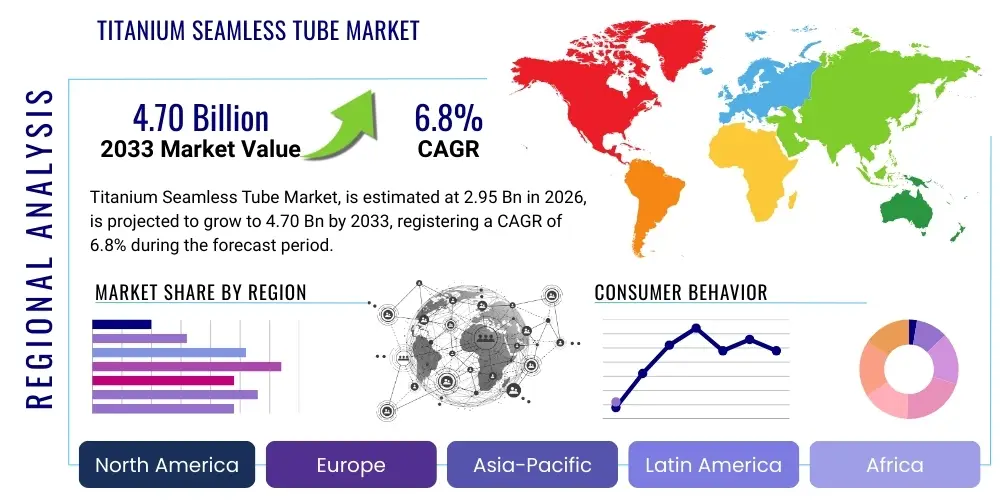

Titanium Seamless Tube Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439652 | Date : Jan, 2026 | Pages : 257 | Region : Global | Publisher : MRU

Titanium Seamless Tube Market Size

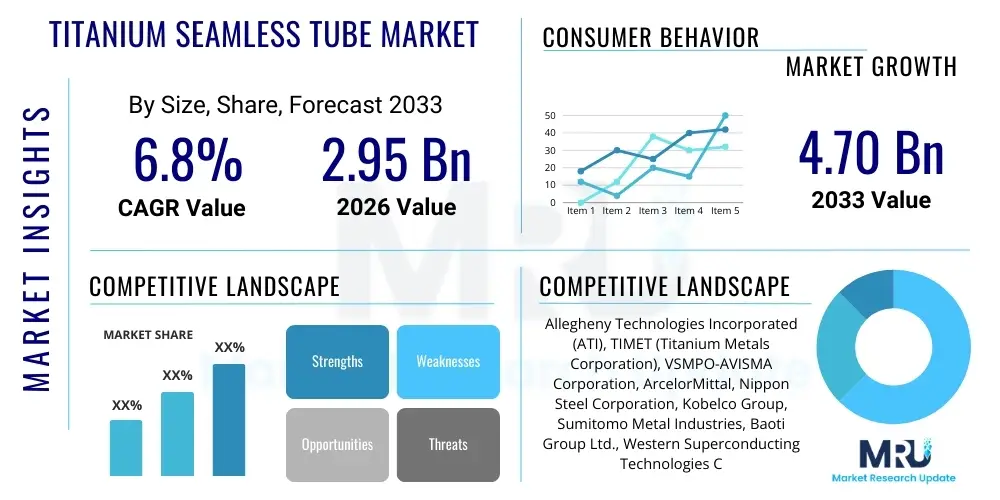

The Titanium Seamless Tube Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 2.95 Billion in 2026 and is projected to reach USD 4.70 Billion by the end of the forecast period in 2033.

Titanium Seamless Tube Market introduction

The Titanium Seamless Tube Market encompasses the production and distribution of high-performance tubular products made from various grades of titanium and its alloys, characterized by their lack of a welded seam. These tubes are highly valued across diverse industries due to titanium's exceptional properties, including outstanding corrosion resistance, high strength-to-weight ratio, excellent biocompatibility, and superior performance at elevated temperatures. Their manufacturing process, typically involving extrusion or cold pilgering, ensures structural integrity and uniform mechanical properties, making them indispensable for critical applications where reliability and durability are paramount.

The primary applications for titanium seamless tubes span a wide array of high-stakes environments. The aerospace and defense sectors are major consumers, utilizing these tubes in hydraulic systems, landing gear, engine components, and structural frames where weight reduction and high performance under extreme conditions are crucial. Similarly, the chemical and petrochemical industries rely on them for heat exchangers, condensers, and piping systems due to their unparalleled resistance to corrosive media, including acids, chlorides, and hostile chemical compounds. The medical field is another significant user, employing titanium seamless tubes for surgical instruments, implants, and prosthetic devices, leveraging titanium's biocompatibility and inertness within the human body. Other key sectors include power generation, marine engineering, and oil and gas, where harsh operating conditions necessitate materials that can withstand severe environments.

The market's growth is predominantly driven by increasing demand from these burgeoning end-use industries. The expanding global aerospace industry, fueled by rising passenger traffic and military modernization efforts, directly translates into higher demand for lightweight, high-strength titanium components. Concurrently, the proliferation of complex chemical processes and the need for more efficient and durable infrastructure in the energy sector continue to bolster the market. Furthermore, advancements in medical technology and an aging global population requiring more implants and medical devices further contribute to sustained demand. The inherent benefits of titanium seamless tubes – their longevity, minimal maintenance requirements, and ability to perform in environments where other materials fail – solidify their position as a material of choice, reinforcing market expansion.

Titanium Seamless Tube Market Executive Summary

The Titanium Seamless Tube Market is experiencing robust expansion, driven by sustained demand from key end-use sectors such as aerospace, chemical processing, medical, and energy. Current business trends highlight an increasing focus on supply chain resilience and diversification, particularly in light of recent global disruptions, leading to strategic partnerships and localized production initiatives. Regional dynamics indicate strong growth in Asia Pacific, propelled by industrialization and infrastructure development, while North America and Europe maintain significant market shares due to established aerospace and medical industries. Segment-wise, high-grade titanium alloys are seeing accelerated adoption, especially in applications requiring superior mechanical properties and temperature resistance, reflecting a broader industry trend towards performance optimization and material innovation.

From a business trend perspective, the market is characterized by a drive towards advanced manufacturing techniques, including additive manufacturing and enhanced cold pilgering processes, aimed at improving production efficiency, reducing waste, and enabling the creation of more complex geometries. There is also a notable shift towards sustainable practices within the titanium production lifecycle, with companies exploring methods for reducing energy consumption and increasing the recyclability of titanium scrap. Strategic mergers and acquisitions are frequently observed as key players seek to consolidate market share, expand product portfolios, and gain access to new technologies or geographical markets. Furthermore, customization and tailor-made solutions are gaining prominence, as end-users require tubes with specific dimensions, surface finishes, and material properties to meet highly specialized application needs.

Regionally, the Asia Pacific market is poised for significant growth, largely attributed to rapid industrialization in countries like China and India, alongside robust investments in infrastructure, power generation, and chemical industries. This region is also becoming a hub for both titanium production and consumption. North America continues to be a dominant force, supported by a strong aerospace and defense manufacturing base and significant research and development investments. Europe, with its advanced medical device manufacturing and stringent environmental regulations driving demand for corrosion-resistant materials, also holds a substantial share. Emerging economies in Latin America and the Middle East & Africa are showing promising potential, particularly with increasing investments in oil & gas, petrochemicals, and renewable energy infrastructure. The dynamics across these regions are influenced by regulatory frameworks, economic stability, and technological advancements.

AI Impact Analysis on Titanium Seamless Tube Market

User inquiries regarding AI's influence on the Titanium Seamless Tube Market predominantly center around its potential to revolutionize manufacturing processes, enhance quality control, optimize supply chains, and accelerate research and development. Key themes emerging from these questions include expectations for increased automation and precision in production, the ability of AI to predict material defects and machine failures, and its role in streamlining complex global logistics. Users are keen to understand how AI can lead to cost efficiencies, improved material utilization, and faster innovation cycles, ultimately contributing to higher-quality products and more responsive market supply, while also raising concerns about the investment required and the need for skilled personnel to implement these advanced systems.

- AI-driven predictive maintenance optimizes machinery performance, reducing downtime and extending equipment lifespan in tube manufacturing.

- Enhanced quality control through AI-powered visual inspection systems identifies minute defects, ensuring higher product integrity and consistency.

- Supply chain optimization using AI algorithms improves logistics, inventory management, and raw material sourcing, leading to cost efficiencies and reduced lead times.

- AI accelerates material R&D by simulating new alloy compositions and processing parameters, shortening the innovation cycle for advanced titanium tubes.

- Process automation and robotics, guided by AI, increase precision and efficiency in cold pilgering, extrusion, and other manufacturing stages.

- Real-time data analytics provided by AI enables manufacturers to monitor and adjust production parameters dynamically, improving yield and reducing waste.

- Market forecasting and demand prediction capabilities of AI assist companies in strategic planning, inventory management, and resource allocation.

- AI facilitates advanced non-destructive testing (NDT) techniques, providing more accurate and faster assessments of tube integrity.

DRO & Impact Forces Of Titanium Seamless Tube Market

The Titanium Seamless Tube Market is propelled by significant demand from the aerospace, chemical, medical, and energy sectors, driven by the material's unparalleled properties such as corrosion resistance and high strength-to-weight ratio. However, the market faces notable restraints including the high cost of raw titanium, complex and energy-intensive manufacturing processes, and potential supply chain vulnerabilities. Opportunities lie in emerging applications like additive manufacturing, customization demands, and increasing adoption in new industrial areas. These dynamics are shaped by various impact forces, including intense competition among manufacturers, the bargaining power of key raw material suppliers, the stringent regulatory environment in end-use industries, and the continuous threat of substitute materials, all influencing market profitability and strategic decisions.

Drivers: The global aerospace industry's consistent growth, marked by increasing aircraft orders and defense expenditure, serves as a primary driver. Titanium seamless tubes are critical components in aircraft hydraulic systems, engine parts, and structural elements, where their lightweight and high-strength characteristics are indispensable. The burgeoning chemical and petrochemical industries, especially in developing economies, are also driving demand due to the increasing need for corrosion-resistant piping and heat exchangers in aggressive chemical environments. Furthermore, the expansion of the healthcare sector, fueled by an aging population and advancements in medical device technology, propels the demand for biocompatible titanium tubes in implants and surgical instruments. The growing focus on renewable energy and nuclear power also requires robust, high-performance materials like titanium for critical infrastructure.

Restraints: Despite its superior properties, the high cost of titanium raw materials, particularly titanium sponge, poses a significant restraint. The extraction and processing of titanium are energy-intensive and technologically complex, contributing to higher production costs compared to other metals like stainless steel or aluminum. This high cost often limits its adoption in price-sensitive applications. Moreover, the manufacturing of seamless titanium tubes involves sophisticated processes such as cold pilgering and extrusion, which require specialized equipment, skilled labor, and significant capital investment. Supply chain disruptions, often stemming from geopolitical tensions or reliance on a few primary producers of titanium sponge, can also impact material availability and pricing stability, further constraining market growth.

Opportunities: The market benefits from significant opportunities presented by technological advancements and expanding application areas. The advent of additive manufacturing (3D printing) for titanium components opens new avenues for complex geometries and customized tube structures, potentially reducing material waste and lead times. There is a growing demand for customized titanium seamless tubes tailored to specific project requirements, offering manufacturers a premium market segment. Furthermore, emerging applications in automotive lightweighting, high-performance sports equipment, and advanced consumer electronics are creating new demand pockets. Research into new titanium alloys with enhanced properties, such as improved fatigue resistance or lower cost alternatives, also presents substantial growth opportunities, enabling broader market penetration and innovation.

- Drivers:

- Growing demand from aerospace and defense industries for lightweight, high-strength components.

- Increasing application in chemical and petrochemical sectors due to superior corrosion resistance.

- Expansion of the medical device industry requiring biocompatible and durable materials.

- Rising investments in power generation (conventional and nuclear) and marine engineering.

- Technological advancements leading to new product development and improved manufacturing processes.

- Restraints:

- High cost of raw titanium materials and energy-intensive manufacturing processes.

- Complex production methods requiring specialized equipment and skilled labor.

- Fluctuations in raw material prices and potential supply chain vulnerabilities.

- Competition from alternative materials such as high-grade stainless steel and superalloys in certain applications.

- Stringent regulatory approvals and certifications required for specific end-use industries.

- Opportunity:

- Emergence of additive manufacturing (3D printing) for customized and complex tube geometries.

- Increasing demand for customized and high-performance tubes for niche applications.

- Exploration of new titanium alloys with enhanced mechanical and physical properties.

- Growth in emerging economies driving industrialization and infrastructure development.

- Development of sustainable production methods and recycling technologies.

Segmentation Analysis

The Titanium Seamless Tube Market is meticulously segmented across various critical dimensions to provide a comprehensive understanding of its structure, dynamics, and potential growth avenues. This segmentation allows for precise market analysis, identifying key demand drivers, competitive landscapes, and regional consumption patterns that influence product development and strategic market positioning. The primary segmentation categories include manufacturing process, grade of titanium, tube diameter, application industry, and end-use industry, each revealing distinct market characteristics and growth trajectories based on specific performance requirements and technological innovations. Analyzing these segments helps stakeholders in tailoring their offerings and penetrating target markets more effectively.

Understanding the interplay between these segments is vital for predicting market evolution. For instance, the demand for specific grades like Ti-6Al-4V (Grade 5) is heavily influenced by the aerospace and medical sectors, which prioritize strength and biocompatibility, respectively, over potential cost implications. Conversely, commercially pure titanium tubes (Grades 1-4) find broader application in less demanding chemical processing or consumer goods where corrosion resistance is key, but extreme strength is not. The evolution of manufacturing processes, such as advancements in cold pilgering or extrusion, not only affects the cost and efficiency of production but also enables the creation of tubes with more refined properties and tighter tolerances, catering to the increasingly stringent requirements of high-tech industries. The size and diameter of tubes are often dictated by the specific fluid transfer or structural integrity needs of an application, impacting production scale and distribution channels.

- By Manufacturing Process:

- Cold Pilgering

- Cold Drawing

- Extrusion

- By Grade:

- Commercially Pure (CP) Titanium (Grades 1-4)

- Titanium Alloys (e.g., Ti-6Al-4V - Grade 5, Ti-3Al-2.5V - Grade 9)

- By Diameter:

- Small Diameter (up to 25mm)

- Medium Diameter (25mm to 100mm)

- Large Diameter (above 100mm)

- By Application:

- Aerospace & Defense

- Chemical & Petrochemical

- Oil & Gas

- Medical

- Power Generation

- Marine

- Automotive

- Consumer Goods

- By End-Use Industry:

- Automotive

- Building & Construction

- Aerospace

- Healthcare

- Energy

- Others

Value Chain Analysis For Titanium Seamless Tube Market

The value chain for the Titanium Seamless Tube Market is a complex network involving multiple stages, beginning from raw material extraction and extending to the end-use industries. Upstream activities are critical, focusing on the mining and processing of titanium ore to produce titanium sponge, a highly energy-intensive and capital-intensive process that forms the foundation of all titanium products. Downstream, the value chain involves sophisticated manufacturing of seamless tubes, distribution, and ultimately, integration into high-value applications by end-users. The efficiency and reliability of distribution channels, encompassing both direct sales and indirect intermediary networks, are paramount for ensuring timely delivery and market penetration across diverse global geographies.

Upstream Analysis: The upstream segment of the titanium seamless tube value chain is dominated by a few key players involved in titanium sponge production. This stage commences with the mining of titanium minerals like ilmenite and rutile, followed by their processing into titanium dioxide. Subsequently, the Kroll process or Hunter process converts titanium dioxide into titanium tetrachloride, which is then reduced to form titanium sponge. This entire process is highly technical, capital-intensive, and energy-intensive, requiring specialized facilities and expertise. The availability and pricing of titanium sponge, which is a critical raw material, significantly influence the overall cost structure and supply dynamics of the seamless tube market. Major producers of titanium sponge exert considerable influence on global supply and pricing, making this a strategic choke point in the value chain.

Downstream Analysis: The downstream segment primarily involves the transformation of titanium ingots or billets (derived from titanium sponge) into seamless tubes through specialized manufacturing processes such as hot extrusion, cold pilgering, and cold drawing. These processes impart the desired dimensions, mechanical properties, and surface finish to the tubes, meeting stringent industry specifications. Following manufacturing, the tubes undergo rigorous quality control and testing, including non-destructive testing, to ensure compliance with international standards. The downstream activities also encompass custom fabrication, cutting, and shaping to meet specific client requirements. The performance and reliability of these manufactured tubes are directly linked to their eventual adoption in critical applications across aerospace, chemical processing, medical, and other industries.

Distribution Channel (Direct and Indirect): The distribution of titanium seamless tubes is a multifaceted process that caters to diverse customer bases. Direct distribution channels involve manufacturers selling directly to large-scale end-users, such as major aerospace companies, large chemical plants, or national defense contractors. This approach allows for direct communication, custom solutions, and often involves long-term contracts. It also helps in maintaining quality control and offering specialized technical support. In contrast, indirect distribution relies on a network of distributors, wholesalers, and specialized stockists who cater to smaller businesses, provide local inventory, and handle logistics for a wider range of customers. These intermediaries often add value through cutting, fabrication, and just-in-time delivery services. The choice between direct and indirect channels often depends on order volume, geographical reach, and the level of technical support required by the end-user, with many manufacturers employing a hybrid approach to maximize market penetration.

Titanium Seamless Tube Market Potential Customers

The Titanium Seamless Tube Market serves a highly specialized and diverse clientele, primarily comprising industries that demand materials with exceptional performance characteristics under extreme conditions. Potential customers are typically found in sectors where material failure can lead to catastrophic consequences, necessitating components that offer unparalleled reliability, corrosion resistance, high strength-to-weight ratios, and thermal stability. These end-users are driven by stringent regulatory standards, performance optimization goals, and a critical need for components that can withstand harsh operational environments, making titanium seamless tubes an indispensable choice for their specific applications. The investment in titanium tubes often reflects a strategic decision to ensure longevity, safety, and efficiency in their critical systems.

The primary end-user segments represent a significant portion of the demand for titanium seamless tubes. The aerospace and defense industry stands as a paramount customer, utilizing these tubes in hydraulic lines, fuel lines, structural components, and landing gear systems of commercial aircraft, military jets, and spacecraft. The need for lightweighting, superior fatigue strength, and resistance to high temperatures and corrosive aviation fluids makes titanium the material of choice. Similarly, the chemical and petrochemical industries are major consumers, requiring titanium tubes for heat exchangers, condensers, reactors, and piping systems that handle highly corrosive chemicals, acids, and high-purity media. Their applications demand materials that can withstand aggressive chemical attack and prevent contamination, ensuring operational safety and product integrity.

Beyond these, the medical device industry represents a growing customer base, where titanium’s biocompatibility, non-toxicity, and high strength are critical for surgical implants, prosthetics, and medical instrumentation. Tubes are used for intricate devices, instrumentation, and even for drug delivery systems. The power generation sector, encompassing nuclear, thermal, and renewable energy plants, also relies on titanium seamless tubes for steam condensers, heat exchangers, and cooling systems due to their excellent corrosion resistance in seawater and brackish water environments. The marine industry uses them in shipbuilding, offshore platforms, and submarines for piping systems handling seawater. Emerging demand is also observed in the automotive sector for high-performance vehicles, where lightweighting contributes to fuel efficiency and enhanced performance, extending the customer landscape to include specialized automotive component manufacturers and luxury car brands.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.95 Billion |

| Market Forecast in 2033 | USD 4.70 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Allegheny Technologies Incorporated (ATI), TIMET (Titanium Metals Corporation), VSMPO-AVISMA Corporation, ArcelorMittal, Nippon Steel Corporation, Kobelco Group, Sumitomo Metal Industries, Baoti Group Ltd., Western Superconducting Technologies Co., Ltd. (WST), Zhejiang Wending Seamless Tube Co., Ltd., Shanghai Jinfu Titanium Industry Co., Ltd., Fushun Special Steel Co., Ltd., Tubes Technologies (A VDM Metals Company), SENCO, Continental Steel & Tube Company, Penn Stainless Products, Special Metals Corporation, Sandvik AB, Seamless Pipes & Tubes (India), TW Metals |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Titanium Seamless Tube Market Key Technology Landscape

The Titanium Seamless Tube Market is characterized by a dynamic technology landscape, driven by continuous innovation aimed at enhancing material properties, optimizing manufacturing efficiency, and reducing production costs. Key technologies encompass advanced metallurgical processes for alloy development, precision manufacturing techniques such as cold pilgering and specialized extrusion, and sophisticated non-destructive testing methodologies. Furthermore, emerging technologies like additive manufacturing are beginning to reshape how titanium tubes are designed and produced, offering opportunities for complex geometries and customized solutions that were previously unachievable. These technological advancements collectively contribute to the ability to meet the increasingly stringent performance requirements of critical end-use applications.

A cornerstone of the technological landscape is the continuous refinement of manufacturing processes. Cold pilgering remains a dominant method, valued for its ability to produce tubes with exceptional surface finish, tight dimensional tolerances, and improved mechanical properties, including enhanced strength and ductility. Innovations in pilger mill design, tooling materials, and lubrication systems are constantly reducing cycle times and increasing yield. Similarly, advanced extrusion techniques, particularly hot extrusion followed by cold drawing, are essential for producing larger diameter tubes and initial blanks for subsequent cold working. Research in process modeling and simulation (e.g., Finite Element Analysis) is vital for optimizing die design and process parameters, minimizing defects, and improving material flow, thus enhancing the overall efficiency and quality of tube production.

Beyond traditional manufacturing, the market is also influenced by advancements in materials science and testing. The development of new titanium alloys, such as those with improved high-temperature strength, creep resistance, or even superplastic properties, expands the potential applications for seamless tubes in extreme environments. Surface treatment technologies, including anodizing, chemical polishing, and various coating techniques, are employed to further enhance corrosion resistance, wear resistance, or biocompatibility for specific applications. Moreover, sophisticated non-destructive testing (NDT) methods like ultrasonic testing, eddy current testing, and radiographic inspection are critical for ensuring the structural integrity and quality of seamless tubes, meeting the rigorous standards demanded by industries such as aerospace and medical. The integration of automation and robotics into these processes also contributes to consistent quality and increased throughput, marking a significant evolution in the technological capabilities of the market.

Regional Highlights

- North America: This region holds a significant share in the Titanium Seamless Tube Market, primarily driven by a robust aerospace and defense industry, coupled with substantial investments in the chemical processing and medical sectors. The presence of major aircraft manufacturers and military contractors, along with advanced healthcare infrastructure, ensures a consistent demand for high-performance titanium tubes. The United States, in particular, leads in both consumption and technological innovation within the region.

- Europe: Europe represents another key market, characterized by stringent environmental regulations, which favor the use of corrosion-resistant titanium in chemical and petrochemical plants. The region also boasts a strong medical device manufacturing base, especially in countries like Germany and Switzerland, and a substantial aerospace industry. Innovation in advanced materials and manufacturing processes is also a key driver in European countries.

- Asia Pacific (APAC): The APAC region is projected to exhibit the highest growth rate, fueled by rapid industrialization, infrastructure development, and growing investments in chemical, power generation, and automotive industries, particularly in China, India, and Japan. The burgeoning aerospace sector in countries like China and India, coupled with increasing healthcare expenditure, significantly contributes to market expansion. Localized production capabilities are also expanding to meet regional demand.

- Latin America: This region is experiencing steady growth, largely due to increasing investments in the oil & gas sector, particularly in countries like Brazil and Mexico, where titanium seamless tubes are used for corrosive environments and deep-sea exploration. The developing infrastructure and manufacturing sectors also present emerging opportunities for market growth.

- Middle East and Africa (MEA): The MEA region's market growth is primarily driven by significant investments in the oil & gas and petrochemical industries, especially in Saudi Arabia and the UAE, where titanium's corrosion resistance is crucial for offshore and onshore applications. Growing infrastructure projects and diversification efforts in these economies are also contributing to a gradual increase in demand.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Titanium Seamless Tube Market.- Allegheny Technologies Incorporated (ATI)

- TIMET (Titanium Metals Corporation)

- VSMPO-AVISMA Corporation

- ArcelorMittal

- Nippon Steel Corporation

- Kobelco Group (Kobe Steel, Ltd.)

- Sumitomo Metal Industries (now Nippon Steel & Sumitomo Metal Corporation)

- Baoti Group Ltd.

- Western Superconducting Technologies Co., Ltd. (WST)

- Zhejiang Wending Seamless Tube Co., Ltd.

- Shanghai Jinfu Titanium Industry Co., Ltd.

- Fushun Special Steel Co., Ltd.

- Tubes Technologies (A VDM Metals Company)

- SENCO

- Continental Steel & Tube Company

- Penn Stainless Products

- Special Metals Corporation

- Sandvik AB

- Seamless Pipes & Tubes (India)

- TW Metals

Frequently Asked Questions

What are the primary applications of titanium seamless tubes?

Titanium seamless tubes are predominantly used in aerospace and defense for hydraulic systems, chemical and petrochemical industries for corrosion-resistant piping, medical devices for implants due to biocompatibility, and in power generation for heat exchangers.

Why are titanium seamless tubes preferred over other materials in certain industries?

They are preferred due to their exceptional corrosion resistance, high strength-to-weight ratio, excellent biocompatibility, and superior performance at elevated temperatures, making them ideal for critical and harsh environments where other materials would fail.

What manufacturing processes are used for titanium seamless tubes?

Common manufacturing processes include cold pilgering, which ensures tight tolerances and smooth surfaces, and extrusion followed by cold drawing, used to achieve specific dimensions and mechanical properties for various applications.

What factors restrain the growth of the Titanium Seamless Tube Market?

Key restraints include the high cost of raw titanium materials, the energy-intensive and complex manufacturing processes involved, and potential vulnerabilities in the global supply chain for titanium sponge.

How does AI impact the Titanium Seamless Tube Market?

AI impacts the market through predictive maintenance, enhanced quality control via visual inspection, optimization of supply chains, acceleration of R&D for new alloys, and increased automation in production, leading to greater efficiency and precision.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager