Torque Motors Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432772 | Date : Dec, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Torque Motors Market Size

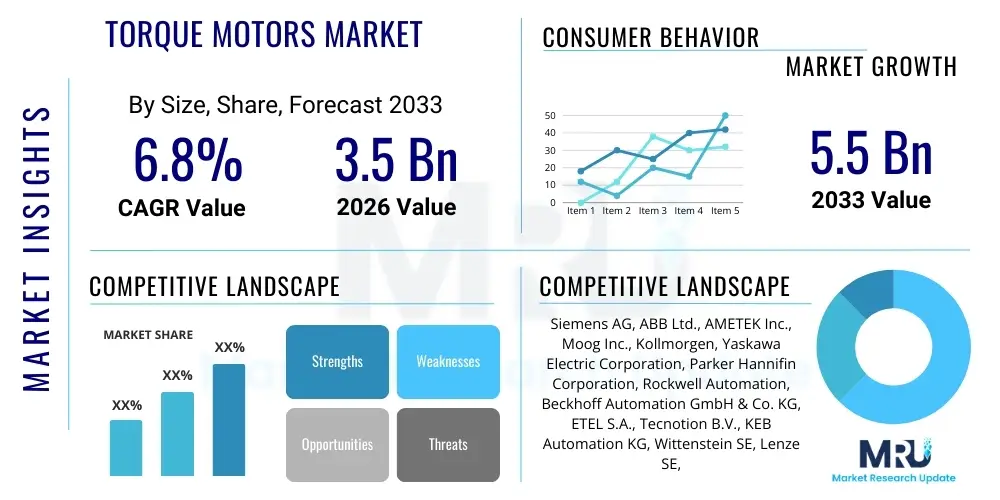

The Torque Motors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 3.5 Billion in 2026 and is projected to reach USD 5.5 Billion by the end of the forecast period in 2033.

Torque Motors Market introduction

The Torque Motors Market encompasses the manufacturing, distribution, and utilization of specialized electric motors designed to produce high torque at very low speeds, often without the need for mechanical gearboxes. These motors, frequently based on permanent magnet synchronous technology, function primarily as direct drives, offering exceptional precision, stiffness, and dynamic performance. The core product characteristic is their ability to deliver high moment of force directly to the load, eliminating backlash and enhancing overall system accuracy, making them indispensable components in advanced industrial automation and sophisticated motion control systems.

Major applications driving the demand for torque motors include high-precision machine tools, advanced robotics (especially multi-axis articulated robots), semiconductor manufacturing equipment, printing presses, and sophisticated test benches used in aerospace and automotive sectors. The inherent benefits of torque motors—such as reduced maintenance due to fewer moving parts, higher efficiency, compact design, and excellent thermal stability—position them favorably against traditional geared servo systems, particularly in environments requiring continuous high torque and precise angular positioning.

Key driving factors accelerating market adoption include the global trend toward Industry 4.0, which mandates higher levels of automation, speed, and reliability in manufacturing processes. Furthermore, the increasing complexity of machinery, requiring direct drive solutions to manage intricate motion profiles and high dynamic responses, substantially contributes to market expansion. The technological advancements in magnetic materials, motor winding techniques, and integrated feedback sensors further enhance the power density and performance envelope of modern torque motors, making them the preferred choice for mission-critical applications globally.

Torque Motors Market Executive Summary

The Torque Motors Market is characterized by rapid technological innovation focused on improving power density and reducing physical footprint, aligning with global business trends favoring compact and modular machinery designs. A significant trend involves the increasing preference for frameless torque motors, which offer maximum integration flexibility directly into the machine structure, thereby optimizing thermal dissipation and mechanical stiffness. Geographically, the Asia Pacific region, particularly China and Japan, remains the epicenter of market growth, driven by massive investments in domestic manufacturing automation, electric vehicle production lines, and high-volume consumer electronics manufacturing, positioning the region as both the largest producer and consumer of advanced torque motor solutions.

Segment trends reveal that the application in robotics and machine tools collectively dominates market revenue, reflecting the critical need for precision control in cutting-edge fabrication and assembly processes. Within the product type segmentation, permanent magnet torque motors are securing the largest share due to their superior efficiency and torque-to-size ratio compared to older induction-based designs. Furthermore, the integration of sophisticated digital encoders and Internet of Things (IoT) capabilities into torque motor systems is transforming predictive maintenance practices, allowing end-users to monitor motor health in real-time and significantly reduce unplanned downtime, thereby enhancing operational efficiency across multiple industries.

The competitive landscape is defined by specialized manufacturers intensely focused on customization and system integration capabilities. Strategic imperatives for key players include enhancing production capacity to meet rising APAC demand and investing heavily in R&D to develop motors capable of handling harsher environments and higher operational speeds. While the market faces challenges related to the complexity of integrating these motors and high initial investment costs, the long-term operational savings, coupled with governmental mandates favoring energy-efficient industrial components, solidify a strong growth trajectory through the forecast period, underpinning the indispensable role of torque motors in the next generation of industrial infrastructure.

AI Impact Analysis on Torque Motors Market

User queries regarding the impact of Artificial Intelligence (AI) on the Torque Motors Market generally revolve around three core themes: How AI can optimize motor performance and energy efficiency; the role of AI in predictive maintenance for complex direct-drive systems; and the use of machine learning algorithms to fine-tune motion control parameters in real-time. Users are seeking assurances that the substantial investment in torque motor technology can be further maximized through intelligent monitoring and adaptive operational strategies. Concerns often focus on the complexity of integrating AI models with proprietary motor control hardware and ensuring data integrity and security within networked industrial environments.

AI is fundamentally transforming the operational paradigm of torque motors by enabling unprecedented levels of efficiency and lifespan management. Machine learning algorithms analyze vast datasets generated by integrated sensors (temperature, vibration, load profiles, encoder feedback) to create highly accurate digital twins of the motor system. This allows the system to instantaneously adjust drive current, voltage, and phase alignment based on changing load conditions, moving beyond traditional, rigid PID control loops. This adaptive control not only maximizes torque output while minimizing energy consumption but also significantly reduces thermal stress, thereby extending the motor's operational life and improving overall system reliability, which is crucial in high-throughput applications like high-speed milling or semiconductor etching.

Furthermore, AI-powered predictive maintenance represents a major paradigm shift away from scheduled servicing. By identifying subtle anomalies in vibration signatures or winding resistance trends, AI algorithms can predict impending component failures (such as bearing degradation or demagnetization) days or weeks in advance, alerting maintenance teams before critical failure occurs. This capability is paramount for expensive, mission-critical torque motor installations in aerospace and medical sectors, where downtime costs are prohibitive. The adoption of AI is therefore not just an incremental improvement but a foundational enhancement that unlocks the full potential of high-performance direct-drive technology by guaranteeing continuous, optimized, and failure-resistant operation.

- AI enables real-time, adaptive motion control, optimizing torque output and reducing energy expenditure.

- Predictive maintenance algorithms analyze sensor data (vibration, thermal profiles) to forecast motor component failure.

- Machine learning enhances commutation smoothness and precision, critical for ultra-high-accuracy positioning systems.

- AI facilitates the creation of comprehensive digital twins for effective system simulation and remote diagnostics.

- Integration of AI minimizes motor resonance and acoustic noise during high-speed operation.

DRO & Impact Forces Of Torque Motors Market

The Torque Motors Market is principally driven by the global imperative for enhanced manufacturing precision and speed, directly facilitated by the inherent advantages of direct drive technology. The key drivers include the relentless progression of industrial automation, epitomized by Industry 4.0 initiatives, which necessitates motors capable of extremely precise positioning and high dynamic response in complex machinery like sophisticated CNC machines and multi-axis industrial robots. Simultaneously, the market faces restraints, primarily the significantly higher initial cost of torque motors compared to conventional geared servo systems, alongside the specialized technical expertise required for their complex integration and tuning into existing production lines, often involving intricate magnetic shielding and advanced control algorithms.

Opportunities for market expansion are significant, particularly in emerging applications such as high-performance haptic feedback systems used in surgical robotics and simulators, where rapid, nuanced force application is mandatory. Furthermore, the growing electric vehicle (EV) sector offers untapped potential, not only in automated EV battery and component manufacturing lines but potentially in propulsion systems that leverage the direct drive principle. The overarching impact force shaping this market is the shift toward miniaturization and high power density; end-users increasingly demand maximum torque in the smallest possible footprint, pushing manufacturers to continuously innovate in magnet materials and winding geometries to maintain a competitive edge and address these evolving technological demands.

The market impact is characterized by strong regulatory backing for energy efficiency in industrialized economies, favoring the highly efficient, low-loss operation characteristic of modern permanent magnet torque motors. This environmental impetus, coupled with the structural necessity of these motors in high-value manufacturing segments—where the cost of error outweighs the initial motor investment—ensures sustained demand. The competitive rivalry remains intense, centered around performance metrics such as peak torque, thermal management capacity, and the sophistication of integrated feedback mechanisms. The confluence of technological advancement and industrial necessity positions the market for resilient growth, mitigating the restraints posed by high costs through demonstrated long-term gains in productivity and reliability.

Segmentation Analysis

The Torque Motors Market is broadly segmented based on Type, Application, and End-Use Industry, providing a nuanced view of market dynamics and adoption patterns across various technological and industrial landscapes. Segmentation by Type predominantly separates the market into Frameless Torque Motors and Housed Torque Motors, reflecting different integration needs, with frameless versions gaining rapid adoption due to their flexibility in custom machinery design. Application segmentation highlights the critical sectors utilizing these components, dominated by precision manufacturing processes, while the End-Use segmentation delineates the final consuming industries, allowing for tailored market strategy and product development focused on specific sector requirements such as medical sterility or aerospace durability.

- Type: Frameless Torque Motors, Housed/Cased Torque Motors

- Motor Technology: Permanent Magnet Synchronous Motors (PMSM), Induction Torque Motors

- Application: Machine Tools (Milling, Turning, Grinding), Robotics, Semiconductor Manufacturing Equipment, Printing and Packaging Machinery, Medical Equipment, Test and Measurement Equipment, Aerospace and Defense

- End-Use Industry: Industrial Automation, Automotive and Transportation, Electronics and Semiconductor, Medical and Healthcare, Aerospace and Defense, Food and Beverages

Value Chain Analysis For Torque Motors Market

The value chain for the Torque Motors Market initiates with the upstream segment, which is dominated by the sourcing and processing of specialized raw materials critical for motor performance. This includes high-grade magnetic materials (such as Neodymium and Samarium-Cobalt alloys), precision-machined steel and aluminum components for housing, high-purity copper wiring, and specialized insulation materials. The reliance on rare earth metals for permanent magnets introduces vulnerability to supply chain volatility and geopolitical risks, making strategic sourcing and long-term contracts vital for manufacturers. Suppliers in this segment heavily influence the final motor performance metrics, particularly the power density and operational temperature range, acting as key stakeholders in innovation.

The midstream phase involves the core manufacturing and assembly processes. This highly technical segment includes precision winding of coils (often requiring specialized robotic systems for accuracy), magnet assembly and bonding, high-accuracy balancing, and the integration of sophisticated feedback systems like high-resolution optical or magnetic encoders. Direct drive motor manufacturing demands stringent quality control, thermal management design expertise, and the integration of advanced control electronics (motor drives). Manufacturers often differentiate themselves here through intellectual property related to proprietary winding techniques, core designs, and advanced cooling mechanisms, aiming for superior continuous torque capabilities and minimized cogging torque.

The downstream segment encompasses distribution channels and end-user deployment. Direct distribution is common for highly customized or large-scale projects, involving close collaboration between the manufacturer and the system integrator or original equipment manufacturer (OEM) to ensure seamless mechanical and electrical integration. Indirect distribution utilizes specialized industrial distributors and local agents who provide technical support and localized inventory, primarily serving smaller OEMs or aftermarket service needs. The end of the value chain rests with the industrial end-users, who rely heavily on aftermarket support, maintenance training, and rapid spare parts availability to maintain the high operational uptimes expected from critical direct-drive systems.

Torque Motors Market Potential Customers

The potential customers for high-performance torque motors are primarily entities operating in manufacturing sectors that demand unparalleled precision, dynamic performance, and high throughput, where traditional servo solutions fall short due to limitations such as backlash, compliance, and maintenance requirements. These buyers are typically sophisticated Original Equipment Manufacturers (OEMs) and large-scale industrial end-users who integrate these motors directly into their capital equipment. Key purchase criteria revolve around continuous torque capability, resolution of the integrated feedback system, thermal dissipation effectiveness, and long-term reliability under severe operational cycles.

Specific high-value target customers include manufacturers of five-axis and seven-axis CNC machining centers, which require direct drive rotary tables for flawless contouring and high stiffness. Another core segment is the advanced robotics industry, encompassing manufacturers of collaborative robots (cobots) and specialized surgical robots, where the motor’s low-profile design and high torque density enable complex, fluid movements. Furthermore, the highly controlled environment of semiconductor fabrication plants represents a major customer base, utilizing frameless torque motors in wafer handling, inspection, and photolithography stages to achieve nanometer-level positional accuracy necessary for microchip production.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.5 Billion |

| Market Forecast in 2033 | USD 5.5 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Siemens AG, ABB Ltd., AMETEK Inc., Moog Inc., Kollmorgen, Yaskawa Electric Corporation, Parker Hannifin Corporation, Rockwell Automation, Beckhoff Automation GmbH & Co. KG, ETEL S.A., Tecnotion B.V., KEB Automation KG, Wittenstein SE, Lenze SE, Bibus AG, Allied Motion Technologies Inc., Shenzhen Casun Motor Co., Ltd., Harmonic Drive Systems Inc., Fanuc Corporation, Estun Automation Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Torque Motors Market Key Technology Landscape

The technological landscape of the Torque Motors Market is rapidly evolving, driven primarily by advancements in magnetic materials and sophisticated motor control electronics, focused on maximizing torque density and minimizing thermal losses. Permanent Magnet Synchronous Motor (PMSM) technology forms the cornerstone of modern torque motor design, leveraging high-energy rare earth magnets, particularly Neodymium Iron Boron (NdFeB), to achieve unprecedented torque-to-volume ratios. The current technological focus is on developing advanced magnet arrangements, such as flux focusing designs and specialized Halbach arrays, which optimize the magnetic field distribution, thereby boosting continuous torque output and reducing the inherent cogging torque that can impact low-speed precision.

A second critical area of innovation lies in winding technology and thermal management. Conventional winding methods are being replaced by highly compact and specialized techniques, such as concentrated winding and specialized segmented stator designs, which improve slot fill factors and reduce copper losses. Effective thermal management is paramount, as continuous torque is directly limited by the motor's ability to dissipate heat. Advanced cooling solutions, including integrated liquid cooling jackets and phase-change materials, are now standard for high-performance motors, allowing them to maintain peak performance during continuous duty cycles essential for heavy industrial tasks like metal cutting or complex robotics movement. These thermal optimizations ensure that the magnetic properties of the rare earth materials are maintained even under extreme load.

Finally, the integration of high-resolution feedback devices and digital drives defines the motor’s operational effectiveness. Modern torque motors rely on ultra-high-resolution absolute encoders—both optical and inductive—capable of delivering positional feedback with sub-arc-second accuracy. This precision is coupled with advanced digital servo drives that utilize Field-Oriented Control (FOC) algorithms to precisely manage the motor’s magnetic flux and torque generation. The integration of these components allows for minimal latency in control loops and facilitates sophisticated functions like vibration suppression, self-tuning capabilities, and seamless communication across industrial network protocols (e.g., EtherCAT, PROFINET), enabling the motor to act as an integral and highly intelligent node within the automated system architecture.

Regional Highlights

Regional dynamics heavily influence the consumption and production patterns of torque motors, reflecting varying levels of industrialization, technological adoption rates, and governmental investment in advanced manufacturing infrastructure.

- Asia Pacific (APAC): Dominates the global market, driven by China’s massive investment in industrial automation, robotics manufacturing, and the rapidly growing semiconductor and electric vehicle supply chains. Japan and South Korea remain key centers for high-end machine tool and robotics technology, maintaining high demand for high-precision direct drive solutions.

- Europe: Characterized by strong adoption in Germany (Machine Tools and Automation) and Switzerland (Precision Engineering and Medical Devices). Europe focuses heavily on high-quality, customized, and energy-efficient torque motors, supported by stringent industrial safety and efficiency standards.

- North America: Exhibits robust demand fueled by the aerospace and defense sector, demanding highly reliable and performance-critical torque motors for radar systems, flight simulators, and sophisticated military applications. The ongoing revitalization of automotive manufacturing also contributes significantly to market growth.

- Latin America (LATAM) & Middle East and Africa (MEA): Represent emerging markets with increasing adoption in oil and gas automation (MEA) and packaging/food processing industries (LATAM). Growth here is projected to accelerate as local industries modernize their capital equipment bases, moving toward higher levels of process automation.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Torque Motors Market.- Siemens AG

- ABB Ltd.

- AMETEK Inc.

- Moog Inc.

- Kollmorgen

- Yaskawa Electric Corporation

- Parker Hannifin Corporation

- Rockwell Automation

- Beckhoff Automation GmbH & Co. KG

- ETEL S.A.

- Tecnotion B.V.

- KEB Automation KG

- Wittenstein SE

- Lenze SE

- Bibus AG

- Allied Motion Technologies Inc.

- Shenzhen Casun Motor Co., Ltd.

- Harmonic Drive Systems Inc.

- Fanuc Corporation

- Estun Automation Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Torque Motors market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technical advantage of a torque motor over traditional servo motors?

Torque motors offer direct drive capabilities, eliminating mechanical transmissions like gearboxes. This results in zero backlash, higher stiffness, superior dynamic response, and significantly reduced maintenance, crucial for high-precision positioning applications.

Which end-use industry is the largest consumer of frameless torque motors?

The Machine Tools and Industrial Robotics sectors are the largest consumers. Frameless designs allow OEMs to integrate the motor directly into the machine structure, optimizing space, maximizing thermal dissipation, and achieving the highest mechanical rigidity required for cutting-edge fabrication.

How does the high initial cost of torque motors justify the investment for manufacturers?

The investment is justified by lower total cost of ownership (TCO) through reduced maintenance, elimination of gearbox wear-and-tear, superior energy efficiency, and extended component lifespan. Their high precision also leads to improved product quality and reduced scrap rates in critical manufacturing processes.

What role do rare earth magnets play in modern torque motor performance?

Rare earth magnets, primarily Neodymium Iron Boron (NdFeB), are essential as they possess extremely high energy density. This allows modern Permanent Magnet Synchronous Motors (PMSM) to generate maximum torque within a smaller physical footprint, enhancing the motor's power density and efficiency.

How is Industry 4.0 influencing the design requirements of torque motors?

Industry 4.0 mandates higher connectivity, demanding torque motors with integrated smart sensors and industrial Ethernet protocols (like EtherCAT or TSN) for real-time monitoring, predictive maintenance, and seamless integration into interconnected, intelligent manufacturing ecosystems.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager