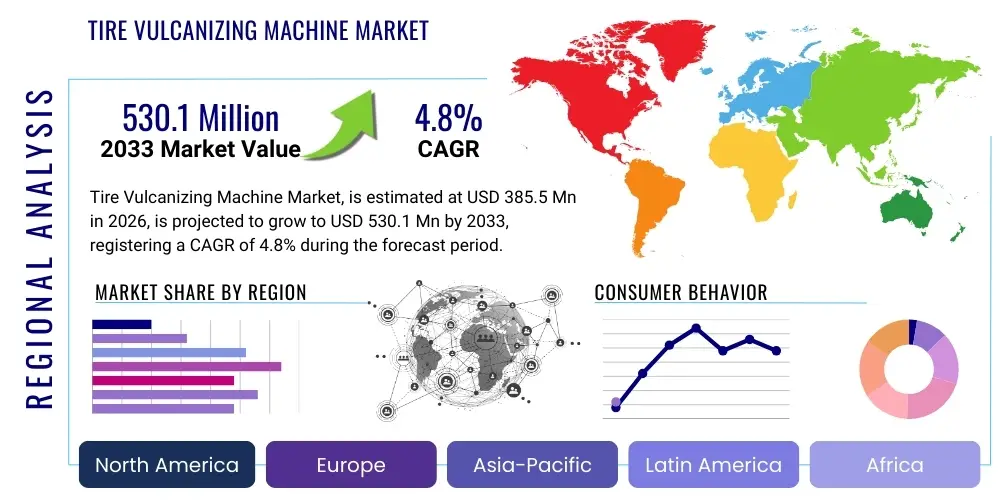

Tire Vulcanizing Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436899 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Tire Vulcanizing Machine Market Size

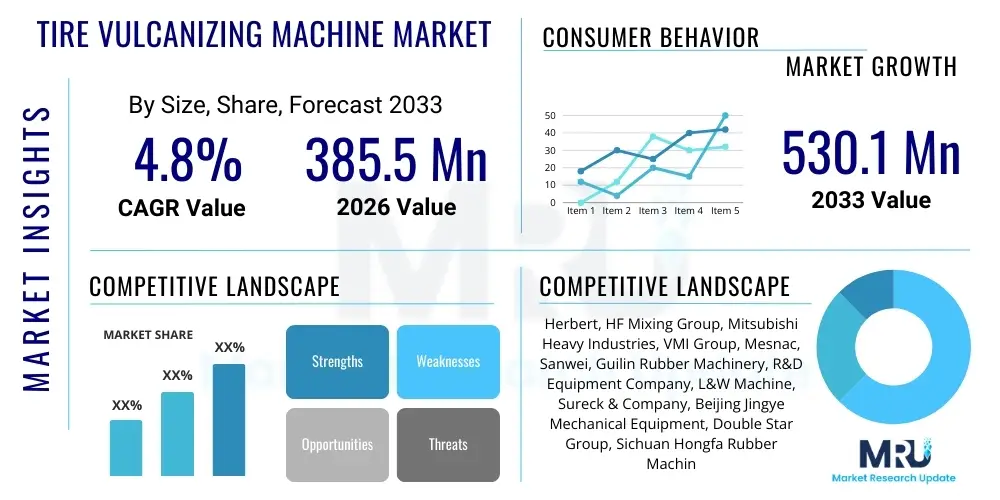

The Tire Vulcanizing Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at $385.5 Million in 2026 and is projected to reach $530.1 Million by the end of the forecast period in 2033.

Tire Vulcanizing Machine Market introduction

The Tire Vulcanizing Machine Market encompasses specialized industrial equipment designed for the curing process of rubber used in manufacturing new tires or retreading existing ones. Vulcanization is a critical chemical process that enhances the rubber's durability, elasticity, and resistance to heat and abrasion by cross-linking polymer chains, typically using sulfur under heat and pressure. These machines range from segmented molds used for passenger car tires to bladder presses and autoclave systems utilized for large off-the-road (OTR) and specialty tires. The core function is to maintain precise temperature and pressure profiles over time, ensuring homogeneous curing across the tire body, which is essential for safety and performance standards globally.

Major applications of these machines are primarily found within tire manufacturing plants (OEMs) and commercial retreading facilities. Original equipment manufacturers utilize high-capacity, automated vulcanizing presses for mass production, focusing on minimizing cycle times and maximizing energy efficiency. Conversely, retread shops deploy more versatile machines capable of handling diverse tire sizes and patterns, often prioritizing repair quality and sustainability. The increasing global demand for passenger, commercial, and specialty vehicles, particularly in rapidly urbanizing economies, directly fuels the necessity for robust and efficient vulcanizing infrastructure.

The key benefits derived from advanced tire vulcanizing machines include improved tire quality consistency, reduced energy consumption through optimized heating cycles, and enhanced operational safety due to sophisticated monitoring and control systems. Driving factors for market growth include stringent regulatory mandates regarding tire performance and lifespan, the rising adoption of tire retreading programs aimed at reducing material waste, and continuous technological advancements in automation and predictive maintenance. Furthermore, the global shift toward electric vehicles (EVs), which require tires with specific weight tolerances and low rolling resistance, necessitates investment in newer, more precise vulcanizing equipment.

Tire Vulcanizing Machine Market Executive Summary

The Tire Vulcanizing Machine Market is characterized by moderate but stable growth, fundamentally driven by the cyclical nature of the automotive industry and increasing infrastructure investments globally. Business trends indicate a strong move toward integrating Industry 4.0 concepts, focusing on fully automated, robotic handling systems and centralized monitoring platforms to optimize the notoriously energy-intensive vulcanization process. Manufacturers are prioritizing modular designs that allow for flexible production runs and quicker mold changeovers, catering to the growing diversity of tire specifications, including run-flat tires and specialized compounds for high-performance vehicles. Competition is centered around providing equipment with the highest Mean Time Between Failures (MTBF) and superior thermal efficiency, moving away from purely capital cost competition.

Regional trends highlight the Asia Pacific (APAC) as the primary growth engine, spearheaded by China, India, and Southeast Asian nations, which are experiencing massive expansion in both domestic vehicle production and tire export capacity. North America and Europe, while representing mature markets, are focusing heavily on replacement and modernization, driven by the need to comply with stringent environmental regulations and improve energy efficiency, particularly in retreading operations. The shift towards sustainable manufacturing practices is also fostering innovation, with regional governmental incentives pushing for the adoption of precision heating methods, such as microwave or induction vulcanization, although conventional steam and hot water curing remains dominant for now.

Segment trends reveal that the segmented mold presses segment, crucial for passenger car tire OEMs, maintains the largest market share due to high volume production requirements. However, the radial tire retreading segment is showing the fastest growth rate, fueled by commercial fleet operators seeking cost efficiencies and reduced environmental impact. Technological segmentation points toward increased adoption of automated tire building and curing systems (ABC systems), which minimize human intervention and enhance product consistency. Furthermore, there is a growing demand for auxiliary equipment, such as curing bladders made from advanced elastomers, which withstand higher temperatures and pressures, thereby extending machine lifespan and reducing maintenance downtime within the vulcanizing ecosystem.

AI Impact Analysis on Tire Vulcanizing Machine Market

Common user questions regarding AI’s influence typically revolve around how artificial intelligence can stabilize the volatile curing process, reduce scrap rates, and predict equipment failure in high-pressure, high-temperature environments. Users are primarily concerned with integrating existing legacy vulcanizing machines with modern AI interfaces for real-time monitoring and control. Key themes analyzed include the use of AI for thermal modeling to optimize energy use, predictive analytics for mold maintenance schedules, and machine learning algorithms to correlate rubber compound inputs with final tire quality outputs, minimizing curing variability. The expectation is that AI will transform vulcanization from a monitored process into a self-optimizing system, drastically improving efficiency metrics.

The integration of AI and Machine Learning (ML) is fundamentally changing the operational paradigm of the Tire Vulcanizing Machine Market by enhancing process control and predictive maintenance capabilities. AI algorithms analyze vast datasets generated by sensors monitoring pressure, temperature, cycle time, and energy consumption across multiple curing presses simultaneously. This allows manufacturers to achieve hyper-precise control over the chemical reaction, adjusting parameters in real-time to account for slight variances in raw material batches or environmental conditions. By identifying optimal curing curves specific to complex tire structures, AI minimizes the risk of under-curing or over-curing, which are major causes of structural defects and premature tire failure, thereby significantly reducing waste and improving final product quality consistency.

Furthermore, AI-driven predictive maintenance represents a major value proposition. Vulcanizing machines operate under immense stress, and unscheduled downtime due to component failure (e.g., bladders, hydraulic systems, or heating elements) is costly. AI models, trained on historical failure data and current operational sensor readings, can accurately forecast the remaining useful life (RUL) of critical components. This enables maintenance activities to be scheduled proactively during planned downtime, moving away from reactive repair models. This shift maximizes machine uptime, optimizes maintenance resource allocation, and extends the overall service life of the expensive vulcanizing equipment, resulting in substantial operational expenditure savings for tire manufacturers globally.

- AI optimizes thermal mapping, reducing energy consumption by up to 15%.

- Machine learning algorithms predict mold fouling and wear, scheduling precise maintenance cycles.

- Real-time process control minimizes curing variations, leading to lower scrap rates.

- Computer vision systems, integrated with AI, detect subtle post-vulcanization defects.

- AI enables rapid commissioning and tuning of new equipment based on existing factory floor performance data.

- Enhanced supply chain integration using AI to adjust curing based on incoming rubber compound variability.

DRO & Impact Forces Of Tire Vulcanizing Machine Market

The dynamics of the Tire Vulcanizing Machine Market are shaped by powerful Drivers (D), Restraints (R), and Opportunities (O), which collectively define the Impact Forces influencing future investment and technological direction. Key drivers include the relentless growth in global vehicle parc, particularly in emerging economies, and the mandatory need for high-quality tires meeting international safety standards. Restraints often revolve around the high initial capital expenditure required for purchasing advanced automated machines and the inherently intensive energy consumption of the vulcanization process, putting pressure on operating margins. Opportunities are concentrated in leveraging digital transformation, adopting green manufacturing techniques, and the burgeoning retreading market driven by sustainability mandates. These factors combine to create a moderate to high impact force, pushing manufacturers towards high-efficiency, highly automated solutions.

Major drivers fueling market expansion involve the infrastructural build-out across Asia and Latin America, necessitating increased production of commercial and OTR tires, which require robust vulcanizing equipment. Furthermore, strict safety regulations imposed by bodies like the NHTSA and ECE mandate higher quality control in the curing process, driving replacement cycles for older, less precise machinery. The accelerating trend towards specialization—such as manufacturing tires for specific EV platforms or high-performance sports cars—demands vulcanizing machines capable of extremely tight tolerances and sophisticated temperature management. This specialized demand justifies the high cost of advanced machinery and drives the replacement of obsolete, manually controlled systems.

Conversely, significant restraints hinder more rapid adoption. The sheer cost of installing large-scale vulcanizing presses, coupled with the long payback period, poses a substantial barrier, especially for smaller manufacturers or independent retreading facilities. Energy cost volatility remains a primary concern, as vulcanization consumes massive amounts of steam or electricity. Moreover, the environmental impact associated with the process, specifically emissions and waste heat generation, necessitates continuous, costly investment in abatement and recovery technologies. Opportunities, however, lie in innovative heating technologies (e.g., microwave, electromagnetic induction) that promise reduced energy consumption and cycle times, along with the growing viability of the retreading segment, which uses vulcanizing technology to extend tire life, aligning with global circular economy goals.

Segmentation Analysis

The Tire Vulcanizing Machine Market is primarily segmented based on machine type, operation type, tire type, and heating medium, reflecting the diverse requirements across the tire manufacturing and retreading value chain. Segmentation by machine type—segmented molds, bladder presses, and hydraulic/mechanical presses—differentiates between OEM production capacity and flexibility needs. Operation type segmentation highlights the shift from manual and semi-automatic systems toward fully automated presses, essential for high-volume, precision manufacturing. The tire type segment (Passenger Car Radial (PCR), Commercial Vehicle (CV), Off-the-Road (OTR), and specialty tires) dictates the size and complexity of the required vulcanizing press, while the heating medium (steam, hot water, electricity) affects operational costs and thermal efficiency.

- By Machine Type:

- Segmented Mold Presses

- Bladder Curing Presses

- Two-piece Curing Molds

- Autoclave Systems (primarily for OTR and Retreading)

- By Operation Type:

- Manual/Semi-Automatic Presses

- Fully Automatic Presses

- By Tire Type:

- Passenger Car Radial (PCR) Tires

- Commercial Vehicle (CV) Tires

- Off-the-Road (OTR) Tires

- Aircraft & Specialty Tires

- By Heating Medium:

- Steam Heated Systems

- Hot Water Systems

- Electrically Heated Systems (Induction/Microwave)

- By End-Use Application:

- Original Equipment Manufacturers (OEM)

- Retreading and Repair Facilities

Value Chain Analysis For Tire Vulcanizing Machine Market

The value chain for the Tire Vulcanizing Machine Market begins with upstream suppliers, focusing heavily on raw materials and specialized components required for high-pressure, high-temperature machinery. This includes manufacturers of high-grade steel alloys (critical for press frames and molds), sophisticated hydraulic components (pumps, valves), precision sensor technology, and high-temperature sealing materials. Upstream profitability is often dictated by raw material price volatility, particularly steel and copper, and the specialized expertise required for component manufacturing. Strong partnerships between machine builders and specialized component suppliers are crucial to ensure durability and reliability under extreme operating conditions.

The midstream stage involves the core activities of the vulcanizing machine manufacturers—design, engineering, assembly, and testing. Manufacturers differentiate themselves through proprietary intellectual property related to thermal management systems, automated handling mechanisms, and software controls (PLC/SCADA systems). The emphasis here is on precision engineering to meet tight dimensional tolerances and integrate advanced automation features, such as robotic tire loading and unloading. Distribution channels are typically direct, given the custom nature and high capital investment of these machines. Manufacturers employ specialized sales engineers to manage complex procurement processes, installation, and long-term maintenance contracts, often partnering with local service providers for rapid regional support.

Downstream activities center on the major end-users: Original Equipment Manufacturers (OEMs) and retreading facilities. OEMs require continuous, high-volume production, focusing on total cost of ownership (TCO) and cycle time efficiency. Retreading facilities prioritize flexibility, reliability, and precision curing for repaired tires. Direct sales and robust aftermarket services, including spare parts, mold maintenance, and operational training, are vital for maintaining customer loyalty and recurring revenue streams. The indirect channel occasionally involves system integrators or authorized regional distributors who manage sales and commissioning in markets where the primary manufacturer does not maintain a large local presence.

Tire Vulcanizing Machine Market Potential Customers

Potential customers for Tire Vulcanizing Machine Market products are dominated by two primary categories: global tire manufacturing giants and regional commercial tire retreading services. The global tire manufacturers, including Michelin, Bridgestone, Continental, and Goodyear, represent the largest volume buyers, consistently investing in new, high-capacity, automated presses to expand production capacity in high-growth regions like APAC and to modernize facilities in North America and Europe. Their procurement decisions are driven by factors like machine throughput, energy efficiency benchmarks, and seamless integration capabilities with existing factory automation systems, seeking machines capable of 24/7 high-intensity operation.

The second major customer segment consists of independent and franchised tire retreading and repair facilities. These end-users typically invest in smaller, more flexible vulcanizing autoclaves and bladder presses that can handle a variety of heavy-duty truck, bus, and off-road tires. For these customers, the primary drivers are machine reliability, low maintenance requirements, and the ability to achieve high-quality, long-lasting repairs that meet strict regulatory standards for fleet usage. As the focus on fleet operational costs and environmental sustainability increases, the demand for sophisticated retreading equipment capable of handling modern radial tire structures is growing significantly.

A smaller, but highly specialized customer group includes manufacturers of specialty rubber products and large industrial entities that manage vast fleets of heavy machinery (e.g., mining or construction companies) who might operate small, dedicated repair shops. Furthermore, emerging EV startups and associated component suppliers are increasingly seeking specialized, precise vulcanizing equipment to produce tires optimized for electric propulsion, which often requires unique compounds and curing profiles to minimize rolling resistance and handle instantaneous torque demands. This niche market represents a future growth area requiring highly customized machine solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $385.5 Million |

| Market Forecast in 2033 | $530.1 Million |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Herbert, HF Mixing Group, Mitsubishi Heavy Industries, VMI Group, Mesnac, Sanwei, Guilin Rubber Machinery, R&D Equipment Company, L&W Machine, Sureck & Company, Beijing Jingye Mechanical Equipment, Double Star Group, Sichuan Hongfa Rubber Machinery, Santosh Rubber & Plastic Machinery, Shenyang Blue Star Rubber and Plastics Machinery. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Tire Vulcanizing Machine Market Key Technology Landscape

The technology landscape of the Tire Vulcanizing Machine Market is evolving rapidly, driven by the need for enhanced energy efficiency, cycle time reduction, and improved product consistency. Traditional technologies relied heavily on saturated steam as the primary heat transfer medium, necessitating massive boiler infrastructure and incurring high energy losses. The shift now is towards technologies that offer superior control and faster heat transfer. A notable advancement is the introduction of segmented presses featuring independent zone temperature control, allowing manufacturers to apply precise thermal profiles across different sections of the tire (tread, sidewall, bead area) simultaneously, which is crucial for maximizing the performance of complex modern rubber compounds.

The most transformative current technologies involve advanced automation and non-conventional heating methods. Fully automated presses integrate robotic systems for pre-curing preparation, tire loading, and post-curing extraction, minimizing human error and significantly reducing cycle times, crucial for high-volume OEMs. On the heating front, technologies such as electrically heated presses utilizing induction or microwave curing are gaining traction. Induction heating offers faster and more precise temperature adjustments than traditional steam, drastically cutting down standby energy consumption and reducing reliance on large centralized steam systems. While capital intensive, these technologies offer compelling long-term operational savings and flexibility.

Furthermore, the integration of sophisticated monitoring and control systems, often leveraging SCADA and Industrial Internet of Things (IIoT) platforms, is now standard. These systems provide comprehensive data logging and real-time visualization of internal mold pressure, temperature gradient, and hydraulic system status. This wealth of data facilitates the implementation of predictive maintenance protocols and supports Quality 4.0 initiatives by ensuring every curing cycle adheres strictly to specified parameters. The continuous development of durable, high-performance curing bladders and optimized mold designs also plays a key role, directly impacting both the longevity of the machine and the final quality finish of the tire surface.

Regional Highlights

The global Tire Vulcanizing Machine Market displays distinct regional investment patterns and demand drivers, heavily correlated with local automotive production rates and fleet management practices.

- Asia Pacific (APAC): APAC is the epicenter of growth, driven by massive new plant establishment and capacity expansion in China, India, and ASEAN countries. These regions benefit from lower manufacturing costs and booming domestic and export tire demand. Investments here focus primarily on fully automated, high-throughput segmented presses for PCR and CV tire production to serve the largest vehicle parc globally.

- North America: This mature market focuses on replacing aging equipment with high-efficiency, Industry 4.0 compliant machines. North America is a major center for advanced retreading operations, driving steady demand for high-precision autoclave and bladder presses, particularly for high-mileage commercial fleets prioritizing sustainability and cost control.

- Europe: Characterized by stringent environmental regulations and a strong focus on high-performance tire manufacturing (especially for premium and EV segments), Europe emphasizes energy-efficient vulcanization technologies and advanced process control systems to maintain product superiority and comply with emissions standards. Modernization of existing facilities, rather than new construction, dominates demand.

- Latin America (LATAM): Growth is stable, driven by the replacement market and moderate expansion in Brazil and Mexico. Demand is mixed, encompassing both new presses for OEM capacity and robust, low-maintenance machines for the regional retreading sector serving vast transportation networks.

- Middle East and Africa (MEA): This region presents emerging opportunities linked to industrialization projects and infrastructure development. Demand is segmented, with interest in basic, reliable vulcanizing equipment for local tire assembly and specialized OTR presses for extensive mining and construction operations.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Tire Vulcanizing Machine Market.- Herbert

- HF Mixing Group

- VMI Group

- Mitsubishi Heavy Industries

- Mesnac

- Sanwei

- Guilin Rubber Machinery

- R&D Equipment Company

- L&W Machine

- Sureck & Company

- Beijing Jingye Mechanical Equipment

- Double Star Group

- Sichuan Hongfa Rubber Machinery

- Santosh Rubber & Plastic Machinery

- Shenyang Blue Star Rubber and Plastics Machinery

- Sino-American Rubber Machinery

- Fujian Huian Xinfeng Machinery

- Kobe Steel

- Takaoka Electric Mfg.

- Comerio Ercole SpA

Frequently Asked Questions

Analyze common user questions about the Tire Vulcanizing Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the adoption of fully automatic vulcanizing machines?

The primary driver is the necessity to achieve consistently high tire quality and reduce labor costs while minimizing cycle times. Fully automatic systems ensure precise thermal and pressure controls, significantly lowering scrap rates and boosting overall production efficiency compared to manual or semi-automatic operations.

How does the vulcanizing machine market address increasing demands for energy efficiency?

The market addresses efficiency through technological innovations, including the transition from traditional steam systems to advanced heating mediums like induction or high-pressure hot water systems. Modern presses also incorporate superior thermal insulation and AI-optimized curing cycles to minimize energy loss during standby and operation, aligning with global sustainability targets.

Which geographical region holds the largest potential for market expansion during the forecast period?

The Asia Pacific (APAC) region is projected to hold the largest potential for expansion. This growth is underpinned by rapid industrialization, massive investments in automotive manufacturing capacity (particularly in China and India), and the escalating regional demand for new tires driven by expanding vehicle ownership.

What is the significance of the retreading segment for the Tire Vulcanizing Machine Market?

The retreading segment is highly significant as it offers a sustainable, cost-effective solution for commercial fleets. Demand in this sector fuels the market for specialized autoclaves and bladder presses designed for curing rebuilt truck and aircraft tires, extending tire lifespan and supporting circular economy objectives.

What are the key technological restraints limiting the widespread adoption of advanced vulcanizing machines?

The primary restraint is the extremely high initial capital expenditure (CapEx) required for advanced automated presses and the necessary ancillary infrastructure (e.g., specialized utility systems). This financial barrier often restricts rapid adoption, particularly among smaller and mid-sized tire manufacturers and retreading facilities globally.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager