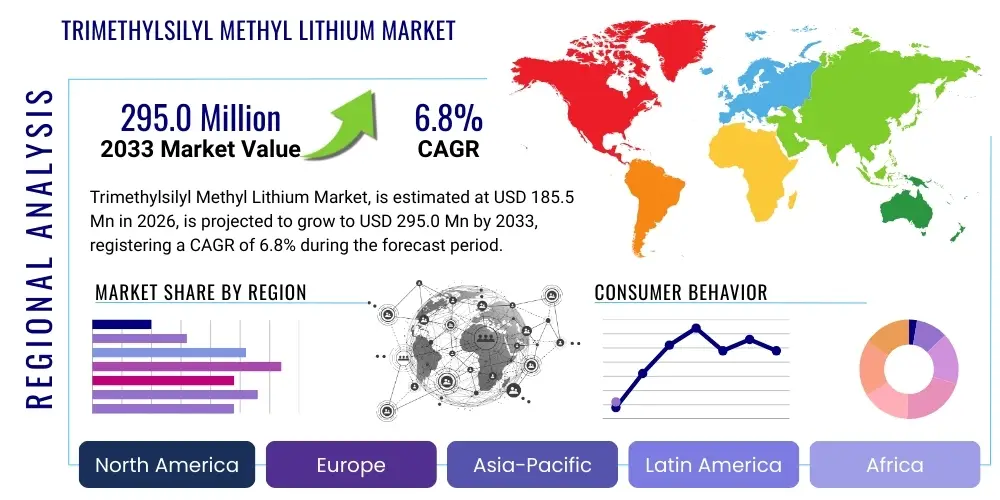

Trimethylsilyl Methyl Lithium Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437467 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Trimethylsilyl Methyl Lithium Market Size

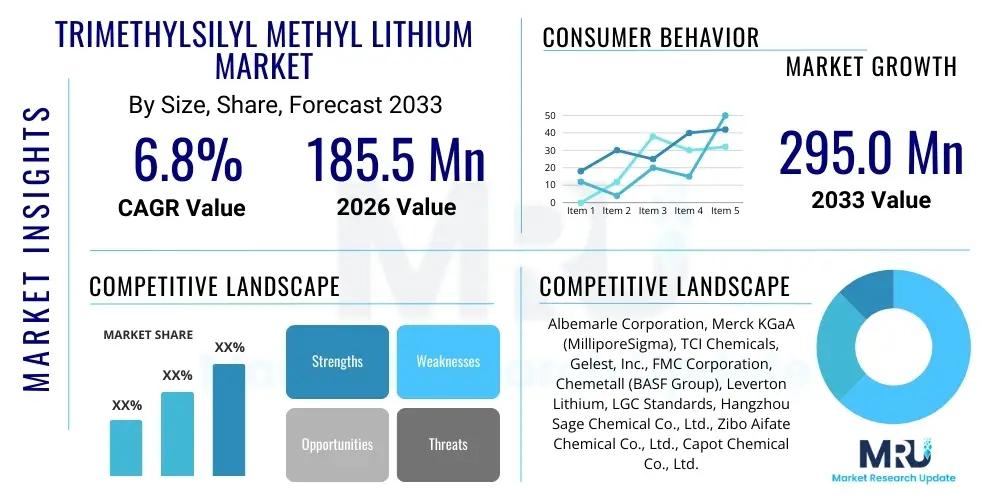

The Trimethylsilyl Methyl Lithium Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at $185.5 million in 2026 and is projected to reach $295.0 million by the end of the forecast period in 2033.

Trimethylsilyl Methyl Lithium Market introduction

Trimethylsilyl Methyl Lithium (TMSML) is a highly specialized organolithium reagent critical for advanced chemical synthesis across multiple high-value industries. Known chemically as ((CH3)3SiCH2Li), this compound serves primarily as a strong, non-nucleophilic base and a versatile reagent for introducing the trimethylsilylmethyl group into various organic molecules. Its unique reactivity profile, which balances strong basicity with specific nucleophilic character, makes it indispensable in the creation of complex pharmaceutical intermediates, specialized polymers, and advanced electronic materials. The market growth is fundamentally driven by the escalating demand for complex Active Pharmaceutical Ingredients (APIs) and the continuous innovation within material science sectors requiring precise molecular architectures.

The primary applications of TMSML lie in its utility as a powerful metalation reagent, facilitating regioselective substitution and enabling the synthesis of silicon-containing organic compounds that are often precursors for high-performance materials. It is widely employed in lithium-halogen exchange reactions, the preparation of silyl-substituted alkenes and alkynes, and as a key component in sophisticated catalytic systems. Due to its extreme sensitivity to moisture and oxygen, TMSML requires stringent handling protocols and specialized inert atmosphere manufacturing, contributing to its high cost structure but ensuring its reliable performance in critical synthetic pathways.

The core benefits derived from using Trimethylsilyl Methyl Lithium include high reaction selectivity, excellent yield generation in complex synthesis steps, and the ability to introduce functional groups that are otherwise difficult to incorporate. Driving factors include the robust pipeline of small molecule drugs relying on intricate synthetic routes, the emergence of silicon-based materials in semiconductor manufacturing, and the increasing investment in R&D aimed at developing novel organosilicon compounds for catalysis and polymer science. These factors collectively establish TMSML as a strategically important, albeit niche, reagent within the global fine chemicals and specialty materials landscape.

Trimethylsilyl Methyl Lithium Market Executive Summary

The Trimethylsilyl Methyl Lithium market is characterized by robust growth driven predominantly by the expanding global pharmaceutical sector, particularly in the synthesis of complex APIs and advanced intermediates where highly controlled organometallic chemistry is non-negotiable. Business trends show a strategic focus on expanding manufacturing capacities within Asia Pacific to leverage lower operating costs, coupled with intensified R&D efforts in North America and Europe to explore novel applications in materials science and microelectronics. Key suppliers are prioritizing the development of high-purity, standardized solutions and specialized packaging to ensure stability during transport and storage, addressing one of the primary historical challenges of this volatile reagent. The market structure remains relatively concentrated, dominated by a few specialized chemical manufacturers capable of handling pyrophoric and moisture-sensitive compounds at commercial scale.

Regional trends indicate that Asia Pacific (APAC) is projected to exhibit the fastest growth rate, fueled by the rapid expansion of generic and specialty chemical manufacturing hubs in China and India, alongside the substantial electronics industry demand in South Korea and Taiwan. North America and Europe, while growing steadily, remain critical markets primarily due to high-value R&D activities, early-stage drug discovery, and the established presence of major pharmaceutical and specialty polymer companies. Demand fluctuations often correlate directly with the launch cycles of new drugs requiring complex silylation steps. Furthermore, stringent regulatory environments in developed economies place a premium on high-quality, traceable reagents, benefiting established suppliers.

Segmentation trends highlight the increasing dominance of the High Purity Grade segment, particularly required by the semiconductor and advanced materials industries to meet exacting specification standards, minimizing defects in final products. Application-wise, the Pharmaceutical segment maintains the largest market share due to the high volume and high value associated with drug synthesis, but the Electronics and Polymer additives segments are gaining traction, driven by ongoing miniaturization trends and the development of high-performance elastomers and coatings. Suppliers are increasingly offering TMSML in specialized forms, such as custom molarity solutions in specific solvents (e.g., hexane, THF), to cater precisely to diverse end-user reaction requirements, thereby improving efficiency and safety at the customer site.

AI Impact Analysis on Trimethylsilyl Methyl Lithium Market

User inquiries regarding AI's influence on the Trimethylsilyl Methyl Lithium market frequently center on how machine learning can enhance the safety and efficiency of synthesizing and utilizing this highly reactive organometallic compound. Common themes include the optimization of reaction parameters, predicting unwanted side reactions or decomposition pathways, and improving supply chain resilience through predictive demand forecasting. Users seek assurance that AI tools can mitigate the inherent risks associated with handling pyrophoric reagents like TMSML, specifically through digital twin modeling of reactor conditions and automated safety monitoring systems. The expectation is that AI-driven process optimization will reduce reagent waste, lower production costs, and accelerate the discovery of new synthetic routes utilizing TMSML in pharmaceutical and material applications, ultimately impacting the demand curve and purity requirements for the reagent itself.

AI's primary influence is manifested in accelerating synthetic chemistry pipelines. Machine learning algorithms are now being used to analyze vast datasets of organolithium reactions, allowing chemists to predict the most effective stoichiometry, solvent choice, and temperature profiles for TMSML-mediated transformations, drastically cutting down empirical testing time. This predictive capability minimizes the risk of thermal runaways or unexpected decomposition, which are significant concerns when working with reactive compounds. Furthermore, generative AI tools are assisting in the design of novel molecules that incorporate the trimethylsilylmethyl group, opening up new application spaces in material science by designing polymers or catalysts with enhanced properties, thus stabilizing future demand for the core reagent.

In the commercial domain, AI enhances logistics and quality control. Predictive maintenance schedules for specialized inert atmosphere reactors and automated purity analysis systems (using chemometrics) ensure consistent product quality, a crucial factor for sensitive end-use applications like microelectronics. Supply chain models use AI to anticipate regional demand spikes for specific TMSML grades, ensuring suppliers can maintain adequate, stable inventory levels while minimizing the risks associated with storing large quantities of a volatile reagent. This integration of AI streamlines complex manufacturing processes, making the high-purity production of TMSML more scalable and economically viable.

- AI optimizes complex synthetic pathways involving TMSML, enhancing reaction yield and selectivity.

- Predictive modeling minimizes safety hazards associated with handling pyrophoric organolithiums.

- Machine learning improves real-time quality control and purity analysis of the manufactured reagent.

- AI-driven supply chain forecasting stabilizes inventory and logistics for highly volatile chemicals.

- Generative chemistry tools accelerate the discovery of novel silicon-containing molecules utilizing TMSML as a key building block.

DRO & Impact Forces Of Trimethylsilyl Methyl Lithium Market

The market dynamics of Trimethylsilyl Methyl Lithium are governed by a complex interplay of high-growth drivers stemming from pharmaceutical synthesis, stringent safety restraints imposed by its inherent reactivity, and substantial opportunities emerging from high-tech materials. The strongest driving force remains the increasing complexity of new chemical entities (NCEs) in drug development, which frequently necessitate highly specific, powerful reagents like TMSML to achieve desired molecular structures with high fidelity. However, the compound’s extreme sensitivity to air and moisture, requiring high-cost, specialized infrastructure for production, handling, and transportation, acts as a significant restraint, limiting the number of capable suppliers and often translating into higher procurement costs for end-users. Opportunities arise from breakthroughs in continuous flow chemistry, which promise safer, more efficient synthesis methods, potentially lowering production barriers and expanding the addressable market, especially in the development of next-generation lithium-ion battery additives and specialized optical materials.

Drivers: The global expansion of the pharmaceutical outsourcing industry, particularly Contract Development and Manufacturing Organizations (CDMOs), is fueling demand, as these entities require reliable access to specialized reagents for their clients' pipelines. The push for greater efficacy and selectivity in new drug molecules often mandates the use of precision reagents, bolstering the necessity for TMSML. Additionally, the proliferation of silicon-based organic compounds in electronic applications, such as organic light-emitting diodes (OLEDs) and specialized protective coatings for semiconductors, necessitates high-purity TMSML as a precursor. This synergy between biomedical and material science sectors provides a diversified, resilient growth base.

Restraints: The primary restraint is the inherent hazard profile of Trimethylsilyl Methyl Lithium, which classifies it as a pyrophoric substance. This requires expensive, specialized handling equipment (e.g., glove boxes, inert gas purging systems) and highly trained personnel, increasing both manufacturing overhead and end-user operational costs. Regulatory scrutiny regarding the transport and storage of hazardous materials further complicates the supply chain, often leading to longer lead times and limiting the accessible geographic market for small-scale buyers. Furthermore, the availability of alternative, less hazardous reagents for certain standard silylation tasks, though often less effective in complex settings, poses a competitive constraint in less demanding applications.

Opportunities: Significant growth potential lies in the continuous advancement of synthesis techniques, specifically micro-reaction technology and flow chemistry, which allow for the safe, continuous production of volatile reagents like TMSML on demand, potentially reducing the need for large-scale storage. Furthermore, the burgeoning field of specialized polymer synthesis, focusing on high-performance elastomers and adhesives that require precise chain termination or functionalization using TMSML, represents a niche but high-value opportunity. The integration of TMSML derivatives into novel battery electrolytes and components for electric vehicles also presents a substantial, long-term growth trajectory as the energy storage market matures.

Segmentation Analysis

The Trimethylsilyl Methyl Lithium market is primarily segmented based on Purity Grade, Application, and geographic region. Analyzing these segments provides crucial insights into market dynamics, price sensitivity, and high-growth areas. Purity Grade is paramount, as the required quality differs significantly between bulk chemical synthesis and high-precision applications like electronics. Standard Grade (95-98% purity) serves general organic synthesis and polymer production, where minor impurities are tolerable. Conversely, High Purity Grade (99%+), often supplied with extremely low transition metal and moisture content, is essential for advanced material science and critical pharmaceutical intermediates where residual contamination can severely compromise product performance or safety.

Application segmentation reveals a dominant role for the Pharmaceutical sector, driven by the synthesis of complex APIs, including antiviral drugs, oncology agents, and cardiovascular medicines, where TMSML acts as a key building block. The Electronic Materials segment is the fastest-growing niche, focusing on the production of specialized coatings, photoresists, and precursors for silicon deposition processes, which require ultra-high purity to ensure device reliability and performance. The Polymers and Catalysts segment encompasses the use of TMSML in polymerization initiation, chain transfer, and the development of highly specialized organometallic catalysts, particularly in elastomer manufacturing and synthetic rubber production.

Geographically, market segmentation reflects a dichotomy between consumption centers (North America and Europe) and production hubs (Asia Pacific). Pricing structures vary significantly across these segments; High Purity Grade reagents command premium prices due to the intense purification requirements and specialized packaging. The trend towards customized solutions, such as different concentrations tailored to specific reactor volumes and solvent preferences, further refines market segmentation, allowing key vendors to offer high-value, bespoke services rather than standardized bulk products.

- Purity Grade

- Standard Grade (95-98%)

- High Purity Grade (>99%)

- Application

- Pharmaceutical Synthesis (APIs and Intermediates)

- Electronic Materials (Semiconductors, OLEDs, Photoresists)

- Polymer and Specialty Chemicals (Elastomers, Catalysts)

- Research and Development

- Form/Concentration

- Solution in Hydrocarbon Solvents (e.g., Hexane)

- Solution in Ethers (e.g., THF)

- Solid/Powder Form (Less Common, Highly Specialized)

- End-Use Industry

- Contract Development and Manufacturing Organizations (CDMOs)

- Integrated Pharmaceutical Companies

- Material Science and Polymer Manufacturers

- Semiconductor Manufacturers

Value Chain Analysis For Trimethylsilyl Methyl Lithium Market

The value chain for Trimethylsilyl Methyl Lithium is highly specialized and characterized by complexity in the synthesis and inherent risks in handling, leading to high margins concentrated at the manufacturing and specialized distribution stages. The upstream analysis focuses on the procurement of primary raw materials: high-quality lithium metal (or its precursors) and trimethylsilyl chloride (TMSCl). The purity and consistent supply of these raw materials are foundational, requiring strong sourcing relationships. The core manufacturing process involves highly controlled reaction conditions, typically utilizing hydrocarbons or ethers as solvents under strictly inert atmospheres (argon or nitrogen). The expertise required for the Grignard-type reaction or related syntheses to achieve high yield and purity limits the number of qualified producers globally, creating a high barrier to entry at this stage. Strict quality control, including real-time spectroscopy and titrimetric analysis, is non-negotiable before packaging.

The distribution channel is critical due to the highly reactive, pyrophoric nature of TMSML. Direct distribution is often favored for large-volume customers (e.g., major CDMOs or integrated chemical firms) to ensure minimal handling risk and maintain product integrity, utilizing specialized tankers or lecture bottles equipped with appropriate safety seals and inert gas blankets. Indirect distribution relies on specialized chemical distributors who possess the requisite hazardous materials handling certifications, cold-chain storage capabilities, and expertise in managing volatile organometallics. These distributors act as crucial intermediaries, servicing smaller R&D laboratories and mid-sized specialty chemical producers globally. The high logistics cost associated with specialized packaging and mandatory inert atmosphere transport significantly contributes to the final price structure, impacting profitability across the downstream segments.

The downstream analysis centers on the utilization of TMSML by end-users. Primary downstream applications are found in the synthesis of complex organic intermediates, where the product is consumed as a critical reagent in stoichiometric amounts. End-users invest heavily in safety infrastructure (glove boxes, pressure regulators, emergency containment) to safely manage the reagent. Feedback from downstream pharmaceutical and electronic material manufacturers, particularly concerning purity specifications and solvent preferences, heavily influences upstream production protocols. Successful value chain participants maintain stringent control over every step, from raw material purification to final delivery, ensuring product stability and minimizing risk for the high-value synthesis performed by the potential customers.

Trimethylsilyl Methyl Lithium Market Potential Customers

The potential customer base for Trimethylsilyl Methyl Lithium spans across highly specialized and technologically advanced industries that require precision chemical synthesis. The largest consumption segment comprises Contract Development and Manufacturing Organizations (CDMOs) and Contract Research Organizations (CROs) serving the pharmaceutical and biotechnology sectors. These organizations utilize TMSML in the non-routine synthesis of novel APIs and complex intermediates, leveraging its unique reactivity for challenging metalation and silylation reactions that are vital for creating next-generation therapeutic compounds. These customers prioritize high purity, guaranteed concentration, and reliable, uninterrupted supply due to the critical nature of their manufacturing operations and regulatory timelines.

Another significant customer category includes integrated pharmaceutical and specialty chemical companies that conduct in-house synthesis of proprietary intermediates or high-value specialty monomers. These firms often require bulk quantities of standard-grade TMSML for routine, high-volume production runs. Their purchasing decisions are highly sensitive to cost-efficiency and security of supply. The third major group consists of manufacturers in the advanced materials and electronics sectors, particularly those involved in producing semiconductor precursors, specialized photoresists, and high-performance silicone-containing polymers. These customers typically demand the highest possible purity grades (often exceeding 99.5%) and require stringent traceability and quality certification to meet the exacting standards of microelectronics manufacturing.

Furthermore, academic and industrial research laboratories focused on organic and organometallic chemistry represent a perpetual, smaller-volume customer base. These entities drive innovation by exploring new synthetic methodologies and novel compounds incorporating the trimethylsilylmethyl group. While their volume is low, they are critical for determining future applications and market growth vectors. These diverse end-users collectively define the demand profile for TMSML, emphasizing the market requirement for highly specialized products coupled with comprehensive technical support regarding safe handling and reaction optimization.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $185.5 Million |

| Market Forecast in 2033 | $295.0 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Albemarle Corporation, Merck KGaA (MilliporeSigma), TCI Chemicals, Gelest, Inc., FMC Corporation, Chemetall (BASF Group), Leverton Lithium, LGC Standards, Hangzhou Sage Chemical Co., Ltd., Zibo Aifate Chemical Co., Ltd., Capot Chemical Co., Ltd., American Elements, J & K Scientific, Strem Chemicals, Parchem fine & specialty chemicals, Nanjing Suru Chemical Co., Ltd., Alfa Aesar (Thermo Fisher Scientific), Toronto Research Chemicals. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Trimethylsilyl Methyl Lithium Market Key Technology Landscape

The technology landscape governing the Trimethylsilyl Methyl Lithium market is centered on safety, purity, and efficiency in handling highly reactive organometallic reagents. The core technology involves highly sophisticated inert atmosphere manufacturing systems, utilizing high-vacuum lines, strictly purified inert gases (usually argon or high-purity nitrogen), and specialized stainless steel reactors capable of withstanding extreme pressure and temperature variations. Achieving ultra-high purity, essential for electronic applications, relies on advanced purification techniques such as precise distillation and fractional crystallization under cryogenic conditions, followed by rigorous analytical testing (e.g., quantitative NMR spectroscopy, specialized titration methods, and ICP-MS for metal trace analysis) to confirm final concentration and impurity profile.

A burgeoning technological trend is the adoption of continuous flow chemistry (CFC) for the synthesis of TMSML. Traditional batch processes carry inherent risks when dealing with highly exothermic reactions involving organolithiums; CFC utilizes microreactors to manage reaction intermediates instantly, offering superior control over temperature and residence time, which significantly enhances safety, reduces the inventory of hazardous materials at any given time, and often improves product uniformity. This shift towards flow manufacturing not only mitigates safety concerns but also allows for modular, scalable production, enabling suppliers to respond quickly to varying market demands for specific concentrations and purities. Investment in specialized pumping systems capable of handling corrosive and volatile solvents under inert conditions is central to this technological pivot.

Furthermore, the packaging and logistics segment employs cutting-edge technologies crucial for product stability. Specialized septum-sealed bottles, lecture bottles, and larger transport containers are engineered to maintain a strict inert atmosphere and prevent any ingress of oxygen or moisture, often requiring real-time pressure and temperature monitoring during transit. Specialized dosing and transfer systems, such as advanced cannulation setups and automated liquid dispensing tools, are becoming standard requirements for end-users, ensuring that the high-purity reagent can be safely introduced into their reactors without contamination or exposure. This technological push is focused less on the chemical synthesis itself and more on the safe, reproducible delivery and integration of the reactive compound into customer processes.

Regional Highlights

The market distribution of Trimethylsilyl Methyl Lithium is geographically polarized, reflecting global patterns of high-value chemical production and specialized R&D investment.

- North America: This region holds a significant market share, driven primarily by robust biomedical and pharmaceutical R&D activities, particularly in the United States. Major integrated pharmaceutical companies and leading CROs maintain high demand for high-purity TMSML for early-stage drug discovery and clinical trial material production. The presence of advanced materials research institutions and established semiconductor manufacturers also contributes substantially to the market, especially for reagents requiring stringent quality control. The regulatory environment here is demanding regarding chemical safety and handling, favoring established suppliers with proven track records.

- Europe: Europe represents a mature market characterized by strong demand from the fine chemicals industry, advanced material science centers, and specialized polymer manufacturers, notably in Germany, Switzerland, and the UK. The European market emphasizes innovation in sustainable chemistry and process efficiency, increasingly utilizing TMSML in highly selective catalytic processes. While R&D activity is strong, there is also a significant manufacturing base for specialty polymers and additives, maintaining steady demand for standard and high-purity grades.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region during the forecast period. This growth is underpinned by the massive expansion of the generics and specialty chemical manufacturing sectors in China and India, which are increasingly using complex reagents like TMSML to produce sophisticated intermediates for global supply chains. Furthermore, the region’s dominance in electronics manufacturing (South Korea, Taiwan, Japan) creates enormous demand for ultra-high purity grades used in semiconductor and display panel production. Investment in local manufacturing capacity for organolithiums is accelerating across the region to reduce reliance on Western suppliers.

- Latin America, Middle East, and Africa (MEA): These regions currently account for a smaller share of the global market. Demand is generally restricted to academic research institutions and small-scale specialty chemical production, often relying heavily on imports from European or North American distributors. However, emerging investments in local pharmaceutical and petrochemical industries, particularly in countries like Brazil and Saudi Arabia, suggest future growth potential as these economies diversify their manufacturing capabilities and increase their complexity of chemical output.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Trimethylsilyl Methyl Lithium Market.- Albemarle Corporation

- Merck KGaA (MilliporeSigma)

- TCI Chemicals

- Gelest, Inc.

- FMC Corporation

- Chemetall (BASF Group)

- Leverton Lithium

- LGC Standards

- Hangzhou Sage Chemical Co., Ltd.

- Zibo Aifate Chemical Co., Ltd.

- Capot Chemical Co., Ltd.

- American Elements

- J & K Scientific

- Strem Chemicals

- Parchem fine & specialty chemicals

- Nanjing Suru Chemical Co., Ltd.

- Alfa Aesar (Thermo Fisher Scientific)

- Toronto Research Chemicals

- Santa Cruz Biotechnology

- Wacker Chemie AG

Frequently Asked Questions

Analyze common user questions about the Trimethylsilyl Methyl Lithium market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Trimethylsilyl Methyl Lithium (TMSML) and what are its primary uses?

Trimethylsilyl Methyl Lithium (TMSML) is a highly reactive organolithium compound used primarily as a strong, non-nucleophilic base or a trimethylsilylmethylating reagent in advanced organic synthesis. Its primary applications include synthesizing complex Active Pharmaceutical Ingredients (APIs), creating specialized electronic materials, and functioning as an initiator or functionalization agent in specialty polymer production.

What factors are driving the growth of the Trimethylsilyl Methyl Lithium market?

Market growth is driven by the increasing global demand for complex small molecule drugs requiring precision synthesis, the expansion of the electronics sector (especially semiconductors and OLEDs) requiring ultra-high purity organosilicon precursors, and ongoing innovation in high-performance polymer and catalyst development utilizing TMSML's unique reactivity.

What major challenges or restraints affect the supply of TMSML?

The primary restraints include the extreme inherent reactivity of TMSML, which is pyrophoric and highly moisture-sensitive, necessitating specialized, expensive inert-atmosphere manufacturing and handling infrastructure. High regulatory burden, complex logistics for hazardous materials transport, and the need for specialized end-user safety equipment also significantly restrict market expansion and availability.

Which purity grade of Trimethylsilyl Methyl Lithium is most important for the electronics industry?

The High Purity Grade (>99%) of Trimethylsilyl Methyl Lithium is essential for the electronics industry, particularly for semiconductor and display panel manufacturing. This grade minimizes trace metal impurities and water content, which are critical requirements to prevent defects and ensure the reliability and performance of advanced electronic components.

How is technological advancement influencing the safety of TMSML production?

Technological advancement is heavily focused on implementing continuous flow chemistry (CFC) and micro-reactor technology. CFC significantly enhances safety by reducing the overall inventory of the volatile reagent present at any moment, offering superior control over exothermic reactions, and ensuring faster, more stable synthesis under strictly controlled inert conditions compared to traditional batch processes.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager