Triallyl Isocyanurate Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432317 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Triallyl Isocyanurate Market Size

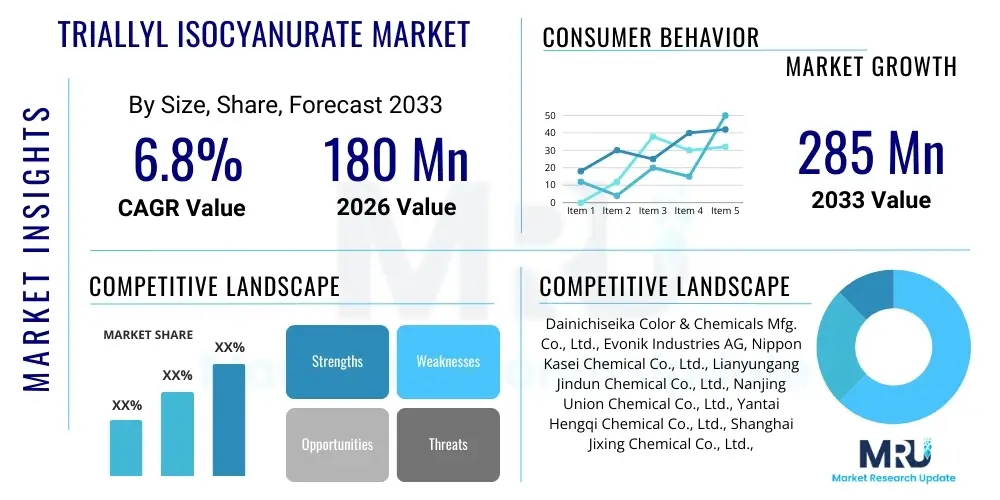

The Triallyl Isocyanurate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 180 Million in 2026 and is projected to reach USD 285 Million by the end of the forecast period in 2033.

Triallyl Isocyanurate Market introduction

Triallyl Isocyanurate (TAIC) is a trifunctional monomer distinguished by its high reactivity and excellent cross-linking capabilities, making it indispensable across several high-performance material applications. Chemically, it is a derivative of isocyanuric acid, where three allyl groups are substituted onto the nitrogen atoms, providing three active sites for radical cross-linking reactions. The primary function of TAIC is to act as a cross-linking agent or an additive that significantly enhances the thermal stability, mechanical strength, and electrical properties of polymers and resins, particularly in systems utilizing radical initiators or ionizing radiation.

Major applications of TAIC span highly demanding industries, including the production of cross-linked polyethylene (XLPE) for power cables, specialized photovoltaic (PV) encapsulation films, advanced composite matrices, and high-temperature insulating materials. In the wire and cable sector, the incorporation of TAIC allows polyethylene to be successfully cross-linked, thereby preventing melting at elevated temperatures and dramatically improving abrasion resistance and resistance to environmental stress cracking. Furthermore, in the electronics domain, it is utilized in molding compounds and laminates where superior dielectric properties and dimensional stability under heat are paramount requirements for reliable performance.

The market growth for TAIC is fundamentally driven by the accelerating global transition toward advanced infrastructure and renewable energy systems. The massive deployment of solar energy capacity necessitates high volumes of durable photovoltaic module encapsulation materials, where TAIC ensures long-term UV resistance and performance longevity. Concurrently, the increasing complexity and miniaturization of electronic devices require high-quality insulating and protective materials that can withstand rigorous operational conditions. These technological shifts, coupled with stringent safety standards requiring flame-retardant and high-thermal-stability plastics, cement TAIC’s position as a crucial performance chemical additive.

Triallyl Isocyanurate Market Executive Summary

The Triallyl Isocyanurate (TAIC) market is characterized by robust growth, primarily propelled by sustained demand from the wire and cable, and electronics sectors, particularly within Asia Pacific. Business trends indicate a strong move towards higher purity grades of TAIC, necessitated by sophisticated applications like high-voltage direct current (HVDC) cables and precision electronic encapsulation, where impurities can compromise performance. Manufacturers are investing in process optimization, such as chromatography and advanced filtration, to meet the stringent quality standards of Tier 1 end-users, focusing on enhancing yield efficiency while maintaining superior product specification consistency. Furthermore, the push for sustainable chemistry is influencing innovation, prompting research into bio-based alternatives or more energy-efficient cross-linking methodologies, although TAIC remains the industry benchmark for performance.

Regionally, Asia Pacific dominates the TAIC consumption landscape, driven overwhelmingly by China’s massive manufacturing base for electronics, construction materials, and power infrastructure expansion, followed closely by South Korea and Japan, key hubs for advanced semiconductor and display technologies. North America and Europe demonstrate mature market characteristics, focusing on high-value applications, such as specialized aerospace composites and medical-grade polymers, rather than sheer volume. Regulatory trends, especially concerning chemical registration (like REACH in Europe), impact supply chain decisions, often favoring local production or suppliers capable of rigorous compliance documentation, thereby creating regional supply differentiation. The expansion of 5G infrastructure globally is a critical regional driver, demanding superior dielectric properties in cable insulation materials, favoring high-purity TAIC grades.

Segmentation trends reveal that the cross-linking agent application segment remains the largest volume consumer, particularly for wire and cable insulation (XLPE) due to ongoing global urbanization and power grid modernization initiatives. However, the photovoltaic (PV) encapsulation segment exhibits the highest growth trajectory, fueled by global governmental commitments to renewable energy targets and the subsequent boom in solar panel production, demanding specialized TAIC-modified polymers for enhanced longevity and weather resistance in harsh environments. Product purity segmentation, particularly TAIC 98% and 99% grades, is rapidly outpacing standard purity levels, commanding premium pricing reflective of the precision required in modern polymer modification, thereby impacting overall market valuation dynamics significantly.

AI Impact Analysis on Triallyl Isocyanurate Market

User queries regarding the impact of Artificial Intelligence (AI) on the Triallyl Isocyanurate (TAIC) market primarily revolve around operational efficiency, material discovery, and supply chain robustness. Users frequently ask how AI can optimize the chemical synthesis process of TAIC, predict polymer performance characteristics when cross-linked with TAIC, and improve quality control in high-purity production lines. Key themes include the expectation that AI and Machine Learning (ML) algorithms will be instrumental in accelerating the development of novel polymer formulations that require precise cross-linking stoichiometry, minimizing raw material waste during manufacturing, and anticipating demand fluctuations across varied application sectors like electronics and renewable energy. Concerns often center on the initial investment required for digitalization and the specialized data infrastructure needed to effectively train predictive models relevant to complex chemical processes.

The adoption of AI is fundamentally shifting the focus from purely physical experimentation to integrated digital modeling in specialty chemical R&D. AI tools are increasingly used for Quantitative Structure-Activity Relationship (QSAR) modeling, enabling researchers to predict how varying concentrations of TAIC, or different copolymer systems, will affect final material properties such as thermal decomposition temperature, tensile strength, and dielectric constant, without exhaustive laboratory work. This capability drastically reduces the time-to-market for TAIC-based performance materials, offering a significant competitive advantage to early adopters. Furthermore, in the manufacturing phase, predictive maintenance systems, powered by ML, monitor reactor conditions in real-time, ensuring optimal reaction rates and maximizing the yield of high-purity TAIC grades, which are critical for high-end applications like semiconductor encapsulation.

In the commercial sphere, AI applications extend to demand forecasting and inventory management, optimizing the volatile supply chain characteristic of specialized chemical inputs. By analyzing global commodity prices, regional construction indices, and electronics production forecasts, AI models provide far more accurate predictions of future TAIC needs than traditional statistical methods. This allows manufacturers to better manage fluctuating feedstock costs (e.g., isocyanuric acid and allyl chloride) and ensure timely delivery to global clients, improving overall market responsiveness. Additionally, computer vision systems are being deployed for automated quality inspection of TAIC powders and liquids, identifying particle size distribution abnormalities or contamination in real-time, thereby guaranteeing product quality consistency necessary for sensitive applications such as medical devices and aerospace composites.

- AI-driven optimization of TAIC chemical reaction parameters (temperature, pressure, catalyst concentration) to maximize yield and purity.

- Machine Learning (ML) prediction of material properties (thermal, mechanical, electrical) for new TAIC-crosslinked polymers, accelerating R&D cycles.

- Predictive maintenance programs using sensors and AI to minimize downtime and prevent catastrophic failures in TAIC production facilities.

- Enhanced quality control through computer vision systems for real-time inspection of TAIC powder morphology and purity levels.

- Advanced demand forecasting and supply chain optimization based on external economic indicators and end-user market dynamics.

DRO & Impact Forces Of Triallyl Isocyanurate Market

The Triallyl Isocyanurate (TAIC) market dynamics are powerfully shaped by a confluence of driving factors, substantial restraints, and emerging opportunities, all acting as critical impact forces defining its trajectory through 2033. The principal drivers include the unrelenting global demand for cross-linked polyethylene (XLPE) in medium- and high-voltage power transmission cables, necessitated by continuous urbanization and the modernization of electrical grids worldwide. This demand is further amplified by the exponential growth in the photovoltaic sector, where TAIC is essential for producing durable encapsulation materials that extend the service life of solar modules in harsh environmental conditions. Restraints, however, pose significant challenges, most notably the price volatility of key raw materials like isocyanuric acid and allyl chloride, which are derivatives of petrochemical processes, leading to cost fluctuations that compress manufacturer margins. Furthermore, stringent environmental regulations regarding the production and handling of specialty chemicals, particularly in developed regions, impose high operational and compliance costs, which can slow down market entry and expansion.

Opportunities within the TAIC market are primarily centered on technological innovation and market diversification. The exploration of TAIC derivatives and customized formulations tailored for niche, high-value applications, such as high-performance thermal barriers, advanced structural adhesives in automotive light-weighting initiatives, and specialized electronics packaging, represents a significant avenue for growth. The development of radiation-curable TAIC systems offers a faster, solvent-free alternative to traditional thermal curing methods, aligning with industry desires for increased throughput and reduced environmental footprint, especially in coating and composite manufacturing. Additionally, penetrating emerging markets in Southeast Asia, Latin America, and Africa, where infrastructure development is accelerating, presents substantial untapped demand for high-performance insulation and construction materials that rely on TAIC for superior durability.

The impact forces exerted on the market include competitive intensity, technological innovation, and regulatory changes. Intense competition, especially from established Asian manufacturers capable of large-scale, cost-effective production, keeps pricing under constant pressure. Technological advancements, particularly in polymerization techniques and cross-linking efficiency, continuously redefine the performance benchmarks expected of TAIC. Lastly, regulatory shifts, such as stricter fire safety codes in construction and electrical infrastructure, act as a positive force, favoring the adoption of high-performance additives like TAIC that inherently improve material fire resistance and thermal stability, thus ensuring that high-quality, specialized products maintain market relevance despite cost pressures. These interwoven forces dictate the investment strategies, R&D priorities, and geographical focus of major market participants.

Segmentation Analysis

The Triallyl Isocyanurate (TAIC) market is comprehensively segmented based on product purity, primary application methods, and the crucial end-use industries that define consumption patterns globally. Understanding these segments is vital for analyzing market structure and identifying specific growth pockets. Segmentation by purity grade reflects the increasingly complex requirements of end-users; for instance, high-purity TAIC (98% and above) is mandated in sensitive applications such as high-voltage direct current (HVDC) cable insulation and semiconductor encapsulation where even minor impurities can lead to dielectric breakdown or component failure. Conversely, standard grades (95% and below) are typically sufficient for general-purpose rubber cross-linking and lower-specification composite materials, driving volume in the broader industrial sector. This purity-based differentiation influences pricing structures significantly, with ultra-high purity materials commanding a substantial premium.

From an application standpoint, the market is broadly divided into plastics and rubber cross-linking, photopolymerization, and specialty additives for resins and coatings. The dominance of cross-linking applications underscores TAIC's role as a potent promoter that drastically improves the physical properties of polymers like PE, EVA, and various elastomers, lending them superior heat resistance, chemical resistance, and mechanical robustness. Growth in photopolymerization segments, involving UV and E-beam curing, is particularly notable as industries seek faster, lower-temperature curing methods for coatings and 3D printing resins. These segments require highly reactive multifunctional monomers like TAIC to achieve rapid cross-linking and high surface hardness, offering an accelerated path for manufacturing high-quality products across electronics and automotive sectors.

Analyzing the end-use industries reveals the primary consumption drivers. The Wire and Cable industry is the cornerstone, relying heavily on TAIC for the production of XLPE insulated power cables, ensuring reliability and longevity in critical electrical infrastructure. The Electronics sector utilizes TAIC in encapsulants, laminates, and molding compounds to protect sensitive components from thermal stress and moisture ingress, a requirement that intensifies with device miniaturization. Furthermore, the burgeoning Solar Power industry, specifically the manufacturing of PV backsheets and encapsulation films, represents the fastest growing segment, where TAIC-modified EVA or polyolefin materials provide the necessary durability to withstand decades of outdoor exposure, ensuring module efficiency and longevity, thereby tying TAIC market health directly to global renewable energy adoption rates.

- By Purity Grade

- TAIC 99% (Ultra-High Purity)

- TAIC 98% (High Purity)

- TAIC 95% (Standard Grade)

- By Application

- Plastics and Rubber Cross-linking

- Photovoltaic Encapsulation

- Insulation Materials

- Composite Materials and Laminates

- Radiation Curing and Coatings

- Adhesives and Sealants

- By End-Use Industry

- Wire and Cable

- Electronics and Semiconductors

- Solar Power (Photovoltaics)

- Automotive and Aerospace

- Construction and Infrastructure

- Medical Devices

Value Chain Analysis For Triallyl Isocyanurate Market

The value chain for the Triallyl Isocyanurate (TAIC) market is intricate, starting from upstream raw material procurement through complex chemical synthesis, culminating in distribution to diverse industrial end-users. The upstream segment involves securing two primary precursors: Isocyanuric Acid (typically synthesized from urea) and Allyl Chloride (derived from propylene). The stability and price volatility of these commodities significantly dictate the cost structure for TAIC manufacturers. As the synthesis process for high-purity TAIC is energy-intensive and requires sophisticated reaction control, specialized manufacturers capable of maintaining stringent quality control—particularly minimizing residual moisture and achieving ultra-high purity grades (99%)—occupy a critical position in the chain. These manufacturers are strategically focused on long-term supplier agreements to mitigate feedstock price fluctuations and ensure consistent supply volume, essential for serving the demanding electronics and wire/cable industries.

Midstream activities involve the chemical transformation of raw materials into TAIC, followed by quality testing, packaging, and branding. Because TAIC is a specialty chemical requiring careful handling, storage, and transport, manufacturers often integrate advanced purification steps, such as crystallization or distillation, to achieve the required purity standards tailored for specific customer applications (e.g., medical-grade polymers or high-voltage insulators). Distribution channels are structured into direct and indirect routes. Direct distribution is common for large-volume customers, particularly Tier 1 manufacturers in the wire/cable and solar encapsulation sectors, allowing for specialized technical support and customized logistical arrangements. This direct engagement fosters deeper relationships and proprietary formulation knowledge exchange between TAIC producers and major consumers, ensuring alignment on technical specifications.

The downstream segment, encompassing indirect distribution and final consumption, relies heavily on chemical distributors and agents, particularly for reaching smaller manufacturers, research institutions, and geographically dispersed customers in segments like coatings and niche composites. These indirect channels provide necessary warehousing, small-volume packaging, and regional regulatory compliance assistance, facilitating market penetration. The ultimate end-users are defined by sectors requiring enhanced thermal and mechanical properties, such as high-temperature resistant plastics, radiation-cured coatings, and durable insulation materials. The criticality of TAIC's performance ensures that downstream buyers prioritize product consistency and certified quality over marginal price differences, reinforcing the value of suppliers with robust quality management systems and established reputations in the specialty chemical market.

Triallyl Isocyanurate Market Potential Customers

Potential customers for Triallyl Isocyanurate are predominantly large-scale industrial processors operating within sectors that require materials exhibiting superior thermal, electrical, and mechanical performance under extreme conditions. The primary buyers are manufacturers specializing in wire and cable insulation, specifically producers of cross-linked polyethylene (XLPE) power cables for medium, high, and extra-high voltage applications. These customers rely on TAIC to achieve the necessary degree of cross-linking, which prevents the polyethylene from melting under thermal overload and significantly improves its resistance to abrasion and environmental cracking, crucial for long-term power grid reliability. As global electrification projects, including smart grids and underground cabling initiatives, accelerate, these infrastructure providers represent a stable and high-volume demand base for TAIC.

Another rapidly expanding customer base is found within the Photovoltaic (PV) industry, specifically companies manufacturing solar module encapsulation films and backsheets. These buyers utilize TAIC to modify ethylene-vinyl acetate (EVA) or polyolefin elastomers, dramatically improving their resistance to UV degradation, heat, and moisture penetration over the projected 25-30 year lifespan of a solar module. Given the aggressive global expansion of solar energy production driven by net-zero commitments, manufacturers of PV components, particularly those targeting utility-scale projects and installations in harsh climates (deserts, high humidity regions), are critical growth customers demanding specialized, high-performance TAIC grades for enhanced durability and weatherability in the protective layers of solar panels.

Furthermore, the Electronics and Specialty Composites industries represent high-value potential customers. Electronics manufacturers use TAIC in molding compounds for semiconductor encapsulation, printed circuit board (PCB) laminates, and flame-retardant materials, where superior dielectric properties, dimensional stability, and resistance to thermal cycling are non-negotiable requirements for component reliability. Similarly, automotive and aerospace composite manufacturers utilize TAIC as a co-monomer in advanced resin systems (like thermosetting polyesters and acrylics) to create lightweight, high-strength parts with enhanced temperature tolerance. These buyers are typically focused on technical partnership and demanding high-purity, consistent supply to meet stringent certification standards for safety and performance in their respective high-stakes applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 180 Million |

| Market Forecast in 2033 | USD 285 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Dainichiseika Color & Chemicals Mfg. Co., Ltd., Evonik Industries AG, Nippon Kasei Chemical Co., Ltd., Lianyungang Jindun Chemical Co., Ltd., Nanjing Union Chemical Co., Ltd., Yantai Hengqi Chemical Co., Ltd., Shanghai Jixing Chemical Co., Ltd., Changzhou Tronly New Electronic Materials Co., Ltd., Jining Huakai Resin Co., Ltd., Dow Chemical Company, BASF SE, Arkema S.A., Shandong Xinglu Chemical Co., Ltd., Suzhou Sinseachem Co., Ltd., Jiangsu Lanyu Chemical Co., Ltd., Zhejiang Sanhe Chemical Co., Ltd., Guangzhou Dongri Chemical Co., Ltd., Shenzhen Jinhui Chemical Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Triallyl Isocyanurate Market Key Technology Landscape

The technology landscape for the Triallyl Isocyanurate (TAIC) market encompasses innovations spanning synthesis, purification, and application integration, all focused on enhancing product quality and efficiency. In synthesis, advanced catalytic systems and continuous flow reaction technologies are being adopted to increase yield, reduce reaction time, and minimize energy consumption compared to traditional batch processes. Critical technological development centers on highly selective separation and purification methods, such as fractional crystallization under controlled temperature regimes and multi-stage distillation, essential for achieving the ultra-high purity grades (e.g., 99%) demanded by sensitive applications like high-voltage cable insulation and micro-electronic encapsulation. Manufacturers capable of consistently delivering these superior purity levels gain a significant competitive edge, as product inconsistency can lead to catastrophic failure in the final engineered product.

A major technological frontier involves the development and deployment of radiation curing technologies, including Electron Beam (E-beam) and Ultraviolet (UV) light curing, where TAIC serves as a highly efficient cross-linking agent. E-beam curing, in particular, offers instantaneous curing without the need for thermal energy or photoinitiators, making it ideal for high-speed production lines in coatings, inks, and certain composite manufacturing. TAIC’s trifunctional structure is highly reactive to these energy sources, enabling the formation of dense, tightly cross-linked polymer networks that exhibit exceptional hardness, chemical resistance, and thermal stability almost instantly. This transition away from traditional oven curing methods addresses industry pressures for faster throughput, reduced Volatile Organic Compound (VOC) emissions, and lower operational temperatures, thereby integrating TAIC into next-generation industrial coating and additive manufacturing processes.

Furthermore, technology related to the final application is evolving, particularly in the wire and cable sector with the refinement of XLPE compounding techniques. New compounding technologies ensure homogeneous dispersion of TAIC within the polyethylene matrix, optimizing the cross-linking efficiency and preventing localized defects that could compromise the cable’s dielectric performance. Research is also focused on developing synergistic stabilizer packages that work in conjunction with TAIC to enhance long-term thermal aging properties and oxidation resistance, crucial for infrastructure applications designed for multi-decade service life. These advancements are supported by sophisticated analytical instrumentation, including advanced chromatography and thermal analysis (TGA/DSC), used to characterize the material and validate the performance benefits delivered by the specific TAIC formulations in the end product.

Regional Highlights

The global Triallyl Isocyanurate market exhibits distinct regional consumption and production patterns, with market dynamics heavily influenced by regional industrial output, infrastructure investment, and regulatory environments.

- Asia Pacific (APAC): APAC is the epicenter of the TAIC market, dominating both production capacity and consumption. This dominance is driven by China, which houses massive manufacturing bases for electronics, power infrastructure, and solar photovoltaics. Rapid urbanization, governmental investment in high-voltage power transmission grids (including HVDC lines requiring high-purity XLPE), and the colossal build-out of solar farms are the primary demand engines. Countries such as South Korea, Japan, and Taiwan also contribute substantially due to their specialized roles in advanced semiconductor and display manufacturing, which require ultra-pure TAIC in molding compounds and laminates. The region benefits from lower operating costs, though environmental regulations are slowly tightening, influencing local production practices.

- North America: This region is characterized by steady, high-value demand, focusing less on volume than on specialized, high-specification applications. Key drivers include the stringent performance requirements in aerospace composites, automotive components (for vehicle lightweighting and battery systems), and specialized high-reliability wire and cable for industrial automation and data centers. The market here emphasizes technological innovation and compliance, driving demand for TAIC grades suitable for radiation curing processes and complex engineering resins. The U.S. remains the largest consumer, supported by a mature manufacturing base and stringent quality standards.

- Europe: European market growth is moderate but extremely quality-conscious, heavily influenced by the REACH regulatory framework, which necessitates thorough documentation and sustainable sourcing practices. Demand is focused on specialized applications in the automotive (electric vehicle components), medical device manufacturing, and the construction sectors, where high thermal stability and flame retardancy are mandatory. Germany, France, and Italy are significant consumers, driven by their established positions in high-end engineering and chemical manufacturing. The strong commitment to renewable energy deployment also supports demand from the region’s specialized PV encapsulation producers.

- Latin America (LATAM): This is an emerging market with potential driven by ongoing infrastructure modernization and industrial expansion, particularly in Brazil and Mexico. Demand for TAIC is closely linked to investments in power transmission grids and the growing local manufacturing of cables and construction materials. While currently smaller in volume compared to APAC, the anticipated increase in solar energy projects and foreign direct investment in manufacturing is projected to accelerate TAIC consumption over the forecast period.

- Middle East and Africa (MEA): Consumption in MEA is primarily concentrated in large-scale infrastructure projects, particularly oil and gas facilities, construction, and nascent renewable energy projects in the GCC (Gulf Cooperation Council) countries. TAIC is crucial here for producing durable materials capable of withstanding the region’s extreme temperatures and harsh climatic conditions. Growth is episodic, tied directly to the execution of major national development plans and investments in power generation and transmission capacity, requiring high-reliability wire and cable products.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Triallyl Isocyanurate Market.- Dainichiseika Color & Chemicals Mfg. Co., Ltd.

- Evonik Industries AG

- Nippon Kasei Chemical Co., Ltd.

- Lianyungang Jindun Chemical Co., Ltd.

- Nanjing Union Chemical Co., Ltd.

- Yantai Hengqi Chemical Co., Ltd.

- Shanghai Jixing Chemical Co., Ltd.

- Changzhou Tronly New Electronic Materials Co., Ltd.

- Jining Huakai Resin Co., Ltd.

- Dow Chemical Company

- BASF SE

- Arkema S.A.

- Shandong Xinglu Chemical Co., Ltd.

- Suzhou Sinseachem Co., Ltd.

- Jiangsu Lanyu Chemical Co., Ltd.

- Zhejiang Sanhe Chemical Co., Ltd.

- Guangzhou Dongri Chemical Co., Ltd.

- Shenzhen Jinhui Chemical Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Triallyl Isocyanurate market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Triallyl Isocyanurate (TAIC) used for primarily?

TAIC is primarily used as a powerful cross-linking agent and co-monomer in polymers, resins, and elastomers. Its main function is to enhance thermal stability, mechanical strength, and electrical properties, making it essential for high-performance applications like cross-linked polyethylene (XLPE) for power cables, photovoltaic (solar) encapsulation, and advanced composite materials.

Which end-use industry drives the highest demand for TAIC?

The Wire and Cable industry currently represents the largest volumetric demand segment for TAIC, using it extensively in the manufacture of XLPE insulation for medium and high-voltage power transmission cables to ensure durability and reliability under challenging operational conditions.

How does TAIC purity level affect its application?

Higher purity grades of TAIC (98% and 99%) are critical for sensitive applications such as high-voltage cable insulation and electronic encapsulation, where even trace impurities can compromise dielectric strength and component performance. Standard grades are used in general rubber cross-linking and less demanding composite applications.

What major trend is accelerating the growth of the TAIC market?

The massive global expansion of renewable energy capacity, specifically solar power generation, is a key growth accelerator. TAIC is vital for manufacturing durable, UV-resistant encapsulation materials that protect photovoltaic modules, ensuring long operational lifetimes for solar installations worldwide.

What challenges restrain the growth of the Triallyl Isocyanurate market?

The primary restraint is the significant price volatility of key petrochemical-derived raw materials, particularly allyl chloride and isocyanuric acid. These fluctuations create unstable cost structures for TAIC manufacturers, necessitating careful supply chain management and pricing strategies.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager