Trefoil Cable Cleat Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435491 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Trefoil Cable Cleat Market Size

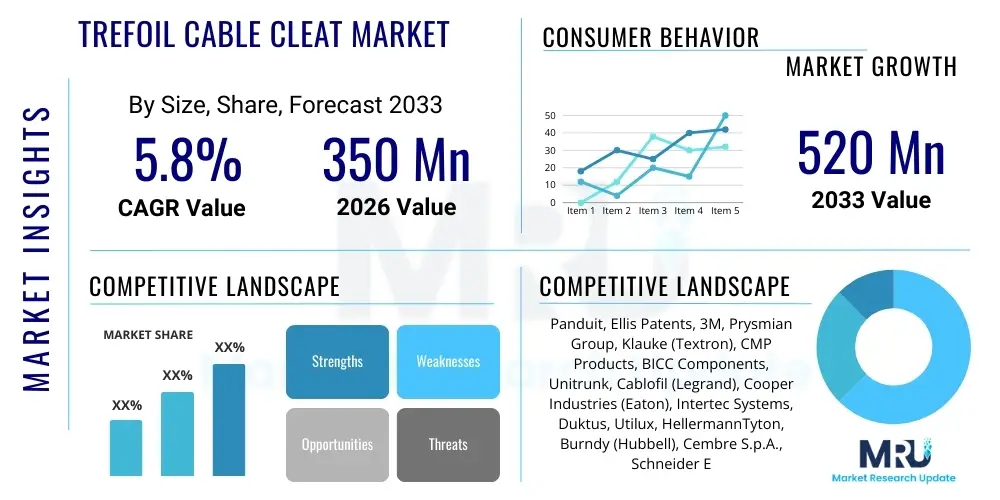

The Trefoil Cable Cleat Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 350 Million in 2026 and is projected to reach USD 520 Million by the end of the forecast period in 2033.

Trefoil Cable Cleat Market introduction

The Trefoil Cable Cleat Market encompasses the manufacturing, distribution, and utilization of specialized devices designed to secure three single-core power cables in a triangular (trefoil) configuration. This specific arrangement is crucial in three-phase electrical systems, particularly those operating at medium to high voltages, as it minimizes electromagnetic forces, reduces eddy currents, and ensures efficient current flow. The primary function of a trefoil cable cleat is to maintain the cable formation and, critically, to restrain the cables during severe dynamic forces generated by a short circuit fault. Maintaining cable integrity under these extreme conditions is paramount to preventing catastrophic equipment failure, protecting personnel, and ensuring system uptime.

Trefoil cable cleats are fabricated from various robust materials, including glass-reinforced polymer (GRP), nylon, aluminum, and stainless steel, chosen based on the installation environment, required short-circuit withstand rating, and resistance to corrosion, UV exposure, and fire. Major applications driving the market demand include high-capacity transmission and distribution networks, renewable energy projects such as solar and wind farms, heavy industrial plants (mining, petrochemical), and transportation infrastructure (railways, metros). The growing global focus on reliable electricity supply, coupled with stringent safety regulations mandating adherence to standards like IEC 61914, solidifies the foundational demand for these essential cable management components.

The benefits derived from using certified trefoil cable cleats are significant, including enhanced system safety, prevention of cable damage and unnecessary downtime, and improved thermal management by reducing localized heating. Driving factors for market expansion include massive global investments in grid modernization and expansion, the rapid deployment of offshore and onshore renewable energy infrastructure requiring high-voltage cable protection, and increasing industrialization in emerging economies, all of which necessitate robust, safety-compliant cable restraint systems capable of handling elevated power loads and fault conditions effectively.

Trefoil Cable Cleat Market Executive Summary

The Trefoil Cable Cleat Market is experiencing robust expansion, fundamentally driven by pervasive global trends in infrastructure development and energy transition. Business trends highlight a shift towards higher performance materials, such as specialized marine-grade stainless steel and advanced low-smoke, zero-halogen (LSOH) polymers, catering to demanding environments like tunnels, offshore platforms, and hazardous areas. Manufacturers are focusing on modular designs and universal compatibility to simplify installation processes and reduce project complexity for Engineering, Procurement, and Construction (EPC) firms. Furthermore, increasing regulatory scrutiny regarding electrical safety standards, particularly in developed regions like Europe and North America, accelerates the replacement cycle of older, non-compliant cable supports, providing a strong underlying demand vector.

Regional trends indicate that the Asia Pacific (APAC) region is poised for the most significant growth, fueled by ambitious state-backed investments in utility infrastructure expansion, rapid urbanization, and extensive renewable energy commitments, particularly in China and India. North America and Europe remain mature markets, characterized by high adoption rates of premium, high-specification cleats due to established short-circuit testing protocols and strict safety enforcement. Conversely, the Middle East and Africa (MEA) region is exhibiting strong potential, driven by large-scale oil and gas projects and smart city developments requiring resilient power distribution networks. The market dynamics are highly sensitive to global commodity prices, affecting the cost of materials like aluminum and high-grade stainless steel, which subsequently influences product pricing and manufacturer margins.

Segment trends reveal that the Polymer/Nylon cleat segment holds a dominant share, preferred for its lightweight nature, excellent insulation properties, and corrosion resistance, suitable for medium-voltage applications. However, the metallic segment (aluminum and stainless steel) is growing faster, largely due to its superior mechanical strength and required usage in high-voltage (HV) and ultra-high-voltage (UHV) systems where short-circuit forces are extreme. By voltage rating, the high-voltage segment (above 66 kV) is projected to outpace others, directly correlating with the proliferation of major renewable energy transmission backbone projects and interconnector cables.

AI Impact Analysis on Trefoil Cable Cleat Market

User inquiries frequently center around how AI and advanced analytics can enhance the reliability and reduce the installation costs associated with cable management systems, particularly trefoil cleats. Key user concerns revolve around predictive failure analysis—whether AI can use real-time grid data (temperature, load fluctuations, vibration) to predict potential cleat or cable insulation stress before a fault occurs. There is also significant interest in leveraging AI for optimizing the manufacturing process, specifically in automated quality control to ensure precise adherence to IEC short-circuit testing parameters and material consistency. Users also anticipate AI tools assisting engineers in rapid, site-specific cleat selection, moving beyond manual calculations based solely on fault current levels to incorporating environmental factors, thermal cycling, and proximity effects in complex cable routing scenarios, thereby optimizing procurement and installation efficiency while minimizing over-engineering.

- AI-driven Predictive Maintenance: Utilizing machine learning algorithms on sensor data (temperature, humidity, vibration) embedded near cable installations to predict potential material degradation or mechanical stress on cleats, enabling proactive replacement or maintenance cycles and reducing unexpected outages.

- Optimized Cleat Design and Simulation: Employing AI to run complex finite element analysis (FEA) simulations faster than traditional methods, optimizing material distribution and cleat geometry to maximize short-circuit withstand capability while minimizing raw material usage, leading to more cost-effective designs.

- Automated Manufacturing Quality Control: Implementing computer vision and deep learning models on production lines to instantly inspect manufactured cleats for dimensional accuracy, surface defects, and material homogeneity, ensuring 100% compliance with strict quality standards (e.g., molding flash, inconsistent wall thickness).

- Smart Inventory and Supply Chain Management: Using AI to forecast demand based on regional infrastructure project timelines, optimizing inventory levels of various cleat materials and sizes (e.g., aluminum vs. polymer) to reduce lead times for major EPC contractors.

- Enhanced Site Selection Tools: Developing AI platforms that integrate spatial data, fault current calculations, and environmental parameters (soil type, solar exposure, seismic activity) to recommend the optimal cleat type, spacing, and fixing methods for highly specific installation locations, minimizing installation errors.

DRO & Impact Forces Of Trefoil Cable Cleat Market

The Trefoil Cable Cleat Market is primarily driven by global infrastructure modernization, constrained by material cost volatility, and uplifted by opportunities in smart grid integration and specialized material development. Drivers include the accelerating shift towards renewable energy sources—wind and solar farms inherently rely on extensive high-voltage AC and DC cabling requiring secure trefoil arrangements. Furthermore, significant investments by utility companies globally to replace aging transmission and distribution (T&D) networks necessitate the use of modern, certified cable cleats compliant with latest safety mandates, particularly in urban environments where system failure is intolerable. Restraints center on the high initial cost of certified, high-performance cleats, especially those made from marine-grade stainless steel, which can be prohibitive for budget-sensitive projects in emerging economies. Moreover, the market faces challenges from fluctuations in commodity prices (plastics, aluminum, and steel), impacting production costs and requiring constant price adjustments that can complicate long-term project budgeting for buyers. The presence of counterfeit or non-certified products in less regulated markets also poses a threat to legitimate manufacturers, undermining the safety focus that defines this niche.

Opportunities for growth are concentrated in the development of specialized cleats tailored for extreme environments, such as those used in high-temperature subsea cable systems, cryogenic environments, or areas requiring extreme fire resistance (e.g., railway tunnels). The increasing adoption of smart grid technologies presents an opportunity for manufacturers to integrate sensors or monitoring capabilities directly into cleat designs, allowing for continuous surveillance of cable parameters (temperature, vibration) which enhances the cleat’s value proposition beyond simple mechanical restraint. Additionally, manufacturers focusing on sustainable and recycled materials will tap into the growing corporate demand for environmentally responsible infrastructure components, particularly among European and North American utilities. Impact forces include the stringent enforcement of international standards like IEC 61914, which mandates dynamic short-circuit testing, acting as a major positive influence by eliminating low-quality entrants and forcing all market participants to invest heavily in R&D and rigorous testing methodologies, ultimately benefiting end-users by ensuring superior product reliability and safety.

The macroeconomic environment, characterized by inflation and supply chain disruptions, acts as a significant external impact force, affecting lead times and inventory management for both cleat suppliers and major electrical contractors. Geopolitical stability also plays a role, as massive cross-border energy projects (like HVDC interconnectors) are major consumers of high-specification cleats, meaning project delays or cancellations due to political instability directly curb market demand. However, the fundamental, non-negotiable nature of cable restraint in high-voltage systems ensures that demand remains relatively inelastic, protecting the market from severe cyclical downturns, though purchase volumes correlate heavily with global CapEx cycles in the utility and infrastructure sectors.

Segmentation Analysis

The Trefoil Cable Cleat Market is meticulously segmented based on material type, voltage rating, application sector, and regional presence, reflecting the diverse and specialized requirements across the global electrical infrastructure landscape. Understanding these segment dynamics is crucial for strategizing, as the choice of a cleat material is intrinsically linked to the maximum short-circuit force it must withstand, the installation environment (e.g., corrosive vs. benign), and the specific regulatory framework governing the end-use application. For instance, high-voltage substations often require metallic cleats (aluminum or stainless steel) for superior mechanical integrity, whereas low-to-medium voltage commercial installations may opt for polymer-based solutions due to cost and insulation benefits. The Application segmentation clearly defines where the high-value, high-volume demand originates, with Utilities and Renewables dominating the market landscape due to ongoing grid infrastructure expansion and the continuous need for robust cable systems securing generation and transmission assets.

- By Material Type:

- Polymer/Nylon Cleats (Polyamide, GRP)

- Metallic Cleats (Aluminum, Stainless Steel 304/316)

- Composite Cleats

- By Voltage Rating:

- Low Voltage (Below 1 kV)

- Medium Voltage (1 kV to 66 kV)

- High Voltage (Above 66 kV)

- By Application:

- Utilities and Transmission & Distribution (T&D) Networks

- Renewable Energy (Wind Farms, Solar Parks)

- Oil & Gas and Petrochemical Plants

- Industrial Manufacturing and Heavy Industry

- Transportation Infrastructure (Rail, Subway)

- By End-Use Industry:

- EPC Contractors

- Utilities

- OEMs

Value Chain Analysis For Trefoil Cable Cleat Market

The value chain for the Trefoil Cable Cleat Market begins with the Upstream activities, focused heavily on securing high-quality raw materials, primarily specialized engineering polymers (such as glass-reinforced polyamide, often LSOH formulations), high-grade aluminum alloys, and various grades of stainless steel (304 and 316). Suppliers of these raw materials, which are subject to global commodity pricing volatility, form the foundation of the cost structure. Downstream activities involve the highly technical manufacturing processes, which include injection molding for polymer cleats or casting and fabrication for metallic cleats. A crucial element here is rigorous in-house R&D and testing facilities required to perform dynamic short-circuit testing according to the demanding IEC 61914 standard. Compliance and certification costs represent a significant barrier to entry and value addition at this stage. Manufacturers often possess specialized tooling to produce cleats that meet precise dimensions and specific fault current ratings requested by high-voltage system designers.

The distribution channel is multifaceted and strategically critical due to the specialized nature of the product. Direct distribution involves manufacturers selling directly to large Utilities or Tier-1 Engineering, Procurement, and Construction (EPC) firms responsible for major grid projects, ensuring technical support and tailored solutions. This channel provides high margins but requires extensive sales engineering teams. Indirect distribution relies heavily on global and regional electrical distributors and wholesalers who maintain stock and cater to smaller industrial projects, maintenance, repair, and operations (MRO) needs, or smaller EPCs. Effective inventory management within this indirect network is vital, given the wide array of cleat sizes, materials, and fault ratings required globally.

The final consumption stage involves the end-users—primarily T&D Utilities, renewable energy project owners, and industrial plant managers—who rely on the cleat’s performance for system integrity and safety. Value capture throughout the chain is highest for manufacturers who successfully innovate materials (e.g., developing stronger, lighter, or more fire-resistant composites) and those who achieve global regulatory approval, allowing them to participate in high-specification, high-value projects where non-compliance is strictly prohibited. The consulting engineering firms and system integrators also play an influential role, acting as gatekeepers by specifying the required cleat type and fault rating early in the project design phase.

Trefoil Cable Cleat Market Potential Customers

The primary consumers and end-users of trefoil cable cleats are entities involved in the generation, transmission, and heavy-duty industrial consumption of high-voltage electrical power. The most significant customer base comprises T&D Utilities, encompassing national grid operators and regional power distribution companies. These entities perpetually invest in new substation construction, cable routing infrastructure, and maintenance upgrades, necessitating vast quantities of certified cleats for securing feeder and primary power cables. Utilities prioritize safety, longevity, and adherence to international standards (like IEC 61914) above all else, often specifying metallic or high-grade polymer solutions.

Another rapidly expanding segment of buyers includes developers and operators within the Renewable Energy sector, specifically onshore and offshore wind farms, and large-scale solar parks. The cabling systems in these facilities, especially the high-voltage collector and transmission lines connecting the generation source to the grid, require robust cable restraints to withstand environmental stressors and short-circuit forces. Moreover, EPC contractors specializing in large infrastructure projects, such as railway modernization, tunnel construction, and airport expansions, constitute a vital buying segment. They procure cleats in bulk, driven by project timelines and specific engineering requirements.

Finally, heavy industrial sectors, including Oil & Gas, Mining, Petrochemicals, and large Data Center operators, are consistent consumers. These facilities operate highly complex, critical power systems where downtime is extremely costly. They typically demand cleats certified for hazardous locations (ATEX) or those made from stainless steel (316) for superior corrosion resistance in harsh industrial environments. Customer procurement decisions in this market are therefore heavily influenced by safety certifications, short-circuit performance reports, and total cost of ownership rather than solely initial unit cost.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350 Million |

| Market Forecast in 2033 | USD 520 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Panduit, Ellis Patents, 3M, Prysmian Group, Klauke (Textron), CMP Products, BICC Components, Unitrunk, Cablofil (Legrand), Cooper Industries (Eaton), Intertec Systems, Duktus, Utilux, HellermannTyton, Burndy (Hubbell), Cembre S.p.A., Schneider Electric, Thomas & Betts (ABB), Greenlee (Emerson), TE Connectivity |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Trefoil Cable Cleat Market Key Technology Landscape

The technological landscape of the Trefoil Cable Cleat Market is primarily defined by material science innovation, advanced manufacturing processes, and rigorous, standardized testing methodologies, all aimed at maximizing fault current withstand capability and durability. A critical technological aspect is the development and use of advanced polymers, specifically glass-reinforced polyamides (nylon) and composites, which offer high mechanical strength while maintaining electrical insulating properties and lightweight characteristics. Recent innovations focus on engineering these polymers to be Low-Smoke, Zero-Halogen (LSOH) and fire-retardant (FR), crucial for installations in enclosed spaces like tunnels, ships, and data centers, where smoke toxicity is a major safety concern. For metallic cleats, technology involves using specialized grades of stainless steel (like 316L) to ensure maximum resistance to corrosion in offshore and petrochemical environments, often combined with specialized anti-vibration coatings or internal liners to protect cable jackets.

Manufacturing technology emphasizes precision engineering, particularly through high-pressure injection molding for polymer components and sophisticated casting techniques for aluminum and stainless steel parts. Achieving dimensional consistency across large production volumes is essential to ensure that the cleats perform reliably when subjected to multi-ton forces during a short-circuit event. Furthermore, modular design technology is gaining traction, allowing manufacturers to create cleats with adjustable features or stackable components that can accommodate a wider range of cable diameters with fewer SKU variations, simplifying inventory and increasing installation flexibility on-site. The fixation methods themselves are also evolving, with quick-release and bolt-free systems being developed to accelerate installation without compromising mechanical integrity.

Perhaps the most defining technological requirement is the adherence to the IEC 61914 standard (Cable cleats for electrical installations), which dictates the dynamic short-circuit testing protocols. Manufacturers must possess specialized high-current testing laboratories, or partner with certified facilities, to dynamically prove that their cleats can withstand the calculated peak short-circuit forces without allowing the cables to escape the containment system. This technology involves complex instrumentation, high-speed photography, and force measurement equipment to document compliance. Ongoing R&D is dedicated to optimizing the geometry of the cleat’s saddle and retention straps to better distribute fault forces and minimize stress concentration points, further pushing the boundaries of safe operational parameters, especially for 400kV and higher voltage transmission lines.

Regional Highlights

- Asia Pacific (APAC): This region represents the fastest-growing market globally, driven by massive public investment in electrical grids, rapid urbanization, and significant clean energy mandates, particularly in China, India, and Southeast Asian nations. The demand is high for both medium-voltage polymeric cleats for urban distribution and high-voltage metallic cleats for regional interconnectors and large-scale infrastructure projects, such as high-speed rail.

- North America: Characterized by a mature market with high safety standards and stringent regulatory compliance. Growth is propelled by grid modernization initiatives, replacement of aging T&D infrastructure, and major renewable energy build-outs (especially utility-scale solar and wind in the US and Canada). The market here prioritizes premium, certified cleats with superior corrosion resistance and fire ratings.

- Europe: A safety-conscious market driven heavily by the adoption of sophisticated safety standards (IEC 61914) and the push toward decarbonization. Major drivers include offshore wind energy projects, requiring highly specialized marine-grade stainless steel cleats, and upgrades to existing subterranean cable networks in dense urban areas, demanding LSOH and fire-retardant polymer solutions.

- Middle East and Africa (MEA): Growth is stimulated by large oil and gas capital expenditure projects, smart city developments (like NEOM in Saudi Arabia), and rapid utility expansion in countries like the UAE and South Africa. The demand leans towards robust, UV-resistant, and high-temperature tolerant cleats suitable for harsh desert and coastal environments.

- Latin America: Characterized by fluctuating infrastructure investment cycles. The market shows steady growth due to localized renewable energy projects (hydro and solar) and necessary grid expansion in high-population areas. Procurement often balances cost-efficiency with basic IEC compliance.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Trefoil Cable Cleat Market.- Panduit

- Ellis Patents

- 3M

- Prysmian Group

- Klauke (Textron)

- CMP Products

- BICC Components

- Unitrunk

- Cablofil (Legrand)

- Cooper Industries (Eaton)

- Intertec Systems

- Duktus

- Utilux

- HellermannTyton

- Burndy (Hubbell)

- Cembre S.p.A.

- Schneider Electric

- Thomas & Betts (ABB)

- Greenlee (Emerson)

- TE Connectivity

Frequently Asked Questions

Analyze common user questions about the Trefoil Cable Cleat market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a trefoil cable cleat?

The primary function is to secure three single-core cables in a triangular configuration, crucial for three-phase systems, and to restrain these cables against the extreme dynamic forces generated during a short circuit fault, preventing system damage and ensuring safety.

Why are trefoil cleats essential for high-voltage systems?

Trefoil cleats are essential for high-voltage systems because the high current levels mean short circuit faults generate massive electromagnetic forces. Only properly certified and securely installed trefoil cleats can prevent the cables from violently parting or causing structural damage during such a catastrophic event, maintaining compliance with safety standards.

What regulatory standard governs the testing and certification of cable cleats?

The primary international regulatory standard governing the design, testing, and performance of cable cleats for electrical installations is IEC 61914. Compliance with this standard, particularly the dynamic short-circuit testing requirement, is mandatory for most critical infrastructure projects globally.

Which material type dominates the Trefoil Cable Cleat Market?

Polymer (Nylon/GRP) cleats currently hold a significant market share due to their cost-effectiveness, insulating properties, and corrosion resistance, suitable for medium-voltage applications. However, the metallic segment (aluminum and stainless steel) is growing rapidly, driven by high-voltage and specialized infrastructure projects requiring maximum strength.

How does the growth of renewable energy impact the demand for trefoil cable cleats?

The global growth of renewable energy, especially large-scale solar and wind farms (both onshore and offshore), significantly increases demand for trefoil cable cleats. These facilities require extensive high-voltage AC and DC transmission cabling to connect power sources to the grid, all of which necessitate robust, safety-certified cleating systems to manage high fault current levels and environmental exposure.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager