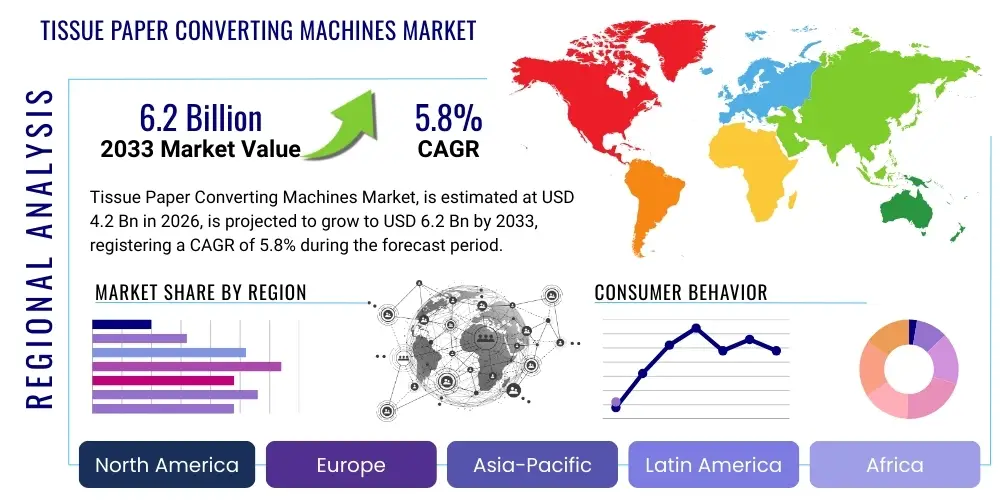

Tissue Paper Converting Machines Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438559 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Tissue Paper Converting Machines Market Size

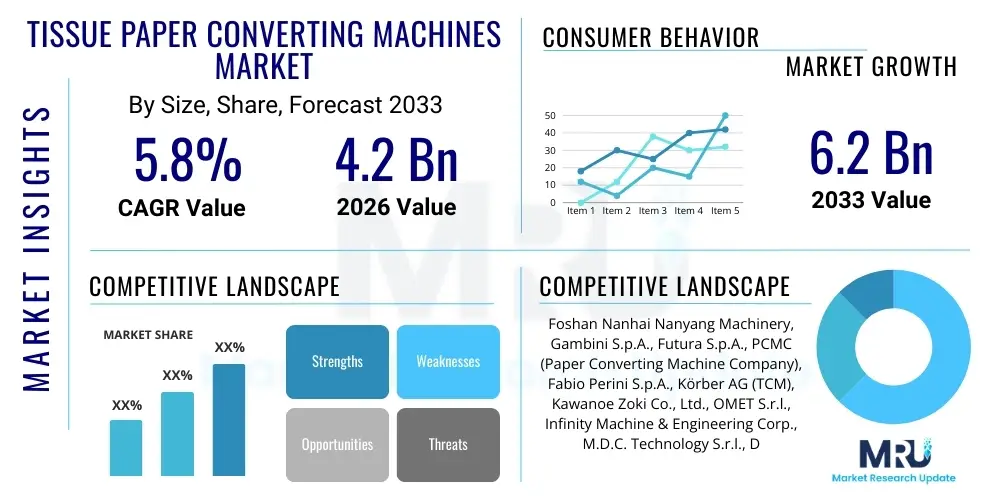

The Tissue Paper Converting Machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 4.2 Billion in 2026 and is projected to reach USD 6.2 Billion by the end of the forecast period in 2033. This robust growth trajectory is primarily fueled by increasing global demand for hygiene products, rapid urbanization, and significant technological advancements focused on higher efficiency and sustainable production within emerging economies.

Tissue Paper Converting Machines Market introduction

The Tissue Paper Converting Machines Market encompasses specialized industrial equipment designed to transform large parent rolls of paper (jumbo rolls) into consumer-ready sanitary products such as toilet paper, facial tissues, paper towels, and napkins. These machines handle the complex processes of unwinding, slitting, rewinding, folding, embossing, laminating, perforating, and packaging at high speeds and volumes. The core objective of these machines is to ensure precision, efficiency, and consistent quality across diverse product specifications required by modern consumers and commercial entities.

Major applications for tissue paper converting machines span the entire hygiene and sanitary product spectrum, driven by public health awareness and evolving consumer preferences. Key applications include the high-volume production of multi-ply toilet rolls, specialized medical-grade tissues, absorbent kitchen towels, and customized napkin sizes for the hospitality industry. The increasing emphasis on premiumization, such as three-ply or scented products, necessitates sophisticated converting machinery capable of handling complex layering and precise material integration.

Driving factors for market expansion include the burgeoning population in Asia Pacific demanding basic hygiene products, stringent health regulations requiring better sanitary standards in commercial spaces, and continuous innovation in machine design. These innovations focus on minimizing material waste, reducing energy consumption, and enhancing automation levels (Industry 4.0 integration) to optimize operational costs for manufacturers globally. The benefits of modern converting machinery, such as increased throughput and operational flexibility, position them as critical investments for tissue manufacturers aiming for market competitiveness.

Tissue Paper Converting Machines Market Executive Summary

The Tissue Paper Converting Machines Market is undergoing a significant transformation characterized by the push for high automation and sustainability. Business trends indicate a strong shift toward integrated production lines that combine converting, packaging, and palletizing processes into seamless, high-speed operations. Manufacturers are increasingly investing in modular machine designs that allow for rapid product changeovers and customization, addressing the fragmented and evolving consumer demand for specialized tissue formats and materials. Mergers and acquisitions focusing on technology integration and market share expansion, particularly in high-growth regions like Southeast Asia and Latin America, remain prominent business strategies.

Segment trends highlight the dominance of fully automatic rewinders and folders due to their capacity for continuous, high-volume output and reduced reliance on manual labor. The application segment sees substantial growth in the paper towel and napkin categories, correlating with rising sanitation standards in the commercial sector, especially post-pandemic. The focus on energy efficiency is driving the adoption of servo motor technology over traditional hydraulic or pneumatic systems, offering precision control and lower operational expenditures across all machinery types.

Regionally, Asia Pacific (APAC) stands out as the primary growth engine, fueled by infrastructure development, rising disposable incomes, and the migration of manufacturing bases seeking lower operational costs. North America and Europe, while mature markets, are leading in adopting advanced, high-technology converting solutions centered around robotics and waste reduction technologies, adhering to strict environmental regulations. The Middle East and Africa (MEA) region shows significant potential due to new capacity additions driven by localized manufacturing initiatives aimed at reducing reliance on imports and catering to rapidly expanding urban centers.

AI Impact Analysis on Tissue Paper Converting Machines Market

User queries regarding the intersection of Artificial Intelligence (AI) and the Tissue Paper Converting Machines Market frequently revolve around topics such as predictive maintenance optimization, enhanced quality control, and the role of AI in supply chain resilience. Users are keen to understand how AI algorithms can minimize downtime, which is critical in high-speed converting environments. Key concerns center on the capital investment required for AI implementation, data security, and the need for upskilling the existing workforce to manage complex, AI-driven systems. Expectations are high regarding AI's ability to optimize energy usage, predict material defects (like inconsistent paper density or splicing errors) instantaneously, and fine-tune machine parameters for maximum throughput based on real-time operational data and historical performance benchmarks.

AI's influence is transforming the operational paradigms of tissue converting lines, moving them from reactive maintenance models to proactive, data-driven systems. By analyzing sensor data streams from components like embossing rollers, tension controls, and cutting blades, AI systems can accurately predict equipment failure hours or days in advance, allowing for scheduled maintenance interventions that significantly boost Overall Equipment Effectiveness (OEE). Furthermore, machine vision systems powered by deep learning enable instantaneous, non-destructive inspection of finished products, ensuring that aesthetic flaws or structural defects are identified and rejected before packaging, drastically improving the perceived quality and reducing consumer complaints.

The integration of AI also extends into complex production scheduling and material utilization. AI algorithms can analyze incoming jumbo roll characteristics (weight, moisture content, width) and dynamically adjust machine settings—such as web tension or perforation length—to maximize usable output and minimize trim waste. This optimization is particularly valuable in the highly competitive and cost-sensitive tissue industry. The adoption of AI is increasingly becoming a competitive necessity, offering a clear path to achieving higher production speeds, greater operational stability, and improved resource management, thereby future-proofing manufacturing investments.

- AI-driven Predictive Maintenance: Minimizes unplanned downtime by forecasting equipment failures using real-time sensor data analysis.

- Enhanced Quality Control (Q-AIO): Utilizes machine vision and deep learning for automated, high-speed defect detection (e.g., tears, incorrect embossing patterns).

- Dynamic Process Optimization: AI algorithms adjust converting parameters (speed, tension, perforation) based on raw material variability to maximize yield and reduce waste.

- Optimized Energy Management: AI systems learn optimal operating modes to minimize energy consumption during start-up, run-time, and idle phases.

- Supply Chain Integration: Improved forecasting of spare parts requirements and raw material needs, enhancing logistics efficiency.

- Autonomous Operation: Enables higher levels of automation, where machines self-calibrate and troubleshoot minor issues without human intervention.

DRO & Impact Forces Of Tissue Paper Converting Machines Market

The market is predominantly driven by increasing global hygiene awareness, rapid population growth, especially in developing economies, and significant technological advancements promoting high-speed, automated production. Restraints include the high initial capital investment required for sophisticated machinery, fluctuating raw material pulp prices, and stringent environmental regulations concerning energy usage and material waste. Opportunities lie in expanding into untapped rural markets, developing highly sustainable and biodegradable machine components, and offering integrated smart factory solutions (Industry 4.0). These factors collectively define the trajectory of the tissue converting sector, pushing manufacturers toward efficiency and technological sophistication to maintain competitiveness.

The principal impact forces governing this market are the increasing consumer demand for premium and specialized tissue products (like ultra-soft or septic-safe toilet paper), which necessitates more complex machine capabilities such as advanced lamination and micro-embossing. Secondly, the regulatory environment in developed regions dictates the adoption of cleaner production technologies, favoring manufacturers that integrate energy-efficient motors and closed-loop water systems into their designs. Thirdly, the intense competitive landscape drives continuous innovation in machine speed and output capacity, making the investment cycle shorter for tissue manufacturers needing to keep pace with industry throughput standards.

The balance between high production efficiency (Driver) and the massive capital expenditure (Restraint) required forms a critical equilibrium point in market growth. Companies that can leverage technological opportunities, particularly those related to modular design and sustainable manufacturing, are best positioned to mitigate regulatory impacts and raw material volatility. The shift towards digitized operations (OEE monitoring, remote diagnostics) further intensifies the competitive force, making data utilization a key differentiator among leading converting machine suppliers.

Segmentation Analysis

The Tissue Paper Converting Machines Market segmentation provides a granular view of market dynamics based on machine type, operation, application, and end-user. This layered analysis helps stakeholders understand where investment and innovation are concentrated. The complexity of converting jumbo rolls into varied consumer products necessitates distinct machinery types, with rewinders being crucial for roll products (toilet paper, kitchen towels) and folders dominating the facial tissue and napkin segments. The high growth in emerging markets emphasizes the increasing adoption of fully automatic, integrated lines, pushing semi-automatic solutions towards niche or small-scale operations. Application analysis reveals sustained demand for toilet tissue, while the paper towel category exhibits accelerated growth due to elevated hygiene standards in public and commercial settings globally.

Understanding the interplay between machine type and operation is key to predicting future purchasing trends. High-volume manufacturers serving mass markets prioritize speed and fully automated lines, often integrating robotics for automated core loading and packaging. Conversely, specialty converters focusing on unique product characteristics, such as decorative napkins or specific industrial wipes, might prioritize flexibility and customization over sheer speed. This bifurcation in manufacturer requirement drives innovation toward highly configurable machine platforms that can swiftly switch between different product specifications, minimizing downtime associated with tooling changes and setup times.

Geographic segmentation remains vital, linking specific technology adoption rates to regional maturity. Developed markets primarily seek replacement and upgrade cycles focused on advanced features like energy recovery systems and highly precise servo controls. Emerging economies, however, are characterized by greenfield investments and the establishment of new production capacities, leading to high demand for reliable, robust, and cost-effective mid-to-high speed automatic machinery. The end-user segregation confirms that commercial and industrial applications collectively represent the largest revenue share, reflecting the vast consumption of tissue products in hotels, hospitals, offices, and food service sectors globally.

- By Machine Type

- Rewinders (For Toilet Rolls and Kitchen Towels)

- Folders (For Napkins, Facial Tissues, Interfolded Towels)

- Laminators and Embossers

- Packaging and Wrapping Machines (Including Bundlers and Case Packers)

- Slitters and Cutters

- Core Winders and Accumulators

- By Operation

- Fully Automatic Converting Lines

- Semi-Automatic Converting Lines

- By Application

- Toilet Paper Converting Machines

- Facial Tissue Converting Machines

- Paper Towel Converting Machines

- Napkin and Tabletop Tissue Converting Machines

- Specialty Tissue Converting Machines (Industrial Wipes, Medical Tissues)

- By End-User

- Commercial/Institutional (Hospitals, Hotels, Offices)

- Industrial

- Household/Retail

Value Chain Analysis For Tissue Paper Converting Machines Market

The value chain for tissue paper converting machines begins with upstream activities, dominated by raw material and component suppliers, particularly specialized metallurgy, robotics, servo systems, and sophisticated electronics for controls and automation. Precision engineering firms provide the critical components such as high-tolerance cutting blades, complex embossing rollers, and reliable web tension controls. The quality and reliability of these upstream inputs directly influence the performance and lifespan of the finished converting machinery. Key dependencies here include the global supply of specialized steel alloys and advanced sensor technology, which are often subject to geopolitical and economic volatility.

The core of the value chain involves the machine manufacturers (OEMs) themselves, who undertake design, assembly, integration, and stringent quality testing. These companies often differentiate themselves through proprietary software, modular designs, and deep domain expertise in web handling and perforation techniques. Distribution channels are typically a mix of direct sales (for large, custom-built, fully integrated lines) and indirect distribution through regional agents or specialized industrial distributors, particularly for standard, mid-range equipment and aftermarket parts. The complexity of installation, commissioning, and specialized training often necessitates a direct involvement of the OEM's technical team.

Downstream activities include the extensive services provided post-sale, such as preventative maintenance contracts, spare parts supply, remote diagnostics, and line upgrades. The lifecycle support provided by OEMs is a significant revenue driver and a crucial factor in customer loyalty, given the high operational stakes of tissue production lines. The final tier of the value chain involves the end-user tissue manufacturers, who integrate the converting machines into their production facilities to serve retailers, commercial consumers, and industrial clients globally. Efficient supply chain management, particularly relating to the rapid delivery of consumables and wear parts, is critical to ensuring continuous throughput at the customer level.

Tissue Paper Converting Machines Market Potential Customers

Potential customers for tissue paper converting machines are primarily large-scale integrated paper manufacturers and specialized non-integrated converters who focus solely on turning parent reels into finished consumer products. These buyers are typically characterized by a continuous need for high throughput, high levels of automation, and a demand for machinery that can efficiently handle various paper grades, from virgin pulp to recycled fiber. Geographically, major end-users are concentrated in regions experiencing rapid urbanization and regulatory pressure to enhance hygiene standards, such as India, China, Brazil, and across Southeast Asia, alongside established manufacturers in Western Europe and North America seeking efficiency upgrades.

The customer base can be further segmented into multinational corporations (MNCs) that prioritize globally standardized equipment specifications, reliability, and comprehensive service contracts, and local or regional players who may prioritize lower initial investment and faster lead times. Industrial buyers, often involved in producing specialty wipes or medical-grade papers, represent a distinct segment requiring highly customized and precise slitting and folding equipment. The decision-making process for these high-value purchases is long and involves multiple stakeholders, including production engineering, finance, and procurement departments, emphasizing the need for robust total cost of ownership (TCO) assessments.

Specific end-users include major consumer packaged goods (CPG) companies that have integrated tissue manufacturing operations, private label manufacturers serving major retailers, and specialized suppliers to the hospitality and healthcare sectors. The demand characteristics of these segments differ significantly: CPG companies seek high-speed, 24/7 reliability, while institutional suppliers often require flexibility in packaging and unit count presentation. Identifying these specific buyer needs allows converting machine suppliers to tailor their offerings, whether focusing on high-volume production efficiency or machine adaptability for diverse product lines.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.2 Billion |

| Market Forecast in 2033 | USD 6.2 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Foshan Nanhai Nanyang Machinery, Gambini S.p.A., Futura S.p.A., PCMC (Paper Converting Machine Company), Fabio Perini S.p.A., Körber AG (TCM), Kawanoe Zoki Co., Ltd., OMET S.r.l., Infinity Machine & Engineering Corp., M.D.C. Technology S.r.l., Dechangyu Paper Machinery Manufacturing Co., Ltd., STAX Technologies, Elettric80 S.p.A., Bretting Manufacturing, and Zhejiang Guangda Paper Technology Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Tissue Paper Converting Machines Market Key Technology Landscape

The Tissue Paper Converting Machines Market is driven by continuous engineering innovation aimed at enhancing throughput, reducing operational expenditure (OPEX), and improving product quality consistency. A primary technological focus is the widespread adoption of advanced servo motor technology, replacing older mechanical linkages and drives. Servo systems offer unparalleled precision in controlling web tension, perforation accuracy, and cutting cycles, which is critical for handling lightweight paper grades at high speeds (often exceeding 600 meters per minute). This shift also facilitates quick, digital changeovers between different product specifications, significantly improving line flexibility and reducing setup downtime, directly impacting profitability for tissue manufacturers.

Another pivotal technological trend is the integration of Industry 4.0 concepts, characterized by comprehensive connectivity and data utilization. Modern converting lines are equipped with thousands of sensors feeding data into centralized Manufacturing Execution Systems (MES) and Cloud-based analytics platforms. This digitalization supports remote diagnostics, real-time OEE monitoring, and sophisticated preventive maintenance scheduling. Furthermore, advanced embossing techniques, such as registered embossing and point-to-point lamination systems, are becoming standard features, allowing manufacturers to create complex, multi-layered products that offer enhanced softness, bulk, and absorbency, catering to the premium segment demand.

Sustainability is also fundamentally reshaping the technology landscape. Machine builders are developing components and processes specifically optimized for sustainable production, including highly efficient vacuum systems to manage paper dust, closed-loop waste handling systems that minimize trim waste, and energy recovery mechanisms. Furthermore, there is growing interest in machinery capable of handling alternative raw materials, such as bamboo pulp or specialized recycled fibers, which often require more delicate and precise web handling technologies to maintain structural integrity during the high-speed converting process. The increasing use of robotic automation in secondary packaging (bundling, palletizing) further reduces labor costs and increases the overall efficiency of the integrated converting line.

Regional Highlights

The global Tissue Paper Converting Machines Market exhibits distinct regional consumption and production patterns. Asia Pacific (APAC) dominates the market both in terms of production capacity expansion and consumption growth. Countries like China, India, and Indonesia are experiencing robust demand driven by demographic factors, rising middle-class disposable incomes, and government initiatives promoting sanitation. This region is characterized by significant greenfield investments, favoring reliable, mid-to-high-speed automatic converting lines that offer a good balance between cost and performance. The sheer volume required to satisfy the APAC consumer base ensures this region remains the key growth engine for new machinery sales throughout the forecast period.

North America and Europe represent mature yet highly sophisticated markets. Growth here is primarily driven by replacement cycles and the demand for technological upgrades focused on efficiency, sustainability, and flexibility. Manufacturers in these regions prioritize machines incorporating advanced automation (e.g., robotic core loading, automated reel splicing), advanced diagnostics, and features that comply with strict environmental standards, such as low energy consumption and the ability to process innovative sustainable raw materials. The highly competitive retail environment also forces regional manufacturers to invest in machines capable of rapid SKU (Stock Keeping Unit) changeovers to address dynamic private label demands.

Latin America (LATAM) and the Middle East & Africa (MEA) are emerging as significant investment destinations. LATAM, particularly Brazil and Mexico, is seeing localized expansion to mitigate import dependencies and serve large domestic populations. The MEA region is witnessing infrastructure development and a push towards local manufacturing capacity, supported by government investment. These regions often require rugged, reliable machinery suitable for challenging operating environments, with an emphasis on robust after-sales support and technical training. The growth in the hospitality and healthcare sectors in major urban hubs across the Gulf Cooperation Council (GCC) countries and South Africa is fueling specific demand for high-volume napkin and paper towel converting equipment.

- Asia Pacific (APAC): Highest growth rate, driven by urbanization, population increase, and extensive greenfield investment in countries such as China, India, and Vietnam. Focus on high-volume automatic rewinders.

- North America: Market stability, driven by replacement and technological upgrades. Strong focus on servo technology, energy efficiency, and secondary packaging automation (robotics).

- Europe: High adoption of Industry 4.0 standards, emphasizing precision engineering, sustainable machine components, and flexibility for niche product specialization and handling recycled paper fibers.

- Latin America (LATAM): Moderate growth supported by domestic capacity expansion in key economies like Brazil and Mexico. Demand for robust, reliable automatic machines with strong local service support.

- Middle East and Africa (MEA): Emerging market characterized by new capacity building, particularly in the GCC countries and South Africa, targeting commercial/institutional tissue consumption growth.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Tissue Paper Converting Machines Market.- Foshan Nanhai Nanyang Machinery

- Gambini S.p.A.

- Futura S.p.A.

- PCMC (Paper Converting Machine Company)

- Fabio Perini S.p.A.

- Körber AG (TCM)

- Kawanoe Zoki Co., Ltd.

- OMET S.r.l.

- Infinity Machine & Engineering Corp.

- M.D.C. Technology S.r.l.

- Dechangyu Paper Machinery Manufacturing Co., Ltd.

- STAX Technologies

- Elettric80 S.p.A. (Automation Solutions)

- Bretting Manufacturing

- Zhejiang Guangda Paper Technology Co., Ltd.

- Xi’an Aerospace Huayang Converting Equipment Co., Ltd.

- Wangda Industrial Co., Ltd.

- Toscotec S.p.A. (Integrated solutions)

- A. Celli Paper S.p.A.

- Helios Automazioni S.r.l.

Frequently Asked Questions

Analyze common user questions about the Tissue Paper Converting Machines market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the projected Compound Annual Growth Rate (CAGR) for the Tissue Paper Converting Machines Market?

The market is projected to exhibit a CAGR of 5.8% between 2026 and 2033, driven primarily by increasing global demand for hygiene products and technological investments in automation.

Which machine type holds the largest market share in the converting sector?

High-speed Automatic Rewinders, specifically those used for producing toilet paper and kitchen towels, currently hold the largest market share due to the consistently high global consumption volume of these roll products.

How is Industry 4.0 influencing the design of tissue converting machines?

Industry 4.0 integration involves deploying sophisticated sensors, AI-driven predictive maintenance, and remote diagnostics capabilities, enabling higher machine efficiency, reduced downtime, and optimization of operational expenditure (OPEX).

Which geographical region is expected to drive the highest growth in the market?

The Asia Pacific (APAC) region is expected to register the highest growth rate, fueled by rapid urbanization, significant population growth, and extensive greenfield investment in new production facilities across key emerging economies.

What are the primary factors restraining growth in the tissue paper converting machinery market?

Key restraints include the substantial initial capital investment required for high-speed, automated converting lines, high maintenance costs, and volatility in global pulp prices affecting overall profitability for end-user manufacturers.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager