Tool Belts Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434460 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Tool Belts Market Size

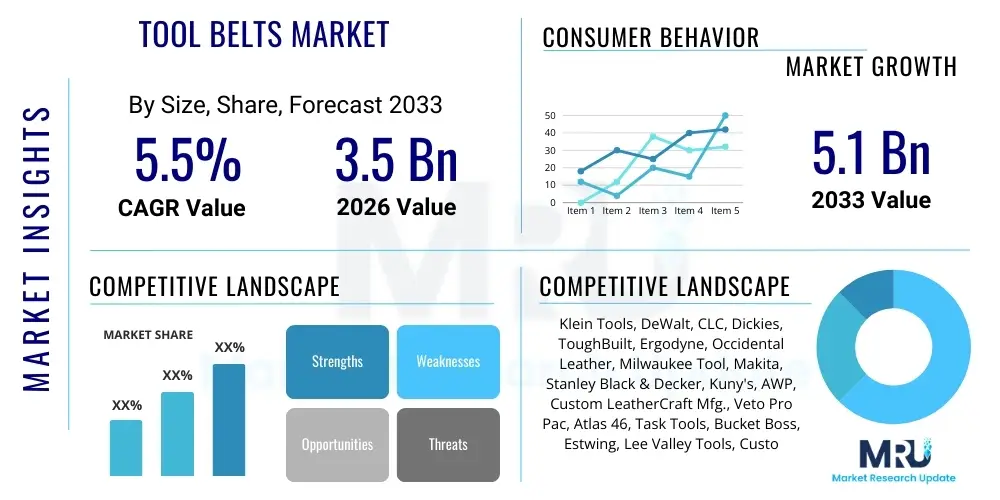

The Tool Belts Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.5% between 2026 and 2033. The market is estimated at USD 3.5 Billion in 2026 and is projected to reach USD 5.1 Billion by the end of the forecast period in 2033.

Tool Belts Market introduction

The Tool Belts Market encompasses the manufacturing, distribution, and sale of specialized belts designed to carry, organize, and provide easy access to essential tools and equipment for professional tradespeople and DIY enthusiasts. These indispensable accessories enhance job site efficiency and safety by allowing workers to keep heavy or frequently used tools secured to their person, reducing the need for constant trips to toolboxes. The market exhibits diversity across materials, including heavy-duty leather, lightweight nylon, and durable synthetic polyesters, each catering to specific industry requirements concerning durability, weight management, and resistance to environmental factors such as moisture or abrasives. Product evolution focuses heavily on ergonomic design, aiming to distribute weight evenly across the user's hips and lower back, thereby mitigating the risk of musculoskeletal injuries associated with prolonged carrying of heavy loads, a critical factor driving modern product innovation.

Major applications for tool belts span across several high-growth sectors, primarily including residential and commercial construction, carpentry, electrical installation, plumbing, HVAC services, and general utility work. The increasing global investment in infrastructure development and renovation projects serves as a primary driver for sustained demand. Benefits derived from utilizing high-quality tool belts include significantly improved productivity through minimized search time for tools, enhanced safety by reducing clutter and potential tripping hazards on the ground, and superior organization that allows tradespeople to maintain control over their specialized inventory. Modern tool belts frequently integrate advanced features such as reinforced stitching, integrated suspender attachment points, modular pouch systems, and specialized pockets tailored for mobile devices and safety equipment.

Driving factors propelling this market forward are multifaceted, incorporating global economic trends and regulatory compliance mandates. The resurgence in residential housing starts and significant government funding directed towards public infrastructure repairs necessitate a highly equipped workforce, boosting the demand for professional-grade tool retention systems. Furthermore, stringent occupational safety regulations in regions like North America and Europe mandate secure tool carrying methods to prevent accidental drops, particularly when working at height. The increasing popularity of DIY and home improvement culture, particularly post-pandemic, has also expanded the consumer base, introducing a segment interested in lighter, more aesthetically pleasing, and versatile belt systems for household tasks. Manufacturers are continuously responding to these dynamics by introducing products that balance ruggedness with comfort and user-centric design.

Tool Belts Market Executive Summary

The Tool Belts Market is experiencing robust growth fueled by several converging global business trends, including the rapid digitization of retail channels and a strong emphasis on worker health and safety. Key business trends indicate a shift towards modular and customizable tool retention solutions, allowing end-users to tailor their setups based on specific task requirements, significantly boosting product appeal among specialized contractors. Major manufacturers are investing heavily in material science innovations, focusing on lightweight composites and abrasion-resistant fabrics to increase product lifespan while simultaneously decreasing user fatigue. Consolidation among smaller players and strategic acquisitions aimed at expanding ergonomic design patents and regional distribution networks characterize the current competitive landscape, ensuring that market leaders maintain a significant technological and distribution advantage over new entrants.

Regionally, the market exhibits dominance in developed economies, particularly North America, due to high spending on construction and strict adherence to occupational safety standards like OSHA. However, the Asia Pacific region is forecast to demonstrate the highest growth rate, primarily driven by massive urbanization and infrastructure initiatives in countries such as India and China, which are rapidly increasing the pool of skilled tradespeople requiring professional equipment. European markets, characterized by a preference for high-end, leather-based, and sustainably sourced products, focus on niche markets emphasizing longevity and superior craftsmanship. Emerging regional trends involve the proliferation of localized manufacturing hubs closer to major construction zones to reduce logistical costs and improve supply chain responsiveness.

Segmentation trends highlight the increasing consumer preference for synthetic materials (Nylon and Polyester) over traditional leather due to their lighter weight, water resistance, and often lower maintenance requirements, although high-end carpentry and traditional trades continue to favor premium leather for its durability and aging properties. The Application segment remains dominated by the Construction sector, but the growth rate within the utility and maintenance sectors is accelerating, driven by the expansion of complex urban utility networks. Crucially, the Distribution Channel segment shows a decisive shift, with e-commerce platforms and online specialty retailers gaining substantial ground over traditional brick-and-mortar hardware stores, offering consumers wider choice, competitive pricing, and in-depth product reviews, influencing purchasing decisions.

AI Impact Analysis on Tool Belts Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Tool Belts Market often center on themes of supply chain efficiency, smart tool integration, predictive maintenance, and personalized product recommendations. Users frequently ask how AI-driven analytics can optimize raw material procurement and inventory management for manufacturers, particularly concerning fluctuating global supply chains for specialized materials like high-grade nylon or chromium-tanned leather. A major concern revolves around the potential for 'smart belts'—belts integrated with sensors—to monitor worker posture, load balance, and fatigue, providing real-time safety alerts. Users also express interest in how machine learning algorithms could personalize tool belt configurations based on an individual worker's job profile and body ergonomics, moving beyond standard sizing toward precision-fit equipment that minimizes long-term strain, thus redefining the value proposition of a premium tool retention system.

While tool belts themselves are fundamentally mechanical products, AI substantially influences the periphery of their manufacturing and utilization ecosystems. In manufacturing, AI applications improve quality control through automated vision systems that detect stitching flaws or material inconsistencies, ensuring higher compliance with safety standards before products reach the consumer. Furthermore, predictive modeling in the retail space, powered by AI, enables manufacturers and distributors to accurately forecast regional demand fluctuations, optimizing stock levels and reducing warehousing costs, ultimately stabilizing consumer pricing. This sophisticated supply chain planning minimizes lead times for custom or modular tool belt systems, which are becoming increasingly popular.

The long-term impact analysis suggests that AI will primarily enhance the safety and ergonomic features of tool belts through indirect means. For instance, data collected from job site wearables (separate from the belt) and analyzed by AI systems could inform the next generation of belt and harness designs, prioritizing weight distribution and material placement based on documented stress points for various trade professions. Although full AI integration into the belt structure remains nascent, the use of computer vision and machine learning for analyzing field performance and influencing design iterations is a critical development area, solidifying AI's role as an optimization engine rather than a direct feature of the physical product.

- AI-driven supply chain optimization reducing material wastage and procurement lead times for specialized materials.

- Predictive maintenance analytics informing the replacement cycle of heavy-duty tool belt components in industrial settings.

- Machine learning algorithms enhancing quality control by automating defect detection during the manufacturing phase.

- AI-powered e-commerce engines providing highly personalized tool belt and pouch configuration recommendations based on user history and trade requirements.

- Potential development of AI-informed ergonomic designs based on large datasets of worker stress points and posture analysis.

DRO & Impact Forces Of Tool Belts Market

The market dynamics of tool belts are governed by a complex interplay of Drivers (D), Restraints (R), and Opportunities (O), which collectively define the Impact Forces (I) shaping its trajectory. The primary driver is the pervasive and sustained increase in global construction and infrastructure spending, particularly in developing nations where rapid urbanization necessitates the employment of large, skilled labor forces, all requiring reliable equipment. Additionally, regulatory mandates focusing on occupational health and safety across major industrialized regions push companies and individuals to invest in certified and ergonomically advanced tool retention systems, forcing market evolution away from rudimentary designs. These factors create strong fundamental demand, underpinning the sector’s resilience against minor economic downturns.

Conversely, the market faces significant restraints, including the persistent volatility in the prices of key raw materials, such as high-grade leather, nylon, and specialized metal hardware, which directly impacts manufacturing costs and, consequently, final consumer prices. Furthermore, intense competition from alternative tool carrying solutions, notably specialized tool vests, utility backpacks, and advanced rolling tool storage systems, presents a continuous challenge, diverting consumer purchasing power away from traditional belt setups, especially among trades where mobility and minimal load are prioritized. The cyclical nature of the construction industry itself represents an economic restraint, as demand for tool belts often mirrors peaks and troughs in construction activity, leading to unpredictable revenue streams for manufacturers.

Opportunities for market expansion are centered on technological advancements and geographic penetration. The development of smart tool belts incorporating lightweight, durable materials, superior ergonomic features (such as sophisticated load-bearing suspenders), and modular connectivity represents a key avenue for premium market growth. Geographically, untapped potential resides in emerging markets across Africa and Southeast Asia, where rising safety awareness and professionalization of construction trades open new consumer bases receptive to quality imports. Strategic alliances between tool belt manufacturers and major power tool brands offer cross-promotion opportunities, driving combined sales and enhancing brand visibility among professional contractors, effectively leveraging the combined marketing reach of established industry names.

Segmentation Analysis

The Tool Belts Market segmentation provides a granular view of demand distribution across various product characteristics, application sectors, and material compositions. Understanding these segments is critical for manufacturers aiming to align their product development and marketing strategies with specific end-user needs and purchasing behaviors. The market is broadly categorized based on Material Type (Leather, Nylon/Polyester, Others), Application (Construction, Carpentry, Electrical, HVAC, DIY), and Distribution Channel (Online and Offline). Each segment displays unique growth dynamics; for instance, the synthetic material segment is growing rapidly due to cost-effectiveness and water resistance, while the high-end leather segment maintains stability through specialized trades valuing tradition and longevity.

In terms of application, the construction industry remains the dominant revenue generator globally, driven by large-scale commercial and residential projects that require heavy-duty, multi-pouch systems capable of carrying substantial weight. However, the electrical and HVAC segments show strong localized growth, demanding specialized belts with dedicated pockets for small instruments, meters, and sensitive equipment, often preferring lighter, non-conductive materials. The DIY segment, while lower in individual purchase value, contributes significantly to volume, favoring multipurpose, adjustable, and aesthetically appealing tool belts purchased primarily through mass-market retailers and e-commerce platforms, reflecting a shift towards accessibility and convenience.

The distribution landscape is undergoing a notable transformation, with the online segment exhibiting a superior CAGR due to the enhanced ability of digital platforms to offer customization, detailed product specifications, and direct-to-consumer services, bypassing traditional retail intermediaries. Conversely, the offline channel, comprising large hardware chains and specialized industrial supply stores, continues to be crucial for professional buyers who prefer physical assessment of product quality, material feel, and ergonomic fit before committing to a purchase, particularly for high-investment premium leather products. Strategic focus must therefore be placed on developing an omnichannel strategy that caters effectively to both high-volume digital sales and high-touch physical interactions.

- By Material Type:

- Leather (Premium, Standard Grade)

- Nylon/Polyester (Heavy-Duty, Lightweight)

- Others (Canvas, Specialized Composites)

- By Application:

- Construction (General Contractors, Framers)

- Carpentry and Woodworking

- Electrical and Telecommunications

- HVAC and Plumbing

- Utility and Maintenance

- DIY and Household

- By Distribution Channel:

- Offline (Hardware Stores, Specialty Retailers, Industrial Suppliers)

- Online (E-commerce Platforms, Direct Manufacturer Websites)

Value Chain Analysis For Tool Belts Market

The Value Chain of the Tool Belts Market begins with the sourcing and preparation of raw materials, which represents the upstream segment. This involves securing high-quality inputs such as tanned leather hides (requiring specialized chemical processing), various grades of synthetic fibers (nylon, polyester), and specialized metal components (buckles, rivets, suspender hardware). Efficiency and sustainability in this phase are paramount, as material quality dictates the final product's durability and price point. Manufacturers often establish long-term relationships with certified suppliers to ensure consistent material quality and compliance with environmental regulations, particularly concerning leather tanning and synthetic material production, which is a major focus for corporate social responsibility initiatives.

The core manufacturing process involves intricate design, cutting, stitching, and assembly, where highly specialized machinery and skilled labor are required to achieve the ergonomic precision and robust construction necessary for professional-grade belts. Quality control checks, particularly for load-bearing capacity and seam integrity, are critical at this stage. After manufacturing, the products move into the downstream segment, involving logistics, warehousing, and distribution. Tool belts are distributed through a dual channel approach: direct and indirect. Direct distribution often targets major commercial contractors or government agencies through specialized procurement teams, ensuring bulk orders are managed efficiently and often customized.

Indirect distribution relies heavily on a network of wholesalers, regional distributors, and retailers. The major distribution channels include large big-box hardware stores (Offline), which provide immediate availability and consumer interaction, and increasingly, powerful global e-commerce platforms (Online). The online channel offers the advantage of reaching niche customer segments with specialized requirements (e.g., specific ergonomic features or highly specialized pouch configurations). Successful market participants leverage integrated systems to manage inventory across both channels, ensuring seamless fulfillment and a unified customer experience, ultimately maximizing market reach and minimizing inventory obsolescence.

Tool Belts Market Potential Customers

The potential customer base for the Tool Belts Market is exceptionally broad, spanning various professional trades and extending into the vast consumer segment focused on home improvement. The primary end-users are professional contractors and skilled tradespeople working in high-intensity environments. This demographic prioritizes durability, specific tool organization capabilities, and superior ergonomic support necessary for 8 to 12 hours of daily use. Key professional buyer groups include residential and commercial construction crews (framers, roofers), specialized installers (electrical linesmen, HVAC technicians), and industrial maintenance personnel who require reliable, heavy-duty belts that comply with site safety standards and can withstand harsh working conditions, driving demand for premium, high-cost items.

A secondary, yet rapidly expanding, customer segment is the semi-professional and enthusiast DIY market. These buyers, typically focused on home repairs, hobbyist carpentry, or small-scale renovations, look for versatility, comfort, and ease of use rather than extreme industrial ruggedness. This segment is highly sensitive to marketing trends, product aesthetics, and price points, frequently making purchasing decisions based on online reviews and recommendations from popular home improvement content creators. Manufacturers target this group with lighter-weight synthetic options, often featuring brighter colors or highly adjustable designs, catering to a less frequent but wider range of applications.

Furthermore, institutional buyers, such as educational vocational schools, military installations, and municipal utility departments, represent important bulk purchasers. These organizations require standardized, safety-compliant equipment for training or field operations. Their procurement decisions are often driven by regulatory compliance, bulk pricing discounts, and requirements for consistent performance across a large fleet of personnel. Understanding the distinct purchasing motivations—whether it is safety compliance for professionals, versatility for DIY users, or standardization for institutional buyers—is key to effective product positioning and sales channel optimization within the competitive landscape.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.5 Billion |

| Market Forecast in 2033 | USD 5.1 Billion |

| Growth Rate | 5.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Klein Tools, DeWalt, CLC, Dickies, ToughBuilt, Ergodyne, Occidental Leather, Milwaukee Tool, Makita, Stanley Black & Decker, Kuny's, AWP, Custom LeatherCraft Mfg., Veto Pro Pac, Atlas 46, Task Tools, Bucket Boss, Estwing, Lee Valley Tools, Custom Tool Bags. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Tool Belts Market Key Technology Landscape

The technology landscape in the Tool Belts Market is primarily characterized by advancements in material science and ergonomic engineering rather than digital hardware integration. The focus remains heavily on improving the mechanical performance, longevity, and comfort of the product. Key materials innovation involves the adoption of ballistic nylon and heavy-duty polyester blends treated with water-resistant or flame-retardant coatings, offering superior abrasion resistance and lighter weight compared to traditional leather. Furthermore, manufacturers utilize advanced synthetic stitching techniques and reinforced riveting technology to ensure joints and stress points can withstand extreme static and dynamic loads, dramatically increasing product lifespan under industrial conditions.

Ergonomic design technology is crucial and continuously evolving. This includes sophisticated load-balancing systems, often achieved through patented suspender and yoke designs that transfer weight from the lower back and hips to the shoulders, reducing strain and preventing long-term physical ailments. Manufacturers employ three-dimensional modeling and pressure mapping during product development to optimize the curvature and padding of the waist belt and integrate features like contoured lumbar support, providing personalized fit options. The modularity technology, using robust clip systems or quick-release mechanisms, allows users to rapidly reconfigure their pouch layout depending on the task at hand, which is highly valued by specialized trades requiring frequent tool switching.

Although the core product is mechanical, manufacturing technology leverages automation, specifically computer-controlled cutting (CNC) and robotic sewing systems, which ensure precision in material assembly and consistency in complex designs, particularly for multi-layered synthetic belts. The increasing integration of Near Field Communication (NFC) or RFID tags within specialized industrial belts, although still niche, represents an emerging technology designed for asset tracking and inventory management on large construction sites, allowing companies to digitally monitor and locate high-value tools, thereby minimizing loss and improving site accountability. This blend of material enhancement, ergonomic optimization, and subtle digital integration defines the current technological trajectory.

Regional Highlights

The global distribution of the Tool Belts Market is highly differentiated, reflecting varying levels of construction activity, safety regulation stringency, and consumer purchasing power across major geopolitical areas. North America currently dominates the market both in terms of value and volume. This dominance is attributable to continuous large-scale infrastructure projects, a highly developed construction sector, and stringent occupational safety standards enforced by bodies like OSHA, which necessitate the use of high-quality, professional-grade equipment. The U.S. market, in particular, exhibits a strong preference for large, heavy-duty modular systems and is the primary innovation hub for premium, ergonomic designs and advanced material adoption.

Europe represents a mature and stable market characterized by high consumer demand for longevity and craftsmanship, especially within Western European nations such as Germany and the UK. European users often prefer traditional, high-quality leather belts, coupled with a growing demand for sustainable and environmentally conscious manufacturing processes. Strict EU labor laws and safety directives further reinforce the need for certified, ergonomically sound products, driving manufacturers to focus on comfort and long-term worker health. The adoption of modular systems is also high, supporting diverse and specialized European trade practices.

The Asia Pacific (APAC) region is projected to be the fastest-growing market globally throughout the forecast period. This accelerated growth is fundamentally driven by unprecedented urbanization, massive government investment in new infrastructure (roads, railways, smart cities), and industrialization across nations like China, India, and Southeast Asian countries. While cost sensitivity remains high, leading to substantial demand for lower-cost nylon and polyester belts, the increasing professionalization of trades and improving safety awareness are gradually driving demand toward higher-quality, durable equipment, creating significant long-term growth opportunities for international brands. Emerging markets in Latin America and the Middle East & Africa (MEA) are also showing promising signs of growth, primarily linked to rising oil prices fueling regional construction booms and necessary utility modernization projects.

- North America (Dominant Market): High regulatory compliance (OSHA), significant commercial construction activity, strong demand for premium ergonomic and modular tool belt systems.

- Europe (Mature Market): Emphasis on traditional craftsmanship, high-quality leather, sustainable sourcing, and advanced ergonomic requirements mandated by strict EU labor standards.

- Asia Pacific (Fastest Growth): Driven by rapid urbanization, large-scale infrastructure investments, and increasing awareness of occupational safety standards across emerging economies.

- Latin America & MEA (Emerging Markets): Growth spurred by increased government spending on utility modernization and residential construction projects, particularly in Gulf nations and key South American countries.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Tool Belts Market.- Klein Tools

- DeWalt

- Custom LeatherCraft Mfg. (CLC)

- Dickies

- ToughBuilt Industries, Inc.

- Ergodyne

- Occidental Leather

- Milwaukee Tool

- Makita Corporation

- Stanley Black & Decker

- Kuny's

- AWP (AmazonBasics Tool Belts)

- Veto Pro Pac

- Atlas 46

- Task Tools

- Bucket Boss (Pullman-Holt Corp.)

- FastCap, LLC

- Gatorback Tool Belts

- Black + Decker

Frequently Asked Questions

Analyze common user questions about the Tool Belts market and generate a concise list of summarized FAQs reflecting key topics and concerns.What materials are driving current market growth in the tool belts segment?

The primary materials driving current market growth are high-denier synthetic fabrics, specifically nylon and polyester blends. These materials offer superior water resistance, lighter weight, and high durability compared to traditional leather, appealing strongly to professional contractors who prioritize comfort and performance in diverse weather conditions.

How significant is the impact of ergonomic design on tool belt purchasing decisions?

Ergonomic design is a critical differentiating factor, especially in the premium segment. Professionals are highly motivated to invest in belts featuring contoured padding, sophisticated suspender systems, and weight-distribution technologies to mitigate back strain and long-term musculoskeletal injuries, directly linking ergonomics to enhanced productivity and reduced long-term health risks.

Which application segment accounts for the highest revenue share in the Tool Belts Market?

The Construction sector holds the highest revenue share globally. This dominance is due to the sheer volume of skilled labor required for commercial and residential development projects and the necessity for workers to carry a wide variety of heavy tools simultaneously, thereby demanding robust and large-capacity tool belt systems.

Are e-commerce platforms replacing traditional hardware stores for tool belt purchases?

E-commerce platforms are rapidly gaining market share due to convenience, price transparency, and customizable options, offering a superior CAGR. However, physical hardware stores remain essential for professional buyers who require in-person assessment of quality, fit, and material feel before purchasing high-investment, professional-grade tool belts.

What are the key restraint factors affecting the profitability of tool belt manufacturers?

Key restraint factors include the persistent volatility and high cost of raw materials (especially leather and specialized metal hardware) and intense competition from sophisticated alternative tool storage solutions, such as high-capacity vests and specialized backpacks, which challenge the traditional market dominance of waist-worn systems.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager