Transfer Cabinets Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431408 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Transfer Cabinets Market Size

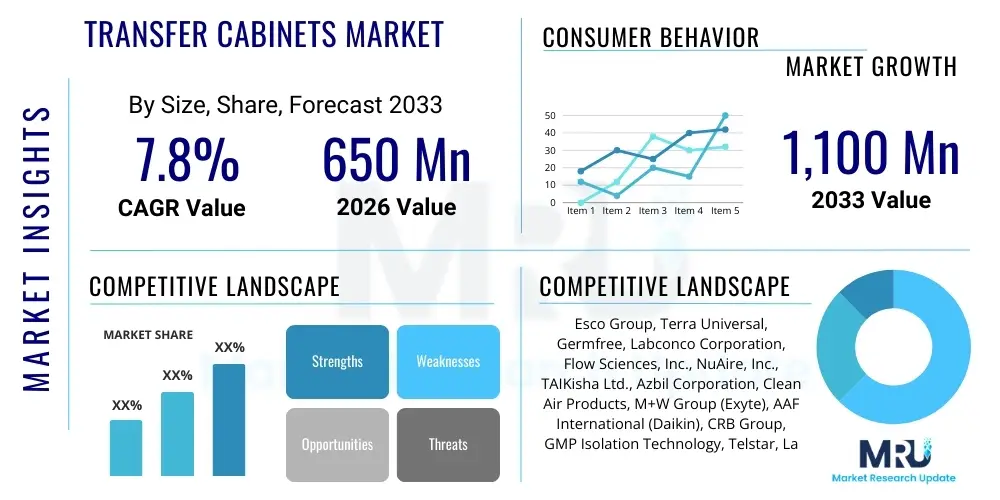

The Transfer Cabinets Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 650 Million in 2026 and is projected to reach USD 1,100 Million by the end of the forecast period in 2033.

Transfer Cabinets Market introduction

The Transfer Cabinets Market encompasses specialized equipment designed for the safe and contamination-controlled transfer of materials into and out of controlled environments, such as cleanrooms, isolation wards, and biological safety laboratories. These systems, often referred to as pass-through boxes or transfer chambers, are essential for maintaining the integrity of classified spaces by preventing the ingress or egress of particulate matter and microorganisms. The fundamental principle governing their operation involves using interlocking doors, often combined with high-efficiency particulate air (HEPA) filtration systems, to ensure that only decontaminated items or materials are moved between zones of differing cleanliness classifications. Market growth is inherently tied to the rigorous expansion of highly regulated industries, particularly pharmaceuticals, biotechnology, and semiconductor manufacturing, all of which prioritize strict environmental control to guarantee product quality and safety.

Transfer cabinets are categorized based on their functional capabilities, including static (non-powered), dynamic (powered with airflow filtration), and integrated decontamination systems (like vaporized hydrogen peroxide – VHP). Dynamic cabinets are increasingly adopted due to their ability to actively purge particles and introduce sterile air into the transfer zone, thereby providing a superior level of protection against cross-contamination, which is paramount in aseptic processing. The driving factors for market expansion include escalating global health concerns demanding sterile manufacturing processes, stringent regulatory frameworks enforced by bodies such as the FDA and EMA requiring documented proof of contamination control, and the massive investment surge in advanced pharmaceutical research and development, particularly in gene therapy and personalized medicine where product sterility is non-negotiable. The reliability and compliance offered by these sophisticated transfer systems make them indispensable infrastructure within modern controlled environments.

Transfer Cabinets Market Executive Summary

The Transfer Cabinets Market is witnessing robust growth, primarily fueled by significant capital investments in pharmaceutical manufacturing facilities and the global push for enhanced biosecurity standards in research laboratories. Key business trends indicate a shift towards incorporating automated and smart transfer solutions, integrating features such as IoT connectivity for remote monitoring, advanced sensor technology to verify decontamination cycles, and automated material handling systems to minimize human intervention and potential errors. This focus on automation addresses increasing labor costs and the demand for higher throughput while maintaining stringent cleanroom protocols. Furthermore, companies are prioritizing modular and customizable cabinet designs that can be seamlessly integrated into existing cleanroom walls and tailored to specific operational workflows, catering to both large-scale production environments and smaller, specialized compounding pharmacies.

Regionally, Asia Pacific (APAC) is emerging as the fastest-growing market, driven by massive governmental and private investments in healthcare infrastructure, the establishment of large-scale vaccine manufacturing hubs in countries like India and China, and the rapid expansion of the electronics and semiconductor industry requiring ultra-clean environments. North America and Europe remain foundational markets, characterized by high adoption rates of advanced, dynamic transfer cabinets, underpinned by mature regulatory environments and the presence of major biopharmaceutical companies demanding best-in-class aseptic transfer solutions. Segment trends highlight the dominance of dynamic cabinets due to their active contamination control capabilities, and the increasing utilization of VHP-enabled transfer systems, especially in high-containment laboratories dealing with sensitive biological materials, reflecting a market preference for validated and highly effective decontamination technologies.

AI Impact Analysis on Transfer Cabinets Market

Common user questions regarding AI's impact on the Transfer Cabinets Market often revolve around operational efficiency, predictive maintenance, and validation processes. Users inquire whether AI can optimize transfer cycle times, reduce energy consumption in dynamic units, and provide proactive alerts about potential HEPA filter failures or interlocking mechanism malfunctions. There is significant interest in how machine learning algorithms could analyze vast amounts of cycle data (e.g., pressure differentials, decontamination residue levels) to ensure continuous cGMP compliance and simplify the onerous task of regulatory validation. Users expect AI integration to transition transfer cabinets from simple mechanical barriers to smart, self-diagnosing, and efficiency-optimizing components of the overall cleanroom ecosystem, ultimately leading to higher uptime and reduced risk of contamination incidents due to equipment failure or suboptimal operational settings.

- AI optimizes transfer cycle scheduling based on real-time cleanroom status and operational demand, minimizing energy usage.

- Predictive maintenance algorithms analyze sensor data (airflow, pressure, vibration) to forecast potential mechanical failures in blowers or interlocking mechanisms, increasing equipment reliability.

- Machine learning enhances decontamination cycle validation by rapidly analyzing VHP dispersion patterns and residue clearance data, ensuring compliance faster than manual analysis.

- AI-driven anomaly detection flags unauthorized or suboptimal transfer attempts, providing an immediate contamination risk alert to cleanroom operators.

- Integration with overall Cleanroom Management Systems (CMS) allows AI to coordinate cabinet operations with surrounding air handling units (AHUs) for maximized environmental stability.

DRO & Impact Forces Of Transfer Cabinets Market

The market is primarily driven by the escalating demand for advanced aseptic processing techniques in the pharmaceutical and biotechnology sectors, necessitating validated barrier technologies to prevent cross-contamination, particularly for high-value biological products and cell therapies. Restraints include the high initial capital investment required for sophisticated dynamic and VHP-enabled transfer cabinets, coupled with ongoing costs associated with filter replacement and regulatory validation documentation. Opportunities abound in developing markets where new cleanroom construction is accelerating, and through the implementation of IoT and AI integration to enhance operational efficiency, remote diagnostics, and predictive maintenance capabilities. The overall impact forces are high, largely governed by stringent global regulatory standards (FDA, EMA) that dictate the necessity and design parameters of these critical transfer devices, making compliance the ultimate non-negotiable factor influencing procurement decisions across all major end-use sectors.

Segmentation Analysis

The Transfer Cabinets Market is comprehensively segmented based on Type, Operation, End-User, and Mechanism, providing granular insights into varying demand patterns across industries. The segmentation by Type, specifically distinguishing between static and dynamic units, reflects the ongoing technological shift towards powered systems that offer active air filtration and decontamination capabilities, crucial for achieving ISO Class 5 and better environments. Segmentation by End-User is critical, as the requirements of a pharmaceutical aseptic filling line differ significantly from those of a microelectronics fabrication facility, especially concerning material compatibility and required particulate cleanliness levels. Analyzing these segments helps manufacturers tailor product specifications, ranging from standard stainless steel pharmaceutical models to specialized polyolefin cabinets designed for chemical resistance in certain industrial applications.

Further segmentation based on Operation (Automated vs. Manual) highlights the increasing preference for fully automated systems in high-throughput manufacturing environments, where minimizing human interaction is paramount for both contamination control and operational speed. The geographical segmentation remains vital, illustrating how regional regulatory stringency and the maturity of the life sciences industry influence the adoption of premium versus standard cabinet models. Understanding these nuanced segments is key for strategic market penetration, allowing stakeholders to focus resources on areas demonstrating the highest growth potential, such as the adoption of integrated VHP systems across all major pharmaceutical manufacturing regions, particularly in vaccine production and compounding pharmacy operations globally.

- Type: Static Transfer Cabinets, Dynamic Transfer Cabinets, Integrated Decontamination Transfer Cabinets (VHP, UV-C).

- Operation: Automated Transfer Cabinets, Manual Transfer Cabinets.

- End-User: Pharmaceutical & Biotechnology, Healthcare & Hospitals, Semiconductor & Electronics, Academia & Research Laboratories, Food & Beverage.

- Mechanism: Two-Door Interlock Systems, Air Shower Transfer Systems, Clean Bench Transfer Systems.

Value Chain Analysis For Transfer Cabinets Market

The value chain for the Transfer Cabinets Market begins with the Upstream Analysis, which involves the sourcing of critical raw materials, primarily high-grade stainless steel (304 or 316L) for cabinet construction, specialized HEPA/ULPA filters, high-reliability components such as blowers, interlocking mechanisms, and electronic control systems. Key strategic activities at this stage focus on securing certified, traceable materials that meet industry standards for cleanability and chemical resistance. Manufacturers often integrate backwards or establish long-term contracts with specialized filter media suppliers to ensure a consistent supply of components that comply with EN 1822 or IEST standards, which is vital for maintaining product quality and validation credibility in the highly regulated end-use sectors.

The Midstream component involves the manufacturing and assembly process, including precision fabrication, welding, sealing (critical for air tightness), and the installation and rigorous testing of filtration and control systems. This stage requires high technical expertise and dedicated clean production environments to ensure the final product integrity. Downstream analysis focuses on Distribution Channel management, encompassing direct sales teams that handle large, customized cleanroom projects, and specialized distributors or agents who manage sales to smaller research labs or hospitals. Direct channels allow for detailed technical consultation and seamless integration into large facility designs, whereas indirect channels leverage existing relationships within regional research and clinical networks. Post-sale services, including installation qualification (IQ), operational qualification (OQ), performance qualification (PQ), and ongoing calibration and filter replacement services, constitute a significant portion of the downstream value proposition and customer retention strategy.

Transfer Cabinets Market Potential Customers

Potential customers for Transfer Cabinets are predominantly organizations operating regulated controlled environments where cross-contamination must be strictly mitigated, and product sterility or environmental cleanliness is mandated by global regulations. The primary end-user/buyer segment is the Pharmaceutical and Biotechnology industry, encompassing major drug manufacturers, contract manufacturing organizations (CMOs), and specialized compounding pharmacies that utilize aseptic processing lines for injectables, sterile APIs, and highly potent active ingredients (HPAPIs). These customers require high-end, dynamic cabinets with integrated decontamination capabilities to ensure compliance with current Good Manufacturing Practices (cGMP) and maintain ISO 5 or better conditions during material ingress.

The second substantial customer base lies within the Healthcare and Hospital sector, specifically hospital pharmacies preparing sterile intravenous (IV) solutions, oncology drugs, and critical patient-specific formulations, as well as isolation units requiring controlled transfer to prevent the spread of infectious agents. Furthermore, the semiconductor and electronics industry represents a growing demand segment, though their requirements focus less on biological sterility and more on minimizing particulate contamination (nanoparticles) in processes sensitive to environmental dust. Finally, academic and commercial research laboratories, especially those working with Biosafety Level (BSL) 2 and BSL 3 agents, are consistent buyers, prioritizing transfer cabinets that facilitate safe handling and disposal while strictly maintaining containment integrity, relying heavily on validated, interlocked systems.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 650 Million |

| Market Forecast in 2033 | USD 1,100 Million |

| Growth Rate | CAGR 7.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Esco Group, Terra Universal, Germfree, Labconco Corporation, Flow Sciences, Inc., NuAire, Inc., TAIKisha Ltd., Azbil Corporation, Clean Air Products, M+W Group (Exyte), AAF International (Daikin), CRB Group, GMP Isolation Technology, Telstar, Laminar Flow, CBE Group, Clean Rooms International, Inc., Aseptic Technology, G-Con Manufacturing, Inc., Airfiltronix. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Transfer Cabinets Market Key Technology Landscape

The technological landscape of the Transfer Cabinets Market is dominated by advancements in high-efficiency filtration, automation, and integrated decontamination technologies designed to enhance product safety and operational compliance. Core technology centers on the use of HEPA (High-Efficiency Particulate Air) and ULPA (Ultra-Low Penetration Air) filters, which are fundamental to dynamic pass-throughs, ensuring unidirectional, laminar airflow that rapidly purges the transfer chamber of airborne particulates down to 0.3 microns (HEPA) or 0.12 microns (ULPA). Recent innovations focus on developing filters with extended lifespan and specialized filter integrity testing capabilities (e.g., DOP or PAO testing ports integrated into the cabinet structure) to facilitate easier and faster regulatory compliance checks without compromising cleanroom conditions.

A significant shift involves the sophisticated integration of Vaporized Hydrogen Peroxide (VHP) decontamination systems, which offer a validated, sporicidal process to achieve a six-log reduction in bioburden within the cabinet prior to transfer. VHP systems require complex engineering to ensure effective vapor dispersion, material compatibility, and rapid aeration cycles, minimizing downtime. Furthermore, the incorporation of advanced monitoring and control systems, utilizing PLC (Programmable Logic Controller) or microprocessor controls, enables precise control over door interlocking, pressure differential maintenance, and cycle sequencing. This technological refinement allows for seamless integration into supervisory control and data acquisition (SCADA) systems used across the cleanroom facility, providing comprehensive audit trails essential for meeting strict global pharmaceutical guidelines.

Regional Highlights

- North America: North America remains a mature and dominant market segment, driven by robust pharmaceutical R&D, substantial investment in biotechnology startups, and the presence of stringent regulatory bodies like the FDA, which mandates high standards for aseptic processing. Demand is concentrated on high-end, dynamic cabinets and VHP decontamination systems, primarily in the U.S. and Canada, supporting advanced manufacturing facilities focused on biologics and highly potent drugs. The region leads in adopting integrated automation and predictive maintenance technologies within cleanroom infrastructure.

- Europe: Europe holds a strong position, characterized by significant healthcare expenditure, high standards set by the European Medicines Agency (EMA), and a large base of established pharmaceutical and medical device manufacturers. Key growth areas include the expansion of compounding pharmacies in Germany and the UK, and robust investments in advanced ATMP (Advanced Therapy Medicinal Products) manufacturing sites across Ireland, Switzerland, and Benelux countries, fueling demand for specialized, customizable transfer solutions.

- Asia Pacific (APAC): APAC is projected to exhibit the highest growth rate due to rapidly industrializing economies, government initiatives promoting domestic pharmaceutical manufacturing (e.g., "Make in India"), and massive construction of new cleanroom facilities for electronics and semiconductor production in China, South Korea, and Taiwan. The increasing need for affordable healthcare and growing adoption of Western regulatory standards are accelerating the uptake of both static and cost-effective dynamic transfer cabinets across the region.

- Latin America (LATAM): Growth in LATAM is steady, primarily concentrated in Brazil and Mexico, driven by foreign investment in manufacturing facilities and the local pharmaceutical industry's efforts to modernize and meet international quality benchmarks. The market typically favors economically viable standard dynamic models, with emerging demand for localized service and maintenance support being a key purchasing criterion.

- Middle East and Africa (MEA): This region is an emerging market, driven by substantial government investments in healthcare infrastructure and efforts to establish localized pharmaceutical production capabilities, particularly in the UAE, Saudi Arabia, and South Africa. While adoption is currently lower than other regions, future growth potential is high, supported by large-scale projects aiming for self-sufficiency in medical supplies and vaccines, demanding reliable, certified transfer systems.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Transfer Cabinets Market.- Esco Group

- Terra Universal

- Germfree

- Labconco Corporation

- Flow Sciences, Inc.

- NuAire, Inc.

- TAIKisha Ltd.

- Azbil Corporation

- Clean Air Products

- M+W Group (Exyte)

- AAF International (Daikin)

- CRB Group

- GMP Isolation Technology

- Telstar

- Laminar Flow

- CBE Group

- Clean Rooms International, Inc.

- Aseptic Technology

- G-Con Manufacturing, Inc.

- Airfiltronix

- Block Scientific

- Bioquell (Ecolab)

- Steris Corporation

- Kewaunee Scientific Corporation

- The Baker Company

Frequently Asked Questions

Analyze common user questions about the Transfer Cabinets market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a dynamic transfer cabinet compared to a static unit?

A dynamic transfer cabinet is powered and includes integrated HEPA or ULPA filtration, providing active, unidirectional airflow to purge particulate contaminants and maintain an ISO classified environment within the chamber during transfer. Static units, conversely, rely solely on passive barrier containment and are typically used between zones of the same or very close cleanliness classifications.

Which regulatory standards govern the use and design of transfer cabinets in pharmaceutical manufacturing?

Transfer cabinets used in pharmaceutical aseptic processing must comply rigorously with Current Good Manufacturing Practices (cGMP), specifically guidelines established by the FDA (21 CFR Part 211) and the European Medicines Agency (EMA). These standards require detailed validation protocols (IQ, OQ, PQ) to ensure the system consistently prevents contamination and maintains specified cleanroom pressure differentials.

How does Vaporized Hydrogen Peroxide (VHP) technology impact the transfer cabinet market?

VHP technology allows the transfer cabinet to function as a validated decontamination chamber, providing a sporicidal bio-decontamination cycle (6-log reduction) for materials moving into highly critical aseptic core areas. This integration reduces reliance on liquid disinfectants and significantly enhances regulatory compliance, driving demand for specialized, VHP-compatible dynamic units.

What are the primary factors driving the high adoption rate of transfer cabinets in the Asia Pacific region?

The high adoption rate in APAC is driven by rapid industrialization, large-scale investment in domestic vaccine and biotechnology manufacturing centers (particularly in China and India), and the increasing adoption of international cleanroom standards in the burgeoning electronics and semiconductor industries, all necessitating reliable contamination control solutions.

What are the main constraints hindering substantial market growth globally?

The primary constraints include the significant initial capital expenditure required for automated, high-specification dynamic and VHP transfer cabinets, particularly for smaller facilities or compounding pharmacies. Furthermore, the complexities and recurrent costs associated with regular filter replacement, certification, and required regulatory validation cycles also restrain market access for some smaller or emerging organizations.

The preceding sections constitute a comprehensive analysis of the Transfer Cabinets Market, detailing its size, growth trajectory, technological drivers, regulatory environment, and strategic regional dynamics. The market's future remains inextricably linked to the continued stringent enforcement of aseptic processing standards across critical sectors globally. The integration of advanced monitoring and automation technologies will further solidify the transfer cabinet's role as a mission-critical component in maintaining cleanroom integrity and product safety, particularly as complex biopharmaceuticals and high-potency drugs become more prevalent in global manufacturing pipelines. Manufacturers must focus on enhancing validation ease, energy efficiency, and modularity to meet the evolving demands of advanced cleanroom environments.

Detailed analysis confirms that the pharmaceutical sector remains the bedrock of demand, necessitating highly validated, often VHP-integrated systems. However, diversification into specialized applications, such as nanotechnology and advanced materials research, is opening new avenues for customized transfer solutions. The trend toward digitalization, spurred by AI and IoT integration, promises to transform maintenance protocols from reactive to predictive, ensuring higher uptime and reduced operational risk. Companies strategically positioned to offer compliant, smart, and fully validated solutions are expected to capture the highest market share in the forecast period. Furthermore, sustainability considerations, including reduced energy consumption and recyclable components, are beginning to influence procurement decisions, reflecting a broader industry commitment to environmental responsibility alongside regulatory compliance.

The competitive landscape is characterized by established global players and niche specialists, all vying to offer solutions that simplify complex regulatory burdens. Future market competition is anticipated to center on the development of highly reliable interlocking mechanisms and superior air management designs that guarantee minimal turbulence and maximum purge effectiveness within the transfer chamber. Success will depend on the ability to provide comprehensive service packages, including seamless installation, robust performance qualification documentation, and readily available global technical support, crucial for organizations operating multi-site cleanroom facilities worldwide. The overall market resilience is high, driven fundamentally by the non-negotiable requirement for contamination control in life-saving and high-technology industries.

Technological advancement is not limited to filtration; it also involves enhancing the user interface and data logging capabilities of the cabinets. Modern transfer systems are equipped with touch-screen controls, detailed visual indicators of cleanroom status (e.g., green/red status lights for door access), and secure, tamper-proof electronic records. This focus on verifiable data output supports the growing requirement for electronic batch records (eBR) and simplifies the audit process significantly. The shift towards single-use technologies in bioprocessing also influences cabinet design, requiring specialized ports and internal configurations to accommodate single-use bags and components while maintaining sterility during introduction into the isolator or cleanroom environment. The market is thus innovating to support both traditional stainless steel architecture and novel single-use material handling paradigms, ensuring broad applicability across diverse manufacturing techniques.

Moreover, the adoption of modular cleanroom technologies has significantly affected the design of transfer cabinets. Modern cabinets are often designed to be factory-integrated into modular walls or prefabricated cleanroom units, drastically reducing on-site installation time and complexity. This modular approach ensures better sealing integrity and reduces validation effort compared to traditional stick-built cleanrooms. Manufacturers are thus focusing on standardized interfaces and adaptable sizing options to cater effectively to this rapidly expanding segment of the cleanroom construction industry. This emphasis on ease of integration is particularly important in fast-track projects, such as vaccine manufacturing facilities built in response to pandemic preparedness needs, where rapid deployment and validated performance are paramount strategic requirements for global organizations.

The impact of Industry 4.0 principles, including pervasive sensor networks and the Industrial Internet of Things (IIoT), is manifesting in transfer cabinet designs through enhanced connectivity. Cabinets are being equipped with sensors monitoring internal humidity, temperature, pressure differential across filters, and even VHP concentration levels, transmitting this data instantly to central monitoring systems. This real-time data flow enables facilities managers to maintain tight environmental control, predict maintenance needs well before failures occur, and generate automated, compliant reports. This level of data visibility and control is a major differentiator, moving the market away from purely passive equipment towards intelligent, proactive components integral to the overall facility management system. The convergence of hardware precision and data intelligence is setting the new benchmark for transfer cabinet performance and regulatory assurance in high-stakes environments.

Global economic fluctuations, while generally presenting minimal restraint due to the essential nature of the equipment, can impact large capital expenditure projects, particularly in developing regions. However, the consistent need for replacement of aging equipment and the cyclical nature of regulatory updates often ensure sustained demand. Furthermore, the increasing global focus on containment facilities (BSL-3 and BSL-4 labs) drives a premium segment of the market, where highly specialized, complex transfer chambers are required to ensure operator and public safety while handling high-risk pathogens. These high-containment applications demand robust engineering, redundant safety features, and often customized integration with chemical shower or negative pressure systems, representing a lucrative, high-margin niche within the overall transfer cabinet ecosystem.

Educational outreach and technical training are emerging as critical value-added services offered by leading manufacturers. Due to the complexity of validation and operation, end-users require comprehensive training on proper material handling protocols, routine cleaning procedures, filter replacement schedules, and response strategies for alarm conditions. Companies that invest in sophisticated training programs, often utilizing augmented reality (AR) or virtual reality (VR) tools to simulate operations and maintenance procedures, are achieving higher customer satisfaction and securing stronger long-term relationships. This focus on enhancing user competency directly translates into reduced risk of contamination, maximizing the return on investment for sophisticated transfer cabinet installations.

The market also sees segmentation based on the specific material being transferred. For instance, cabinets designed for transferring highly toxic or potent compounds (like HPAPIs in oncology drug manufacturing) require specialized features such as glove ports for safe internal manipulation, specialized washing capabilities, and often integrated weighing scales, ensuring complete containment and precise handling. In contrast, cabinets for electronics might prioritize static dissipation features and ultra-low vibration profiles. This customization ensures that the transfer cabinet not only meets cleanliness requirements but also integrates seamlessly into the specific safety and process needs of the end-user application, highlighting the necessity for deep industry-specific expertise among market players.

The future trend in design innovation includes self-decontaminating surfaces and advanced material treatments. Manufacturers are exploring the use of anti-microbial coatings or specialized polymers within the cabinet interior to further mitigate the risk of biological accumulation, even in between major decontamination cycles. Additionally, developments in seal technology, utilizing inflatable gaskets or magnetic seals, are improving airtightness significantly, which is vital for maintaining required pressure differentials and ensuring the efficacy of VHP cycles. These incremental but critical improvements underscore the continuous drive towards achieving zero-contamination risk in sensitive manufacturing and research environments, maintaining the strong technological momentum underpinning the market's forecasted growth trajectory. The commitment to engineering redundancy, focusing on back-up power supply options and dual-sensor validation, is becoming standard for high-assurance applications, reflecting the essential nature of these components.

The pharmaceutical segment's increasing reliance on smaller, portable, and often disposable cleanroom solutions, such as isolators and Restricted Access Barrier Systems (RABS), has led to the development of dedicated transfer cabinets designed specifically for connection to these advanced barrier technologies. These specialized cabinets act as interface gateways, ensuring validated connection integrity and minimizing particle generation during docking and transfer operations. This niche demand requires precision engineering and compatibility testing to ensure seamless integration across different vendor components. As decentralized and flexible manufacturing models gain traction, the importance of these adaptable and highly functional transfer interfaces will only increase, further solidifying the need for continuous product development and specialization within the market.

Furthermore, sustainability is gaining prominence, influencing manufacturers to develop transfer cabinets that are more energy-efficient. Optimization of blower speeds, implementation of energy-saving standby modes when the cabinet is inactive, and the use of modern LED lighting instead of fluorescent tubes are common features. The environmental footprint of filter disposal is also a growing concern, prompting R&D into longer-lasting filter media and designs that minimize material waste. Companies demonstrating a commitment to reduced energy consumption and end-of-life recycling options are finding a competitive edge, particularly when tendering for large corporate or governmental contracts that mandate environmental performance criteria alongside technical specifications and regulatory compliance records.

The expansion of the food and beverage industry, particularly in aseptic packaging and specialized processing of sensitive food products, represents an undervalued yet growing end-user segment. While less stringent than pharmaceutical cGMP, the demand for high standards of hygiene and contamination prevention in products like infant formula, specialized dairy, and ready-to-eat meals requires reliable, easy-to-clean transfer systems. This segment often demands simpler, more robust stainless steel static and dynamic cabinets focused on rapid throughput and wash-down compatibility, expanding the overall market volume outside the traditional life sciences core.

In summary, the Transfer Cabinets Market is characterized by a high barrier to entry due to regulatory complexity and the specialized engineering required. Success hinges on a robust understanding of cGMP requirements, continuous innovation in filtration and decontamination technologies, and the strategic integration of Industry 4.0 principles to deliver smart, validated, and reliable contamination control solutions that meet the increasing demands for purity and safety across global manufacturing and research ecosystems. The high financial impact associated with batch contamination ensures that premium, technologically advanced solutions will continue to command dominance in high-stakes operational environments, driving steady market expansion.

The requirement for seamless integration into Building Management Systems (BMS) and Environmental Monitoring Systems (EMS) is a defining feature of the modern transfer cabinet. This integration ensures that the cabinet’s operational status, including pressure logging and cycle completion, is recorded directly alongside the overall cleanroom environmental data, simplifying regulatory audits and demonstrating consistent control. Leading market players are investing heavily in proprietary software interfaces that offer standardized communication protocols (such as Modbus or OPC UA) to facilitate this interoperability, positioning their products as intelligent components within the broader facility infrastructure rather than isolated pieces of equipment. This holistic approach to system management reduces validation burden and enhances the overall safety margin of the controlled environment, creating significant value for large-scale pharmaceutical and electronics manufacturers.

Technological differentiation is also occurring through enhanced ergonomics and user safety features. For dynamic systems, features like integrated air showers or controlled turbulence zones within the transfer space are being deployed to more effectively dislodge particles from items prior to ingress into the core zone. Furthermore, safety features such as emergency stop buttons, visual and auditory alarms for interlock failure, and sophisticated sensors to prevent door crushing are becoming standard, ensuring both operational efficiency and personnel protection. The development of transfer cabinets specifically for personnel use, often integrated within airlocks or gowning rooms, demonstrates the versatility and expanding application scope beyond simple material handling, further contributing to market complexity and growth opportunity.

The long-term market sustainability hinges on innovation in filter technology. Future filters are expected to offer higher efficiency with lower pressure drop, reducing the energy consumption of the cabinet blowers and extending the operational lifespan between replacements. Research into advanced filter media, potentially incorporating nanofiber technology, aims to maintain ultra-low particulate counts while minimizing operational costs. The successful implementation of AI for predictive maintenance, particularly in monitoring filter saturation and anticipating necessary change-outs, will transform the service model, shifting revenue generation towards long-term service contracts and consumable sales, rather than relying solely on initial capital equipment purchases.

In conclusion, the Transfer Cabinets Market is evolving rapidly, driven by global regulatory pressures and technological leaps in automation and data integrity. The core mission—preventing cross-contamination—remains constant, but the methods are becoming significantly more sophisticated. The emphasis is on systems that are not only effective barriers but also verifiable, intelligent, and seamlessly integrated into the high-tech, regulated environments they serve. Strategic investment in compliance-enabling technologies, such as VHP and predictive diagnostics, will determine competitive leadership through the forecast period, especially as the global biopharmaceutical industry continues its robust expansion in complex and sensitive therapeutic areas.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager