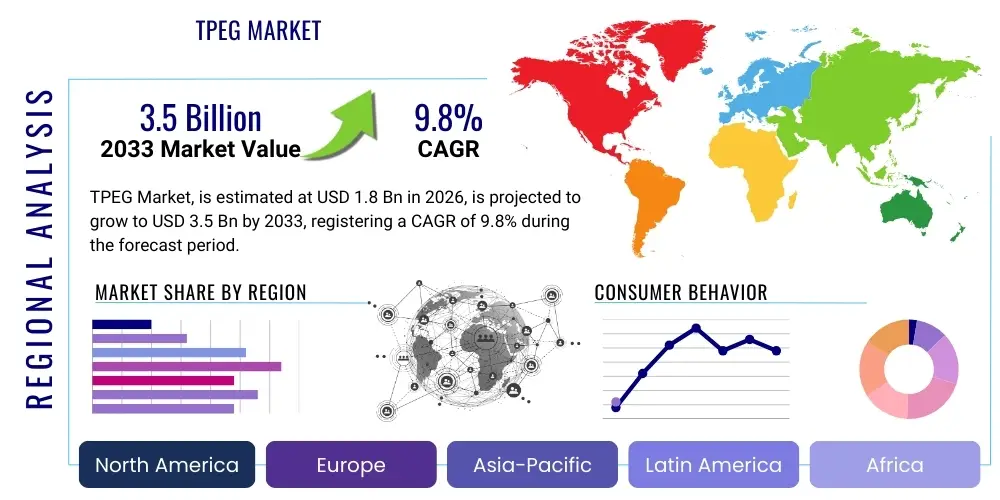

TPEG Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436728 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

TPEG Market Size

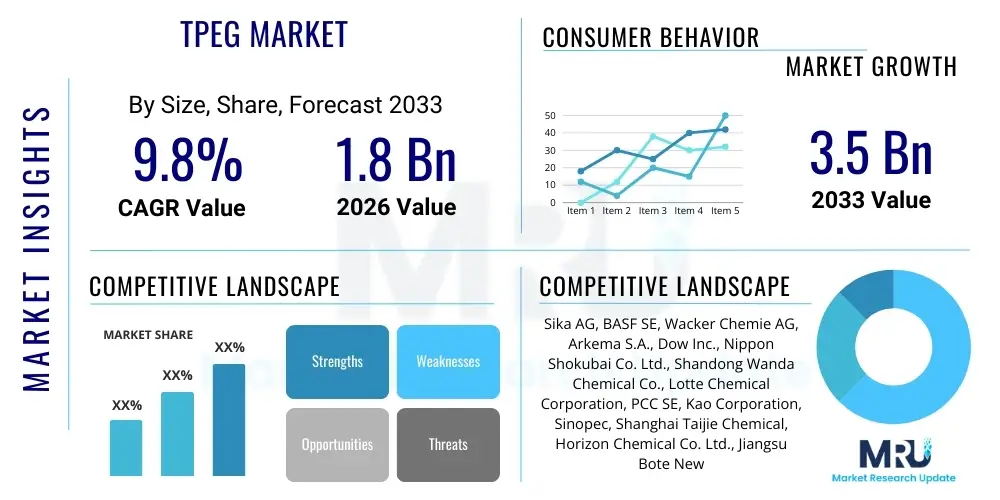

The TPEG Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.8% between 2026 and 2033. The market is estimated at USD 1.8 Billion in 2026 and is projected to reach USD 3.5 Billion by the end of the forecast period in 2033.

TPEG Market introduction

The TPEG (Terminal Polyethylene Glycol) Market, predominantly referring to the Methoxypolyethylene glycol allyl ether, is fundamental to the construction chemicals sector, serving as a primary raw material precursor for high-performance polycarboxylate ether (PCE) superplasticizers. These PCE admixtures are critical in modern concrete technology, enabling significant water reduction while maintaining or enhancing workability and strength. The demand for TPEG is intrinsically linked to global infrastructure development, urbanization, and the increasing adoption of high-strength, durable, and sustainable concrete formulations. Its molecular structure, featuring an unsaturated double bond and a polyethylene glycol chain, allows for tailored chemical modification, making it versatile for producing superplasticizers customized to various cement types and environmental conditions.

Product description highlights TPEG’s role as a highly reactive monomer utilized in free-radical polymerization processes to create PCE superplasticizers. The quality and molecular weight distribution of the TPEG precursor directly influence the performance characteristics of the resulting PCE, such as slump retention, dispersion efficiency, and setting time control in concrete mixes. Major applications are overwhelmingly dominated by the construction industry, particularly in ready-mix concrete, precast elements, high-rise buildings, bridges, and tunnels, where high fluidity and low water-cement ratios are essential for structural integrity and longevity. The benefits of using TPEG-derived superplasticizers include improved concrete strength, reduced material costs due to less water usage, and enhanced construction speed.

The market is primarily driven by accelerating infrastructure investment in emerging economies, strict regulatory requirements mandating the use of durable and resource-efficient construction materials, and technological advancements leading to the development of higher purity and optimized molecular weight TPEG products. Furthermore, the global shift towards green building initiatives and sustainable construction practices encourages the use of advanced concrete admixtures that minimize environmental impact and prolong the service life of structures. Controlling the quality and consistency of TPEG is paramount, as inconsistencies can lead to variable performance in critical concrete applications, necessitating stringent quality control throughout the supply chain.

TPEG Market Executive Summary

The TPEG market trajectory is characterized by robust growth, primarily fueled by the burgeoning demand for high-performance construction chemicals across Asia Pacific and specific high-growth urban centers globally. Business trends indicate a move towards vertical integration among key manufacturers, where chemical producers are increasingly acquiring or forming strategic alliances with PCE formulation specialists to secure the supply chain and maintain quality control over the final superplasticizer product. This consolidation strategy aims to mitigate risks associated with raw material price volatility and enhance market share by offering customized performance solutions. Additionally, there is a significant trend focused on the development of bio-based or more environmentally benign TPEG variants, addressing mounting pressures from environmental regulations and consumer preferences for sustainable materials in construction.

Regionally, the Asia Pacific (APAC) region continues to dominate the market in terms of volume and growth rate, driven by massive infrastructure projects, rapid urbanization in China, India, and Southeast Asian nations, and high population density requiring extensive residential and commercial development. North America and Europe, while mature, exhibit stable demand, focusing on premium TPEG grades used in specialized applications like self-compacting concrete (SCC) and high-strength concrete for critical civil engineering structures. The Middle East and Africa (MEA) are emerging as high-potential markets, linked to large-scale construction programs related to urbanization and preparation for major international events, demanding large volumes of durable concrete admixtures.

Segmentation trends reveal that the high-purity TPEG segment (typically >98%) is experiencing faster value growth due to its superior performance characteristics when polymerized into PCE, offering better slump retention and dispersion efficiency essential for complex construction projects. The application segment remains heavily concentrated in polycarboxylate superplasticizers, which account for the majority of TPEG consumption. However, peripheral segments, including specialized coatings and non-cementitious construction materials, are showing incremental growth. Strategic insights suggest that manufacturers prioritizing R&D into novel molecular weights and polydispersity control of TPEG will be best positioned to capture premium market segments and differentiate their offerings in a highly competitive chemical supply landscape.

AI Impact Analysis on TPEG Market

Common user questions regarding AI's influence in the TPEG market often revolve around how artificial intelligence can optimize the chemical synthesis process, predict raw material price fluctuations, and enhance the quality control of the final PCE admixture performance. Users are highly interested in AI's role in optimizing monomer design and predicting the final concrete performance based on TPEG specifications, aiming to reduce experimental costs and time-to-market for new admixture formulations. Key concerns include the initial investment required for sophisticated AI models, the necessity for high-quality input data from production batches, and the potential disruption to traditional chemical engineering roles. The central expectation is that AI will introduce unprecedented efficiency in production, supply chain management, and formulation optimization, ensuring consistent performance and rapid response to varying construction requirements.

- AI-driven optimization of TPEG synthesis parameters, enhancing yield and purity levels.

- Predictive modeling using machine learning to forecast demand patterns for PCE, stabilizing TPEG supply chains.

- Automated quality control systems applying computer vision and data analytics to monitor TPEG molecular structure consistency in real-time.

- Development of AI-assisted formulation tools that predict optimal TPEG molecular weight distribution for specific concrete performance targets (e.g., slump flow, early strength).

- Improved raw material procurement strategies utilizing AI for predictive pricing and risk assessment of key feedstock chemicals.

- Enhanced industrial safety through AI monitoring of reaction vessel conditions during TPEG production processes.

DRO & Impact Forces Of TPEG Market

The TPEG market is significantly influenced by a dynamic interplay of drivers (D), restraints (R), opportunities (O), and intrinsic impact forces. Primary drivers include the global mandate for sustainable and durable infrastructure, which necessitates the use of high-performance concrete facilitated by TPEG-derived superplasticizers. Restraints largely center on the high volatility of upstream petrochemical raw material prices (e.g., ethylene oxide), which directly impact TPEG manufacturing costs and subsequent market pricing, potentially hindering adoption in highly price-sensitive developing markets. Furthermore, the inherent complexity in standardizing TPEG chemical characteristics across different suppliers poses technical challenges for end-users seeking consistent concrete performance, acting as a moderate restraint.

Opportunities for market expansion are abundant, particularly through strategic product differentiation, focusing on developing specialized TPEG grades tailored for extreme climatic conditions (hot or cold weather concreting) and specific cement chemistries (like blended cements incorporating supplementary cementitious materials). Another major opportunity lies in expanding the application scope beyond conventional PCE, exploring TPEG derivatives for use in high-value, niche chemical applications such as specialized coatings, water treatment polymers, and cosmetic ingredients. Innovations in sustainable synthesis methods, reducing dependence on fossil fuel derivatives, also present a significant long-term growth avenue and competitive advantage.

Impact forces governing the TPEG market are primarily related to regulatory shifts in construction standards globally, mandating higher durability and longevity for public works projects. Economic impact forces, such as fluctuating GDP growth and interest rates, directly influence construction spending, thus affecting TPEG demand. Technological forces drive constant improvement in TPEG purity and structural homogeneity, enabling the production of new generation PCE superplasticizers that offer superior performance parameters, such as ultra-high slump retention without detrimental side effects. Finally, competitive rivalry remains high, driven by the presence of numerous regional and international chemical manufacturers vying for market share through pricing strategies, supply chain efficiencies, and technical support services offered to concrete admixture formulators.

Segmentation Analysis

The TPEG market segmentation provides a granular view of product diversification and application specificity crucial for strategic planning. The market is primarily dissected based on molecular weight, purity level, application type, and end-use industry, reflecting the varied performance requirements across different geographical and construction environments. High-molecular-weight TPEG generally caters to applications requiring enhanced slump retention and dispersion over extended periods, while high-purity grades are preferred for specialized, high-performance concrete mixes where chemical interference must be minimized. Understanding these segments is vital for producers to align their production capabilities with evolving end-user demands, particularly the increasing reliance on complex cement compositions that require highly specific admixture chemistries.

The distinction in market segments highlights the premiumization trend driven by performance. While standard TPEG remains a commodity for general ready-mix concrete, the market is increasingly valuing specialized TPEG derivatives that offer unique functional groups, enabling the formulation of superplasticizers with multi-functional capabilities, such as air-entrainment reduction or enhanced early-age strength development. Geographically, segmentation informs manufacturers about localized preferences; for instance, European markets often prioritize low-alkali, high-purity TPEG, whereas developing Asian markets focus more on cost-effectiveness and volume.

- By Molecular Weight (MW):

- Low Molecular Weight TPEG (e.g., MW 2000–3000)

- Medium Molecular Weight TPEG (e.g., MW 3000–5000)

- High Molecular Weight TPEG (e.g., MW 5000+)

- By Purity Grade:

- Standard Grade (97%-98%)

- High Purity Grade (>98%)

- By Application:

- Polycarboxylate Superplasticizers (PCE Admixtures)

- Coatings and Resins

- Emulsifiers and Surfactants

- Other Specialty Chemicals

- By End-Use Industry:

- Construction and Infrastructure

- Chemical Manufacturing

- Oil and Gas (Drilling Fluids)

- Personal Care and Cosmetics

Value Chain Analysis For TPEG Market

The TPEG market value chain commences with upstream crude oil and natural gas derivatives, which are processed into ethylene, the precursor for ethylene oxide (EO). EO is then reacted to form polyethylene glycol (PEG), followed by etherification and specific chemical modifications involving allyl chloride or similar reactants to yield the final TPEG monomer. Upstream analysis reveals that raw material procurement, particularly EO, constitutes the most significant cost component and introduces the primary risk of supply volatility. Major chemical giants often control the upstream supply of EO, granting them leverage over the downstream TPEG producers. Strategic alliances or long-term contracts with EO suppliers are critical for TPEG manufacturers to ensure cost stability and continuous production flow in this highly complex chemical market.

The midstream stage involves the highly technical process of TPEG synthesis, requiring specialized reactors, stringent temperature control, and purification processes to achieve the desired molecular weight distribution and purity necessary for optimal PCE performance. TPEG producers typically focus on customizing molecular weights based on the specific requirements of their downstream customers—the concrete admixture formulators. The distribution channel is bifurcated: direct distribution is common for large-volume contracts with major global PCE producers, ensuring technical support and tailored logistics; while indirect distribution utilizes chemical distributors and agents, particularly for smaller regional admixture manufacturers or niche application end-users, facilitating broader market penetration.

Downstream analysis focuses on the transformation of TPEG into PCE superplasticizers, which are then integrated into the construction value chain. Direct sales of PCE admixtures occur between the formulators and large construction companies or ready-mix concrete plants. Indirect sales involve local distributors providing PCE to smaller construction sites and contractors. The ultimate success of TPEG in the market is determined by the performance validation at the construction site, where the efficacy of the PCE admixture in terms of concrete workability, strength gain, and durability is judged. Therefore, close collaboration between TPEG producers, PCE formulators, and construction engineers is crucial to ensure product quality and application effectiveness, driving the entire value chain toward high-performance solutions.

TPEG Market Potential Customers

The primary customer base for TPEG monomers consists of manufacturers of specialized construction chemicals, specifically companies that formulate Polycarboxylate Ether (PCE) superplasticizers. These admixture companies represent the bulk purchasers, relying on consistent, high-quality TPEG supply to maintain the performance integrity of their final products, which are marketed globally to the construction industry. The choice of TPEG supplier is heavily influenced by factors such as batch consistency, technical support for polymerization processes, and the ability to supply customized molecular weight ranges tailored to regional cement characteristics and specific project requirements, such as high-rise construction or marine environments.

Beyond the core construction chemicals sector, other potential customers include producers of specialty polymers, particularly those focused on dispersion agents, thickeners, and rheology modifiers used in coatings, paints, and protective resin systems. These end-users typically require smaller volumes but demand extremely high purity and specific functional characteristics, often necessitating customized TPEG derivatives. Additionally, the pharmaceutical and personal care sectors represent niche, high-value markets for specific, highly purified grades of PEG derivatives, potentially utilizing TPEG in applications such as drug encapsulation or as an excipient, although this application requires compliance with stringent regulatory standards like pharmacopoeial grades, driving up the required investment in quality assurance.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.8 Billion |

| Market Forecast in 2033 | USD 3.5 Billion |

| Growth Rate | 9.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sika AG, BASF SE, Wacker Chemie AG, Arkema S.A., Dow Inc., Nippon Shokubai Co. Ltd., Shandong Wanda Chemical Co., Lotte Chemical Corporation, PCC SE, Kao Corporation, Sinopec, Shanghai Taijie Chemical, Horizon Chemical Co. Ltd., Jiangsu Bote New Materials Co., Mapei S.p.A. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

TPEG Market Key Technology Landscape

The technology landscape governing the TPEG market is primarily focused on advanced polymerization and purification techniques essential for producing high-quality, uniform monomers. Key technological advancements revolve around controlling the molecular weight distribution (polydispersity index) of the PEG chain and ensuring the complete terminal capping with the reactive allyl group. Modern TPEG synthesis leverages highly efficient, continuous flow chemical processes rather than traditional batch processing, which enhances throughput, improves energy efficiency, and ensures greater consistency from one batch to the next. The adoption of specialized catalyst systems for the etherification reaction is crucial, as catalysts not only speed up the reaction but also help minimize unwanted byproducts, leading to higher purity grades necessary for premium PCE formulations used in demanding concrete applications.

A significant area of technological focus is the integration of advanced analytical chemistry tools, such as Gel Permeation Chromatography (GPC) and sophisticated Nuclear Magnetic Resonance (NMR) spectroscopy, directly into the production line. These technologies enable real-time monitoring of TPEG structural integrity, molecular weight, and the concentration of the reactive allyl end-group. Real-time feedback mechanisms allow manufacturers to quickly adjust reaction parameters, minimizing off-spec product creation and significantly reducing manufacturing costs associated with waste and reprocessing. This level of technical control is non-negotiable for manufacturers aiming to supply the global leaders in construction chemicals who demand rigorous quality specifications.

Furthermore, technology is rapidly evolving in the area of sustainable TPEG production. Research and development efforts are concentrated on utilizing bio-based feedstocks, potentially moving away from petrochemical-derived ethylene oxide, which would lower the environmental footprint of the product and provide a hedging strategy against fossil fuel price volatility. Another frontier involves developing TPEG derivatives that can effectively incorporate non-traditional cementitious materials, such as calcined clay or slag, into concrete mixes without compromising fluidity or strength development. This technological push aligns directly with industry goals for decarbonization and resource efficiency in construction, positioning TPEG as an enabler of low-carbon concrete solutions through superior admixture performance.

Regional Highlights

- North America: The North American market, characterized by stringent infrastructure standards and a high adoption rate of advanced concrete technology, demonstrates stable demand for high-purity TPEG. Key growth areas include specialized infrastructure projects (bridges, highways) and the rapidly expanding market for self-consolidating concrete (SCC). Regulatory emphasis on durability and reduced maintenance costs ensures continued investment in premium PCE admixtures, translating to steady TPEG consumption, predominantly driven by the United States and Canada. The market here values technical service and customized solutions greatly.

- Europe: Europe represents a mature but technologically demanding market, with significant focus on green building certifications and reduced carbon emissions in construction. Demand is high for TPEG that supports formulations enabling the maximum substitution of Portland cement with supplementary cementitious materials (SCMs). Germany, France, and the UK are primary consumers. The implementation of REACH regulations necessitates compliance and transparency in the supply chain, often favoring local or technically compliant international suppliers offering low-alkali TPEG grades. Innovation in prefabricated housing also drives specialized PCE demand.

- Asia Pacific (APAC): APAC is the engine of global TPEG market growth, accounting for the largest share in both volume and value. Rapid urbanization, massive residential construction, and extensive government investment in transportation networks (e.g., high-speed rail, ports) across China, India, and Southeast Asia (Vietnam, Indonesia) propel consumption. While price sensitivity exists, the increasing shift towards high-rise construction and mega-projects is driving up the demand for higher molecular weight TPEG offering superior slump retention necessary for hot weather concreting and long transportation times. Local manufacturing capacity is rapidly expanding to meet regional demand, intensifying competition.

- Latin America: The TPEG market in Latin America is characterized by periodic large-scale infrastructure investments, particularly in Brazil and Mexico, alongside fluctuating economic conditions. Market growth is moderately constrained by economic instability but remains promising due to ongoing needs for housing and commercial development. Adoption of advanced PCE technology is gradual but increasing, driven by international construction firms operating in the region. Local sourcing and efficient logistics are critical due to geographical challenges.

- Middle East and Africa (MEA): MEA exhibits high potential, especially in the Gulf Cooperation Council (GCC) countries, fueled by multi-billion dollar real estate and tourism infrastructure projects (e.g., Saudi Arabia’s Vision 2030, UAE’s expansion). The severe climatic conditions (extreme heat) necessitate high-performance concrete and specialized PCE formulations that rely heavily on high-quality TPEG to manage slump loss and hydration. The African market, particularly South Africa and Nigeria, offers emerging opportunities linked to urbanization and resource extraction infrastructure development. Strategic partnerships with regional distributors are essential for market penetration.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the TPEG Market.- Sika AG

- BASF SE

- Wacker Chemie AG

- Arkema S.A.

- Dow Inc.

- Nippon Shokubai Co. Ltd.

- Shandong Wanda Chemical Co.

- Lotte Chemical Corporation

- PCC SE

- Kao Corporation

- Sinopec

- Shanghai Taijie Chemical

- Horizon Chemical Co. Ltd.

- Jiangsu Bote New Materials Co.

- Mapei S.p.A.

- Reliance Industries Limited

- Huntsman Corporation

- Mitsubishi Chemical Corporation

- Clariant AG

- GCP Applied Technologies

Frequently Asked Questions

Analyze common user questions about the TPEG market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is TPEG and how does it function in construction chemicals?

TPEG, or Methoxypolyethylene glycol allyl ether, is a critical chemical monomer utilized as a raw material for synthesizing Polycarboxylate Ether (PCE) superplasticizers. Its primary function is to provide the main chain and side chains in PCE polymers, which adsorb onto cement particles, creating strong steric hindrance that disperses the particles, allowing for significant water reduction while dramatically enhancing concrete fluidity and workability.

Which geographical region exhibits the highest growth potential for the TPEG market?

The Asia Pacific (APAC) region, driven by continuous, large-scale infrastructure investments, rapid urbanization, and high-density residential and commercial construction in major economies like China and India, represents the highest growth potential. This region's construction volume necessitates vast quantities of TPEG-derived concrete admixtures.

How does the molecular weight of TPEG affect the final concrete performance?

The molecular weight of the TPEG monomer directly influences the side chain length of the resulting PCE superplasticizer. Higher molecular weight TPEG typically yields PCE with longer side chains, which enhances the steric hindrance effect, resulting in superior slump retention and delayed setting times, particularly advantageous for long-distance transport or hot weather concrete placement.

What are the main market restraints impacting the TPEG industry profitability?

The primary restraint is the significant price volatility and supply dependency of its key raw material, ethylene oxide (EO), a petrochemical derivative. Fluctuations in crude oil and natural gas prices directly translate into variable manufacturing costs for TPEG, posing challenges to consistent pricing and profitability margins for downstream PCE formulators.

What technological trends are shaping the future production of TPEG?

Key technological trends include the shift towards continuous flow manufacturing processes for improved efficiency and consistency, the implementation of advanced analytical monitoring (GPC, NMR) for real-time quality control, and extensive research into bio-based TPEG synthesis routes to reduce reliance on fossil fuel feedstocks and align with global sustainability mandates in the construction sector.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager