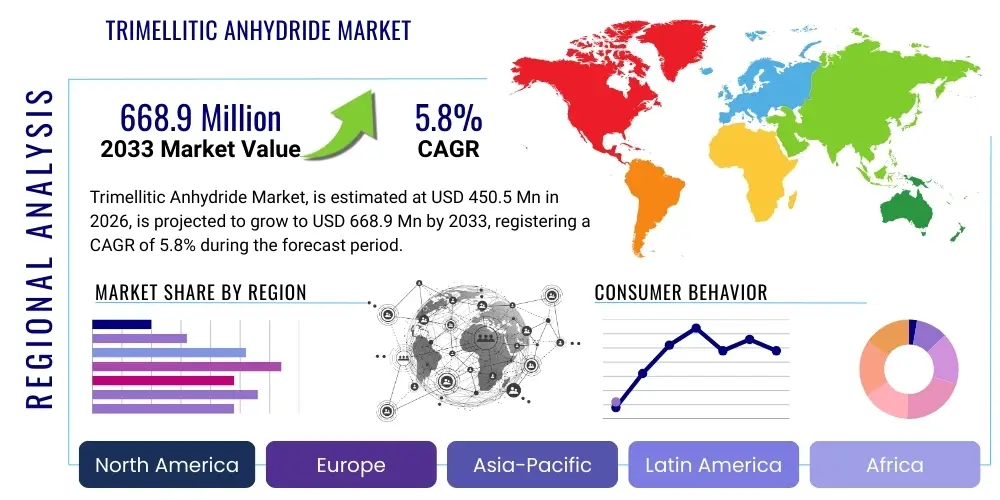

Trimellitic Anhydride Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439163 | Date : Dec, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Trimellitic Anhydride Market Size

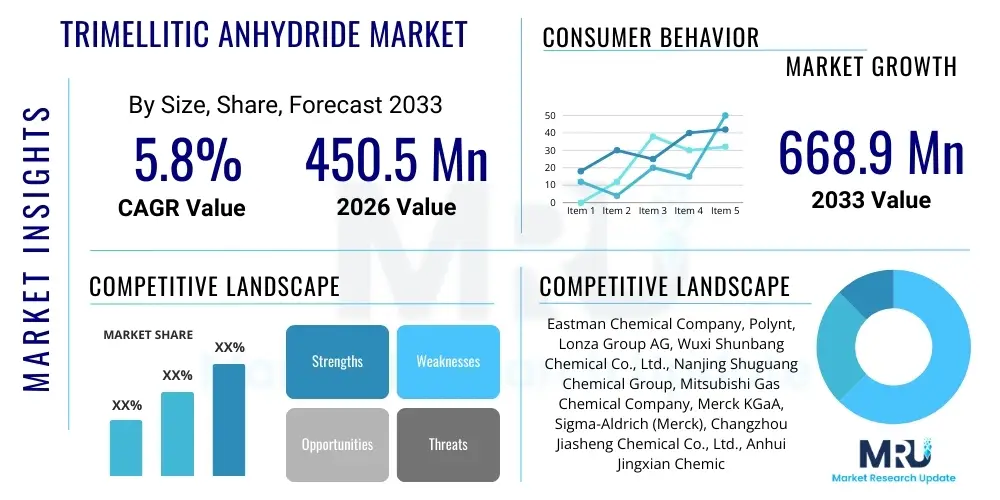

The Trimellitic Anhydride Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 668.9 Million by the end of the forecast period in 2033.

Trimellitic Anhydride Market introduction

The Trimellitic Anhydride (TMA) market revolves around a crucial intermediate chemical utilized extensively in the production of high-performance polymers, specialized plasticizers, and thermosetting resins. TMA is a versatile trifunctional anhydride, making it exceptionally valuable in applications requiring thermal stability, chemical resistance, and excellent electrical insulation properties. Its primary function is as a curing agent or raw material for synthesizing trimellitate esters, which are non-phthalate plasticizers noted for their performance in high-temperature wire and cable insulation, automotive components, and medical devices. The intrinsic benefits of TMA-derived products, such as low volatility and superior performance compared to conventional alternatives, solidify its critical position in demanding industrial sectors like electrical & electronics and automotive manufacturing.

The product is primarily manufactured through the oxidation of pseudocumene, followed by dehydration, resulting in a white, crystalline powder. Major applications hinge on its ability to impart durability and flexibility. For instance, in the formulation of high-solid coatings and powder coatings, TMA-based polyester resins enhance adhesion and surface hardness, crucial for industrial metal finishing and appliance coatings. The ongoing global transition towards safer, high-performance materials in consumer and industrial goods further amplifies the demand for TMA-derived products, particularly in regions enforcing stringent environmental regulations regarding traditional plasticizers.

Driving factors for market expansion include the exponential growth of the electrical vehicle (EV) sector, which requires specialized, heat-resistant insulation materials derived from TMA. Furthermore, the increasing demand for durable, scratch-resistant powder coatings in the construction and automotive industries supports volume growth. The continued investment in advanced infrastructure, particularly smart grids and renewable energy installations, also fuels the need for high-specification insulating varnishes and wire coatings, cementing TMA's role as an essential chemical building block in modern industrial development.

Trimellitic Anhydride Market Executive Summary

The Trimellitic Anhydride (TMA) market is characterized by robust growth driven fundamentally by technological advancements in materials science and rigorous regulatory pressures favoring high-performance, safer chemical intermediates. Current business trends indicate a significant shift in production capacity towards Asia Pacific, specifically China and India, leveraging cost advantages and rapidly escalating regional demand from the electrical and electronics, and construction sectors. A key segment trend is the accelerated adoption of TMA in non-phthalate plasticizers, driven by global health and environmental directives, making trimellitate esters a preferred substitute in sensitive applications such as food contact materials and medical tubing. Furthermore, the market structure is witnessing strategic vertical integration among major producers aiming to secure raw material supply (pseudocumene) and optimize production costs, enhancing overall supply chain resilience.

Regionally, Asia Pacific maintains market dominance due to high volume manufacturing of automotive components and consumer electronics, coupled with massive infrastructure development projects requiring advanced coatings and insulation. North America and Europe, while slower in terms of production capacity expansion compared to APAC, exhibit high demand for premium-grade TMA, specifically for specialized applications in aerospace, high-end automotive coatings, and complex electrical systems where performance specifications are critical and non-negotiable. These mature markets are innovators in formulating highly specialized TMA derivatives that offer superior thermal properties.

The segmentation analysis highlights that the plasticizers application segment continues to command the largest market share, directly benefiting from the phasing out of traditional orthophthalates. However, the fastest growth is observed within the polyester resins segment, largely due to the surge in demand for powder coatings and high-solid coatings used for protective and decorative finishes in sustainable building materials and industrial equipment. This sustained momentum across diverse end-use industries mitigates dependency on any single application, ensuring steady market progression throughout the forecast period, contingent primarily on stable feedstock pricing and effective regulatory management.

AI Impact Analysis on Trimellitic Anhydride Market

User queries regarding the impact of Artificial Intelligence (AI) on the Trimellitic Anhydride market primarily focus on three areas: optimization of the complex chemical synthesis process, efficiency improvements in supply chain management, and the role of AI in accelerating the discovery and formulation of new TMA-based derivatives. Users are keen to understand how AI-driven predictive modeling can mitigate the volatility associated with pseudocumene sourcing and pricing, a critical feedstock component. Furthermore, there is significant interest in how machine learning algorithms can analyze performance data to optimize the chemical structure of trimellitate plasticizers, tailoring them for specific end-user requirements in sectors like high-voltage electrical insulation or flexible photovoltaics. The expectation is that AI will minimize waste, reduce reaction times, and enhance product consistency, thereby lowering production costs and improving competitive positioning for manufacturers.

- AI-driven optimization of synthesis reaction parameters (temperature, pressure, catalyst concentration) to maximize TMA yield and purity, minimizing energy consumption during the complex oxidation and dehydration steps.

- Predictive maintenance analytics applied to production facilities, utilizing sensor data to forecast equipment failure, thus reducing unplanned downtime and enhancing operational efficiency and asset utilization rates.

- Machine learning models used for predictive feedstock (pseudocumene) pricing and supply chain risk management, providing proactive procurement strategies to buffer against commodity market volatility.

- Accelerated R&D through AI-guided formulation, simulating the performance characteristics of new TMA-derived plasticizers and resins under various stress conditions (heat, UV exposure, chemical aging) before laboratory synthesis.

- Enhanced quality control systems using computer vision and AI analytics to detect microscopic impurities or structural anomalies in the final TMA powder product, ensuring compliance with stringent industry purity standards for sensitive applications.

- Optimization of logistics routes and inventory management for sensitive chemical transport, reducing transportation costs and carbon footprint.

DRO & Impact Forces Of Trimellitic Anhydride Market

The Trimellitic Anhydride market dynamics are currently shaped by several strong drivers, including the legislative push towards non-phthalate plasticizers, the rapid expansion of the electrical and electronics industry requiring high-performance insulation, and increasing adoption of powder coatings in industrial applications. However, the market faces significant restraints, primarily centered around the volatility and scarcity of the key raw material, pseudocumene, which is derived from C9 aromatics. Additionally, the complex and capital-intensive nature of the TMA manufacturing process poses barriers to entry for new players, leading to a concentrated supply structure. Opportunities for growth lie in developing bio-based or alternative feedstocks to mitigate dependence on petrochemicals and expanding applications in emerging sectors like aerospace composites and advanced battery components, where superior thermal resistance is crucial. These factors interact as impact forces, where the high demand (Driver) often clashes with limited and price-volatile supply (Restraint), necessitating technological innovation (Opportunity) to stabilize the market equilibrium.

Segmentation Analysis

The Trimellitic Anhydride market is meticulously segmented based on purity level, specific application, and end-use industry, reflecting the diverse requirements of various industrial processes. Segmentation by purity is crucial because high-purity TMA (typically >99.5%) is mandated for sensitive applications such as electrical insulation varnishes and medical-grade plasticizers, where even minor impurities can compromise performance specifications. Lower purity grades are generally utilized in bulk applications like general-purpose polyester resins and some intermediate chemical synthesis processes.

The application segmentation is the most impactful differentiator, highlighting the versatility of TMA. The plasticizers segment, which involves converting TMA into trimellitate esters (like Trioctyl Trimellitate, TOTM), dominates the market value, catering primarily to the wire & cable and automotive sectors seeking superior performance under high-heat conditions. Meanwhile, the use of TMA in polyester resins for powder coatings represents a high-growth area due to its environmental advantage over solvent-based coatings and its superior physical properties. Understanding these distinct segments allows manufacturers to align their production capabilities and marketing efforts with specific high-growth or high-value niches.

- By Type:

- Purity > 99% (High-Grade)

- Purity 95% - 99% (Technical Grade)

- By Application:

- Plasticizers (Trimellitate Esters)

- Polyester Resins (For Powder Coatings)

- Curing Agents

- Insulation Materials (Varnishes)

- Others (Dyes, Pigments, Pharmaceuticals Intermediates)

- By End-Use Industry:

- Electrical & Electronics (Wire & Cable Insulation, Capacitors)

- Automotive (Interior Components, Under-the-Hood Parts)

- Construction (Coatings, Sealants)

- Industrial Coatings (Appliance Finishes, Metal Protection)

- Aerospace & Defense

- Medical Devices

Value Chain Analysis For Trimellitic Anhydride Market

The value chain for the Trimellitic Anhydride market begins fundamentally with the upstream segment, which is highly reliant on the petrochemical industry for the supply of key raw material: pseudocumene (1,2,4-trimethylbenzene). Pseudocumene is sourced from C9 aromatic streams generated during crude oil refining and petrochemical cracking processes. The upstream analysis is critical because the availability and fluctuating prices of pseudocumene directly dictate the production cost and profitability of TMA manufacturers. Integration into or long-term contracts with large petrochemical suppliers provides a significant competitive advantage in managing input costs, which are frequently subject to global oil market volatility and geopolitical stability. Efficient upstream management ensures a steady supply necessary for continuous operation of TMA synthesis plants, which require high energy input for the oxidation reaction.

The midstream segment involves the actual manufacturing of TMA through complex catalytic oxidation processes. This stage is dominated by specialized chemical companies that possess proprietary technology and adhere to rigorous quality control standards, especially for high-purity grades required by the electrical and aerospace industries. Distribution channels are varied; direct sales channels are common for large-volume customers (like major plasticizer producers or resin manufacturers) who purchase technical-grade TMA in bulk. Indirect distribution channels, utilizing specialized chemical distributors and regional agents, handle smaller orders or reach niche markets, particularly in regions with fragmented end-user bases. The choice of channel is often influenced by geographical distance, volume requirements, and the specific regulatory environment governing chemical transport and storage.

The downstream analysis focuses on the transformation of TMA into finished products, primarily high-performance plasticizers (trimellitate esters) and specialized polyester resins. These downstream users—operating in sectors such as wire and cable manufacturing, automotive part production, and industrial coating formulation—add significant value by integrating TMA derivatives into complex systems designed for durability and high-temperature performance. The success of the downstream industry is intrinsically linked to the performance specifications of the TMA supplied, underscoring the necessity for stringent quality compliance throughout the entire chain. Innovations downstream, such as the development of novel applications for TMA-derived products in next-generation lithium-ion batteries or advanced construction materials, continuously drive demand back up the chain.

Trimellitic Anhydride Market Potential Customers

Potential customers for Trimellitic Anhydride are predominantly large-scale industrial manufacturers that require high-performance chemical intermediates to formulate specialized products demanding superior thermal stability and electrical properties. The primary end-users or buyers are major chemical processors specializing in plasticizer synthesis, particularly those producing trimellitate esters like Trioctyl Trimellitate (TOTM) and Triisononyl Trimellitate (TINTM), which serve as key non-phthalate alternatives. These customers are driven by regulatory compliance and the need for materials suitable for high-specification applications, such as high-temperature wire insulation used in demanding automotive and aerospace environments, where conventional plasticizers fail to meet thermal criteria.

A second major customer segment includes manufacturers of high-solid and powder coatings. These companies purchase TMA for use in synthesizing polyester resins that form the backbone of protective and decorative coatings for appliances, industrial machinery, and architectural elements. The demand here is fueled by sustainability initiatives, as powder coatings offer zero or near-zero volatile organic compound (VOC) emissions, aligning with stricter environmental regulations globally. Customers in the construction and automotive sectors value the durability, scratch resistance, and enhanced aesthetic finish imparted by TMA-based resins.

Furthermore, specialized chemical formulators serving the electrical and electronics industries constitute a crucial customer base. They utilize TMA for synthesizing insulating varnishes and epoxy curing agents essential for motors, transformers, capacitors, and complex circuitry boards. These applications require exceptional dielectric strength and resistance to heat and moisture degradation, making the high-purity characteristics of TMA indispensable. The growth in electric vehicles (EVs) and sophisticated grid infrastructure further expands the buyer pool, as these technologies place increasing stress on electrical insulation materials, necessitating the superior performance characteristics provided by TMA derivatives.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 668.9 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Eastman Chemical Company, Polynt, Lonza Group AG, Wuxi Shunbang Chemical Co., Ltd., Nanjing Shuguang Chemical Group, Mitsubishi Gas Chemical Company, Merck KGaA, Sigma-Aldrich (Merck), Changzhou Jiasheng Chemical Co., Ltd., Anhui Jingxian Chemical Co., Ltd., Jiangsu Guotai International Group, Hangzhou Qianyang Chemical Co., Ltd., Shandong Xingguang Chemical Co., Ltd., Lotte Fine Chemical, ExxonMobil Chemical (Feedstock Supplier). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Trimellitic Anhydride Market Key Technology Landscape

The Trimellitic Anhydride (TMA) market relies heavily on sophisticated chemical engineering technologies, primarily centered around the catalytic oxidation of pseudocumene. The prevailing technology is the liquid-phase oxidation process, typically involving air or oxygen and a heavy metal catalyst system (often based on cobalt, manganese, and bromine). Critical technological advancements in this landscape focus on improving the yield, reducing energy intensity, and enhancing the purity of the final product, which is vital for high-specification applications. Manufacturers are continuously investing in process intensification technologies, such as improved reactor designs (e.g., bubble columns or loop reactors) and advanced heat integration systems, to manage the highly exothermic nature of the oxidation reaction safely and efficiently. The goal is to maximize the conversion of pseudocumene while minimizing the formation of unwanted byproducts, thus optimizing downstream purification steps like distillation and crystallization.

A significant area of technological focus is the development and commercialization of highly selective and robust catalyst systems. Traditional catalysts can deactivate over time, leading to reduced efficiency and increased operational costs. Newer catalyst technologies aim for longer lifecycles, improved resistance to poisons, and enhanced selectivity towards trimellitic acid formation, which is the precursor to TMA. Furthermore, the integration of advanced process control (APC) and sensor technologies plays a crucial role. These systems allow for real-time monitoring and adjustment of reaction kinetics, temperature profiles, and feedstock flow rates, ensuring consistent quality and enabling agile response to variations in raw material composition. This precision is especially important for producing the high-purity TMA grade demanded by the sensitive electrical insulation market.

Beyond synthesis, technological advancements are also impacting the downstream derivatives market. For plasticizers, there is significant R&D dedicated to optimizing esterification processes to create low-volatility, high-molecular-weight trimellitate esters that meet increasingly stringent regulatory standards (like REACH in Europe). For powder coatings, advancements involve customizing the molecular weight distribution and branching of TMA-based polyester resins to control flow properties, curing characteristics, and ultimate film performance. Emerging research is exploring sustainable production routes, including potential bio-based pathways for generating C9 aromatics, though these are still largely at the laboratory stage and present a long-term technological opportunity rather than a current commercial reality.

Regional Highlights

- Asia Pacific (APAC): APAC dominates the global Trimellitic Anhydride market in terms of production volume and consumption, driven primarily by robust growth in major economies such as China, India, and South Korea. China is both the largest producer and consumer, utilizing vast quantities of TMA in its rapidly expanding manufacturing sectors, including automotive, construction, and high-volume electronics production. The region benefits from lower manufacturing costs and substantial governmental investment in infrastructure development, which fuels demand for durable coatings and high-performance wire insulation. The shift of global manufacturing hubs to this region ensures sustained, rapid growth, making APAC the key focus for capacity expansion and strategic investment.

- North America: North America represents a mature, high-value market characterized by stringent performance standards, particularly in the aerospace and specialized automotive sectors. Consumption growth here is steady, prioritizing high-purity TMA for critical applications such as specialized insulating varnishes and non-phthalate medical-grade plasticizers. Regulatory pressure, especially the move away from traditional phthalates, is a strong regional driver, ensuring sustained demand for trimellitate esters. Technological innovation and specialized formulating capabilities define this market segment.

- Europe: Europe is defined by pioneering environmental regulations, notably the Registration, Evaluation, Authorisation, and Restriction of Chemicals (REACH) framework, which strongly favors the adoption of non-phthalate plasticizers like trimellitates. This regulatory environment fuels demand for TMA derivatives, particularly in sophisticated applications such as high-temperature cable sheathing and powder coatings for industrial and appliance finishing. While manufacturing capacity is constrained compared to APAC, Europe commands premium pricing for its high-specification, compliance-focused TMA products.

- Latin America and Middle East & Africa (MEA): These regions are emerging markets for TMA consumption. Latin America's demand is tied to cyclical construction activities and local automotive production. MEA, particularly the GCC nations, is seeing increasing demand linked to diversification efforts in industrial manufacturing and massive petrochemical infrastructure projects. Growth rates in these regions are projected to accelerate, driven by industrialization and urbanization requiring durable construction materials and reliable electrical systems, though the markets currently represent a smaller global share.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Trimellitic Anhydride Market.- Eastman Chemical Company

- Polynt

- Lonza Group AG

- Wuxi Shunbang Chemical Co., Ltd.

- Nanjing Shuguang Chemical Group

- Mitsubishi Gas Chemical Company

- Merck KGaA

- Sigma-Aldrich (Merck)

- Changzhou Jiasheng Chemical Co., Ltd.

- Anhui Jingxian Chemical Co., Ltd.

- Jiangsu Guotai International Group

- Hangzhou Qianyang Chemical Co., Ltd.

- Shandong Xingguang Chemical Co., Ltd.

- Lotte Fine Chemical

- ExxonMobil Chemical (Feedstock Supplier)

- BASF SE (Derivative Producer)

- Dairen Chemical Corporation

- Kao Corporation

Frequently Asked Questions

Analyze common user questions about the Trimellitic Anhydride market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary factors driving the growth of the Trimellitic Anhydride market?

Market growth is primarily driven by the mandatory shift towards non-phthalate plasticizers (trimellitate esters) due to global regulatory changes. Additional momentum comes from the expanding electrical and electronics sector, particularly the need for heat-resistant insulation in electric vehicles (EVs) and high-specification industrial coatings.

How does the volatility of pseudocumene affect the profitability of TMA producers?

Pseudocumene, derived from C9 aromatics, is the essential raw material for TMA production. Its price volatility, stemming from fluctuations in the petrochemical market, directly increases operational costs and reduces profit margins for TMA manufacturers who lack backward integration capabilities for secure feedstock supply.

Which application segment holds the largest share in the Trimellitic Anhydride market?

The plasticizers segment, responsible for the production of high-performance trimellitate esters (such as TOTM), currently holds the largest revenue share. These plasticizers are crucial for wire and cable jacketing, medical devices, and other applications requiring superior thermal stability and low volatility compared to standard plasticizers.

What is the significance of high-purity Trimellitic Anhydride in the industry?

High-purity TMA (typically >99.5%) is mandatory for specialized end-use sectors like electrical insulation varnishes, aerospace components, and sensitive medical applications. Purity directly influences the dielectric properties, thermal endurance, and overall reliability of the final formulated products in these mission-critical systems.

Which region is expected to exhibit the highest Compound Annual Growth Rate (CAGR) for TMA consumption?

Asia Pacific (APAC), led by countries such as China and India, is projected to register the highest CAGR. This growth is fueled by massive infrastructure investments, robust manufacturing output in the automotive and electronics sectors, and regional cost advantages in production.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager