Torque Limiter Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432347 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Torque Limiter Market Size

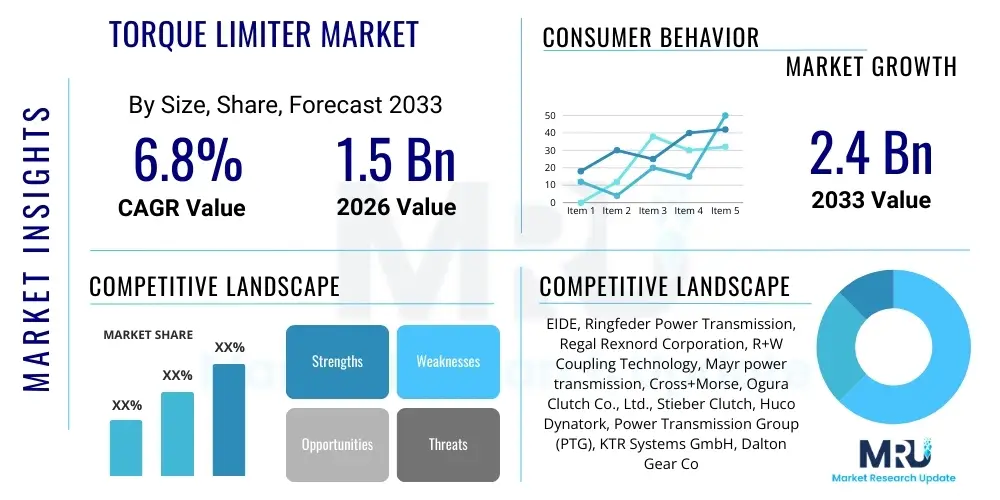

The Torque Limiter Market is projected to grow at a Compound Annual Growth Rate (CAGR) of [6.8%] between 2026 and 2033. The market is estimated at [USD 1.5 Billion] in 2026 and is projected to reach [USD 2.4 Billion] by the end of the forecast period in 2033.

Torque Limiter Market introduction

Torque limiters are essential mechanical safety devices designed to protect drive systems, machinery components, and finished products from damage caused by momentary torque overloads, jams, or sudden speed changes. These devices automatically disengage or slip when the preset torque limit is exceeded, thereby interrupting the power transmission and preventing catastrophic failure of expensive equipment. The fundamental mechanism involves a precise calibration of engagement force, ensuring reliable operation under normal loads while providing instantaneous protection during fault conditions. The increasing complexity and speed of automated industrial machinery necessitate the integration of these fail-safe mechanisms to maintain operational integrity and worker safety, positioning torque limiters as indispensable components across various manufacturing sectors.

The primary applications for torque limiters span across heavy machinery, packaging equipment, material handling systems, aerospace, and robotics. In packaging lines, for example, they prevent damage when a product jams the conveyor, minimizing downtime and maintenance costs. The core benefits derived from implementing torque limiters include enhanced equipment longevity, reduced operational downtime, protection against high-inertia loads, and improved safety compliance with industrial standards. These devices are particularly critical in high-speed and precision environments where even a momentary overload can lead to significant financial losses and production bottlenecks.

The market is predominantly driven by stringent industrial safety regulations across developed economies, mandating the use of fail-safe power transmission components. Furthermore, the global expansion of automation in manufacturing, particularly the proliferation of industrial robotics and complex CNC machines, fuels demand for highly responsive and accurate overload protection systems. The need for increased productivity and minimized maintenance expenditure in sectors like food and beverage, automotive, and mining acts as a significant catalyst for market growth. The continuous evolution of torque limiter technology, including digital and intelligent systems, further enhances their reliability and integration capabilities within modern smart factories.

Torque Limiter Market Executive Summary

The Torque Limiter Market exhibits robust growth, underpinned by significant advancements in automation technologies and a global focus on industrial safety compliance. Current business trends indicate a strong pivot towards sophisticated electronic and pneumatic torque limiting solutions that offer higher precision and faster reaction times compared to traditional mechanical shear pin or friction plate models. Manufacturers are increasingly prioritizing customized solutions tailored for high-speed applications in the packaging and bottling industries, alongside heavy-duty, high-torque applications prevalent in mining and steel production. Mergers and acquisitions focused on consolidating specialized technological expertise, particularly in intelligent monitoring and predictive maintenance integration, define the competitive landscape, ensuring market maturity remains high and innovation is continuous.

Regional trends highlight the Asia Pacific (APAC) as the fastest-growing market, driven primarily by rapid industrialization, extensive capital investment in manufacturing capacity in China and India, and the adoption of advanced automation solutions across sectors like automotive and electronics. North America and Europe maintain substantial market shares, characterized by demand for high-end, maintenance-free torque limiters that comply with stringent quality and environmental standards (such as ISO 13849 for machinery safety). These mature regions show greater uptake of sensor-equipped torque limiters integrated into IoT platforms for real-time monitoring and predictive failure analysis, emphasizing operational efficiency alongside fundamental safety.

Segment trends underscore the dominance of the friction type torque limiter segment due to its reliability and adjustability, although the ball detent and synchronous clutch segment is gaining traction rapidly owing to its superior precision and instantaneous disengagement capability, essential for sensitive robotic applications. By application, the material handling and heavy machinery sectors remain the primary revenue generators, reflecting the critical need for overload protection in conveyors, cranes, and large gearboxes. The shift towards automated warehousing and the proliferation of logistics systems are expected to further bolster demand within the material handling segment over the forecast period, emphasizing robust and durable torque management solutions.

AI Impact Analysis on Torque Limiter Market

Common user inquiries regarding the influence of Artificial Intelligence (AI) on the Torque Limiter Market center on optimizing safety thresholds, enabling predictive maintenance, and integrating mechanical components into smart manufacturing ecosystems. Users frequently ask: "How can AI determine the optimal slip torque value dynamically?" and "Will AI integration replace traditional mechanical limiters entirely?" The consensus among analysts is that AI will not replace the fundamental mechanical function but will profoundly enhance the operational efficiency and reliability of torque limiters. The key themes revolve around leveraging machine learning algorithms to process operational data (vibration, temperature, load profiles) captured by sensors embedded in or adjacent to the torque limiters. This data analysis allows for proactive adjustments to system parameters, anticipating potential overload situations before they occur, thus moving the market towards highly adaptive safety mechanisms.

The primary expectation is that AI will transform torque limiters from purely reactive safety mechanisms into proactive, intelligence-gathering components within an industrial IoT (IIoT) framework. By analyzing historical load cycles and environmental variables, AI models can predict component wear, identify deviations from normal operating patterns, and alert maintenance teams regarding necessary calibration or component replacement. This paradigm shift minimizes nuisance tripping while ensuring maximum equipment utilization and reduced unplanned downtime. Moreover, AI aids in fine-tuning the trip-torque setting dynamically based on the specific phase of the machine cycle, offering unprecedented levels of precision and safety tailored to immediate operational needs.

This integration of AI and machine learning capabilities into torque limiter monitoring systems allows manufacturers to offer value-added services focused on asset performance management (APM). The ability to provide real-time condition monitoring and fault diagnostics differentiates product offerings in a highly competitive market. Furthermore, AI algorithms can optimize the design and material selection process for new torque limiter generations by simulating millions of load scenarios, leading to lighter, more durable, and highly customized mechanical safety components that are fit for the demands of Industry 4.0 environments.

- AI enables dynamic torque threshold optimization based on real-time operational data and load profiles.

- Predictive maintenance analytics, powered by machine learning, forecasts potential mechanical failure of limiters or associated drive components.

- Integration into IIoT platforms allows for remote monitoring and automated recalibration of digital torque limiters.

- AI assists in optimizing material durability and design parameters by simulating stress and fatigue under varied conditions.

- Reduces instances of nuisance tripping by distinguishing between transient operational peaks and genuine system overloads.

DRO & Impact Forces Of Torque Limiter Market

The Torque Limiter Market is primarily shaped by the compelling need for operational safety (Driver) countered by the high initial investment required for precision limiters (Restraint), offering significant opportunities through integrating smart monitoring technologies (Opportunity). The fundamental driving force is the global regulatory environment, particularly the enforcement of machinery directives and standards (e.g., OSHA, Machinery Directive 2006/42/EC), which necessitates robust safety mechanisms in all industrial equipment. Simultaneously, the accelerating trend of industrial automation, marked by the deployment of high-speed robotics and sophisticated production lines, directly increases the risk of torque overloads, thereby boosting demand for reliable, fast-acting limiters. The intrinsic benefits of preventing costly damage and minimizing production halts provide a strong commercial incentive for adoption across all manufacturing sectors, solidifying the market’s positive trajectory.

However, the market faces significant restraining factors, notably the high upfront cost associated with highly precise, maintenance-free torque limiters, particularly the synchronous and electromagnetic types. For Small and Medium Enterprises (SMEs), this initial capital expenditure can be prohibitive, often leading to the retention of older, less reliable shear-pin or basic friction devices. Furthermore, the complexity involved in accurately selecting and correctly sizing the appropriate torque limiter for specific applications requires specialized engineering knowledge, which acts as a barrier to entry or leads to installation errors. The market also contends with the durability challenge; while designed for resilience, limiters used in harsh, abrasive environments (like mining) require frequent maintenance checks and potential replacement of wearable parts, increasing lifecycle costs and reducing perceived value.

Opportunities for market expansion are centered around geographical penetration into emerging economies undergoing rapid infrastructure and manufacturing development, such as Southeast Asia and parts of Latin America. Technologically, the greatest opportunity lies in the proliferation of intelligent torque limiters equipped with sensors and communication modules. These smart limiters facilitate predictive maintenance and real-time monitoring, enabling manufacturers to transition towards service-based models offering optimized operational efficiency rather than just selling hardware. The ongoing miniaturization of components and the demand for zero-backlash operation in aerospace and medical device manufacturing also present lucrative niches for specialized, high-precision product development. These forces collectively indicate a market poised for technologically driven evolution, emphasizing safety and integration into Industry 4.0 architectures.

Segmentation Analysis

The Torque Limiter Market is comprehensively segmented based on Type, Application, and End-Use Industry, providing a structured view of demand dynamics across different industrial requirements. The type segmentation distinguishes between the mechanical principles used for overload protection, ranging from simple friction plates to highly precise hydraulic or electromagnetic systems, each catering to specific torque capacities and reaction speed needs. The application segmentation clarifies where these devices are utilized within machinery, such as in motor drives, gearboxes, or conveyor systems. End-use analysis defines the broad sectors driving procurement, including the high-volume needs of automotive manufacturing versus the specialized demands of the aerospace industry. This multifaceted segmentation helps stakeholders understand market penetration and areas of potential investment, highlighting the critical role torque limiters play in maintaining operational safety and efficiency across the industrial spectrum.

- By Type:

- Friction Type Torque Limiters (Slip Clutches)

- Ball Detent Type Torque Limiters (Roller Detent/Synchronous Clutches)

- Shear Pin Type Torque Limiters

- Hydraulic/Pneumatic Torque Limiters

- Electromagnetic Torque Limiters (Hysteresis and Magnetic Particle)

- By Application:

- Motor Drives

- Gearboxes

- Conveyor Systems

- Packaging Machinery

- Robotics and Automation Equipment

- Pumps and Compressors

- Machine Tools

- By End-Use Industry:

- Automotive

- Aerospace and Defense

- Mining and Metallurgy

- Food and Beverage

- Material Handling

- Manufacturing and Industrial Machinery

- Energy and Power

- By Operating Principle:

- Manual Reset

- Automatic Reset

Value Chain Analysis For Torque Limiter Market

The value chain for the Torque Limiter Market begins with upstream activities focused on the procurement of high-quality raw materials, primarily specialized steels, aluminum alloys, and high-performance friction materials (like specialized elastomers or sintered bronze) required for precision components. Key upstream activities involve meticulous quality control of bearing elements, springs, and surface treatments (such as nitriding or coating) which directly influence the reliability and longevity of the final product. Specialized component suppliers provide standard parts like bearings, fasteners, and sensor elements (for smart limiters). Strategic partnerships with metal fabricators capable of high-tolerance machining are crucial, as the performance of mechanical torque limiters is highly dependent on geometric precision and material hardness, especially in clutch plate and detent mechanisms.

Mid-stream activities encompass the manufacturing, assembly, testing, and final calibration of the torque limiter units. This stage involves sophisticated processes, including precision grinding and heat treatment, followed by critical assembly procedures to ensure the preset torque tolerance is met within strict limits. Rigorous testing protocols, simulating overload events and cyclic loading, are mandated before release. The downstream component of the value chain involves distribution channels, market reach, and after-sales support. Distribution is primarily handled through specialized industrial component distributors and certified engineering representatives who possess the technical expertise to assist end-users in selecting the correct torque device for complex drive train applications. The distinction between direct and indirect distribution is significant, with large Original Equipment Manufacturers (OEMs) often purchasing directly from manufacturers, while smaller industrial consumers rely heavily on indirect channels for local supply and technical consultation.

Direct distribution channels are generally preferred for custom-engineered or highly complex torque management systems sold to Tier 1 automotive suppliers or large integrated automation providers, ensuring direct technical oversight and immediate feedback loops for design improvements. Indirect distribution, leveraging extensive networks of Maintenance, Repair, and Operations (MRO) distributors and specialized mechanical component houses, dominates the general industrial market, providing accessibility and local inventory for standard friction and shear-pin models. A strong focus on after-sales service, including recalibration services and replacement part availability, is essential in maintaining long-term customer relationships, as torque limiters are critical safety components whose performance must be periodically verified to comply with safety standards. The efficiency of the logistics network significantly impacts inventory carrying costs and responsiveness to market demand.

Torque Limiter Market Potential Customers

Potential customers for torque limiters span across virtually all industries utilizing automated machinery, high-power gearboxes, and precision mechanical transmission systems. The primary end-users are Original Equipment Manufacturers (OEMs) who integrate torque limiters directly into their machinery designs, such as manufacturers of packaging equipment, industrial robots, CNC machines, and heavy construction equipment. These OEMs demand high reliability, zero-backlash performance, and compliance with their specific machine footprint and performance specifications. The selection criteria for OEMs are focused on minimizing weight, maximizing lifespan, and ensuring seamless integration with the overall machine control system, driving demand for technologically advanced ball detent and electromagnetic limiters.

Another significant segment of buyers comprises industrial end-users, specifically plant operators and maintenance departments in manufacturing, mining, and energy sectors, who purchase limiters for replacement, retrofit, or maintenance, repair, and overhaul (MRO) purposes. These customers prioritize durability, ease of maintenance, and the ability to quickly source replacements to minimize costly production downtime. Industries dealing with bulk materials, such as mining and aggregate processing, require heavy-duty, high-torque capacity friction limiters to protect large conveyor belts and crushing equipment from frequent jams and sudden overloads. The food and beverage sector, characterized by high-speed, repetitive operations, requires corrosion-resistant, high-precision limiters, often driving demand for stainless steel components.

The rapidly growing segment of system integrators and automation solutions providers also acts as a critical purchaser, acquiring torque limiters as part of broader integrated drive solutions for their clients. These integrators value technical support, modularity, and compatibility with various motor and gearbox brands. Ultimately, any industrial entity relying on continuous mechanical power transmission where operational safety and asset protection are paramount represents a crucial customer base. The expansion of factory automation, particularly in emerging markets, is continuously broadening the demographic of potential buyers across Asia and Latin America, driving sustained market penetration for both standard and customized safety clutches.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.4 Billion |

| Growth Rate | CAGR 6.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | EIDE, Ringfeder Power Transmission, Regal Rexnord Corporation, R+W Coupling Technology, Mayr power transmission, Cross+Morse, Ogura Clutch Co., Ltd., Stieber Clutch, Huco Dynatork, Power Transmission Group (PTG), KTR Systems GmbH, Dalton Gear Company, Hilliard Corporation, Miki Pulley Co., Ltd., Schaeffler AG, ABB Ltd., Altra Industrial Motion Corp., Mitsubishi Electric Corporation, Siemens AG, and ComInTec S.r.l. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Torque Limiter Market Key Technology Landscape

The technological landscape of the Torque Limiter Market is characterized by a significant shift towards digitalization and enhanced precision, moving beyond purely mechanical solutions. A core trend involves the development of hybrid systems that combine the reliable physical protection of mechanical clutches (like ball detent or friction) with advanced electronic controls and monitoring capabilities. Sensor integration, utilizing technologies such as strain gauges, accelerometers, and magnetic position encoders, allows the torque limiter to communicate its operational status, slip events, and remaining lifespan in real-time. This integration facilitates the transition to predictive maintenance models, where the machine system can be shut down preemptively during an overload warning rather than waiting for catastrophic failure or relying solely on post-event analysis. Such advancements are crucial for sectors like high-speed robotics and automated warehouses where instantaneous reaction time is non-negotiable.

The refinement of ball detent and synchronous torque limiters represents another critical technological area. Manufacturers are focusing on reducing backlash and increasing the accuracy of the trip-torque repeatability, essential for precision indexing and positioning tasks in machine tools and sophisticated assembly lines. Advanced materials science plays a key role here, involving the use of specialized coatings and lightweight, high-strength alloys to enhance responsiveness and thermal stability, particularly important for friction-based designs that generate significant heat during prolonged slip events. Zero-backlash designs, achieved through optimized component geometry and material coupling, ensure that the safety mechanism does not introduce angular position errors into highly sensitive drive trains, maintaining the high accuracy required by modern manufacturing processes.

Furthermore, the market is seeing increased adoption of electromagnetic and pneumatic torque limiters, offering fully adjustable and remotely controllable torque settings without requiring physical disassembly. Electromagnetic limiters, often utilizing hysteresis or magnetic particle technology, provide extremely smooth and consistent torque transmission and are ideal for applications requiring continuous slip or highly controlled tensioning, such as in web processing or winding applications. The convergence of these advanced mechanical designs with IIoT connectivity platforms ensures that the latest generation of torque limiters not only protects equipment but also contributes vital data to the overarching factory monitoring and efficiency management systems, solidifying their status as integral components of Industry 4.0 infrastructure.

Regional Highlights

The regional dynamics of the Torque Limiter Market are heavily influenced by industrial infrastructure maturity, regulatory frameworks, and capital expenditure trends across manufacturing sectors. North America, particularly the United States, commands a substantial share of the market due to the robust presence of sophisticated automotive, aerospace, and defense industries, which mandate the use of high-reliability, precision torque limiters. Strict safety standards enforced by bodies like OSHA drive continuous demand for safety-critical components. The region is a leader in adopting advanced, sensor-equipped electromagnetic and synchronous limiters, reflecting a high investment capacity and a focus on integrating safety devices into complex automation systems and digitalized manufacturing processes (Smart Factory initiatives). This focus on technological superiority sustains premium pricing and continuous innovation in the region.

Europe represents a mature market characterized by stringent adherence to the EU Machinery Directive (MD) and ISO standards, making the consistent application of safety clutches mandatory across machine building and processing industries. Germany, Italy, and France are pivotal markets, driven by their strong engineering and manufacturing bases. European demand is focused on high-quality, long-life, and energy-efficient torque limiters, with a growing trend towards modular systems that are easy to install and maintain. The region also exhibits high demand for specialized limiters in the renewable energy sector, particularly in wind turbine pitch control systems, where fail-safe mechanisms must operate reliably under extreme environmental conditions. The emphasis on minimizing lifecycle costs and maximizing equipment uptime guides procurement strategies within this region.

Asia Pacific (APAC) is projected to experience the fastest growth rate during the forecast period. This rapid expansion is primarily fueled by extensive industrialization, substantial Foreign Direct Investment (FDI) into manufacturing hubs in China, South Korea, Japan, and India, and the widespread adoption of automation technologies to enhance productivity and competitiveness. While price sensitivity remains a factor in developing APAC economies, the increasing penetration of global automotive and electronics manufacturing firms elevates the demand for reliable, high-precision friction and ball detent limiters. The material handling sector, driven by massive e-commerce growth and warehousing automation, is a key consumer, seeking durable and cost-effective overload protection solutions for conveyor systems and Automated Guided Vehicles (AGVs). The push for localized manufacturing and supply chain resilience further supports regional market expansion.

- North America: High adoption rate of smart and precision torque limiters in aerospace and automotive; strong emphasis on OSHA compliance and predictive maintenance integration.

- Europe: Demand driven by strict EU Machinery Directive compliance and engineering excellence in Germany and Italy; strong market for customized, energy-efficient solutions in general manufacturing and renewables.

- Asia Pacific (APAC): Fastest-growing region due to rapid industrial automation, particularly in China and India; significant volume demand for standard and medium-precision friction limiters in material handling and heavy machinery.

- Latin America (LATAM): Growth tied to recovery in mining and infrastructure projects, favoring robust, durable shear pin and friction limiters for high-torque applications.

- Middle East and Africa (MEA): Market expansion linked to investment in oil & gas, petrochemicals, and construction; reliance on high-durability limiters capable of operating in harsh, high-temperature environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Torque Limiter Market.- EIDE

- Ringfeder Power Transmission

- Regal Rexnord Corporation

- R+W Coupling Technology

- Mayr power transmission

- Cross+Morse

- Ogura Clutch Co., Ltd.

- Stieber Clutch

- Huco Dynatork

- Power Transmission Group (PTG)

- KTR Systems GmbH

- Dalton Gear Company

- Hilliard Corporation

- Miki Pulley Co., Ltd.

- Schaeffler AG

- ABB Ltd.

- Altra Industrial Motion Corp.

- Mitsubishi Electric Corporation

- Siemens AG

- ComInTec S.r.l.

Frequently Asked Questions

Analyze common user questions about the Torque Limiter market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a torque limiter in industrial machinery?

The primary function of a torque limiter is to act as a mechanical fuse, protecting drive systems, gearboxes, and associated components from damage caused by transient or sustained overloads, jams, or sudden acceleration peaks by instantaneously disengaging power transmission when a preset torque threshold is exceeded. This prevents costly machine downtime and catastrophic failure.

Which type of torque limiter is most suitable for high-precision, zero-backlash applications like robotics?

Ball detent or synchronous torque limiters are most suitable for high-precision, zero-backlash applications, such as robotics and CNC machine tools. These types offer extremely fast disengagement, high repeatability of the trip-torque setting, and instantaneous re-engagement once the overload condition is cleared, ensuring accuracy and minimal angular displacement errors.

How does the integration of IIoT technology benefit torque limiter performance?

IIoT integration benefits torque limiter performance by enabling real-time condition monitoring, remote diagnosis, and predictive maintenance. Sensors embedded within or near the limiter transmit data on load cycles and slip events, allowing maintenance teams to anticipate wear, optimize calibration, and prevent unexpected failures before they result in significant operational disruption.

What factors primarily drive the growth of the Torque Limiter Market in the Asia Pacific region?

The growth of the Torque Limiter Market in the Asia Pacific region is primarily driven by rapid industrial automation adoption, substantial government and private investment in manufacturing capacity expansion (especially in automotive and electronics sectors), and the consequential need for cost-effective safety and efficiency components in high-volume production lines.

Are electromagnetic torque limiters replacing traditional mechanical friction types?

Electromagnetic torque limiters are not fully replacing traditional mechanical friction types but are gaining market share in specialized applications requiring remote adjustability, smooth start-up control, and continuous slip functionality (e.g., tension control). Friction types remain dominant where cost-effectiveness and high static torque capacity are the primary requirements.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager