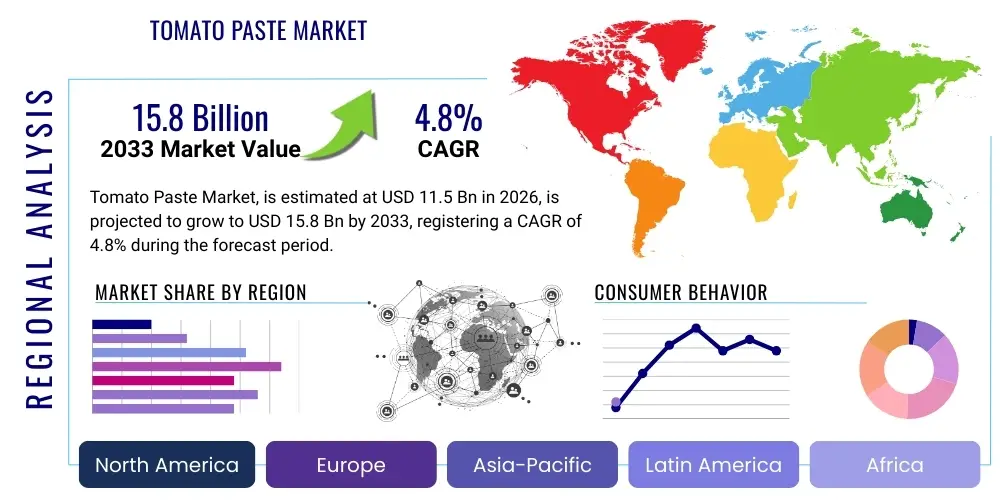

Tomato Paste Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435559 | Date : Dec, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Tomato Paste Market Size

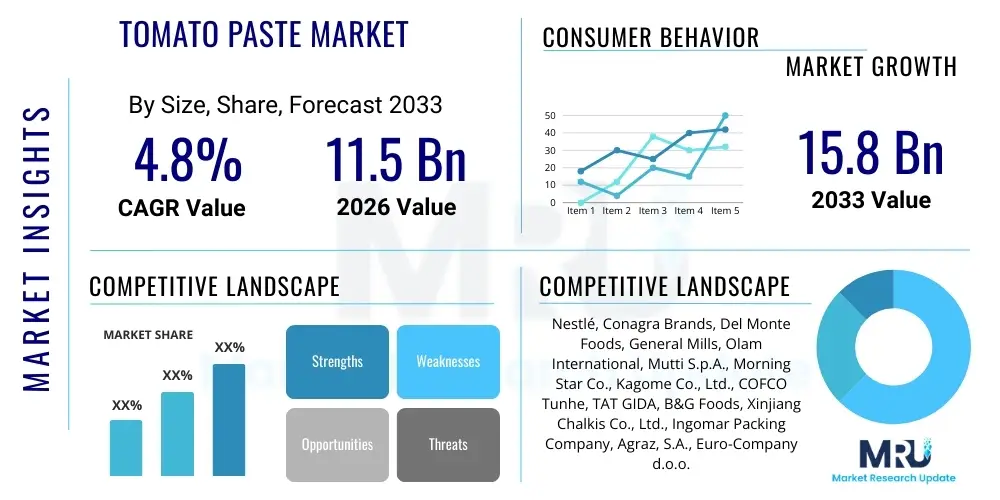

The Tomato Paste Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 11.5 Billion in 2026 and is projected to reach USD 15.8 Billion by the end of the forecast period in 2033.

Tomato Paste Market introduction

The Tomato Paste Market encompasses the global production, distribution, and consumption of concentrated tomato products used primarily as an ingredient in various culinary applications. Tomato paste is manufactured by cooking fresh tomatoes for several hours to reduce moisture, straining out the seeds and skin, and cooking the liquid again to create a thick concentrate. This concentration process significantly enhances the flavor profile, providing a rich, savory umami base crucial for sauces, soups, stews, and ethnic cuisines worldwide. The product's inherent stability and long shelf life, particularly when packaged in aseptic containers or cans, make it a staple ingredient for both industrial food processors and household consumers seeking convenience and depth of flavor in their cooking.

Major applications of tomato paste span across several sectors, including the booming pizza and pasta sauce industry, ready-to-eat meals, canned goods, and condiments like ketchup and BBQ sauces. The benefits driving market adoption include its high concentration of lycopene (a powerful antioxidant), its convenience in storage and preparation, and its role as a cost-effective flavor enhancer. Furthermore, the rising global demand for processed foods, coupled with increased urbanization and busy consumer lifestyles, necessitates readily available, versatile ingredients like tomato paste, cementing its position as a foundational commodity in the global food supply chain. Producers are continually focusing on technological advancements to improve processing efficiency and maintain high nutritional quality.

Tomato Paste Market Executive Summary

The global Tomato Paste Market demonstrates robust growth driven by evolving consumer preferences favoring convenience and diverse global cuisines. Key business trends include the shift towards sustainable sourcing and organic production methods, as major corporations respond to heightened consumer awareness regarding food safety and environmental impact. There is also a notable technological drive focusing on high-efficiency evaporation systems and aseptic packaging, which helps minimize spoilage and extend the product’s shelf life, facilitating easier global distribution. Furthermore, private label brands are gaining significant traction, forcing established market leaders to innovate on pricing strategies and product differentiation, particularly by introducing variations in concentration levels and flavor profiles tailored for specific regional culinary needs.

Regionally, Asia Pacific is emerging as the fastest-growing market, largely due to rapid urbanization, increasing disposable income, and the expanding adoption of Western dietary habits, particularly in China and India where demand for pizza and pasta products is escalating. North America and Europe, while mature markets, continue to dominate in terms of value, driven by strong industrial application sectors (such as large-scale prepared food manufacturers) and a growing demand for premium, high-brix tomato paste varieties. Segment trends highlight the dominance of the Can packaging format, although pouches and tubes are showing accelerated growth, especially in emerging economies, due to their lower cost and greater portability. The industrial processing segment remains the largest end-user, but the food service sector is rapidly recovering post-pandemic, contributing significantly to volume sales through restaurants and institutional kitchens.

AI Impact Analysis on Tomato Paste Market

Common user inquiries regarding AI’s influence on the Tomato Paste Market often revolve around optimizing agricultural yields, predicting commodity price volatility, and enhancing factory efficiency and quality control. Users frequently question how AI-driven precision agriculture techniques, such as predictive harvesting and automated irrigation, can mitigate climate-related risks affecting tomato crops. Additionally, there is significant interest in AI's role in supply chain management—specifically, using machine learning models to forecast demand fluctuations based on complex data inputs (seasonal changes, economic indicators, and retail trends) to minimize inventory waste and improve logistical planning. A core concern remains the implementation cost versus the return on investment for small and medium-sized processing facilities.

AI technology is also anticipated to revolutionize quality assurance within processing plants. Machine vision systems powered by deep learning are capable of instantaneously detecting defects, foreign materials, or inconsistencies in color and viscosity in real-time, far surpassing traditional manual inspection methods. This level of precision ensures higher product quality consistency across batches, which is paramount for global export standards. Furthermore, AI algorithms can optimize the energy-intensive evaporation process by dynamically adjusting temperatures and vacuum levels based on real-time measurements of concentration, leading to substantial energy savings and reduced operational expenditure. However, the successful adoption requires overcoming the data silos within the traditional agricultural and manufacturing ecosystem.

- Optimization of crop management through predictive analytics, maximizing tomato yield and quality.

- Enhanced supply chain forecasting and logistics planning using machine learning to predict demand and optimize shipping routes.

- Real-time quality control and defect detection via AI-powered computer vision systems during processing and packaging.

- Energy optimization in evaporation and concentration processes, reducing utility costs through dynamic process adjustment.

- Automated machinery maintenance scheduling (predictive maintenance) to minimize downtime in processing facilities.

DRO & Impact Forces Of Tomato Paste Market

The dynamics of the Tomato Paste Market are governed by a complex interplay of drivers, restraints, and opportunities. Key drivers include the exponential growth in the global processed food industry, fueled by demographic shifts such as increasing working populations and rising urbanization, which collectively boost the demand for convenient, shelf-stable ingredients. Furthermore, the perceived health benefits associated with tomato products, specifically the high lycopene content, appeal to health-conscious consumers. These factors create sustained momentum for market expansion, particularly in developing economies where modern retail penetration is accelerating.

However, the market faces significant restraints. Tomato production is highly susceptible to volatile weather patterns, including droughts and excessive rainfall, which directly impact crop yield and raw material pricing, leading to supply chain instability. Intense competition from substitute products, such as fresh or diced tomatoes, and volatility in global commodity prices further constrain profitability. Addressing these restraints requires significant investment in climate-resilient agriculture and robust hedging strategies to mitigate financial exposure to price fluctuations, demanding sophisticated risk management from major market players.

Opportunities for growth are primarily centered on innovation in product formulation and geographical expansion. The rising demand for organic, non-GMO, and clean-label tomato paste provides lucrative avenues for premium product development. Moreover, leveraging e-commerce platforms and expanding distribution networks in underserved regions, particularly in parts of Africa and Southeast Asia, allows companies to tap into new consumer bases. The development of specialized, high-performance pastes for niche industrial applications, such as low-sodium or high-acidity formulations, presents an additional area for specialized revenue generation.

Segmentation Analysis

The Tomato Paste Market is broadly segmented based on product type, concentration level, application, and distribution channel, reflecting the diverse consumption patterns and supply chain requirements globally. Analyzing these segments provides crucial insights into market dynamics, enabling producers to tailor their marketing and operational strategies effectively. The concentration level, often measured in Brix, is a fundamental segmentation criterion, directly influencing the product’s usage, quality, and price point. Furthermore, the application segmentation highlights the differential demands arising from household cooking versus large-scale industrial manufacturing, which typically requires bulk, high-volume inputs.

The packaging segment is evolving significantly, moving beyond traditional metal cans to include more flexible and convenient options like pouches and tubes, particularly for single-serve or smaller family sizes. This shift is driven by consumer desire for convenience, reduced waste, and improved shelf stability post-opening. Distribution channel analysis confirms the enduring importance of traditional retail—supermarkets and hypermarkets—but also underscores the rapid ascension of online retail, especially in developed markets where consumers value the ease of bulk purchasing and subscription models. Each segment presents unique growth trajectories influenced by regional dietary habits, economic conditions, and regulatory environments concerning food processing standards.

- By Product Type:

- Jars (Glass)

- Cans (Metal)

- Pouches (Flexible Packaging)

- Tubes

- By Concentration Level (Brix):

- Single Concentrate (28°–30° Brix)

- Double Concentrate (30°–32° Brix)

- Triple Concentrate (36°–38° Brix)

- By Application:

- Household/Retail

- Food Service (Restaurants, Cafeterias)

- Industrial Processing (Sauce Manufacturers, Ready-Meal Producers)

- By Distribution Channel:

- Supermarkets/Hypermarkets

- Convenience Stores

- Online Retail

- Wholesale/B2B

Value Chain Analysis For Tomato Paste Market

The value chain of the Tomato Paste Market begins intensely in the upstream sector with the cultivation and harvesting of processing tomatoes. This initial stage is critical, requiring significant coordination between processors and contracted farmers regarding varietal selection, irrigation, and timely mechanized harvesting. Upstream activities are heavily impacted by agricultural technology investment and weather dependency, posing primary risks to raw material supply stability. Major processors often engage in backward integration, managing their own farms or establishing highly regulated contract farming agreements to ensure consistent quality and predictable yield for high-Brix production. Efficient raw material transportation from the farm gate to the processing facility immediately following harvest is crucial to maintain freshness and minimize post-harvest losses, driving the establishment of plants geographically close to growing regions.

The midstream segment involves the core processing activities: washing, sorting, crushing, pulping, heating, and the crucial evaporation stage that concentrates the solids (Brix level). This stage is capital-intensive, requiring advanced evaporators (such as forced circulation or multi-effect systems) and stringent quality control protocols to meet international food safety standards. Packaging—canning, aseptic boxing, or filling pouches—follows, transforming the bulk product into consumer-ready or industrial ingredients. Downstream analysis focuses on distribution and market access. Direct distribution, often used for large industrial clients, ensures high-volume bulk delivery, whereas indirect channels utilize sophisticated networks of wholesalers, distributors, and retail chains to reach the household and food service segments. The high demand for speed and cold chain management, though less critical than for fresh produce, still influences the efficiency of the overall distribution network, especially for premium, preservative-free products.

The distribution channel landscape is bifurcated between B2B and B2C models. Direct sales dominate the industrial segment, providing economies of scale and custom product specifications. For the retail market (B2C), indirect channels involving hypermarkets, specialized food retailers, and the rapidly growing e-commerce platforms are paramount. The efficacy of indirect channels relies heavily on strong brand presence, shelf space optimization, and promotional activities. Furthermore, third-party logistics (3PL) providers play a vital role in international trade, navigating complex customs regulations and varying regional packaging requirements, adding layers of cost and complexity but also facilitating global market penetration.

Tomato Paste Market Potential Customers

The primary customer base for the Tomato Paste Market is exceptionally diverse, spanning three major categories: industrial food manufacturers, the food service sector, and individual household consumers. Industrial customers represent the largest volume segment, using bulk tomato paste as a foundational ingredient in mass-produced items such as canned soups, ready-made pasta sauces, frozen pizzas, vegetable juices, and ketchup. These buyers prioritize high consistency (Brix level, color index, pH), reliable bulk supply, and competitive pricing, often demanding highly customized product specifications tailored to their specific manufacturing processes and final product formulations. Consistency in industrial-grade paste is non-negotiable, as variations can disrupt automated production lines and alter the final flavor profile of their branded goods.

The food service industry—including hotels, restaurants, and catering (HORECA)—constitutes the second major customer group. These users typically purchase tomato paste in intermediate sizes (e.g., large cans or aseptic bags) that are convenient for professional kitchen use. Quality and flavor profile, combined with ease of storage and minimal waste, are key purchasing criteria. Ethnic restaurants, particularly Italian, Mexican, and Mediterranean establishments, are significant consumers, driving specialized demand for authentic flavor profiles and potentially higher quality, single-source pastes. The growth of quick-service restaurants (QSRs) and institutional cafeterias further reinforces this segment’s importance, as they rely on consistent, high-yield ingredients to maintain operational efficiency.

Household consumers, the retail segment, purchase smaller-format packaged paste (cans, tubes, pouches) primarily through supermarkets or online channels. Their purchasing decisions are influenced by brand recognition, convenience of packaging, nutritional claims (e.g., organic, low-sodium), and price. The trend toward scratch cooking and the adoption of diverse global recipes globally sustain the retail demand. This segment often shows a willingness to pay a premium for specific attributes like organic certification or higher Brix concentrations, provided the product offers perceived superior flavor and quality compared to standard generic options.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 11.5 Billion |

| Market Forecast in 2033 | USD 15.8 Billion |

| Growth Rate | CAGR 4.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Nestlé, Conagra Brands, Del Monte Foods, General Mills, Olam International, Mutti S.p.A., Morning Star Co., Kagome Co., Ltd., COFCO Tunhe, TAT GIDA, B&G Foods, Xinjiang Chalkis Co., Ltd., Ingomar Packing Company, Agraz, S.A., Euro-Company d.o.o., Hain Celestial Group, Premier Foods, S&W Fine Foods. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Tomato Paste Market Key Technology Landscape

The manufacturing of high-quality tomato paste relies heavily on advanced thermal processing and concentration technologies to achieve desired Brix levels efficiently and preserve nutritional integrity. The most critical technologies involve multi-effect and forced circulation evaporators, which significantly reduce the energy needed for water removal by recovering latent heat, thereby lowering operational costs. Modern systems incorporate features like short residence times and low-temperature processing (often under vacuum) to minimize thermal degradation of valuable compounds such as lycopene and to maintain the vibrant red color of the final product. A key technological focus is on enhancing energy efficiency through smart control systems that dynamically adjust evaporation parameters based on real-time measurements of solid content and viscosity.

Beyond concentration, aseptic processing and packaging technologies are foundational to the global market, allowing the product to be sterilized and packaged into large bags-in-box or bulk drums without the need for refrigeration, enabling long-distance, stable distribution. This technology ensures a commercially sterile product with a shelf life often exceeding 18 months. Continuous advancements in sorting and inspection technology are also pivotal; automated optical sorters utilize high-speed cameras and artificial intelligence (AI) to quickly remove foreign material, green tomatoes, and damaged fruit on the processing line, ensuring only the highest quality raw input enters the pulping stage. These technological applications are crucial for meeting stringent export quality requirements across international markets.

Furthermore, precision agriculture technologies are increasingly becoming integrated into the upstream segment of the value chain. This includes the use of drones and satellite imagery combined with sensor data to monitor crop health, soil moisture, and nutrient levels across vast fields. This data-driven approach allows for optimized irrigation and targeted fertilization, leading to higher, more predictable yields of suitable processing tomatoes. Post-harvest, mechanized harvesting technology continues to evolve, focusing on minimizing damage to the fruit during collection and improving the speed and efficiency of bringing the raw material to the plant within the critical window of ripeness, ensuring optimal acidity and flavor profile for paste production.

Regional Highlights

Regional variations in climate, agricultural practices, consumer tastes, and economic development significantly shape the Tomato Paste Market landscape. Europe, traditionally a leader in both production (e.g., Italy, Spain, Portugal) and consumption, represents a mature market characterized by stringent quality standards and a high demand for specialty, single-origin, and organic pastes, driven largely by Mediterranean culinary traditions. North America remains a crucial high-value market, dominated by large industrial manufacturers and a robust food service sector, where efficiency and bulk supply reliability are key differentiators.

Asia Pacific (APAC) stands out as the primary engine for future market growth. Countries like China and India are experiencing a substantial increase in consumption, propelled by rapid adoption of Westernized cuisine (especially pizza and pasta), increasing disposable incomes, and the modernization of retail infrastructure. While China is a massive producer, its domestic consumption is catching up quickly, driving both import and internal market expansion. The demand in APAC is particularly strong for convenient packaging formats such as pouches and tubes that cater to small, frequent purchases in densely populated urban centers.

The Middle East and Africa (MEA) region shows accelerating potential, especially in countries with rising urbanization and expanding retail chains. Local production is often insufficient to meet demand, making this region a significant importer of high-concentration paste, particularly for reconstitution and use in local food preparations. Latin America, particularly Brazil, is both a major producer and consumer, characterized by strong domestic usage in traditional cooking and acting as a significant supplier to North American and European markets. The dynamics in these regions underscore the necessity for multinational companies to adapt their packaging and concentration offerings to specific regional preferences and economic purchasing power.

- Asia Pacific (APAC): Highest CAGR forecast driven by rapid urbanization, increasing processed food consumption, and rising popularity of international cuisines in China and India.

- Europe: Mature market focusing on high-quality, organic, and certified Non-GMO pastes; strong presence of key producers like Italy and Spain dominating global exports.

- North America: Significant consumption driven by the large industrial food processing sector and high demand for convenience foods; focus on bulk and high-Brix concentration products.

- Latin America (LATAM): Major production hub, particularly Brazil and Chile, balancing robust domestic consumption with substantial export capabilities focused on bulk supply.

- Middle East & Africa (MEA): Emerging market characterized by high import dependence and growing demand for affordable, shelf-stable tomato products due to shifting dietary patterns.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Tomato Paste Market.- Nestlé

- Conagra Brands

- Del Monte Foods

- General Mills

- Olam International

- Mutti S.p.A.

- Morning Star Co.

- Kagome Co., Ltd.

- COFCO Tunhe

- TAT GIDA

- B&G Foods

- Xinjiang Chalkis Co., Ltd.

- Ingomar Packing Company

- Agraz, S.A.

- Euro-Company d.o.o.

- Hain Celestial Group

- Premier Foods

- S&W Fine Foods

- Conserve Italia Group

- Princes Group

Frequently Asked Questions

Analyze common user questions about the Tomato Paste market and generate a concise list of summarized FAQs reflecting key topics and concerns.What factors are primarily driving the growth of the Tomato Paste Market?

The primary drivers include the accelerated global demand for processed and convenience foods, rapid urbanization, rising disposable incomes in emerging economies (particularly Asia Pacific), and the intrinsic health benefits associated with the high lycopene content in tomato products.

How does the Brix level impact the usage and price of tomato paste?

Brix level, the measure of soluble solids concentration, significantly affects product quality and usage. Higher Brix pastes (like Triple Concentrate, 36°–38° Brix) are more costly and are typically used by industrial manufacturers for reconstitution or specialized formulations, offering greater yield and concentration of flavor per unit weight.

Which packaging format is experiencing the fastest growth in the market?

While metal cans still dominate the total volume, flexible packaging formats, specifically pouches and tubes, are demonstrating the fastest growth rates. This acceleration is driven by consumer demand for convenience, reduced food waste, and the lower logistical costs associated with these lightweight packaging solutions.

What are the main risks associated with the raw material supply in this market?

The main risks stem from climate change and weather volatility. Extreme weather events like droughts or heavy rains severely impact tomato crop yields, leading to unstable raw material prices, potential supply shortages, and increased operational costs for processors.

How is technology being utilized to improve the efficiency of tomato paste manufacturing?

Technology is employed through advanced multi-effect evaporators for high energy efficiency, real-time AI-powered optical sorting for quality control of raw materials, and aseptic packaging systems that ensure long, stable shelf lives without refrigeration, facilitating efficient global trade.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager