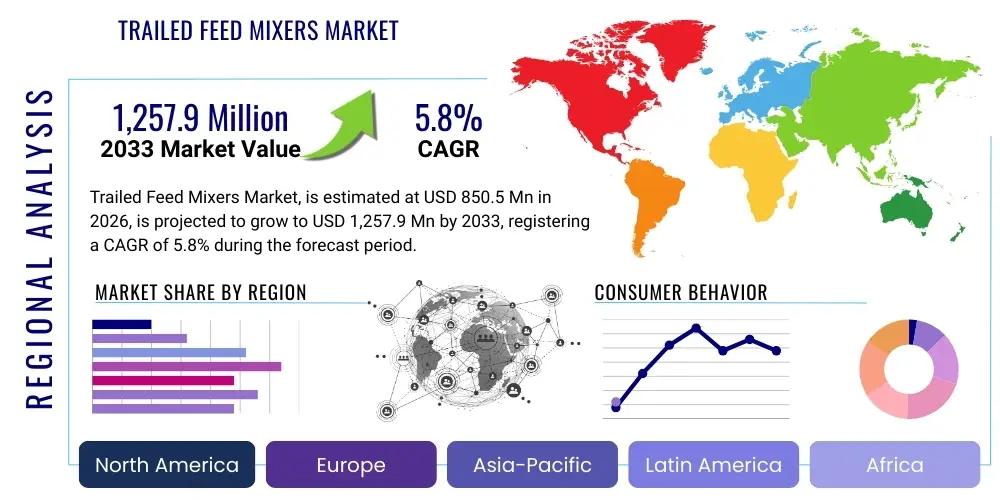

Trailed Feed Mixers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438760 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Trailed Feed Mixers Market Size

The Trailed Feed Mixers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 850.5 Million in 2026 and is projected to reach USD 1,257.9 Million by the end of the forecast period in 2033. This consistent expansion is primarily fueled by the increasing global adoption of precision livestock farming techniques, particularly the utilization of Total Mixed Ration (TMR) systems to optimize animal nutrition and maximize feed efficiency across large-scale dairy and beef operations. The shift toward higher capacity and automated mixing solutions in mature agricultural economies further strengthens this positive growth trajectory.

Trailed Feed Mixers Market introduction

The Trailed Feed Mixers Market encompasses the manufacturing, distribution, and sales of machinery used in livestock operations for the precise preparation of Total Mixed Rations (TMR). These machines, typically attached to a tractor for mobility, are essential for blending various feed ingredients—including forage, concentrates, supplements, and minerals—into a homogeneous mixture that prevents selective feeding by animals. The core product, the trailed feed mixer, comes predominantly in vertical (single, double, or triple auger) and horizontal configurations, distinguished by the mechanism used to cut, mix, and discharge the feed. Adoption is critical for modern farms seeking to improve herd health, boost milk production, and ensure consistent daily nutritional intake across the entire livestock population.

Major applications of trailed feed mixers span large commercial dairy farms, intensive beef cattle fattening operations (feedlots), and specialized custom feed mixing services. These mixers are crucial for delivering balanced nutrition, which directly translates into enhanced productivity, reduced feed waste, and optimization of operational labor costs. Key benefits driving market demand include improved feed efficiency, better control over ration formulation accuracy via integrated weighing systems, and significant time savings compared to manual mixing methods. Furthermore, the robust construction and high capacity of trailed mixers make them ideal for continuous, heavy-duty use in diverse environmental conditions worldwide.

Driving factors for market growth are multifaceted, centered around the increasing sophistication of global agricultural practices. Rapid mechanization in emerging markets, coupled with rising labor costs in developed regions, necessitates efficient, high-throughput machinery. Government subsidies and incentives promoting modern farming techniques, especially in Europe and North America, also contribute significantly. The underlying factor remains the proven economic return on investment derived from optimized feed management, which is paramount for profitability in competitive livestock sectors. Continuous innovation in auger design and material science to handle tougher forage types further enhances the utility and lifespan of these crucial farm implements.

Trailed Feed Mixers Market Executive Summary

The Trailed Feed Mixers Market is characterized by robust business trends focusing on digitalization, capacity expansion, and energy efficiency. Manufacturers are increasingly integrating advanced telematics and IoT sensors to provide real-time data on mixing consistency, load management, and preventative maintenance schedules, thereby enhancing operational uptime and accuracy. The competitive landscape is consolidating, with leading global agricultural machinery companies focusing on acquiring smaller technology specialists or expanding their product lines to offer specialized vertical mixers favored for their thorough mixing and ability to process high-fiber roughages. High initial investment costs remain a critical barrier, particularly for small-to-medium-sized farming operations, yet the long-term efficiency gains continue to drive large-scale capital expenditure.

Regional trends indicate North America and Europe retaining dominant market shares due to the presence of large, commercially managed farms that prioritize automated TMR preparation. However, the Asia Pacific (APAC) region, driven by rapid urbanization and the subsequent professionalization of the dairy and beef sectors in countries like India, China, and Australia, is poised for the fastest growth. Investment in infrastructure and supporting government policies aimed at increasing domestic milk production are accelerating the adoption of mid-to-large capacity mixers in APAC. Latin America, particularly Brazil and Argentina, also shows strong potential, driven by vast cattle populations requiring efficient feeding solutions for high-volume feedlots.

Segment trends reveal a distinct preference for Vertical Trailed Mixers due to their versatility in handling various ingredient types, including large square bales, and their ability to produce a highly uniform Total Mixed Ration (TMR) faster than traditional horizontal models. Furthermore, the demand for medium-capacity mixers (15-25 m³) is surging, catering to the sweet spot for expanding commercial farms managing herd sizes between 300 and 800 head. The integration of advanced features such as automatic dosing systems, remote diagnostic tools, and programmable weighing systems are rapidly transitioning from optional extras to standard requirements, demonstrating a market shift towards precision agricultural tools that maximize nutritional yield per unit of feed input.

AI Impact Analysis on Trailed Feed Mixers Market

User queries regarding the future of the Trailed Feed Mixers Market predominantly center on how Artificial Intelligence (AI) will automate ration formulation, optimize mixing cycles, and enable predictive maintenance. Users are concerned about the integration costs of such smart systems and how AI can ensure the absolute consistency of the Total Mixed Ration (TMR) regardless of operator skill or raw material variability. Key expectations revolve around AI algorithms analyzing real-time data from weigh cells and moisture sensors to adjust ingredient quantities instantaneously, minimizing human error and maximizing nutritional delivery efficiency. The integration of AI-driven diagnostics is expected to predict component failure, transforming current maintenance models from reactive to proactive, thereby drastically improving operational uptime during critical feeding windows.

- AI-Driven Ration Formulation: Algorithms dynamically adjust ingredient inputs based on real-time feed analysis data (e.g., moisture, nutrient content) to maintain target TMR composition, reducing variability.

- Predictive Maintenance: AI analyzes operational metrics (vibration, load cycles, motor temperature) to forecast potential mechanical failures in augers or gearboxes, scheduling maintenance proactively.

- Optimized Mixing Protocols: AI determines the ideal mixing time and speed based on the specific recipe and load size to ensure homogeneous blend quality while minimizing energy consumption.

- Inventory Management: Integration with farm management software uses AI to track feed consumption rates and predict purchasing needs for raw materials automatically.

- Enhanced Operator Training: AI-powered feedback systems provide real-time guidance to operators to ensure best practices in loading and mixing procedures, standardizing TMR quality across shifts.

DRO & Impact Forces Of Trailed Feed Mixers Market

The market dynamics are governed by a complex interplay of Drivers (D), Restraints (R), Opportunities (O), and associated Impact Forces. The primary driver is the global emphasis on enhancing feed conversion ratio (FCR) in livestock farming; farmers are realizing that precise TMR preparation directly correlates with higher output and healthier animals. This is reinforced by global population growth demanding more efficient protein production. However, significant restraints include the inherently high capital outlay required for purchasing these sophisticated machines and the necessary infrastructure (tractors, storage) to support them. Furthermore, the technical expertise required for operating and maintaining advanced electronic weighing and diagnostic systems acts as a hurdle in regions with less mechanized agricultural traditions. The opportunity landscape is vast, centered on incorporating IoT sensors, telematics, and fully automated data capture capabilities, allowing mixers to become integral components of interconnected smart farm ecosystems, particularly appealing to younger, tech-savvy farm managers.

Impact forces currently shaping the market are high. Economic forces, characterized by fluctuating commodity prices (feed ingredients and steel for manufacturing), strongly influence both purchasing decisions and production costs. Technological forces exert a compelling upward pressure, pushing manufacturers towards continuous innovation in auger design for better mixing action and integrating high-accuracy load cell systems to meet increasingly stringent TMR quality standards. Environmental factors, while indirect, are gaining importance as efficient feed usage is tied to sustainability goals, reducing methane emissions associated with poor digestion. Regulatory policies, especially concerning animal welfare and feed quality standards in major agricultural blocs like the EU and North America, mandate the use of precision equipment, providing structural support to market demand.

The cumulative effect of these forces suggests a widening gap between large, commercial farms that can absorb the capital expenditure and benefit maximally from precision TMR technology, and smaller farms which may struggle with the investment. This concentration of usage necessitates manufacturers to focus heavily on providing robust financing options and modular, scalable machine designs. Overcoming restraints through effective operator training programs and emphasizing the long-term return on investment (ROI) via reduced feed waste and increased production are critical strategic imperatives for market penetration, particularly in high-potential emerging economies where mechanization rates are accelerating rapidly.

Segmentation Analysis

The Trailed Feed Mixers market is highly segmented based on configuration, capacity, and end-use application, reflecting the diverse needs of the global livestock industry. Analyzing these segments provides crucial insights into manufacturing focus areas and consumer purchasing preferences. The division between vertical and horizontal configurations remains the most fundamental segmentation. Vertical mixers, dominating new sales, offer superior capabilities in handling large, round or square bales of hay and silage, providing a more versatile solution for farms utilizing diverse forage sources. In contrast, horizontal mixers, while requiring pre-processing of large bales, are often favored for rapid mixing cycles in specific operations focusing on high-density concentrates.

Capacity segmentation directly correlates with herd size and operational scale. Small-capacity mixers (typically 5 to 15 m³) are suited for smaller commercial farms or specialized applications. Medium-capacity mixers (15 to 25 m³) represent the core volume segment, catering to the majority of growing commercial dairy farms globally, balancing throughput with maneuverability. Large-capacity mixers (over 25 m³), including triple-auger models, are reserved for massive feedlots and industrial-scale operations where efficiency and speed in preparing tens of tons of TMR daily are paramount. Manufacturers are increasingly focused on optimizing the capacity-to-weight ratio to improve efficiency and reduce fuel consumption during mixing and transport.

The segmentation by end-user—dairy farms, beef farms, and custom feed operators—highlights varying operational demands. Dairy farms require precise, consistent mixing schedules tailored to specific lactation stages to maximize milk yield and quality, making high-accuracy weighing systems mandatory. Beef farms, particularly feedlots, prioritize high volume, durability, and fast throughput to manage vast numbers of cattle efficiently. Custom feed operators, who provide TMR services to multiple smaller farms, demand versatility and robust reliability, often opting for high-capacity, rugged machines capable of continuous travel and multiple daily mixes across different client locations. Understanding these nuanced needs is vital for developing targeted marketing and product specifications.

- By Type:

- Vertical Trailed Mixers (Single Auger, Double Auger, Triple Auger)

- Horizontal Trailed Mixers (Paddle, Reel)

- By Capacity:

- Small Capacity (5 m³ – 15 m³)

- Medium Capacity (15 m³ – 25 m³)

- Large Capacity (Above 25 m³)

- By End-User:

- Dairy Farms

- Beef Farms/Feedlots

- Custom Feed Operators

- By Technology:

- Standard Mixers (Basic Weighing System)

- Advanced Mixers (Telematics, IoT Integration, Remote Diagnostics)

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East & Africa (MEA)

Value Chain Analysis For Trailed Feed Mixers Market

The value chain for the Trailed Feed Mixers market begins with the upstream supply of raw materials, primarily high-strength steel (for mixer bodies and augers), specialized gearboxes, hydraulic components, and precision electronics (load cells, display units). Fluctuations in global steel prices and the availability of high-quality, durable mechanical components significantly impact manufacturing costs and final pricing. Key strategic considerations at this stage involve securing stable supply contracts and implementing robust quality control over critical components such as heat-treated auger flighting, which must withstand abrasive feed materials over long periods. Efficiency in sourcing and minimizing inventory hold times are crucial for maintaining competitive manufacturing margins in this heavy equipment sector.

The core manufacturing and assembly stage involves complex processes, including welding, surface treatment (e.g., painting and corrosion protection), and the precise integration of hydraulic and electronic systems. Original Equipment Manufacturers (OEMs) often differentiate themselves through innovative auger designs—such as patented knife arrangements or specific mixing patterns—that claim superior TMR homogeneity and shorter mixing times. The distribution channel is pivotal in bridging the gap between factory and farm. Due to the high value, specialized nature, and maintenance requirements of feed mixers, the dominant distribution method is through authorized, independent dealer networks. These dealers provide essential services, including local sales, financing support, spare parts inventory, and post-sale technical service, acting as the primary point of contact for the end-user. Direct sales models are rare, typically reserved only for the largest corporate farming accounts or specialized tenders.

The downstream analysis focuses on the end-user adoption and aftermarket services. Aftermarket support, including the sale of replacement parts (especially knives, auger wear parts, and electrical components) and maintenance contracts, represents a significant and stable revenue stream for both manufacturers and dealers. The lifespan of a trailed feed mixer often exceeds ten years, making robust parts availability essential for sustaining customer loyalty. The end-users—large commercial farms—rely heavily on the continuous performance of these machines; thus, responsiveness of the technical support channel is a critical determinant of brand loyalty. Innovation in the downstream segment is focused on predictive maintenance and remote diagnostics, allowing technicians to troubleshoot issues without costly farm visits, optimizing machine uptime and reducing long-term cost of ownership for the farmer.

Trailed Feed Mixers Market Potential Customers

The primary customer base for Trailed Feed Mixers consists of commercial agricultural enterprises heavily vested in maximizing animal productivity through Total Mixed Ration (TMR) feeding regimes. The most significant segment comprises large-scale dairy farms, particularly those managing herds of 200 or more milking cows. These operations rely on precise nutritional delivery to maintain optimal milk production and health across different lactation groups. Their buying decisions are driven by capacity requirements, mixing accuracy (weighing systems), and the machine’s ability to efficiently process various forage types, demanding high-durability and advanced electronic features.

The second major group includes industrial beef cattle fattening operations, commonly known as feedlots, especially prominent in North America, South America, and Australia. For these customers, the emphasis shifts slightly towards massive volume throughput, rugged reliability, and speed of delivery. Feedlots often require the largest capacity mixers (25 m³ and above) that can handle high volumes of densely packed feed ingredients quickly and efficiently throughout the day. Downtime is severely costly in these continuous operations, making robust build quality and easy maintenance critical purchasing factors.

A rapidly expanding customer segment includes custom feed operators and agricultural contracting services. These businesses offer specialized TMR preparation and delivery services to multiple small-to-medium-sized farms that cannot justify the capital expenditure of purchasing their own high-capacity mixer. This segment values machine versatility, rapid setup/mixing times, durability for constant road travel, and accurate tracking systems (often GPS or telematics) to manage billing and job performance across various client locations. The growth of this segment reflects the ongoing trend towards outsourcing specialized agricultural tasks to achieve economies of scale.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850.5 Million |

| Market Forecast in 2033 | USD 1,257.9 Million |

| Growth Rate | CAGR 5.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | KUHN, Trioliet, Supreme International, Penta TMR, Vicon (Kverneland Group), JF-STOLL, Faresin Industries, BVL V-Mix, Jaylor, Zago, RMH Lachish Industries, Seko Industries, Himel, Sgariboldi, Anderson Group, Alois Pöttinger Maschinenfabrik, Lucas G, Cosmo S.p.A., Siloking Mayer, Storti. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Trailed Feed Mixers Market Key Technology Landscape

The Trailed Feed Mixers market is undergoing a continuous technological evolution, shifting from purely mechanical machines to sophisticated data-generating instruments crucial for precision feeding. The most critical technological advancement lies in highly accurate Electronic Weighing Systems (EWS), which utilize multiple high-precision load cells strategically placed under the mixing container. These systems are essential for guaranteeing the accuracy of the Total Mixed Ration (TMR) by providing real-time weight feedback during loading and ensuring the precise dosage of high-value micro-ingredients. Modern EWS are often programmable, allowing operators to store dozens of specific recipes and track exactly how much feed is delivered to each pen or group, moving beyond simple mixing into comprehensive feed management.

Another pivotal area of innovation is the integration of connectivity and telematics. Many high-end mixers are now equipped with onboard computer systems that connect via cellular networks or Wi-Fi, transmitting operational data—such as mixing time, speed, load history, and error codes—directly to farm management software and manufacturer diagnostic platforms. This IoT integration facilitates real-time performance monitoring, optimizing feeding times, and enabling predictive maintenance by identifying usage patterns that indicate impending mechanical wear. Furthermore, advanced auger and knife technology is constantly being refined, focusing on improved cutting efficiency for long-stem forage while minimizing fiber damage, which can negatively affect rumen health and TMR quality. Specialized knife alloys and hydraulic systems designed for high-torque demands contribute significantly to machine longevity and feed consistency.

Future technological trends emphasize automation and enhanced data analysis. Features like automatic lubrications systems, automated discharge gate controls based on pre-programmed pen locations (utilizing GPS coordinates), and integration with sophisticated moisture and temperature sensors are becoming increasingly common. These sensors feed data back to the EWS, allowing for subtle adjustments to the ration density or liquid additive inclusion. Ultimately, the technology landscape is converging towards creating a fully digitized feeding process, where the trailed mixer operates not just as a piece of machinery, but as a crucial sensor and data collection point within the larger smart farming infrastructure, reducing dependency on operator skill and maximizing nutritional yield per animal.

Regional Highlights

The global market for Trailed Feed Mixers exhibits distinct regional adoption patterns influenced by farm structure, economic development, and existing levels of agricultural mechanization. North America, encompassing the US and Canada, represents a mature market characterized by extremely large commercial dairy and beef operations. The demand here is centered on high-capacity (over 20 m³), high-specification vertical mixers, often incorporating advanced telematics, GPS integration, and automated features to minimize labor requirements and ensure optimal TMR consistency across vast feedlots and large dairies. Regulatory environments promoting animal welfare and feed safety also encourage continuous investment in the latest precision mixing technology.

Europe stands as another major market, particularly in Western countries such as Germany, France, and the Netherlands. While farm sizes may be generally smaller than in North America, the concentration of high-yield dairy herds drives a strong demand for high-quality, efficient feed mixers. European purchasing decisions are heavily influenced by stringent quality regulations, high fuel and labor costs, and a focus on sustainability, leading to robust adoption of energy-efficient, multi-auger vertical mixers. Eastern European countries are rapidly catching up, experiencing a structural shift towards larger commercial farms, providing significant opportunities for medium-capacity mixer sales as mechanization increases.

The Asia Pacific (APAC) region is projected to be the fastest-growing market segment. This rapid growth is fueled by the commercialization and professionalization of dairy farming, moving away from small, traditional operations. Key contributors include China, India, and Australia. In India and China, increasing domestic consumption of dairy products drives investment in large-scale modern farms requiring efficient TMR preparation. While initial adoption favors medium-sized, cost-effective models, the overall trajectory points towards adopting modern vertical mixers to enhance productivity and meet rising quality standards. The Middle East and Africa (MEA) and Latin America (LATAM) also show promising growth, particularly in countries like Brazil, Argentina, and Saudi Arabia, where significant investments in intensive beef and dairy farming necessitate durable, high-capacity machinery capable of operating reliably in often challenging climates.

- North America (US, Canada): Focus on large-capacity vertical mixers, high technological integration (telematics), and labor efficiency. The US Midwest and California lead demand due to concentrated dairy and beef industries.

- Europe (Germany, France, UK): Emphasis on TMR precision, sustainability, and quality. Strong market for medium to high-capacity mixers complying with strict EU agricultural standards. Eastern Europe is a strong growth area due to farm consolidation.

- Asia Pacific (China, India, Australia): Highest growth rate driven by the modernization of the dairy sector, increasing herd sizes, and government support for high-efficiency agriculture. Demand spans small to medium vertical mixers.

- Latin America (Brazil, Argentina): Driven by massive beef feedlot operations. High demand for large-capacity, robust, and durable mixers capable of intense, continuous operation in large agricultural areas.

- Middle East & Africa (MEA): Growth fueled by large, specialized farming projects (often government-backed) aimed at improving food security, demanding reliable imported high-technology feed preparation equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Trailed Feed Mixers Market.- KUHN Group

- Trioliet B.V.

- Supreme International Limited

- Penta TMR

- Vicon (Kverneland Group)

- JF-STOLL

- Faresin Industries S.p.A.

- BVL V-Mix

- Jaylor Fabricating Inc.

- Zago S.p.A.

- RMH Lachish Industries

- Seko Industries

- Himel Maschinentechnik GmbH

- Sgariboldi S.p.A.

- Anderson Group

- Alois Pöttinger Maschinenfabrik GmbH

- Lucas G

- Cosmo S.p.A.

- Siloking Mayer

- Storti SpA

Frequently Asked Questions

Analyze common user questions about the Trailed Feed Mixers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of using a Vertical Trailed Feed Mixer over a Horizontal mixer?

Vertical mixers are favored for their ability to efficiently process large, round, or square bales of hay and silage without extensive pre-processing, resulting in superior TMR homogeneity and flexibility in handling diverse forage materials, making them highly versatile for modern dairy operations.

How does the integration of IoT technology benefit farm profitability?

IoT integration allows for real-time monitoring of mixing cycles, load accuracy, and machine diagnostics. This data ensures highly accurate ration delivery, minimizes feed wastage, optimizes machine uptime through predictive maintenance, and provides verifiable records for feed consistency, directly boosting feed conversion ratio and profitability.

What is the expected average lifespan of a modern Trailed Feed Mixer?

With proper maintenance, a high-quality Trailed Feed Mixer typically has an operational lifespan exceeding 10 to 15 years. Lifespan depends heavily on the robustness of the steel construction, the frequency of use, and the timely replacement of wear parts, especially auger knives and flighting.

What are the key purchasing factors for farmers choosing mixer capacity?

Mixer capacity selection is primarily dictated by the size of the herd (number of animals fed per day), the required number of daily mixes, and the specific density of the ration being prepared. Commercial dairy operations commonly select medium-capacity (15-25 m³) mixers to balance efficiency and operational cost.

How do TMR mixers contribute to improved animal health and productivity?

TMR mixers ensure that all feed ingredients are blended uniformly, preventing selective feeding (sorting) by livestock. This consistency guarantees that every animal receives a balanced, calculated diet, leading to stable rumen health, maximized nutrient absorption, and predictable increases in milk or meat production.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager