efficiency and material handling challenges on construction sites.

Tile Backer Market Executive Summary

The Tile Backer Market is characterized by robust growth, primarily fueled by global construction expenditure in residential remodeling and commercial hospitality sectors, emphasizing moisture management and durability. Business trends indicate a strong shift towards lightweight and easy-to-install foam-based backer boards, which offer significant labor cost savings compared to traditional heavy cement boards, appealing directly to professional contractors and large-scale developers seeking efficiency gains. Strategic mergers and acquisitions aimed at vertical integration, securing raw material supply chains (such as specialized plastics and cement formulations), and expanding geographic reach, particularly in high-growth areas of Southeast Asia and Latin America, define the competitive landscape. Furthermore, sustainability is becoming a pivotal trend, with manufacturers increasingly developing backer products using recycled content or materials with lower embodied carbon footprints to meet green building standards.

Regionally, North America and Europe currently dominate the market due to established building standards demanding high performance in moisture-prone areas and strong consumer spending on home renovations. However, the Asia Pacific region is anticipated to register the highest CAGR, driven by massive infrastructure investments, rapid urbanization, and rising disposable incomes leading to increased demand for high-quality, durable tiling solutions in new housing and commercial complexes. Regulatory harmonization, particularly within the European Union regarding construction product safety and performance (e.g., CPR requirements), continues to shape regional market dynamics, pushing manufacturers towards documented quality assurance and enhanced fire resistance ratings for their offerings.

In terms of segmentation trends, the Foam Board segment (particularly XPS and polyurethane) is witnessing accelerated adoption due to its inherent waterproofing and lightweight attributes, significantly impacting the market share traditionally held by heavy Cement Boards. Application-wise, the Residential Sector remains the largest revenue generator, driven by extensive bathroom and kitchen remodeling activities, while the Commercial Sector, though smaller, exhibits higher growth potential owing to stringent requirements in hotels, hospitals, and industrial wet rooms that necessitate specialized, high-density backer systems capable of withstanding heavy daily use and chemical cleaning protocols.

AI Impact Analysis on Tile Backer Market

Analysis of common user questions related to AI's influence in the Tile Backer Market reveals key themes centered around optimized manufacturing processes, smart inventory management, and personalized material recommendation systems for contractors. Users are frequently inquiring about how AI can predict construction material demand fluctuations (ensuring optimal stock levels for various backer types like cement, fiber cement, and foam board), minimize material waste during production, and enhance quality control systems to detect subtle structural defects in board manufacturing. A significant area of concern and expectation involves AI-driven logistics optimization to reduce transportation costs—a major factor for heavy building materials—and the integration of AI tools within BIM (Building Information Modeling) software to automatically select the most appropriate tile backer material based on project specifications, humidity levels, and structural loads, moving beyond manual material selection.

- AI-Powered Demand Forecasting: Utilizing machine learning algorithms to predict regional and seasonal demand patterns for specific backer types (e.g., high-density vs. lightweight boards), optimizing production schedules and reducing overstocking.

- Automated Quality Inspection: Deployment of computer vision systems on manufacturing lines to identify and reject boards with structural inconsistencies, porosity issues, or incorrect dimensions, ensuring higher product reliability.

- Optimized Material Formulation: AI algorithms assisting R&D teams in simulating material performance, speeding up the development of new, highly water-resistant, and sustainable backer compositions, particularly leveraging novel polymer or recycled inputs.

- Intelligent Logistics and Supply Chain: Using AI to optimize routing and truck loading for heavy materials, minimizing freight costs and lowering the carbon footprint associated with distribution.

- BIM Integration and Design Assistance: AI tools within BIM platforms automatically recommending the optimal tile backer thickness and material type based on the structure’s intended use, moisture exposure risk, and required fire rating.

DRO & Impact Forces Of Tile Backer Market

The Tile Backer Market is fundamentally driven by the critical need for superior moisture protection in construction, underpinned by stringent building codes and the escalating frequency of renovation and retrofitting activities worldwide. The primary drivers include increasing consumer awareness regarding the risks associated with mold and mildew, which necessitates the use of inherently resistant backer materials over traditional gypsum or plywood. However, the market faces significant restraints, notably the high initial cost associated with premium foam or specialized fiber cement boards compared to cheaper alternatives, and the complexity involved in material handling and installation of particularly dense products. Opportunities abound in developing lightweight, high-performance hybrid materials that balance cost-effectiveness with superior waterproofing characteristics, alongside expanding adoption in emerging markets with rapidly evolving construction standards and a focus on sustainable building practices. These factors generate potent impact forces, where the demand for specialized, certified products (Driver) clashes with price sensitivity and material weight (Restraint), pushing innovation towards efficient, value-engineered solutions (Opportunity).

Segmentation Analysis

The Tile Backer Market is extensively segmented across material type, application, and end-use, reflecting the diverse requirements of the construction industry globally. Material segmentation, which includes Cement Board, Fiber Cement Board, Gypsum Board, and Foam Board (XPS/Polyurethane), is critical as it dictates the product’s core performance characteristics, particularly weight, water resistance, and structural stability. Application segmentation distinguishes between residential and commercial projects, each possessing distinct volume requirements and performance mandates, with commercial spaces generally demanding products that offer enhanced fire ratings and superior longevity. Understanding these segments is crucial for manufacturers to tailor product specifications, pricing strategies, and distribution channels to effectively meet the highly specialized needs of various construction stakeholders, from high-volume housing developers to specialized commercial tiling contractors.

- By Material:

- Cement Board

- Fiber Cement Board

- Gypsum Board (Water Resistant/Treated)

- Foam Board (Extruded Polystyrene - XPS, Polyurethane, others)

- By Application:

- Residential (New Construction, Renovation/Remodeling)

- Commercial (Hospitality, Healthcare, Institutional, Retail)

- By End-Use Location:

- Walls

- Floors

- Ceilings and Specialty Areas (e.g., Steam Rooms, External Cladding)

- By Thickness:

- Less than 1/2 inch

- 1/2 inch to 5/8 inch

- More than 5/8 inch

Value Chain Analysis For Tile Backer Market

The value chain for the Tile Backer Market begins with the upstream sourcing of raw materials, which significantly varies depending on the product type; this includes cement, specialized fiberglass mesh, cellulose fibers, polymers (for foam boards like XPS), and various additives. Manufacturers engage in complex processing—mixing, casting, curing (for cementitious products), or extrusion and foaming (for polymer products)—ensuring compliance with stringent performance specifications such as moisture permeability and flexural strength. The efficiency and environmental impact of these upstream processes are critical determinants of the final product cost and market competitiveness.

Downstream activities involve specialized distribution and installation. Products are primarily routed through multi-step channels involving large building material distributors, specialized tiling wholesalers, and retailers (including major DIY chains). The installation phase is dominated by professional tile contractors, though lightweight foam boards are increasingly targeting skilled DIY users due to their ease of cutting and handling. Direct sales channels are often employed for large commercial projects where specifications are highly customized, necessitating close collaboration between the manufacturer and the construction firm to ensure material performance guarantees and timely delivery.

Distribution logistics are a major cost component due to the bulkiness and, in the case of cement boards, the weight of the product, making efficient warehousing and transportation optimization paramount. Direct channels offer better margin control and specialized technical support but require significant investment in sales infrastructure, while indirect channels provide immediate market penetration and access to a broad contractor base. The entire chain emphasizes technical service and product warranty, as failure in tile backer performance can lead to expensive remediation and structural damage, solidifying the importance of quality control at every stage from raw material selection to final installation certification.

Tile Backer Market Potential Customers

Potential customers for the Tile Backer Market primarily encompass entities engaged in construction, renovation, and interior finishing projects where moisture exposure is a concern. The largest consumer base is the professional tile contractor segment, ranging from small independent installers specializing in residential remodels to large commercial contracting firms undertaking complex hotel, healthcare, or municipal wet room projects. These professionals prioritize ease of installation, proven water resistance, compatibility with various thin-set mortars, and guaranteed longevity, often relying on established brands with robust warranty programs.

In addition to contractors, major building material distributors and wholesale retailers serve as key buyers, purchasing in large volumes to supply both the professional and consumer markets. Institutional buyers, such as hospital and school facility managers, are also significant end-users, requiring specialized, often fire-rated and chemical-resistant, tile backers for high-traffic or sterile environments. The residential DIY segment represents a growing customer base, particularly favoring lightweight, pre-waterproofed foam board systems due to their inherent user-friendliness and reduced need for specialized tools, driven by accessible product information and tutorials from major home improvement retailers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 billion |

| Market Forecast in 2033 | USD 1.98 billion |

| Growth Rate | CAGR 6.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Schluter-Systems, James Hardie Industries PLC, USG Corporation, National Gypsum Company, CertainTeed (Saint-Gobain), Johns Manville, WEDI GmbH, Georgia-Pacific LLC, Custom Building Products, Laticrete International Inc., Sika AG, ICP Building Solutions Group, HILTI Corporation, Rmax Operating, Inc., PABCO Gypsum, Knauf Gips KG, Kingspan Group, Toray Industries Inc., Vencorex. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Tile Backer Market Key Technology Landscape

The Tile Backer Market’s technological landscape is characterized by innovation focused on moisture management, weight reduction, and enhanced structural integration. A critical ongoing development is the refinement of extruded polystyrene (XPS) foam core technology, where manufacturers are integrating advanced polymer formulations and applying proprietary surface coatings (often fiberglass mesh reinforced and cementitious) to create boards that are 100% waterproof, exceptionally lightweight, and ready to receive thin-set mortar immediately. This technological shift is disrupting the dominance of heavy, traditional cement-based systems by offering significant logistical and installation advantages, particularly for large-scale commercial projects where speed and efficiency are paramount. Furthermore, the integration of pre-sloped shower pan systems and niche products designed specifically for steam rooms highlights the push towards systems-based solutions rather than standalone backer boards, providing comprehensive waterproofing guarantees.

Another pivotal technological area involves the material science behind cementitious boards, where research focuses on increasing the use of lightweight aggregate fillers, such as expanded clay or recycled materials, and incorporating advanced crystalline waterproofing admixtures. These innovations aim to reduce the overall weight of cement boards without compromising their compressive strength or fire resistance ratings, addressing the key restraint of handling difficulties. Fiber reinforcement, utilizing alkaline-resistant glass fibers or synthetic polymer fibers, is also a standard technology employed to enhance the flexural strength and crack resistance of both cement and fiber cement panels, ensuring superior performance when supporting heavy or large-format tiles that exert significant shear stress.

Digitization and smart manufacturing techniques, while indirect, are increasingly influencing the quality of tile backer production. Precision cutting technologies, computerized batch mixing, and automated curing chambers ensure high dimensional accuracy and consistent material properties across large production runs, which is crucial for AEO (Answer Engine Optimization) related to product reliability and installation success. The shift towards pre-fabricated, ready-to-tile modules, such as customizable shower benches and niches made from foam backer material, represents a systems technology approach, simplifying complex installations and reducing the potential for job site errors, directly impacting contractor satisfaction and repeat business.

Regional Highlights

- North America: North America, particularly the United States and Canada, represents a mature and high-value market segment. Growth is driven by strict building codes emphasizing water and mold resistance (e.g., ANSI standards for tile installation) and a consistently robust residential renovation sector. Demand is high for premium, lightweight foam boards and specialized moisture barrier systems, reflecting consumer willingness to invest in long-term performance and the preference of contractors for installation speed. The stringent nature of building envelope requirements in areas prone to freeze-thaw cycles further necessitates high-quality, durable backer solutions.

- Europe: Europe maintains a significant market share, characterized by a preference for systems-based waterproofing solutions, particularly in Germany and Scandinavia, where WEDI and Schluter systems dominate. Regulatory compliance with the Construction Products Regulation (CPR) ensures high safety and performance standards. The renovation of older building stock and a strong emphasis on thermal insulation properties (where foam backers excel) contribute substantially to market demand, with a noticeable trend towards environmentally certified or low-VOC content products.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing market globally, fueled by unprecedented rates of urbanization, massive residential housing construction, and infrastructure development in countries like China, India, and Indonesia. While price sensitivity remains a factor, the rapid adoption of modern construction techniques and increasing awareness of international quality standards are driving a shift away from traditional, less protective substrates towards standardized fiber cement and budget-friendly foam boards in high-volume projects.

- Latin America (LATAM): The LATAM region presents significant growth opportunities, driven by increasing foreign investment in commercial infrastructure (hotels, resorts) and a gradual improvement in housing quality standards. Market penetration for specialized tile backers is expanding, though traditional materials still hold significant sway. The market trend is moving towards lightweight, affordable solutions that address the common issue of high humidity and seismic activity, requiring materials with good flexibility and durability.

- Middle East and Africa (MEA): The MEA market is largely driven by large-scale commercial and luxury residential projects, particularly in the Gulf Cooperation Council (GCC) states. Extreme climate conditions necessitate materials with exceptional thermal stability and moisture resistance. The rapid construction of hospitality and retail centers supports demand for high-end, certified tile backer systems that offer guaranteed performance under strenuous conditions, with international certification often being a prerequisite for material approval.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Tile Backer Market.- Schluter-Systems

- James Hardie Industries PLC

- USG Corporation

- National Gypsum Company

- CertainTeed (Saint-Gobain)

- Johns Manville

- WEDI GmbH

- Georgia-Pacific LLC

- Custom Building Products

- Laticrete International Inc.

- Sika AG

- ICP Building Solutions Group

- HILTI Corporation

- Rmax Operating, Inc.

- PABCO Gypsum

- Knauf Gips KG

- Kingspan Group

- Toray Industries Inc.

- Vencorex

- Etex Group

Frequently Asked Questions

Analyze common user questions about the Tile Backer market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the shift from cement board to foam tile backer?

The primary factor is the significant advantage in weight and installation efficiency provided by foam backer boards, such as XPS. Foam boards are inherently waterproof, extremely lightweight, and easier to cut and handle, leading to substantial labor and material handling cost savings for contractors, especially in large-scale installations or complex custom showers.

How does the Tile Backer Market address sustainability concerns in construction?

The market addresses sustainability through the development of products utilizing recycled content (especially in fiber cement formulations), reducing Volatile Organic Compounds (VOCs), and optimizing material density to decrease transportation emissions. Lightweight foam boards also reduce the energy required for construction and structural support, contributing to overall green building certifications.

Which regional market holds the highest growth potential for tile backers by 2033?

The Asia Pacific (APAC) region is projected to hold the highest growth potential. This growth is directly attributable to massive, ongoing urbanization projects, increasing infrastructure investment, and rising adoption of modern, standardized construction materials that prioritize durability and moisture protection in new residential and commercial developments.

Are specialized tile backers required for installations involving steam rooms or exterior applications?

Yes, specialized tile backers are required. Steam rooms necessitate non-porous, fully waterproof materials, often high-density foam boards or specialized cement boards, capable of withstanding extreme humidity and temperature fluctuations. Exterior applications require boards that possess superior resistance to freeze-thaw cycles, UV exposure, and specific wind load requirements, typically involving specialized fiber cement products.

What role do waterproofing membranes play alongside tile backer boards?

Waterproofing membranes act as the final defense system against moisture penetration, applied either as a liquid coating or sheet material over the installed tile backer board. While most modern backers (especially foam) offer inherent water resistance, membranes ensure a monolithic, sealed system across seams and fastener penetrations, providing guaranteed water protection required by industry standards (e.g., TCNA guidelines) for shower installations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Fibre Cement Tile Backer Board Market Statistics 2025 Analysis By Application (Floors, Walls, Ceilings, Others), By Type (1/4" Board, 3/8" Board, 1/2" Board, Others), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Backer Board Market Statistics 2025 Analysis By Application (Residential, Multifamily, Commercial), By Type (Glass Mat Gypsum Wall Board, Cement Board, Foam Tile Backer Boards), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Tile Backer Board Market Statistics 2025 Analysis By Application (Floors, Walls, Ceilings), By Type (1/4" Board, 3/8" Board, 1/2" Board), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager