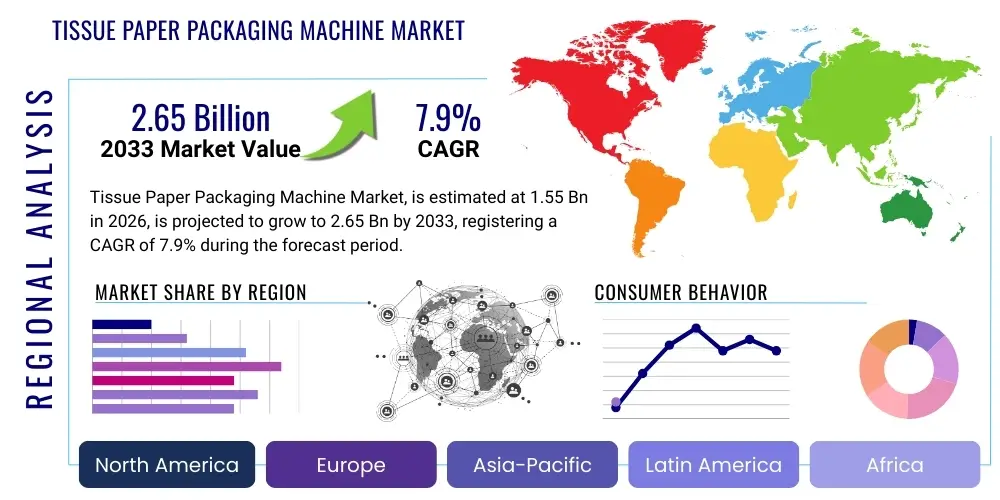

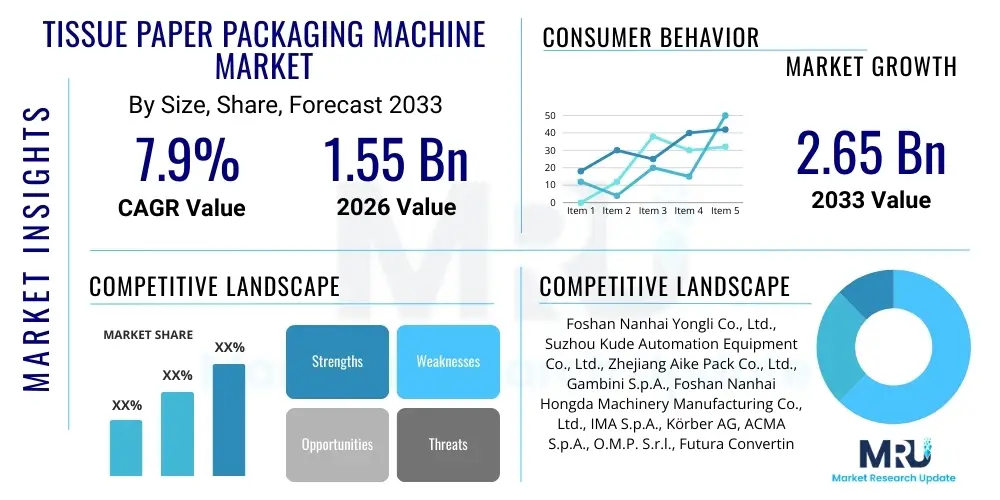

Tissue Paper Packaging Machine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440396 | Date : Jan, 2026 | Pages : 253 | Region : Global | Publisher : MRU

Tissue Paper Packaging Machine Market Size

The Tissue Paper Packaging Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.9% between 2026 and 2033. The market is estimated at USD 1.55 Billion in 2026 and is projected to reach USD 2.65 Billion by the end of the forecast period in 2033.

Tissue Paper Packaging Machine Market introduction

The Tissue Paper Packaging Machine Market encompasses the manufacturing, sales, and servicing of specialized machinery designed for wrapping, bagging, bundling, and otherwise packaging various forms of tissue paper products. These machines are crucial for maintaining hygiene, optimizing logistics, enhancing product presentation, and extending the shelf life of items like facial tissues, toilet paper rolls, paper towels, and napkins. The sophisticated equipment involved ranges from semi-automatic systems suitable for smaller operations to fully automated, high-speed lines integrated into large-scale production facilities. Their primary function is to transform bulk tissue products into consumer-ready packages, ensuring efficiency, consistency, and adherence to quality standards throughout the packaging process.

Key product descriptions within this market include primary packaging machines that wrap individual tissue units, secondary packaging machines that bundle multiple units together, and tertiary packaging machines that prepare bundled products for shipment. These machines are engineered to handle a wide array of packaging materials, including various plastics, films, and sometimes paper-based solutions, catering to diverse market demands and sustainability objectives. The major applications for these machines span household tissue product manufacturing, commercial and institutional tissue suppliers, and industrial-scale production lines. The versatility of modern packaging solutions allows for customization in terms of package size, design, and material, offering flexibility to manufacturers.

The benefits derived from advanced tissue paper packaging machines are manifold, significantly contributing to operational excellence and market competitiveness. These include enhanced production efficiency through automation, reduced labor costs, improved product hygiene and protection, superior aesthetic appeal of packaged goods, and precise portion control. Driving factors for market growth are profoundly influenced by global demographic trends, escalating urbanization, rising disposable incomes, and an increasing emphasis on health and hygiene, particularly in the wake of global health events. Furthermore, the burgeoning e-commerce sector necessitates robust and reliable packaging solutions that can withstand the rigors of shipping and handling, thereby fueling demand for advanced packaging machinery in the tissue sector.

Tissue Paper Packaging Machine Market Executive Summary

The Tissue Paper Packaging Machine Market is currently experiencing robust growth, driven by an amalgamation of global business trends, evolving regional dynamics, and significant advancements across various product segments. Manufacturers are increasingly prioritizing automation, seeking machines that offer higher speeds, greater precision, and reduced operational complexities to meet the escalating global demand for tissue products. This overarching business trend is supported by an industry-wide push towards digital integration, including the adoption of IoT and AI capabilities to enhance machine performance, facilitate predictive maintenance, and streamline supply chain logistics. Companies are also heavily investing in flexible and modular machine designs that can quickly adapt to changing packaging requirements, product variations, and material innovations, reflecting a strategic pivot towards agility and responsiveness in manufacturing.

Regionally, the market exhibits varied growth trajectories and maturity levels. Asia Pacific continues to emerge as a dominant force, propelled by rapid industrialization, expanding consumer bases, and significant investments in manufacturing infrastructure, especially in countries like China and India. This region benefits from rising disposable incomes and changing lifestyle patterns that foster increased consumption of hygienic tissue products. Conversely, mature markets in North America and Europe, while still significant, are primarily driven by the need for technological upgrades, sustainability initiatives, and the replacement of older machinery with more efficient and eco-friendly models. These regions are at the forefront of adopting advanced automation and smart factory concepts, influencing global standards for packaging efficiency and environmental responsibility.

Segmentation trends within the market highlight distinct areas of innovation and demand. The fully automatic machine segment is experiencing accelerated growth due to its superior efficiency, reliability, and capacity to handle high production volumes with minimal human intervention. Furthermore, there is a notable shift towards specialized packaging solutions tailored for specific tissue products, such as high-speed bundlers for toilet rolls or precise overwrappers for facial tissues, indicating a market demand for customized machinery. The integration of sustainable packaging features, including the ability to handle recyclable or compostable films, is gaining traction across all segments, reflecting heightened consumer and regulatory pressure for environmentally responsible manufacturing practices. These integrated trends collectively underscore a dynamic and expanding market landscape for tissue paper packaging machines.

AI Impact Analysis on Tissue Paper Packaging Machine Market

The integration of Artificial Intelligence (AI) into the Tissue Paper Packaging Machine Market is revolutionizing operational paradigms, addressing critical user concerns related to efficiency, quality, and cost-effectiveness. Users frequently inquire about how AI can enhance production speed without compromising precision, automate complex decision-making processes, and provide real-time insights for optimizing machine performance. There is a strong expectation that AI will deliver significant improvements in areas such as predictive maintenance, reducing costly downtime and extending equipment lifespan, as well as enabling more dynamic and responsive production scheduling. Furthermore, users are keen to understand AI's capability to detect subtle defects, ensure consistent product quality, and facilitate rapid adaptation to varying packaging specifications and material types, driving a paradigm shift towards smarter, more autonomous packaging lines.

- AI-powered vision systems enhance quality control by detecting minuscule defects in packaging materials or product presentation, far surpassing human capabilities.

- Predictive maintenance algorithms analyze machine data to forecast potential component failures, enabling proactive servicing and minimizing unexpected downtime.

- Optimized production scheduling through AI dynamically adjusts packaging lines to changing demand, raw material availability, and machine status, maximizing throughput.

- AI-driven robotics improve precision and speed in complex packaging tasks, such as stacking, sorting, and palletizing, reducing labor requirements and errors.

- Customization and personalization are facilitated by AI, allowing machines to quickly reconfigure for different product variants, package sizes, or promotional designs.

- Energy efficiency is boosted by AI systems that monitor and optimize machine operations, reducing power consumption during various stages of the packaging process.

- Supply chain integration is enhanced as AI analyzes packaging data in conjunction with inventory and logistics, ensuring optimal stock levels and timely delivery of finished goods.

- Operator assistance systems leverage AI to provide real-time guidance, troubleshooting support, and training for machine operators, improving skill transfer and operational consistency.

DRO & Impact Forces Of Tissue Paper Packaging Machine Market

The Tissue Paper Packaging Machine Market is influenced by a complex interplay of drivers, restraints, and opportunities, all shaped by significant impact forces. Key drivers include the relentless growth in global tissue paper consumption, propelled by increasing urbanization, rising disposable incomes, and a heightened awareness of hygiene, especially in emerging economies. The expansion of the e-commerce sector further necessitates robust and efficient packaging solutions, as products must be securely packaged for transit and presentation. Additionally, the continuous drive for automation across industries to reduce labor costs, improve operational efficiency, and ensure consistent product quality significantly fuels the demand for advanced packaging machinery. These factors collectively create a strong positive impetus for market expansion, pushing manufacturers to innovate and scale their offerings to meet diverse market needs.

However, the market also faces considerable restraints that temper its growth potential. The most significant is the high initial capital investment required for purchasing and implementing sophisticated tissue paper packaging machines, which can be a barrier for small and medium-sized enterprises (SMEs) or new entrants. The rapid pace of technological advancements, while a driver, also poses a restraint by leading to potential technological obsolescence, requiring manufacturers to frequently upgrade or replace machinery to remain competitive. Furthermore, fluctuations in raw material prices for packaging films and components can impact production costs for both machine manufacturers and their end-users. Stringent regulatory standards concerning food contact materials, packaging waste, and energy consumption also add layers of complexity and cost to machine design and operation, requiring constant adaptation and compliance.

Amidst these dynamics, several opportunities emerge that promise future growth and innovation. The increasing global emphasis on sustainable packaging presents a significant opportunity for manufacturers to develop machines compatible with eco-friendly materials like biodegradable films, recycled content, and paper-based solutions, aligning with consumer preferences and regulatory pushes. Emerging markets in Asia Pacific, Latin America, and Africa offer untapped potential due to their rapidly growing populations and increasing adoption of Western hygiene standards, creating new avenues for market penetration. Moreover, the integration of smart factory concepts, including the use of IoT, AI, and robotics, offers opportunities for enhanced automation, predictive maintenance, and optimized production, enabling manufacturers to provide more value-added solutions. These opportunities, when strategically leveraged, can help overcome restraints and unlock substantial market growth.

Segmentation Analysis

The Tissue Paper Packaging Machine Market is meticulously segmented based on various critical attributes, allowing for a granular understanding of market dynamics, consumer preferences, and technological adoption patterns. These segments dissect the market by machine type, the specific tissue product being packaged, the application environment, and the ultimate end-use industry, providing a comprehensive framework for market analysis and strategic planning. This detailed segmentation helps in identifying high-growth areas, understanding competitive landscapes, and tailoring product development and marketing efforts to specific market niches. Each segment represents distinct technological requirements, operational scales, and customer value propositions, contributing to the overall complexity and opportunity within the market.

- By Machine Type:

- Semi-Automatic Packaging Machines: Requiring some manual intervention, suitable for lower production volumes or specialized tasks.

- Fully Automatic Packaging Machines: Operating with minimal human input, ideal for high-volume, continuous production lines.

- By Product Type:

- Toilet Rolls Packaging Machines: Specialized for wrapping and bundling toilet paper.

- Facial Tissues Packaging Machines: Designed for box or soft-pack facial tissue packaging.

- Paper Napkins Packaging Machines: Equipment for packaging various sizes of paper napkins.

- Paper Towels Packaging Machines: For single or multiple roll paper towel packaging.

- Handkerchiefs Packaging Machines: Machines tailored for individual or multi-pack tissue handkerchiefs.

- By Application:

- Primary Packaging: Direct wrapping of individual tissue products.

- Secondary Packaging: Bundling multiple primary-packaged units together.

- Tertiary Packaging: Preparing bundles for transportation, e.g., case packing.

- By End-Use Industry:

- Tissue Manufacturing Companies: Large-scale producers of various tissue products.

- Food & Beverage Industry: Utilizing tissue products for hygiene and service.

- Pharmaceutical Industry: For sterile packaging needs related to medical tissues.

- Personal Care Industry: Including companies manufacturing wet wipes and other hygiene products.

Value Chain Analysis For Tissue Paper Packaging Machine Market

The value chain for the Tissue Paper Packaging Machine Market commences with a robust upstream segment, primarily involving the suppliers of critical raw materials, components, and sophisticated sub-systems. This includes manufacturers of high-precision metals and alloys, advanced electronic components such as Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), servo motors, sensors, and vision systems, which are foundational to the functionality and automation capabilities of packaging machines. Furthermore, specialized software developers provide the intelligent control systems, AI algorithms, and data analytics platforms that drive modern, smart packaging solutions. The quality, cost, and reliability of these upstream inputs directly influence the performance, durability, and competitiveness of the final packaging machinery, making strong supplier relationships and effective supply chain management crucial for machine manufacturers.

Moving downstream, the value chain extends to the distribution channels and the ultimate end-users of these advanced machines. Machine manufacturers engage in both direct sales, particularly for large, customized projects or strategic clients, and indirect sales through a network of distributors, agents, and system integrators. These intermediaries play a vital role in reaching a broader customer base, especially in diverse geographical regions, by providing local sales support, technical assistance, installation services, and after-sales maintenance. The distributors often possess specialized market knowledge and established relationships with potential buyers, facilitating market penetration and customer retention. Effective distribution strategies are paramount for ensuring timely delivery, installation, and ongoing support, which are critical factors for customer satisfaction and operational continuity in the tissue manufacturing sector.

The end-users, predominantly large-scale tissue paper manufacturers, small and medium-sized enterprises (SMEs) in the hygiene product sector, and contract packaging service providers, represent the final stage of the value chain. These customers procure packaging machines to enhance their production efficiency, reduce labor costs, improve product presentation, and ensure compliance with hygiene and safety standards. The feedback from these end-users regarding machine performance, maintenance requirements, and evolving packaging trends is invaluable, as it directly influences research and development efforts, driving innovation and product improvement within the packaging machine industry. The symbiotic relationship between machine manufacturers, distributors, and end-users forms a cohesive value chain that continuously adapts to market demands and technological advancements, ensuring a steady supply of efficient and reliable tissue paper packaging solutions.

Tissue Paper Packaging Machine Market Potential Customers

The Tissue Paper Packaging Machine Market caters to a diverse array of potential customers, all sharing the common need for efficient, reliable, and hygienic packaging solutions for tissue products. Primarily, large-scale tissue manufacturing companies form the bedrock of the customer base. These global and regional giants, producing enormous volumes of toilet paper, facial tissues, paper towels, and napkins, require high-speed, fully automatic, and integrated packaging lines that can operate continuously with minimal downtime. Their procurement decisions are often driven by factors such as machine throughput, automation levels, energy efficiency, ease of maintenance, and the ability to handle a variety of packaging materials and formats, ensuring their products meet stringent market demands and regulatory standards globally.

Beyond the major players, small and medium-sized enterprises (SMEs) engaged in tissue product manufacturing represent a rapidly growing segment of potential customers. These businesses may focus on niche markets, private label production, or regional distribution, requiring more flexible, often semi-automatic or modular packaging solutions that can adapt to smaller batch sizes and diverse product offerings. For SMEs, considerations such as initial investment cost, scalability, and ease of operation are crucial, often leading them to seek machines that balance cost-effectiveness with performance. The expanding middle class in emerging economies is fostering the growth of such SMEs, thereby broadening the customer landscape for packaging machine manufacturers who can offer tailored, cost-efficient solutions.

Furthermore, contract packaging service providers constitute another significant customer segment. These companies offer specialized packaging services to various brands, including those in the tissue sector, and require versatile machines capable of handling different product specifications, packaging designs, and material types for multiple clients. Their purchasing decisions are heavily influenced by machine flexibility, quick changeover capabilities, and the ability to meet diverse client demands efficiently. The hospitality and healthcare sectors, though often indirect buyers, also drive demand for packaged tissue products, influencing the requirements for robust and hygienic packaging from their suppliers. This multifaceted customer base underscores the need for packaging machine manufacturers to offer a broad portfolio of products, from entry-level to advanced, fully integrated systems, to capture the full spectrum of market opportunities.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.55 Billion |

| Market Forecast in 2033 | USD 2.65 Billion |

| Growth Rate | 7.9% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Foshan Nanhai Yongli Co., Ltd., Suzhou Kude Automation Equipment Co., Ltd., Zhejiang Aike Pack Co., Ltd., Gambini S.p.A., Foshan Nanhai Hongda Machinery Manufacturing Co., Ltd., IMA S.p.A., Körber AG, ACMA S.p.A., O.M.P. S.r.l., Futura Converting S.p.A., PFM Group, C.E.M.I. S.r.l., Saintyco Group, Wenzhou Zhongke Packaging Machinery Co., Ltd., LoeschPack, BFM Machinery Co., Ltd., Utkal Plastics, Synchropack, N.P. & Sons Packaging Machinery, M.C.P. S.r.l. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Tissue Paper Packaging Machine Market Key Technology Landscape

The Tissue Paper Packaging Machine Market is characterized by a dynamic and continuously evolving technology landscape, with manufacturers heavily investing in innovation to meet growing demands for efficiency, flexibility, and intelligence. At the core of modern packaging machines are advanced control systems, primarily based on Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs), which enable precise control over machine functions, offer intuitive operator interaction, and facilitate rapid adjustments to production parameters. These systems are often integrated with sophisticated servo motor technology, providing accurate motion control, higher speeds, and energy efficiency, which are critical for high-speed, high-precision packaging operations that define the tissue sector. The integration of these core technologies allows for seamless operation, reduced changeover times, and enhanced overall equipment effectiveness (OEE).

Beyond basic automation, the market is rapidly adopting Industry 4.0 paradigms, integrating technologies such as the Internet of Things (IoT) and Artificial Intelligence (AI). IoT sensors are embedded throughout the packaging lines to collect real-time data on machine performance, environmental conditions, and product quality, enabling comprehensive monitoring and analytics. This data feeds into AI-powered algorithms that facilitate predictive maintenance, identifying potential issues before they lead to breakdowns, thereby minimizing downtime and extending machine lifespan. AI also enhances vision systems for meticulous quality control, automatically detecting defects or inconsistencies in packaging, ensuring only flawless products reach the market. The application of AI further extends to optimizing production schedules, dynamically adjusting to demand fluctuations and raw material availability, leading to greater operational agility.

Furthermore, the technology landscape is seeing increased adoption of robotics for complex and repetitive tasks such as pick-and-place, stacking, and palletizing, significantly improving throughput and reducing the need for manual labor. Modular machine designs are gaining prominence, offering manufacturers the flexibility to reconfigure lines quickly for different product types or packaging formats, enhancing adaptability to market changes. Cloud connectivity is becoming standard, enabling remote monitoring, diagnostics, and software updates, which streamlines maintenance and support services. The emphasis on sustainable packaging solutions is also driving technological development, with machines designed to handle an increasingly diverse range of eco-friendly materials, from thinner films to recycled and biodegradable options. This holistic integration of advanced hardware and intelligent software defines the cutting-edge of tissue paper packaging machine technology, paving the way for fully autonomous and highly efficient production environments.

Regional Highlights

- North America: This region represents a mature yet robust market for tissue paper packaging machines, characterized by a strong emphasis on automation, high-speed machinery, and advanced digital integration. The market here is primarily driven by technological upgrades, replacement of older equipment, and a continuous demand for sophisticated solutions that enhance efficiency and reduce labor costs. Manufacturers in the U.S. and Canada are at the forefront of adopting Industry 4.0 technologies, including AI, IoT, and robotics, to optimize production lines and maintain competitive advantage, pushing for high levels of precision and reliability in packaging operations. The focus on sustainability also drives demand for machines capable of handling eco-friendly packaging materials.

- Europe: Europe is a highly competitive market known for its stringent quality standards, innovation, and a strong push towards sustainable and energy-efficient packaging solutions. Countries like Germany, Italy, and France are key manufacturing hubs for advanced packaging machinery, often setting global trends in design and functionality. The market is propelled by a combination of high consumer awareness regarding product quality and environmental impact, along with regulatory pressures for waste reduction and recycling. European manufacturers prioritize modularity, flexibility, and quick changeover capabilities to cater to diverse product portfolios and shorter production runs, integrating smart factory concepts for enhanced operational transparency and efficiency.

- Asia Pacific (APAC): The Asia Pacific region stands out as the fastest-growing and largest market for tissue paper packaging machines, fueled by rapid urbanization, increasing disposable incomes, and a burgeoning population that drives massive consumption of tissue products. Countries like China, India, and Southeast Asian nations are witnessing significant investments in new tissue manufacturing facilities, directly translating into high demand for packaging machinery. The market here is characterized by a blend of demand for both cost-effective, semi-automatic machines for smaller enterprises and highly advanced, fully automatic lines for large-scale producers. The region's growth trajectory is also influenced by expanding export markets and the proliferation of e-commerce, necessitating efficient and durable packaging.

- Latin America: The Latin American market for tissue paper packaging machines is in a developing phase, showing consistent growth, particularly in countries such as Brazil, Mexico, and Argentina. Growth is stimulated by improving economic conditions, a rising middle class, and increasing hygiene consciousness among consumers. The demand is primarily for reliable and moderately automated machines that offer a good balance between cost and efficiency. As local tissue manufacturers expand their production capacities and aim to compete with international brands, there is a growing need for modern packaging solutions that can enhance product presentation and extend shelf life, though initial investment costs remain a significant consideration.

- Middle East and Africa (MEA): This region presents emerging opportunities for the tissue paper packaging machine market, driven by population growth, rapid urbanization, and an increasing focus on health and hygiene, particularly in the Gulf Cooperation Council (GCC) countries and parts of Africa. Investments in manufacturing infrastructure are gradually increasing, leading to a rising demand for both new installations and upgrades of packaging machinery. While the market is still nascent in many areas, the long-term potential is significant, with a growing preference for automated and efficient solutions that align with global hygiene standards and meet the demands of a diverse consumer base.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Tissue Paper Packaging Machine Market.- Foshan Nanhai Yongli Co., Ltd.

- Suzhou Kude Automation Equipment Co., Ltd.

- Zhejiang Aike Pack Co., Ltd.

- Gambini S.p.A.

- Foshan Nanhai Hongda Machinery Manufacturing Co., Ltd.

- IMA S.p.A.

- Körber AG

- ACMA S.p.A.

- O.M.P. S.r.l.

- Futura Converting S.p.A.

- PFM Group

- C.E.M.I. S.r.l.

- Saintyco Group

- Wenzhou Zhongke Packaging Machinery Co., Ltd.

- LoeschPack

- BFM Machinery Co., Ltd.

- Utkal Plastics

- Synchropack

- N.P. & Sons Packaging Machinery

- M.C.P. S.r.l.

Frequently Asked Questions

Analyze common user questions about the Tissue Paper Packaging Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What factors are primarily driving the growth of the Tissue Paper Packaging Machine Market?

The market's growth is predominantly driven by increasing global consumption of tissue products due to rising populations, urbanization, and heightened hygiene awareness. Additionally, the rapid expansion of e-commerce necessitates robust packaging solutions, and the continuous industry demand for automation to reduce labor costs and improve efficiency are significant contributors. Technological advancements offering greater speed, precision, and flexibility also play a crucial role, pushing manufacturers towards modern, high-performance packaging machinery.

What are the main types of tissue paper packaging machines available in the market?

The market primarily offers two main types of machines: semi-automatic and fully automatic. Semi-automatic machines require some manual intervention and are suitable for lower production volumes or specialized packaging tasks, often favored by smaller enterprises. Fully automatic machines, on the other hand, operate with minimal human input, providing high-speed, continuous production ideal for large-scale manufacturers requiring maximum efficiency, consistency, and throughput across various tissue product types like toilet rolls, facial tissues, and paper towels.

How does automation significantly benefit tissue paper packaging operations?

Automation brings numerous benefits to tissue paper packaging operations, including substantially increased production speed and throughput, leading to higher output and improved operational efficiency. It drastically reduces labor costs by minimizing the need for manual handling, simultaneously enhancing product hygiene and minimizing contamination risks. Automated systems also ensure greater packaging consistency, reduce material waste through precise application, and improve overall product presentation, contributing to a more competitive and cost-effective manufacturing process.

What are the key technological advancements transforming the Tissue Paper Packaging Machine Market?

Key technological advancements include the widespread adoption of Industry 4.0 concepts, incorporating IoT for real-time data collection and AI for predictive maintenance and enhanced quality control through advanced vision systems. The integration of high-precision servo motors, sophisticated PLC and HMI systems, and advanced robotics is improving machine speed, accuracy, and flexibility. Modular machine designs allow for quick changeovers, while cloud connectivity enables remote monitoring and diagnostics, all contributing to smarter, more adaptive, and efficient packaging lines capable of handling diverse and sustainable materials.

Which regions are exhibiting the highest growth potential for Tissue Paper Packaging Machines?

The Asia Pacific (APAC) region currently demonstrates the highest growth potential, driven by rapid industrialization, expanding consumer markets, and significant investments in manufacturing infrastructure, particularly in countries like China and India. This region benefits from rising disposable incomes and increasing hygiene awareness. While North America and Europe remain mature markets focused on technological upgrades and sustainability, emerging economies in Latin America and the Middle East & Africa also present growing opportunities due to urbanization and developing industrial bases.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager