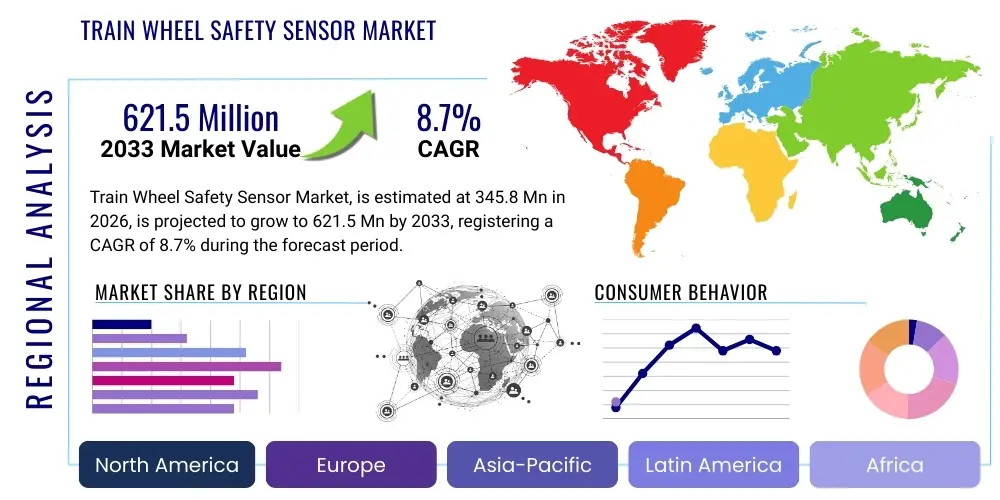

Train Wheel Safety Sensor Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440627 | Date : Jan, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Train Wheel Safety Sensor Market Size

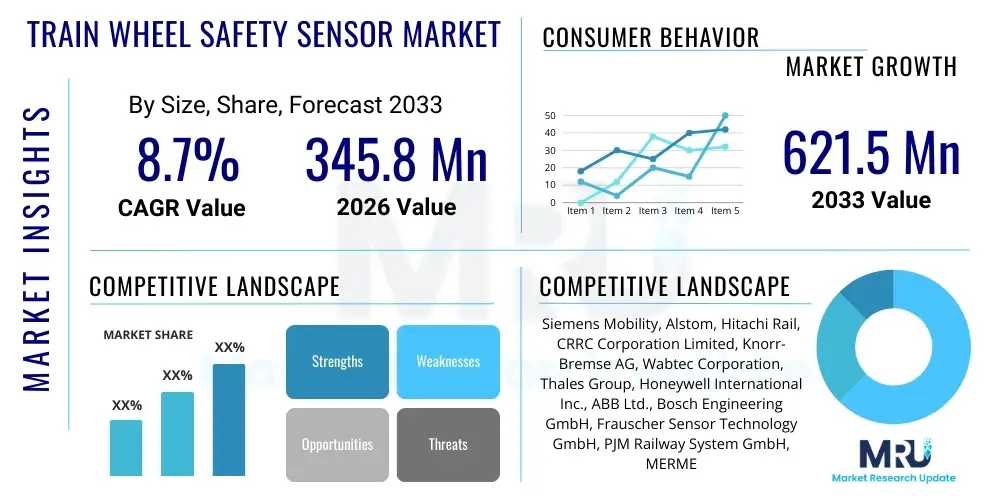

The Train Wheel Safety Sensor Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.7% between 2026 and 2033. The market is estimated at USD 345.8 Million in 2026 and is projected to reach USD 621.5 Million by the end of the forecast period in 2033.

Train Wheel Safety Sensor Market introduction

The Train Wheel Safety Sensor Market encompasses a range of advanced technologies designed to monitor the condition, integrity, and operational parameters of train wheels and axles, ensuring safe and efficient railway operations. These critical devices detect anomalies such as cracks, flat spots, overheating, and excessive wear, which can lead to catastrophic failures if left unaddressed. The primary products include optical, acoustic, electromagnetic, and vibration sensors, each leveraging distinct physical principles to provide real-time data on wheel health. Major applications span high-speed passenger trains, freight locomotives, commuter rail systems, and light rail networks, where they are vital for preventive maintenance and incident prevention. The benefits of these sensors are profound, extending from enhanced passenger and cargo safety to significant reductions in maintenance costs, improved operational efficiency, and minimized service disruptions. Key driving factors propelling market growth include the escalating demand for railway transportation, increasingly stringent safety regulations imposed by global rail authorities, the imperative for predictive maintenance strategies to extend asset lifespan, and continuous technological advancements integrating IoT and AI capabilities into sensing solutions.

Train Wheel Safety Sensor Market Executive Summary

The Train Wheel Safety Sensor Market is experiencing robust growth driven by global investments in modernizing railway infrastructure and an intensified focus on operational safety and efficiency. Business trends indicate a strong shift towards integrated smart railway systems, where sensor data feeds into larger predictive analytics platforms, moving beyond simple fault detection to condition-based monitoring. Partnerships between sensor manufacturers, railway operators, and system integrators are becoming more prevalent to develop comprehensive safety solutions. Regional trends highlight significant market expansion in Asia Pacific, particularly China and India, due to massive rail network development and upgrades, while Europe and North America continue to lead in technological adoption and stringent regulatory compliance. Latin America and the Middle East & Africa are emerging as high-growth potential regions as they expand and modernize their respective rail transport capacities. Segment trends reveal increasing adoption of advanced sensor types, such as optical and acoustic sensors, known for their high precision and ability to detect subtle defects, along with a growing emphasis on aftermarket services for existing rolling stock. The integration of wireless communication and edge computing in sensor networks is also a notable trend, facilitating easier deployment and real-time data transmission.

AI Impact Analysis on Train Wheel Safety Sensor Market

Common user questions regarding AI's impact on the Train Wheel Safety Sensor Market often revolve around how AI can enhance sensor accuracy, predict failures more reliably, reduce false positives, and streamline maintenance processes. Users are keen to understand the role of machine learning in interpreting complex sensor data patterns, identifying subtle anomalies that human inspection might miss, and improving the overall efficiency of rail safety systems. Concerns typically include the initial investment costs, the complexity of AI model deployment and training, data privacy, and the need for robust cybersecurity measures to protect sensitive operational data. Expectations are high for AI to transform reactive maintenance into truly predictive maintenance, optimize resource allocation, and ultimately contribute to a safer, more autonomous future for rail transport.

- AI enhances data analytics, enabling real-time anomaly detection and classification from sensor inputs.

- Machine learning algorithms improve predictive maintenance by forecasting component failures with higher accuracy.

- AI integration reduces false positive alerts, leading to more targeted and efficient maintenance interventions.

- Automated decision-making capabilities can optimize operational parameters based on real-time wheel health data.

- Deep learning models facilitate the identification of complex wear patterns and emerging defects, improving safety.

- AI-driven insights support strategic asset management, extending the lifespan of wheels and rolling stock.

- Natural language processing (NLP) can aid in interpreting maintenance logs and operational reports for better context.

- Edge AI deployment allows for faster data processing and localized decision-making, reducing latency.

- AI assists in the development of self-calibrating and self-diagnosing sensor systems, minimizing manual checks.

- Provides a foundation for autonomous train operation by ensuring continuous, intelligent monitoring of critical components.

DRO & Impact Forces Of Train Wheel Safety Sensor Market

The Train Wheel Safety Sensor Market is significantly influenced by a confluence of driving factors, restrictive challenges, and promising opportunities, all shaped by broader impact forces. Key drivers include the ever-increasing demand for railway safety and operational efficiency, strict government regulations mandating advanced monitoring systems, the global expansion and modernization of railway networks, and the economic benefits derived from predictive maintenance strategies. These forces collectively push railway operators towards adopting sophisticated sensor technologies. However, the market faces restraints such such as the high initial investment costs associated with deploying and integrating these advanced systems, the technical complexities involved in retrofitting existing infrastructure, data security and privacy concerns related to extensive sensor networks, and a persistent challenge in achieving universal standardization across diverse global railway systems. Despite these hurdles, substantial opportunities lie in emerging markets with rapidly developing rail infrastructure, the lucrative aftermarket for upgrading and servicing older rolling stock, and the continuous integration of sensors with advanced analytics, IoT, and artificial intelligence platforms, paving the way for more autonomous and intelligent rail transport solutions. These dynamics are further amplified by impact forces like technological innovation, regulatory evolution, environmental sustainability mandates, and global economic growth which collectively dictate the market's trajectory and potential.

Segmentation Analysis

The Train Wheel Safety Sensor Market is comprehensively segmented to provide a granular understanding of its diverse components and growth dynamics. These segmentations allow for a detailed analysis of market trends, technological preferences, application-specific demands, and end-user adoption patterns, offering crucial insights for stakeholders. The market can be broadly categorized by sensor type, application, end-user, and technology, each reflecting distinct characteristics and market drivers. Understanding these segments is pivotal for strategic planning, product development, and identifying niche opportunities within the broader railway safety ecosystem.

- By Sensor Type

- Optical Sensors

- Acoustic Sensors

- Electromagnetic Sensors

- Vibration Sensors

- Thermal Sensors

- Strain Gauge Sensors

- By Application

- High-Speed Passenger Trains

- Freight Trains

- Commuter Trains

- Trams/Light Rail

- Metro Systems

- By End-User

- Original Equipment Manufacturers (OEMs)

- Aftermarket (Railway Operators, Maintenance Companies, Repair & Overhaul)

- By Technology

- Internet of Things (IoT) Integrated Sensors

- Artificial Intelligence (AI) and Machine Learning (ML) Enhanced Sensors

- Wireless Sensor Networks

- Wired Sensor Networks

- Cloud-Connected Systems

Value Chain Analysis For Train Wheel Safety Sensor Market

The value chain for the Train Wheel Safety Sensor Market begins with upstream activities involving the sourcing of raw materials and the manufacturing of specialized electronic components, sensor elements, and integrated circuits. This stage relies heavily on a sophisticated network of material suppliers and component manufacturers, often operating within highly specialized technological niches. Key inputs include advanced semiconductor materials, specialized metals, optical fibers, and precise electronic parts that form the core of sensor functionality. The quality and reliability of these upstream components directly impact the performance and longevity of the final safety sensor products.

Moving further along the value chain, the core manufacturing and assembly processes transform these components into complete sensor units, which are then integrated into larger monitoring systems by specialized engineering firms. These firms often provide customized solutions tailored to specific railway infrastructure requirements. The distribution channel for these products typically involves a mix of direct sales to large railway operators and Original Equipment Manufacturers (OEMs) for new rolling stock, alongside indirect channels that utilize system integrators and specialized railway equipment distributors for aftermarket installations and upgrades. Aftermarket sales are crucial, covering replacement parts, maintenance services, and technology upgrades for existing fleets, often facilitated by regional distributors or direct service teams.

Downstream analysis focuses on the end-users—primarily railway operators, freight companies, and metropolitan transport authorities—who deploy, operate, and maintain these safety sensor systems. This stage also includes the crucial aspects of installation, calibration, data interpretation, and ongoing maintenance services, often provided by the sensor manufacturers themselves or by third-party specialized service providers. The feedback loop from these end-users is vital for continuous product improvement, influencing future research and development initiatives to address evolving safety standards and operational challenges in the demanding railway environment. The effectiveness of the overall value chain is contingent upon seamless collaboration and information flow between all participating entities, ensuring high-performance safety solutions reach their intended applications efficiently.

Train Wheel Safety Sensor Market Potential Customers

The potential customers for Train Wheel Safety Sensors primarily comprise entities involved in the operation, manufacturing, and maintenance of railway infrastructure and rolling stock. These end-users are driven by the critical need to ensure passenger and cargo safety, enhance operational efficiency, minimize downtime, and comply with rigorous national and international safety regulations. The diverse range of customers includes large-scale national railway companies responsible for extensive networks, private freight operators managing vast fleets of cargo trains, and metropolitan transport authorities overseeing commuter rail and light rail systems.

Original Equipment Manufacturers (OEMs) of rolling stock, such as train builders and locomotive manufacturers, represent a significant customer segment. They integrate these safety sensors directly into new trains and carriages as part of the initial design and construction, ensuring that new fleets meet the highest safety standards from inception. For these OEMs, the reliability, integration capabilities, and advanced features of the sensors are paramount, often influencing their choice of suppliers to maintain their reputation for producing safe and technologically advanced railway vehicles.

Another crucial customer segment exists within the aftermarket, encompassing maintenance, repair, and overhaul (MRO) companies, as well as the maintenance departments of railway operators themselves. These entities are responsible for the ongoing upkeep, inspection, and modernization of existing trains and infrastructure. They purchase train wheel safety sensors for retrofitting older rolling stock, replacing worn-out components, and upgrading their monitoring capabilities to extend the operational life of their assets while enhancing safety. Their purchasing decisions are often influenced by sensor durability, ease of installation, compatibility with existing systems, and the total cost of ownership over the operational lifecycle.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 345.8 Million |

| Market Forecast in 2033 | USD 621.5 Million |

| Growth Rate | 8.7% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Siemens Mobility, Alstom, Hitachi Rail, CRRC Corporation Limited, Knorr-Bremse AG, Wabtec Corporation, Thales Group, Honeywell International Inc., ABB Ltd., Bosch Engineering GmbH, Frauscher Sensor Technology GmbH, PJM Railway System GmbH, MERMEC S.p.A., Fersys GmbH, Dürr AG, Sensata Technologies, TE Connectivity, Analog Devices, Inc., Phoenix Contact GmbH & Co. KG, Railhead Corp. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Train Wheel Safety Sensor Market Key Technology Landscape

The Train Wheel Safety Sensor market is characterized by a rapidly evolving technological landscape, continuously driven by the demand for higher accuracy, reliability, and real-time data processing capabilities. At the forefront are advancements in sensor miniaturization and power efficiency, enabling the development of compact yet robust devices capable of operating in the harsh railway environment. Optical sensors, utilizing laser-based systems and high-resolution cameras, are gaining traction for non-contact measurement of wheel profiles and surface defects, offering unparalleled precision. Acoustic sensors, employing ultrasonic or infrasonic technologies, detect internal defects and cracks through sound wave analysis, providing early warnings before visible signs of wear appear.

Furthermore, electromagnetic sensors, including eddy current and magnetic flux leakage methods, are crucial for detecting subsurface flaws and material inconsistencies in wheels and axles. Vibration sensors, often accelerometer-based, monitor dynamic wheel performance, identifying imbalances, flat spots, and bearing issues through analysis of vibration signatures. Thermal sensors, leveraging infrared technology, are indispensable for detecting overheating in wheels, brakes, and bearings, a common precursor to derailments. The integration of these diverse sensor types into multi-modal systems is a key trend, allowing for a more comprehensive and redundant approach to wheel safety monitoring.

Beyond the core sensing mechanisms, the technological landscape is increasingly defined by connectivity and intelligent data processing. The proliferation of Internet of Things (IoT) platforms allows sensors to be interconnected, wirelessly transmitting data to centralized or cloud-based analytics systems. Artificial intelligence (AI) and machine learning (ML) algorithms are vital for processing the massive datasets generated by these sensors, enabling predictive maintenance, anomaly detection with reduced false positives, and self-learning capabilities that improve accuracy over time. Edge computing is also emerging as a significant technology, facilitating real-time data analysis directly at the sensor level, thereby reducing latency and bandwidth requirements for critical safety alerts.

Regional Highlights

- North America: This region demonstrates strong market growth, driven by significant investments in upgrading aging rail infrastructure, a stringent regulatory framework focused on safety, and the adoption of advanced sensor technologies for freight and passenger rail. The United States and Canada are key contributors, emphasizing predictive maintenance and smart railway initiatives.

- Europe: A mature market with high adoption rates, primarily propelled by extensive high-speed rail networks, ambitious decarbonization goals for transport, and a strong emphasis on interoperability and safety standards set by the European Union. Germany, France, and the UK are leading countries in both sensor deployment and technological innovation.

- Asia Pacific (APAC): Expected to be the fastest-growing region, fueled by massive railway infrastructure development projects in China, India, and Southeast Asian countries. Rapid urbanization, increasing passenger and freight traffic, and government initiatives to expand and modernize rail networks are key drivers, alongside a growing focus on safety and efficiency.

- Latin America: An emerging market showing steady growth, attributed to increasing investments in expanding and modernizing existing railway systems, particularly in countries like Brazil, Mexico, and Argentina. The demand for reliable and cost-effective safety solutions is rising with economic development and trade expansion.

- Middle East and Africa (MEA): This region presents significant growth opportunities, driven by large-scale infrastructure projects, including new high-speed rail lines and metro systems, particularly in the GCC countries. The push for economic diversification and enhanced connectivity is accelerating the adoption of advanced rail safety technologies.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Train Wheel Safety Sensor Market.- Siemens Mobility

- Alstom

- Hitachi Rail

- CRRC Corporation Limited

- Knorr-Bremse AG

- Wabtec Corporation

- Thales Group

- Honeywell International Inc.

- ABB Ltd.

- Bosch Engineering GmbH

- Frauscher Sensor Technology GmbH

- PJM Railway System GmbH

- MERMEC S.p.A.

- Fersys GmbH

- Dürr AG

- Sensata Technologies

- TE Connectivity

- Analog Devices, Inc.

- Phoenix Contact GmbH & Co. KG

- Railhead Corp.

Frequently Asked Questions

Analyze common user questions about the Train Wheel Safety Sensor market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a train wheel safety sensor and why is it important?

A train wheel safety sensor is a device designed to monitor the condition and performance of train wheels and axles in real-time, detecting defects like cracks, flat spots, or overheating. It is crucial for preventing derailments, ensuring passenger and freight safety, reducing maintenance costs, and improving railway operational efficiency.

What types of technologies are commonly used in train wheel safety sensors?

Common technologies include optical sensors (laser-based), acoustic sensors (ultrasonic), electromagnetic sensors (eddy current, magnetic flux), vibration sensors (accelerometers), and thermal sensors (infrared). Modern systems often integrate these with IoT, AI/ML for advanced data analysis and predictive capabilities.

How does AI impact the train wheel safety sensor market?

AI significantly enhances sensor data analysis, enabling more accurate and proactive detection of defects, reducing false positives, and facilitating predictive maintenance. AI algorithms can identify subtle patterns indicative of impending failures, optimize maintenance schedules, and improve the overall intelligence of railway safety systems.

What are the primary drivers and restraints for this market's growth?

Key drivers include increasing rail traffic, stringent safety regulations, the demand for predictive maintenance, and technological advancements. Restraints include high initial investment costs, complex integration challenges, and the need for standardization across diverse railway networks.

Who are the main end-users or potential customers for train wheel safety sensors?

The primary end-users are railway operators (for passenger and freight trains), metropolitan transport authorities, and Original Equipment Manufacturers (OEMs) of rolling stock. The aftermarket, including maintenance and repair organizations, also forms a significant customer segment for retrofitting and upgrades.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager