Tire Pyrolysis Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432448 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Tire Pyrolysis Equipment Market Size

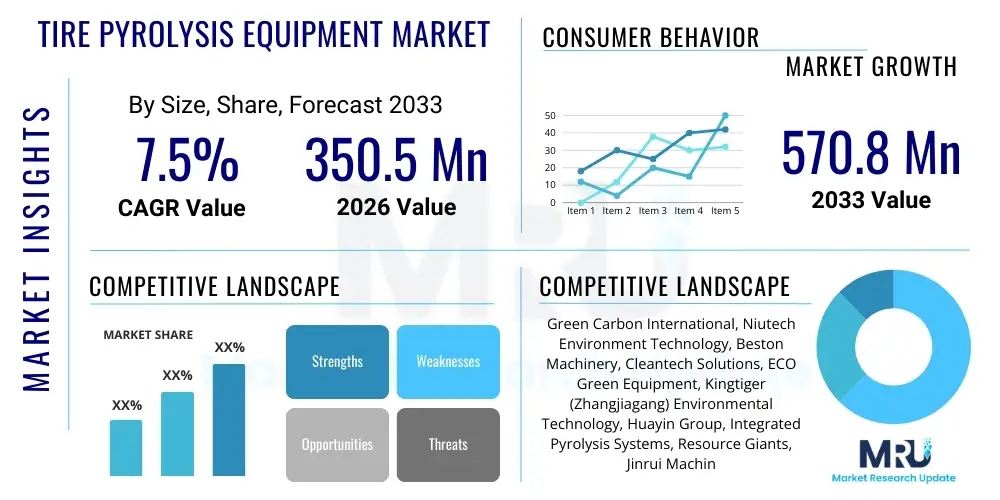

The Tire Pyrolysis Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 350.5 Million in 2026 and is projected to reach USD 570.8 Million by the end of the forecast period in 2033.

Tire Pyrolysis Equipment Market introduction

The Tire Pyrolysis Equipment Market encompasses the specialized machinery used to thermally decompose waste tires in an oxygen-deprived environment. This process, known as pyrolysis, converts end-of-life tires (ELT) into valuable resources, primarily pyrolysis oil, recovered carbon black (rCB), steel wire, and non-condensable gas. The global impetus towards circular economy models and stringent governmental regulations regarding landfill disposal of scrap tires are the primary catalysts fueling the adoption of this equipment. Modern pyrolysis technology aims for high efficiency, scalability, and minimized environmental impact, providing a sustainable solution to the growing problem of tire waste accumulation worldwide.

Tire pyrolysis equipment is fundamentally a chemical processing unit designed for efficient waste management and resource recovery. These systems vary significantly in terms of capacity, ranging from small-scale batch reactors suitable for localized operations to large-scale, continuous-feed plants capable of processing hundreds of tons per day. The core component is the pyrolysis reactor, which operates at elevated temperatures (typically 350°C to 550°C). Major applications span the energy sector, material recycling, and chemical manufacturing, where the recovered outputs serve as feedstocks or fuel sources.

Key benefits driving market penetration include the high recovery yield of usable products, significant reduction in environmental pollution associated with tire waste, and the potential for substantial economic returns from the sale of derived products. The market growth is particularly driven by advancements in reactor design, such as continuous rotary kilns and fluidized bed reactors, which offer improved thermal stability and optimized yields, positioning pyrolysis as a mature and economically viable alternative to traditional tire disposal methods like incineration or simple shredding.

Tire Pyrolysis Equipment Market Executive Summary

The Tire Pyrolysis Equipment Market is characterized by robust growth, largely underpinned by a global shift toward sustainable waste management and resource efficiency. Business trends indicate a strong move away from batch systems toward fully automated, continuous pyrolysis equipment, which maximizes throughput and minimizes operational labor costs, thus improving return on investment (ROI). Furthermore, strategic partnerships between equipment manufacturers and end-users, particularly large recycling conglomerates and cement manufacturers, are becoming prevalent to establish integrated recycling supply chains. The market is also seeing increasing investment in research and development focused on upgrading the quality of recovered products, especially rCB, to meet the specifications required by the rubber and tire manufacturing industries, thereby closing the loop in the tire lifecycle.

Regionally, Asia Pacific dominates the market, driven by massive volumes of ELT generated due to rapid motorization, coupled with governmental mandates in countries like China and India promoting waste-to-energy and resource recovery initiatives. North America and Europe demonstrate mature market growth, primarily influenced by stringent environmental standards and robust subsidies for green technologies, leading to high adoption rates of advanced, highly efficient, and environmentally compliant pyrolysis systems. Emerging economies in Latin America and the Middle East and Africa are demonstrating accelerating adoption, spurred by increasing awareness of environmental liabilities and accessible financing for sustainable infrastructure projects.

Segment trends reveal that the Continuous Pyrolysis Equipment segment is expected to exhibit the fastest growth, owing to its operational superiority and scalability compared to batch processes. In terms of capacity, the 10 TPD to 30 TPD segment remains highly popular, balancing operational costs with required output for medium-sized recycling facilities. The recovered carbon black (rCB) product segment holds significant potential, as market participants focus heavily on refining purification techniques to achieve high-grade rCB suitable for use in new tire production, offering a premium revenue stream beyond just pyrolysis oil for fuel purposes.

AI Impact Analysis on Tire Pyrolysis Equipment Market

Common user inquiries concerning AI in the Tire Pyrolysis Equipment Market often revolve around operational efficiency, predictive maintenance, yield optimization, and the integration of smart controls. Users are keen to understand how AI can minimize energy consumption, predict equipment failure before catastrophic downtime occurs, and dynamically adjust process parameters (like temperature profiles and residence time) to maximize the output quality of products such as pyrolysis oil and rCB. The summary indicates a high expectation for AI to transform these systems from reactive operations into predictive, highly optimized chemical processes, addressing key industry pain points related to variability in feedstock quality and the need for consistent output specification.

The integration of Artificial Intelligence and Machine Learning (ML) is fundamentally enhancing the operational intelligence of modern tire pyrolysis plants. AI algorithms analyze vast datasets generated by sensors monitoring reactor temperature, pressure, feed rate, and flue gas composition. This data-driven approach allows for real-time adjustments, significantly improving thermal efficiency and ensuring product consistency, which is crucial for maximizing the market value of rCB and pyrolysis oil. Furthermore, AI contributes substantially to reducing greenhouse gas emissions by optimizing burner efficiency and controlling exhaust gas treatment systems.

Predictive maintenance powered by AI is another major transformative application. By analyzing vibration, temperature, and historical performance data, ML models can accurately predict component degradation (such as refractories or seals), scheduling maintenance proactively rather than reactively. This minimizes unexpected shutdowns, increases overall equipment effectiveness (OEE), and lowers the total cost of ownership (TCO), making pyrolysis operations more reliable and economically attractive for investors and operators seeking consistent production schedules.

- AI-driven optimization of reaction kinetics for maximum rCB yield and quality.

- Predictive maintenance schedules reducing unplanned downtime by up to 30%.

- Automated anomaly detection in gas emission monitoring for regulatory compliance.

- Real-time adjustment of furnace temperature based on dynamic feedstock composition.

- Machine learning models for forecasting market demand for pyrolysis oil and rCB.

- Enhancement of sorting and preparation processes using AI-powered vision systems.

- Optimization of energy consumption through smart utility management systems.

DRO & Impact Forces Of Tire Pyrolysis Equipment Market

The Tire Pyrolysis Equipment Market is driven primarily by escalating volumes of waste tires globally and increasingly strict environmental regulations prohibiting their landfill disposal or uncontrolled burning. Restraints include the high initial capital investment required for continuous processing plants and challenges related to achieving commercial-grade quality specifications for recovered carbon black (rCB), which limits its use in high-value applications like premium tire manufacturing. Opportunities lie in technological advancements, particularly in catalytic pyrolysis techniques that enhance product quality and yield, and the emerging market for sustainable fuel and chemical feedstocks derived from pyrolysis oil. These factors collectively exert significant impact forces on market trajectory, pushing stakeholders toward innovation and scaling up infrastructure to meet circular economy demands.

Drivers: A paramount driver is the legislative pressure in developed nations, such as the EU’s waste directives and EPA guidelines in the US, mandating sustainable ELT management. Simultaneously, the favorable economics of resource recovery, where the revenue generated from selling rCB and oil can offset operational costs, provides a compelling financial incentive. The global push for renewable and sustainable materials further accelerates adoption, as industries seek alternatives to virgin resources. The increasing demand for low-sulfur industrial fuel, which pyrolysis oil often qualifies as, solidifies its position as a viable alternative in the energy sector.

Restraints: Significant barriers include the difficulty in processing variable feedstock, which necessitates rigorous pre-treatment (shredding, de-beading) and can impact operational consistency. Furthermore, the public perception and regulatory hurdles associated with handling potentially hazardous by-products, such as non-condensable gases and complex waste streams, require specialized environmental management systems, adding to complexity and cost. Financing large-scale continuous plants remains a challenge, particularly for smaller enterprises in developing regions, hindering widespread market expansion despite evident environmental benefits.

Opportunities: The market benefits from substantial opportunities in developing advanced purification and activation techniques for rCB, allowing it to substitute traditional carbon black in higher-grade rubber and plastic applications. Additionally, the increasing interest in deploying decentralized, modular pyrolysis units tailored for remote locations or smaller municipal waste streams presents a scalable market niche. Leveraging catalytic pyrolysis can enhance the yield and quality of light fractions in pyrolysis oil, positioning it as a direct chemical feedstock rather than just industrial fuel, thereby accessing higher-margin markets and driving future investment and technological maturity.

Segmentation Analysis

The Tire Pyrolysis Equipment Market is comprehensively segmented based on the operational type of the equipment, its processing capacity, the primary products recovered, and the ultimate application sectors utilizing the recovered materials. This granular segmentation allows market stakeholders to identify specialized niches and optimize their investment strategies based on regional waste generation rates and local regulatory environments. The technology segmentation between batch, semi-continuous, and continuous processes is especially critical, reflecting the industry's progression toward high-throughput, automated solutions necessary for large-scale commercial viability and stable product supply.

The capacity segments directly correlate with investment scale and target end-user market. Smaller capacity units (Less than 10 TPD) are typically used for pilot projects or localized recycling efforts, while the larger capacity units (More than 30 TPD) cater to major industrial recyclers or integrated waste-to-energy facilities requiring maximum efficiency and economies of scale. Analyzing the product segmentation highlights the critical value proposition of pyrolysis, indicating that while pyrolysis oil serves as the immediate bulk output, the quality and market acceptance of recovered carbon black (rCB) often dictate the long-term profitability and success of a pyrolysis operation.

Application segmentation illustrates the varied demand channels for pyrolysis outputs. Traditional applications involve selling the oil to cement kilns or power generation utilities. However, the future growth hinges on specialized applications, such as using high-grade rCB in tire manufacturing itself or utilizing the derived gas for internal process heat generation, ensuring energy self-sufficiency for the plant and minimizing external utility costs, thereby improving overall operational sustainability.

- By Type:

- Batch Pyrolysis Equipment

- Semi-continuous Pyrolysis Equipment

- Continuous Pyrolysis Equipment

- By Capacity:

- Less than 10 TPD (Tons Per Day)

- 10 TPD to 30 TPD

- More than 30 TPD

- By Product:

- Pyrolysis Oil

- Recovered Carbon Black (rCB)

- Steel Wire

- Syn Gas (Non-condensable Gas)

- By Application:

- Tire Manufacturing

- Rubber Recycling Plants

- Cement Kilns

- Power Generation and Heat Production

- Chemical and Petrochemical Industries

Value Chain Analysis For Tire Pyrolysis Equipment Market

The value chain for the Tire Pyrolysis Equipment Market begins with the upstream sourcing of raw materials, particularly specialized metals and components required for high-temperature and high-pressure reactor construction, demanding stringent quality control and supply chain reliability. Equipment manufacturers then focus on design, fabrication, and technological innovation, integrating advanced features like automatic feeding, continuous discharge systems, and efficient emission control technologies. Distribution channels typically involve direct sales to large industrial clients or specialized engineering procurement and construction (EPC) contractors who manage turnkey project installations globally. The complexity of the equipment necessitates high levels of technical support and post-installation services.

The downstream analysis focuses on the output markets for the recovered products. Pyrolysis oil is often sold directly to large industrial consumers (e.g., cement producers, brick factories) or refined further for use in chemical processes. Recovered carbon black (rCB) requires subsequent processing—including grinding, pelletizing, and sometimes de-ashing—to meet the quality standards demanded by rubber compounders and plastic manufacturers. The value chain is strengthened through indirect channels, such as specialized rCB traders and commodity brokers, who facilitate the movement of large volumes of recovered materials across international borders, ensuring liquidity in the secondary material markets.

The distribution strategy is generally direct for major continuous plants, as these projects involve extensive customization, installation oversight, and training, requiring a close relationship between the manufacturer and the operator. For smaller batch systems, indirect distribution through regional distributors or agents is common. Success in the value chain is increasingly reliant on vertical integration or strong partnership models where equipment providers collaborate with waste tire collectors and product off-takers to ensure consistent feedstock supply and guaranteed product demand, mitigating key market risks for new plant installations.

Tire Pyrolysis Equipment Market Potential Customers

The primary potential customers and end-users of Tire Pyrolysis Equipment are entities committed to large-scale waste management, resource recovery, and industrial energy production. This includes established rubber recycling plants seeking to upgrade from mechanical shredding to chemical processing, and specialized Waste-to-Energy (WTE) facilities aiming to diversify their feedstock to include End-of-Life Tires (ELT). These buyers require high-capacity, reliable, and automated continuous pyrolysis systems that can guarantee consistent uptime and process large, uninterrupted streams of tire waste while adhering to stringent environmental permit requirements.

Another significant customer segment comprises large industrial consumers of energy and heat, such as cement manufacturers and power generation utilities. These companies are interested in purchasing pyrolysis equipment not only for waste diversion benefits but also to utilize the resulting pyrolysis oil and syn gas as a cheaper and often more sustainable alternative to fossil fuels in their high-heat industrial processes. The internal combustion of syn gas derived from the process also provides a pathway toward energy self-sufficiency, which is a major financial draw for energy-intensive manufacturing operations.

Furthermore, new entrants and specialized chemical companies focused on circular economy initiatives represent a high-growth customer base. These buyers are particularly interested in equipment that can produce high-quality, refined recovered carbon black (rCB) suitable for integration into virgin rubber formulations or high-performance plastics. Municipal solid waste (MSW) authorities and governmental agencies also serve as key potential customers, often procuring equipment through public-private partnerships to manage local tire stockpiles and reduce illegal dumping, driven by societal and ecological pressures.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350.5 Million |

| Market Forecast in 2033 | USD 570.8 Million |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Green Carbon International, Niutech Environment Technology, Beston Machinery, Cleantech Solutions, ECO Green Equipment, Kingtiger (Zhangjiagang) Environmental Technology, Huayin Group, Integrated Pyrolysis Systems, Resource Giants, Jinrui Machinery, Skytech Environmental, Rui-Sheng Environmental Protection Equipment, Qilong Machinery, AGICO Group, Brightway Machinery, Doing Group, Gemco Energy, Gansu Environmental Protection, Shandong Suny Group, Wuxi Sinda Thermal Energy. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Tire Pyrolysis Equipment Market Key Technology Landscape

The technological landscape of the Tire Pyrolysis Equipment Market is dominated by advancements aimed at increasing efficiency, enhancing product quality, and ensuring environmental compliance. The shift from outdated, pollution-prone batch reactors to highly engineered continuous pyrolysis systems represents the most significant trend. Continuous systems, which utilize rotary kilns or fluidized bed technology, offer better heat transfer rates, precise temperature control, and consistent material flow, essential for producing standardized, marketable recovered products. Furthermore, these modern systems often incorporate advanced scrubbing and exhaust gas treatment technologies, ensuring emissions (such as dioxins and furans) remain well below regulatory thresholds, a critical factor for securing operating permits in developed markets.

Catalytic pyrolysis is emerging as a critical innovation, utilizing specialized catalysts to lower reaction temperatures and selectively crack the long hydrocarbon chains in tire rubber. This targeted approach results in higher yields of light-fraction oils, making the pyrolysis oil more suitable as a direct chemical feedstock rather than just heavy fuel oil. The technological focus is moving beyond simple recovery to 'upgrading,' where post-pyrolysis treatment systems are integrated. This includes refining units for oil desulfurization and sophisticated mechanical and chemical processing units (e.g., thermal treatment, micronizing) for recovering high-specification carbon black, essential for creating a truly circular material flow back to the tire industry.

Moreover, digitalization and automation play a pivotal role in the current technology landscape. Modern pyrolysis plants are equipped with sophisticated Distributed Control Systems (DCS) and SCADA systems, allowing operators to monitor every stage of the process remotely and implement data-driven adjustments. This integration enhances safety protocols, optimizes energy usage by managing the input of generated syn gas, and provides comprehensive data logging necessary for environmental reporting and process optimization. The convergence of hardware efficiency and software intelligence defines the cutting edge of tire pyrolysis technology.

Regional Highlights

The regional analysis reveals distinct market dynamics driven by differing regulatory frameworks, waste generation rates, and industrial capabilities.

- Asia Pacific (APAC): APAC is the largest and fastest-growing market due to massive ELT generation, rapid industrialization, and favorable governmental policies, particularly in China and India, promoting resource recovery and waste reduction. High-capacity continuous plants are highly sought after to address urban waste challenges efficiently.

- Europe: Europe represents a mature market characterized by strict environmental legislation and a well-established circular economy infrastructure. Demand is focused on technologically advanced, fully compliant, and automated systems capable of producing premium rCB that meets EU chemical standards (REACH).

- North America: Driven by state-level mandates and corporate sustainability goals, North America exhibits high adoption rates, particularly for systems integrated with existing waste management infrastructure. Focus areas include optimizing rCB quality for automotive applications and utilizing pyrolysis gas for energy generation within the plant or nearby industrial complexes.

- Latin America (LATAM): This region is an emerging market with growing investment in waste management infrastructure. Market demand is primarily for cost-effective, semi-continuous or batch systems initially, transitioning towards continuous technology as financing becomes more accessible and regulatory enforcement strengthens across major economies like Brazil and Mexico.

- Middle East and Africa (MEA): The MEA region shows nascent growth, propelled by large-scale energy projects and government diversification strategies away from oil dependence. There is a specific interest in utilizing pyrolysis oil as a localized fuel source for industries, particularly in high-temperature operating environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Tire Pyrolysis Equipment Market.- Green Carbon International

- Niutech Environment Technology

- Beston Machinery

- Cleantech Solutions International Ltd.

- ECO Green Equipment

- Kingtiger (Zhangjiagang) Environmental Technology Co., Ltd.

- Huayin Group

- Integrated Pyrolysis Systems (IPS)

- Resource Giants

- Jinrui Machinery Co., Ltd.

- Skytech Environmental

- Rui-Sheng Environmental Protection Equipment Co., Ltd.

- Qilong Machinery

- AGICO Group

- Brightway Machinery

- Doing Group

- Gemco Energy

- Gansu Environmental Protection Technology Group

- Shandong Suny Group

- Wuxi Sinda Thermal Energy Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Tire Pyrolysis Equipment market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary economic benefit of investing in tire pyrolysis equipment?

The primary economic benefit stems from converting a waste liability (end-of-life tires) into profitable, marketable resources, specifically high-demand pyrolysis oil (industrial fuel) and recovered carbon black (rCB), which offsets operational costs and generates substantial revenue streams.

What are the key differences between batch, semi-continuous, and continuous pyrolysis systems?

Batch systems process fixed quantities and require cooling between cycles, offering lower initial cost but lower capacity. Continuous systems operate without interruption, offering high scalability, better product consistency, and superior efficiency, making them ideal for large commercial operations.

Is recovered carbon black (rCB) suitable for new tire manufacturing?

Standard rCB requires significant post-processing, purification, and activation treatments to meet the stringent quality standards (e.g., low ash content, specific surface area) required for direct use in high-performance new tire compounds. Technological advancement is rapidly closing this quality gap.

Which geographical region leads the global demand for tire pyrolysis equipment?

Asia Pacific (APAC), particularly driven by China and India, leads the global market in terms of volume and new installations, fueled by high waste tire generation rates and strong government support for resource recycling and circular economy mandates.

How does the pyrolysis process address environmental concerns compared to incineration?

Pyrolysis is a thermal decomposition process conducted in an oxygen-free environment, which prevents the combustion that leads to high levels of harmful air pollutants, such as sulfur oxides and nitrogen oxides, significantly reducing the environmental footprint associated with tire waste disposal.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager