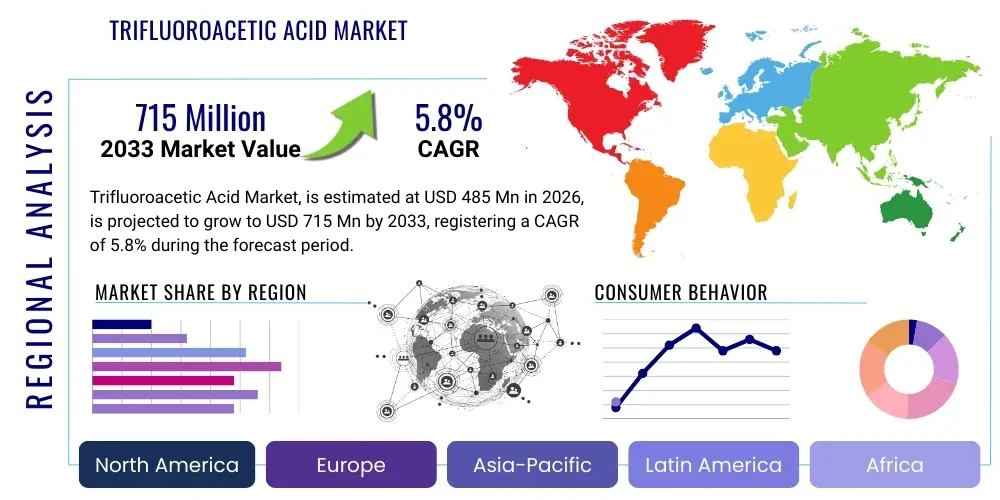

Trifluoroacetic Acid Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435661 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Trifluoroacetic Acid Market Size

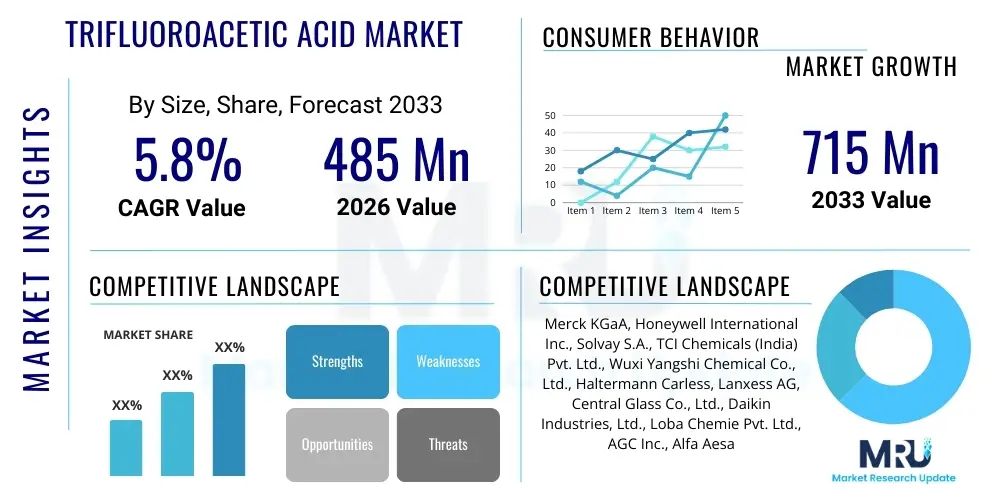

The Trifluoroacetic Acid Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 485 Million in 2026 and is projected to reach USD 715 Million by the end of the forecast period in 2033.

Trifluoroacetic Acid Market introduction

Trifluoroacetic Acid (TFA) is a strong carboxylic acid characterized by its high acidity and volatility, playing a critical role as a non-oxidizing, halogenated solvent and a key precursor in various organic synthesis reactions. Its chemical formula is CF3COOH, and it is widely utilized across high-value industries, primarily due to the strong electron-withdrawing effect of the trifluoromethyl group, making it an excellent catalyst and protecting group remover. The primary applications of TFA span the pharmaceutical and agrochemical sectors, where it is essential for synthesizing complex active pharmaceutical ingredients (APIs), peptides, and specialized intermediates. Furthermore, its use in polymer chemistry for manufacturing specialized resins and fluoropolymers contributes significantly to market demand. The market expansion is primarily fueled by the accelerating R&D activities in drug discovery, particularly in peptide synthesis, where TFA acts as a cleavage reagent for solid-phase peptide synthesis (SPPS), ensuring high yield and purity of therapeutic compounds. Global efforts toward developing new generation crop protection chemicals and the rising demand for specialty chemicals in electronics and material science further underpin the market's robust growth trajectory.

Trifluoroacetic Acid Market Executive Summary

The Trifluoroacetic Acid (TFA) market exhibits strong upward momentum driven by unprecedented growth in pharmaceutical outsourcing and the increasing complexity of synthesized molecules requiring high-purity TFA. Business trends indicate a shift towards strategic regional sourcing and enhanced vertical integration among key manufacturers to stabilize supply chains, which historically faced volatility due to raw material constraints, specifically hydrofluoric acid derivatives. Regionally, the Asia Pacific (APAC) dominates market growth, fueled by massive investment in generic drug production and the establishment of large-scale contract manufacturing organizations (CMOs) and contract development and manufacturing organizations (CDMOs), particularly in China and India. Segment trends reveal that the pharmaceutical application segment maintains the highest revenue share and is expected to witness the fastest CAGR due to intensive R&D pipelines focused on peptide-based drugs and novel biologics. Furthermore, the high-purity grade TFA (99.5% and above) is experiencing heightened demand, reflecting stringent regulatory requirements and the need for precision reagents in modern chemical synthesis, indicating a premiumization trend within the segment. The integration of sustainable manufacturing practices, focusing on reducing fluorine waste, is emerging as a critical competitive differentiator among leading global suppliers.

AI Impact Analysis on Trifluoroacetic Acid Market

User queries regarding AI's influence on the Trifluoroacetic Acid market predominantly center on optimizing chemical synthesis pathways, predicting reaction outcomes involving TFA as a catalyst or solvent, and managing supply chain complexities. Users are keen to understand how AI-driven synthetic route planning—specifically in peptide and agrochemical synthesis—can reduce the consumption of expensive, hazardous reagents like TFA, or alternatively, how machine learning can be applied to optimize the recovery and recycling processes of used TFA. Key concerns revolve around the potential disruption AI might cause to traditional chemical process development and whether AI-assisted material science discovery could rapidly identify superior, less corrosive alternatives to TFA, thereby impacting long-term demand.

The implementation of AI and machine learning (ML) models is significantly enhancing efficiency in research and development (R&D) processes where TFA is utilized. AI algorithms are now capable of analyzing vast datasets of chemical reactions to optimize parameters such as temperature, pressure, and catalyst loading, minimizing the required amount of TFA while maximizing yield and purity in complex organic syntheses. This optimization not only lowers operational costs for end-users, particularly large pharmaceutical companies and specialty chemical manufacturers, but also addresses sustainability concerns by reducing waste generation. Predictive modeling tools are also being deployed to forecast supply chain disruptions concerning key precursors, enabling producers to manage inventory and pricing more effectively, leading to greater stability in the global TFA supply.

Furthermore, AI-powered robotics and automation in laboratories are increasing the speed of high-throughput experimentation (HTE) in drug discovery, where TFA is frequently employed in subsequent purification steps. By automating the cleavage, purification, and analysis stages in peptide synthesis, for instance, AI systems ensure higher reproducibility and faster lead optimization, indirectly bolstering the demand for consistently high-quality TFA grades. The data generated through these automated platforms feeds back into AI models, continuously improving predictive accuracy regarding TFA’s reaction kinetics and stability profile across diverse applications, cementing its critical role despite technological advancements.

- AI optimizes reaction conditions, potentially reducing TFA consumption per unit synthesized product.

- Machine learning models enhance supply chain forecasting and raw material procurement strategies for TFA manufacturers.

- AI-driven automation accelerates high-throughput screening in peptide synthesis, increasing overall R&D activity requiring TFA.

- Predictive analytics aids in designing more efficient purification and recycling processes for spent TFA solvents.

- AI assists in identifying and predicting novel chemical structures where TFA acts as an essential precursor or reagent.

DRO & Impact Forces Of Trifluoroacetic Acid Market

The Trifluoroacetic Acid (TFA) market growth is primarily driven by the escalating demand from the pharmaceutical sector, notably for solid-phase peptide synthesis (SPPS) and the manufacturing of high-potency APIs, alongside robust expansion in agrochemicals requiring fluorine-containing compounds for enhanced efficacy and persistence. However, market growth faces significant restraints, chiefly concerning the high cost and volatile pricing of raw materials, particularly hydrogen fluoride, and the stringent environmental regulations surrounding the handling, storage, and disposal of highly corrosive and toxic fluorinated compounds. Opportunities lie in developing advanced recycling and recovery technologies for TFA, promoting sustainable practices, and expanding its use in emerging high-growth fields like lithium-ion battery electrolytes and specialized electronic materials. The collective impact forces reflect a complex balance: while end-user demand is strong and innovation-driven, environmental and supply chain pressures necessitate continuous process improvements and investment in green chemistry alternatives to mitigate long-term risks and ensure market stability.

Segmentation Analysis

The Trifluoroacetic Acid market is meticulously segmented based on Purity, Application, and geographic region to accurately reflect diverse end-user requirements and regional consumption patterns. Segmentation by Purity, encompassing grades such as 99%, 99.5%, and higher, is critical, as pharmaceutical and advanced material applications demand extremely high purity levels to prevent contamination and ensure reaction integrity, driving pricing differentiation. Application segmentation highlights the dominance of pharmaceuticals and agrochemicals, which utilize TFA for synthesis, solvent properties, and catalysis, followed by its niche but growing use in polymer manufacturing and specialized chemical production. Regional analysis provides insights into production hubs in Asia Pacific and mature consumption markets in North America and Europe, crucial for strategic market positioning and supply chain planning.

- By Purity: 99%, 99.5%, Above 99.5%, Others (Technical Grade)

- By Application: Pharmaceuticals, Agrochemicals, Polymers and Resins, Chemical Synthesis, Others (Including Electronics and Energy)

- By Region: North America, Europe, Asia Pacific (APAC), Latin America, Middle East and Africa (MEA)

Value Chain Analysis For Trifluoroacetic Acid Market

The Trifluoroacetic Acid value chain is complex, starting with the upstream sourcing and processing of core raw materials, predominantly hydrogen fluoride (HF) and halocarbons, followed by specialized chemical synthesis processes to produce high-purity TFA. Upstream analysis focuses heavily on the availability and cost volatility of anhydrous hydrogen fluoride, which is a highly regulated and potentially hazardous material, making raw material supply security a major factor influencing production costs and profitability. Key players often maintain long-term contracts with HF suppliers or invest in captive production facilities to mitigate price fluctuations and ensure consistent quality. The manufacturing stage itself requires specialized, corrosion-resistant equipment due to TFA's aggressive nature, demanding significant capital investment and adherence to stringent environmental, health, and safety (EHS) standards.

The midstream involves the purification, grading, and packaging of TFA into various purities required by end-users. The distribution channel is bifurcated into direct sales and indirect sales. Direct channels are typically employed for high-volume sales to major pharmaceutical and large agrochemical manufacturers who require customized packaging and dedicated technical support, ensuring tight control over product specifications and delivery timelines. Indirect channels involve regional distributors and specialty chemical traders who serve smaller R&D labs, academic institutions, and niche chemical companies, providing smaller batch sizes and localized inventory management, which is particularly relevant in fragmented markets like specialty polymers.

Downstream analysis is defined by the high-value applications in pharmaceuticals and agrochemicals. For pharmaceuticals, TFA is immediately integrated into the synthesis of therapeutic peptides and complex molecules; its quality directly impacts the purity of the final API. The final consumption stage is highly regulated, necessitating robust documentation and traceability throughout the supply chain. The overall value addition occurs significantly at the manufacturing and purification stages (creating high-purity grades) and at the downstream application stage, where TFA enables the creation of proprietary, high-margin end products. Efficient logistics for this hazardous chemical are crucial, requiring specialized transportation and storage protocols.

Trifluoroacetic Acid Market Potential Customers

The primary potential customers and end-users of Trifluoroacetic Acid are large pharmaceutical corporations, Contract Development and Manufacturing Organizations (CDMOs), and leading agrochemical producers. Pharmaceutical companies constitute the largest consumer base, utilizing TFA extensively as a cleavage reagent in Solid Phase Peptide Synthesis (SPPS) and as a crucial catalyst or solvent in the production of complex Active Pharmaceutical Ingredients (APIs). These customers require extremely high-purity grades (99.5% and above) to meet stringent regulatory standards (e.g., FDA, EMA) and ensure drug safety and efficacy. Their purchasing decisions are primarily driven by product consistency, supply reliability, and compliance with global Good Manufacturing Practices (GMP).

Agrochemical manufacturers represent the second largest customer segment. They rely on TFA as a precursor for introducing the trifluoromethyl group into herbicides, insecticides, and fungicides. This chemical modification often enhances the biological activity, metabolic stability, and soil persistence of the final pesticide, leading to more effective crop protection products. These customers typically demand consistent, high-volume supply and often engage in long-term supply agreements with TFA producers to secure competitive pricing and guaranteed capacity, reflecting the seasonal and cyclical nature of agricultural demand. The complexity of new molecule synthesis in this sector continuously drives demand for specialized TFA derivatives.

Beyond these two dominant sectors, other significant potential customers include specialty polymer manufacturers, particularly those focused on fluoropolymers used in high-performance coatings, seals, and specialized membranes for electronics and aerospace. Research institutions, academic labs, and smaller specialty chemical producers also form a consistent customer base, albeit demanding smaller, laboratory-scale quantities, primarily using TFA as a strong non-oxidizing acid catalyst or solvent in niche organic synthesis reactions. The expanding energy sector, particularly R&D labs developing advanced electrolytes for lithium-ion batteries, is emerging as a critical future growth customer segment, requiring specialized grades of TFA for electrolyte precursor synthesis.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 485 Million |

| Market Forecast in 2033 | USD 715 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Merck KGaA, Honeywell International Inc., Solvay S.A., TCI Chemicals (India) Pvt. Ltd., Wuxi Yangshi Chemical Co., Ltd., Haltermann Carless, Lanxess AG, Central Glass Co., Ltd., Daikin Industries, Ltd., Loba Chemie Pvt. Ltd., AGC Inc., Alfa Aesar (Thermo Fisher Scientific), Sinochem Group, Kanto Chemical Co., Inc., SRF Limited, Nouryon, Chemours Company, Shandong Tianyuan Chemical Co., Ltd., J&K Scientific. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Trifluoroacetic Acid Market Key Technology Landscape

The manufacturing technology for Trifluoroacetic Acid predominantly relies on the oxidation of 2,2,2-trifluoroethanol or the reaction of sulfur trioxide with trifluoroacetyl fluoride, processes that have been standardized but are continuously being refined for higher yield, greater energy efficiency, and improved purity profiles. A major technological focus currently revolves around process intensification and continuous flow chemistry. Traditional batch processes are being replaced by continuous reactors, which offer better control over reaction kinetics, enhanced safety, and substantial reductions in manufacturing time and capital expenditure. These advanced methods are particularly crucial for producing the ultra-high-purity grades (Above 99.5%) demanded by sensitive pharmaceutical and electronic applications, where even trace impurities can compromise product performance.

A critical emerging technological trend involves the development and scaling of sustainable and green chemistry techniques to address the severe corrosion and environmental challenges associated with TFA manufacturing and handling. Researchers are exploring novel catalytic systems that operate under milder conditions, reducing energy input and minimizing hazardous byproducts. Furthermore, significant investment is directed towards advanced recovery and purification technologies, such as reactive distillation and membrane separation, specifically designed to reclaim TFA from complex organic synthesis waste streams, including those generated during large-scale peptide cleavage. Successful implementation of these recovery techniques can drastically reduce disposal costs and lower the environmental footprint of downstream users, offering a significant competitive edge to suppliers who integrate them.

The technological landscape is also being shaped by the adoption of sophisticated analytical methods necessary for quality control. High-performance liquid chromatography (HPLC) and Nuclear Magnetic Resonance (NMR) spectroscopy are routinely used, but manufacturers are increasingly integrating real-time process analytical technology (PAT) to monitor purity and concentration throughout the production cycle. This integration, often powered by AI algorithms, ensures batch-to-batch consistency and facilitates rapid adjustment of process parameters, guaranteeing that the delivered TFA meets the exacting specifications of the global supply chain, particularly those serving GMP-regulated environments. The push toward fluorination technologies that utilize less hazardous fluorine sources also indirectly impacts the future TFA synthesis landscape.

Regional Highlights

Geographically, the Trifluoroacetic Acid (TFA) market is categorized into North America, Europe, Asia Pacific (APAC), Latin America, and the Middle East and Africa (MEA). The Asia Pacific region is anticipated to maintain the highest growth trajectory, driven primarily by the massive shift of pharmaceutical and agrochemical manufacturing bases, particularly to China and India. These nations benefit from favorable manufacturing economics, increasing domestic drug consumption, and the rapid expansion of their chemical industry infrastructure. APAC countries serve not only their internal markets but also act as major global suppliers of generic drugs and agrochemical intermediates, creating relentless demand for essential reagents like TFA. Government incentives supporting R&D and large-scale synthesis projects further catalyze market expansion in this region, solidifying its dominant position in terms of production volume and future consumption growth.

North America and Europe currently represent mature markets characterized by high consumption of high-purity TFA, driven by established pharmaceutical R&D hubs and a strong emphasis on specialty chemicals. In North America, demand is stable, underpinned by cutting-edge drug discovery research and the dominance of major global pharmaceutical companies that require continuous supply for peptide therapeutics and novel small-molecule synthesis. Europe mirrors this trend, with strict quality standards favoring premium, high-purity TFA grades. While growth rates may be lower than in APAC, the value generated per unit of TFA consumed is higher due to the premium nature of the end products manufactured in these regions, emphasizing quality and supply chain resilience over pure volume.

Latin America and MEA are emerging markets, showing gradual but steady growth. Demand in these regions is primarily linked to local agrochemical production aimed at bolstering regional food security and, to a lesser extent, nascent pharmaceutical manufacturing efforts. Investment in local chemical infrastructure and increased foreign direct investment in specialty chemical manufacturing facilities will be key drivers for TFA adoption in these regions over the forecast period. Logistical challenges and fluctuating economic conditions, however, require specialized distribution strategies and robust supply chain planning to serve these diverse and geographically dispersed markets effectively.

- Asia Pacific (APAC): Dominates production and fastest-growing consumption hub, fueled by pharmaceutical and agrochemical manufacturing shift.

- North America: Mature market characterized by high consumption of ultra-high-purity TFA, driven by advanced R&D and biotech sectors.

- Europe: Stable demand centered around specialty chemical production and stringent regulatory compliance for pharmaceutical intermediates.

- Latin America: Emerging market with growth tied primarily to expanding agricultural chemical production needs.

- Middle East and Africa (MEA): Growth driven by infrastructure development and increasing regional demand for essential chemicals and agricultural inputs.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Trifluoroacetic Acid Market.- Merck KGaA

- Honeywell International Inc.

- Solvay S.A.

- TCI Chemicals (India) Pvt. Ltd.

- Wuxi Yangshi Chemical Co., Ltd.

- Haltermann Carless

- Lanxess AG

- Central Glass Co., Ltd.

- Daikin Industries, Ltd.

- Loba Chemie Pvt. Ltd.

- AGC Inc.

- Alfa Aesar (Thermo Fisher Scientific)

- Sinochem Group

- Kanto Chemical Co., Inc.

- SRF Limited

- Nouryon

- Chemours Company

- Shandong Tianyuan Chemical Co., Ltd.

- J&K Scientific

- Beijing Chemical Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Trifluoroacetic Acid market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for Trifluoroacetic Acid (TFA)?

The primary factor driving TFA demand is the accelerating expansion of the global pharmaceutical industry, specifically the high reliance on TFA as a cleavage reagent and solvent in the synthesis of complex therapeutic peptides and Active Pharmaceutical Ingredients (APIs).

What are the key purity grades of Trifluoroacetic Acid and where are they used?

Key purity grades include 99%, 99.5%, and above 99.5%. The ultra-high purity grades (99.5%+) are essential for pharmaceutical synthesis and advanced electronics, while lower grades are typically used in general chemical synthesis and certain agrochemical processes.

Which region currently dominates the production and consumption of TFA?

The Asia Pacific (APAC) region dominates both the production and rapidly growing consumption of TFA, driven by large-scale pharmaceutical and agrochemical manufacturing facilities, particularly in China and India.

What are the major restraints affecting the growth of the TFA market?

Major restraints include the high cost volatility and difficulty in sourcing raw materials, primarily hydrogen fluoride (HF), coupled with stringent environmental regulations governing the disposal and handling of corrosive and fluorinated chemical waste.

How is Trifluoroacetic Acid utilized in the agrochemical industry?

In the agrochemical industry, TFA serves as a vital precursor for introducing the trifluoromethyl group into pesticides (herbicides, fungicides), a modification that significantly enhances the efficacy, chemical stability, and biological activity of the final crop protection products.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Trifluoroacetic Acid (TFA) Market Size Report By Type (99.5% Trifluoroacetic Acid (TFA), 99.9% Trifluoroacetic Acid (TFA), Other), By Application (Medical Intermediates, Pesticide Intermediates, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Trifluoroacetic Acid (TFA) Market Statistics 2025 Analysis By Application (Medical Intermediates, Pesticide Intermediates), By Type (99.5% Trifluoroacetic Acid (TFA), 99.9% Trifluoroacetic Acid (TFA)), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Trifluoroacetic Acid Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (99.5% Trifluoroacetic Acid, 99.9% Trifluoroacetic Acid, Other), By Application (Medical Intermediates, Pesticide Intermediates, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager