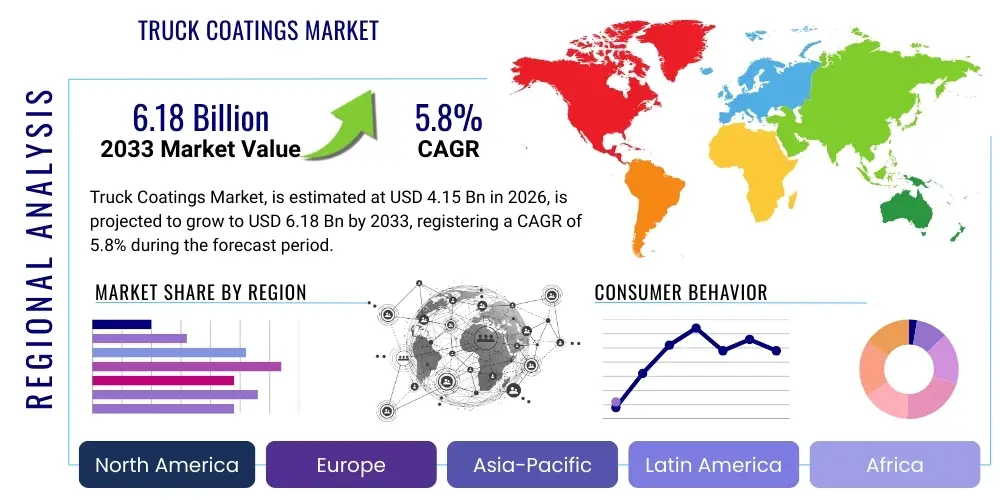

Truck Coatings Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435832 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Truck Coatings Market Size

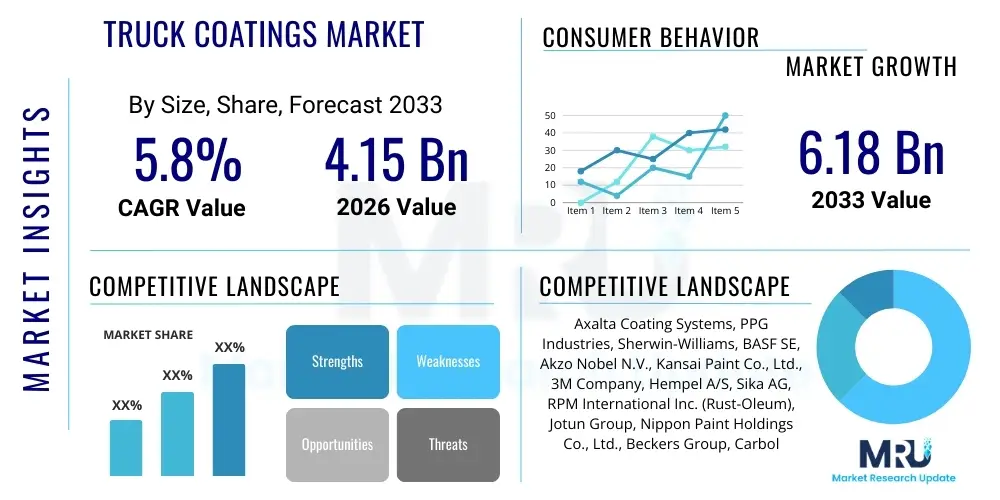

The Truck Coatings Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 4.15 Billion in 2026 and is projected to reach USD 6.18 Billion by the end of the forecast period in 2033. This robust expansion is primarily driven by the increasing global demand for heavy-duty commercial vehicles, coupled with stringent regulatory standards mandating improved vehicle longevity, corrosion protection, and aesthetic durability, especially in regions focusing on infrastructure development and logistics optimization.

Market size determination considers the volumetric usage of various coating types—including primers, basecoats, clearcoats, and specialized bedliners—across Original Equipment Manufacturers (OEMs) and the expansive automotive aftermarket. The valuation encompasses high-performance coating technologies such as polyurethanes, epoxies, and specialized fluoropolymers, which are critical for enhancing resistance against mechanical abrasion, chemical exposure, and UV degradation inherent to truck operations. Furthermore, the shift toward sustainable and low-VOC (Volatile Organic Compound) coating solutions significantly influences pricing structures and market valuation over the forecast period, reflecting investments in eco-friendly formulation research and development.

Truck Coatings Market introduction

The Truck Coatings Market encompasses a specialized segment of the industrial coatings sector dedicated to protecting and enhancing the surfaces of light, medium, and heavy-duty trucks. These coatings are essential functional materials applied to both the exterior body and interior components, including chassis, engine parts, truck beds, and specialized trailers. The primary function of truck coatings extends beyond aesthetics, providing crucial defense mechanisms against environmental stressors such as corrosion, chipping, chemical spills, and extreme weather conditions. Key products include high-solid liquid coatings, powder coatings, and specialized protective linings (such as polyurea and polyurethane bedliners), tailored to meet the rigorous performance requirements of commercial and fleet vehicles that endure high operational mileage and severe working environments.

Major applications of these protective materials span across several key areas: ensuring the structural integrity of truck bodies and frames, maintaining the longevity of valuable fleet assets, and supporting vehicle branding through high-gloss, durable finishes. The benefits derived from superior truck coatings include reduced maintenance frequency, enhanced resale value of commercial assets, and compliance with increasingly stringent regulatory mandates related to environmental protection and vehicle safety. Driving factors accelerating market growth include the steady globalization of logistics networks, necessitating more durable transport vehicles; rapid technological advancements leading to the development of higher-performance, multifunctional coatings (e.g., self-healing and anti-microbial variants); and the continued proliferation of light commercial vehicles (LCVs) and pickup trucks, which demand specialized, ruggedized protective finishes for utility applications.

Truck Coatings Market Executive Summary

The Truck Coatings Market is experiencing robust growth driven by significant business trends focused on sustainability, operational efficiency, and material science innovation. Key business trends involve the accelerated transition from solvent-borne to high-solids, waterborne, and powder coating technologies to meet tightening environmental regulations globally, particularly concerning VOC emissions. Furthermore, strategic partnerships between major coating manufacturers and leading truck OEMs are crucial for co-developing advanced coating systems that integrate seamlessly into modern automated assembly lines, emphasizing rapid cure times and improved durability performance metrics. The aftermarket segment, fueled by fleet refurbishment and maintenance cycles, represents a substantial and stable revenue stream, prompting manufacturers to optimize product availability and service networks internationally.

Regionally, the Asia Pacific (APAC) market is projected to demonstrate the fastest growth rate, largely attributed to burgeoning commercial vehicle production in China and India, coupled with massive government investments in infrastructure and logistics development across Southeast Asia. North America and Europe, while being mature markets, maintain dominance in adopting premium, high-performance coatings, focusing on advanced features like anti-graffiti and ceramic-infused protective layers for premium commercial fleets. These mature markets are also setting the pace for regulatory compliance, pushing for immediate commercialization of ultra-low VOC and bio-based resin systems.

Segment trends reveal a sustained dominance of Polyurethane coatings due to their exceptional abrasion resistance and flexibility, making them ideal for protective liners and exterior finishing. However, Epoxy coatings are gaining traction in chassis and heavy-duty structural applications where maximum corrosion resistance is prioritized. Technology-wise, powder coatings are exhibiting accelerated adoption, especially within OEM segments, due to their near-zero VOC content, efficient material utilization, and ability to provide a thick, durable finish. Application-specific demand, particularly for highly durable bedliners in pickup trucks and specialized cargo transport coatings, continues to dictate innovation in formulation chemistry and application techniques, ensuring market resilience across various truck classifications.

AI Impact Analysis on Truck Coatings Market

Common user questions regarding AI's impact on the Truck Coatings Market frequently center around optimizing the complex coating application process, improving quality control validation, and enhancing supply chain predictability for raw material procurement. Users inquire about how AI-driven machine vision systems can detect microscopic defects in cured coatings, significantly reducing manual inspection time and ensuring uniform film thickness. Furthermore, there is substantial interest in predictive maintenance models leveraging AI to determine the remaining service life of existing truck coatings based on real-time environmental data and operational telemetry, allowing fleet managers to schedule re-coating procedures proactively. The key theme summarized from these inquiries is the expectation that Artificial Intelligence will usher in an era of hyper-efficiency, minimize material waste through optimized spray parameters, and ultimately drive down the total cost of ownership (TCO) for commercial vehicle fleets by maximizing the durability provided by the protective coatings.

The integration of AI into coating manufacturing involves optimizing chemical formulations using machine learning algorithms to predict performance characteristics (e.g., gloss retention, hardness, and curing speed) based on varying input chemistries, accelerating the R&D cycle for new products. In the application phase, AI controls robotic spray painting systems, adjusting nozzle pressure, distance, and trajectory in real-time to account for complex truck body geometries, ensuring unparalleled consistency and adherence to strict OEM specifications. This technological convergence promises not only superior quality finishes but also substantial operational savings through reduced rework and minimized material consumption, transforming the traditional, manual-intensive processes into highly automated, data-driven operations that are central to modern smart factories.

- AI-driven Robotic Application: Optimization of spray parameters (flow rate, temperature, pattern) using sensors and deep learning algorithms for flawless, consistent coating thickness and finish across large truck surfaces, minimizing overspray waste.

- Predictive Quality Control (PQC): Machine vision systems powered by AI detect microscopic defects, pinholes, and uneven curing instantly, ensuring 100% quality inspection without human error, especially critical for high-performance clearcoats.

- Formulation Optimization: Utilizing machine learning to analyze historical performance data and simulate new chemical compositions, significantly reducing time-to-market for specialized coatings with enhanced durability or low-VOC properties.

- Supply Chain Resilience: AI predictive analytics improve inventory management for key raw materials (resins, solvents, pigments), forecasting demand fluctuations in the truck manufacturing sector to mitigate supply chain disruptions.

- Smart Maintenance Scheduling: Telematics data combined with AI models determine the precise degradation rate of applied coatings, enabling fleet operators to schedule protective maintenance only when necessary, maximizing asset utilization.

DRO & Impact Forces Of Truck Coatings Market

The Truck Coatings Market is shaped by a dynamic interaction of drivers, restraints, opportunities, and impactful market forces that dictate its current trajectory and future potential. Key drivers include the accelerated global production of commercial and light trucks, particularly in emerging economies undergoing rapid industrialization and urbanization, which necessitates robust, high-performance protective layers for increased vehicle lifespan. Furthermore, the stringent enforcement of vehicle safety and aesthetic longevity standards by regulatory bodies in North America and Europe compels OEMs and aftermarket service providers to adopt premium coating systems, moving away from conventional, low-durability options. The increasing consumer preference for customized and highly durable truck bedliners and specialized finishes for pickup trucks further fuels demand, requiring continuous innovation in application techniques and material science.

However, the market faces significant restraints, primarily stemming from strict environmental regulations, such as the limitations on Volatile Organic Compound (VOC) emissions, which increase the complexity and cost associated with formulating and manufacturing compliant coatings. The high initial capital investment required for implementing sophisticated application technologies, like robotic painting booths and complex powder coating systems, particularly for smaller service shops, acts as a barrier to rapid adoption. Furthermore, fluctuations in the price and supply of petrochemical-derived raw materials, such as specific resins (epoxies, polyurethanes) and specialty solvents, present persistent margin pressures and supply chain volatility for coating manufacturers, necessitating strategic procurement and hedging against commodity price risks.

Opportunities within the market abound, centered on the development of sustainable, bio-based coatings that align with global green manufacturing mandates and reduce dependence on fossil fuel derivatives. The growing interest in advanced functional coatings, including anti-corrosion smart coatings that signal early breakdown, self-healing polymers, and specialized thermal management coatings for engine components, opens high-value market niches. The expanding aftermarket for truck customization and refurbishment, particularly in the restoration and protection of aging commercial fleets, presents a sustainable opportunity for specialized, easy-to-apply protective products. The increasing penetration of electric trucks also offers unique material challenges and opportunities, requiring coatings optimized for battery enclosures and thermal management systems that can withstand new operational stresses and higher safety standards.

- Drivers: Growing fleet modernization trends globally; increasing demand for anti-corrosion and chemical-resistant coatings; expansion of the pickup truck and light commercial vehicle (LCV) segment; stringent vehicle aesthetic and durability standards.

- Restraints: Strict environmental regulations governing VOC emissions; high cost and complexity of advanced application equipment; volatility in raw material prices (resins and pigments); long curing times for certain high-solid coatings.

- Opportunities: Development and commercialization of bio-based and sustainable coating formulations; increasing adoption of powder coatings in OEM facilities; specialized coatings for electric vehicle (EV) components and battery packs; integration of nanotechnology for enhanced scratch resistance.

- Impact Forces: Technological innovation driving the shift to waterborne and UV-cured systems; regulatory pressure mandating low-VOC compliance; global economic cycles influencing commercial fleet purchasing decisions; competitive landscape driving optimization in application speed and product longevity.

Segmentation Analysis

The Truck Coatings Market is segmented based on several critical parameters, including Coating Type (Primer, Basecoat, Clearcoat, Protective Liner), Resin Type (Polyurethane, Epoxy, Acrylic, Alkyd), Technology (Solvent-borne, Waterborne, Powder, UV-cured), and Application (OEM, Aftermarket). This structured segmentation allows for a detailed analysis of market dynamics, enabling stakeholders to target specific niches and align product development with high-growth areas. The dominance of the Protective Liner segment, driven by the massive popularity and utility focus of pickup trucks, necessitates specialized chemistry, often involving polyurea or robust polyurethane blends engineered for extreme impact and abrasion resistance, differing significantly from the aesthetic requirements of basecoats and clearcoats.

From a technological standpoint, the shift towards environmentally compliant solutions is the most impactful trend. While solvent-borne coatings traditionally offered superior performance and ease of application, the ongoing regulatory clampdown has accelerated the adoption of waterborne and powder coatings, particularly within the OEM segment where consistent quality and zero-VOC compliance are paramount. Furthermore, the resin type segmentation highlights the versatility of Polyurethane and Epoxy resins, which together account for a dominant share due to their superior protective qualities—Polyurethanes for exterior flexibility and UV stability, and Epoxies for robust corrosion protection on frames and underbody components.

- By Coating Type:

- Primer (Surfacer, Sealer)

- Basecoat (Color Coat)

- Clearcoat (Protective Topcoat)

- Protective Liner (Bedliners, Chassis Protection)

- By Resin Type:

- Polyurethane (PU)

- Epoxy

- Acrylic

- Alkyd

- Others (e.g., Polyester, Fluoropolymers)

- By Technology:

- Solvent-borne

- Waterborne

- Powder Coatings

- UV-Cured Coatings

- By Application:

- Original Equipment Manufacturer (OEM)

- Aftermarket (Refinishing and Maintenance)

- By Truck Type:

- Light-Duty Trucks (LDTs)

- Medium-Duty Trucks (MDTs)

- Heavy-Duty Trucks (HDTs)

Value Chain Analysis For Truck Coatings Market

The value chain for the Truck Coatings Market begins with upstream activities focused on the procurement and processing of key raw materials, primarily specialized resins (epoxy, acrylic, PU), high-performance pigments (organic and inorganic), additives (rheology modifiers, anti-foaming agents), and solvents. This segment is dominated by large chemical companies and specialized material suppliers who must adhere to stringent quality standards as raw material purity directly influences the final coating performance, including factors like color stability, durability, and adhesion. Research and development activities, often involving partnerships between raw material suppliers and coating manufacturers to engineer high-performance polymers and novel functional additives, are crucial in this upstream phase to maintain a competitive technological edge and meet evolving regulatory requirements, particularly concerning sustainability and low toxicity.

Midstream activities involve the formulation, compounding, and manufacturing of the finished coating products by specialized coating companies. This phase involves complex chemical synthesis and blending processes, requiring high capital investment in manufacturing facilities capable of producing various coating technologies (e.g., powder, liquid high-solids). Quality assurance and regulatory compliance checks are rigorously performed here to ensure the final products meet both national and international automotive performance specifications. Distribution channels for truck coatings are bifurcated into direct sales to major Original Equipment Manufacturers (OEMs) and indirect sales targeting the fragmented aftermarket segment. Direct sales involve long-term supply agreements and tailored product delivery optimized for OEM assembly lines, emphasizing just-in-time inventory management and dedicated technical support.

Downstream activities center on the application and final consumption of the coatings. The indirect distribution channel relies heavily on a network of regional distributors, specialized automotive paint jobbers, and professional body shops that service the extensive aftermarket for truck repair, refinishing, and customization. These intermediaries provide localized mixing, color matching services, and technical training to ensure proper application, which is vital for coating longevity. The end-users—truck OEMs, large commercial fleet operators, independent repair facilities, and individual truck owners—drive the final demand. Value addition is maximized at the application stage, where skilled technicians utilize sophisticated equipment to ensure the protective layers are applied flawlessly, contributing directly to the asset protection and aesthetic value of the commercial vehicle.

Truck Coatings Market Potential Customers

The primary consumers and end-users of truck coatings are distinctly divided into two major groups: Original Equipment Manufacturers (OEMs) and the expansive Aftermarket segment, which includes professional body shops, fleet maintenance departments, and independent applicators. OEMs, such as Daimler Truck, Volvo Group, Ford, and General Motors, represent the largest volume buyers, requiring massive quantities of technologically advanced, high-performance coating systems (primers, basecoats, clearcoats) tailored for rapid robotic application within high-throughput production environments. Their demand is highly specialized, focusing on consistency, minimal defect rates, and strict adherence to specific corporate color palettes and durability guarantees mandated for new vehicle warranties.

The aftermarket segment, however, is characterized by high-mix, low-volume requirements, servicing vehicle repair, collision restoration, and customization projects. Potential buyers here include independent commercial vehicle body shops specializing in heavy-duty truck repairs, fleet owners with dedicated in-house maintenance facilities requiring bulk purchasing for touch-ups and repainting cycles, and specialized custom shops focused on high-end protective liners (polyurea/polyurethane) for pickup trucks and utility vehicles. For these customers, factors like ease of application, rapid cure times in less controlled environments, and localized technical support for color matching and blending are critical purchasing criteria, often favoring highly durable, two-component systems and specialized bedliner kits over OEM-grade production coatings.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.15 Billion |

| Market Forecast in 2033 | USD 6.18 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Axalta Coating Systems, PPG Industries, Sherwin-Williams, BASF SE, Akzo Nobel N.V., Kansai Paint Co., Ltd., 3M Company, Hempel A/S, Sika AG, RPM International Inc. (Rust-Oleum), Jotun Group, Nippon Paint Holdings Co., Ltd., Beckers Group, Carboline Company, Valspar Corporation (now part of Sherwin-Williams), U-Pol Products, Rhino Linings Corporation, Mascoat, KCC Corporation, Diamond Vogel |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Truck Coatings Market Key Technology Landscape

The technological landscape of the Truck Coatings Market is undergoing rapid transformation, primarily driven by the imperative for environmental compliance, increased performance durability, and efficiency in application. Solvent-borne coatings, historically the standard, are being strategically phased out in favor of advanced low-VOC alternatives. Waterborne coating technology offers a significant reduction in VOC emissions while maintaining acceptable performance characteristics, and its adoption is soaring, particularly in OEM facilities that utilize controlled application environments. However, waterborne systems require precise climate control during application and curing, necessitating specialized infrastructure investment to prevent defects like blistering or sagging, a factor driving continuous improvement in formulation stability and rheology control.

Powder coatings represent another major technological shift, especially for chassis, wheels, and heavy-duty structural components. These coatings are solvent-free, offering virtually zero VOC emissions, excellent edge coverage, and superb mechanical resistance against chipping and abrasion. The main challenge remains adapting the technology for heat-sensitive materials and ensuring uniform coverage on complex, large truck body panels, although advancements in low-cure temperature powders are mitigating these issues. Furthermore, UV-cured technology is gaining traction, particularly for smaller plastic components and specific refinishing tasks in the aftermarket due to its ultra-rapid curing speed, which drastically reduces processing time and energy consumption, leading to high operational efficiencies.

The future of truck coatings is heavily invested in nanotechnology and smart materials. Nanocoatings, incorporating nanoscale particles of silica or ceramics, are being developed to dramatically enhance scratch resistance, gloss retention, and hydro- or oleophobic properties, extending the visual appeal and protective life of the clearcoat layer. Similarly, smart coatings that incorporate sensors or micro-capsules capable of self-healing minor scratches or providing early visual indicators of corrosion beneath the surface are moving from research labs to commercial pilot programs. These innovations are critical for differentiating premium coating brands and addressing the industry demand for coatings that offer both protection and proactive maintenance feedback, fundamentally altering the value proposition in the heavy-duty commercial vehicle segment.

Regional Highlights

The regional dynamics of the Truck Coatings Market reveal a polarized landscape, where mature markets prioritize premium performance and sustainability, while emerging economies focus on high-volume production and infrastructure growth. North America, encompassing the United States and Canada, represents a high-value market segment characterized by strong demand for high-end protective liners for pickup trucks and stringent regulations that enforce the widespread adoption of low-VOC, high-solids coating systems within OEM assembly plants. The large presence of major fleet operators and the maturity of the aftermarket repair network sustain continuous demand for advanced refinishing products, including high-performance polyurethanes and specialized ceramic coatings optimized for extreme weather resistance.

Asia Pacific (APAC) is unequivocally the fastest-growing region, driven primarily by the massive scale of commercial vehicle manufacturing in countries like China, India, and Japan. Rapid industrialization, expansion of logistics and e-commerce sectors, and substantial government spending on public infrastructure projects directly fuel the production of new heavy-duty and light commercial vehicles, creating immense demand for coatings. While historically dominated by conventional coating technologies, regulatory pressure and increasing environmental awareness in key urban centers are rapidly accelerating the shift toward modern, compliant waterborne and powder coating lines within major regional manufacturing hubs.

Europe maintains a leading position in the implementation of the most rigorous environmental standards, pushing the market towards complete dominance by waterborne and powder technologies. European manufacturers and OEMs are focused on maximizing application efficiency and minimizing the environmental footprint across the entire product lifecycle. Latin America and the Middle East & Africa (MEA) represent significant growth potential, linked to infrastructural development and increasing mining and energy sector activities that demand specialized coatings with superior chemical and abrasion resistance for vehicles operating in harsh environments. These regions are primary targets for global coating manufacturers seeking new avenues for expansion, often introducing proven high-solid systems that balance performance with cost-effectiveness.

- North America: Dominant market share fueled by high LCV production and strong aftermarket demand for protective bedliners; early adoption of advanced, high-solid, low-VOC polyurethanes.

- Asia Pacific (APAC): Highest projected growth rate due to soaring commercial vehicle output in China and India; increasing regulatory push towards sustainable coating technologies in key manufacturing zones.

- Europe: Leader in environmental compliance, mandating near-exclusive use of waterborne and powder coatings; strong focus on R&D for highly durable, corrosion-resistant systems for heavy trucks.

- Latin America: Growing market driven by infrastructure projects and logistics expansion; demand focused on balancing cost and performance for fleet maintenance and refurbishment.

- Middle East & Africa (MEA): Requires specialized coatings due to extreme temperatures and harsh conditions (dust, salt); growing construction and energy sector activity drives demand for robust, high-durability epoxy and polyurethane protection.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Truck Coatings Market.- Axalta Coating Systems

- PPG Industries

- Sherwin-Williams

- BASF SE

- Akzo Nobel N.V.

- Kansai Paint Co., Ltd.

- 3M Company

- Hempel A/S

- Sika AG

- RPM International Inc. (Rust-Oleum)

- Jotun Group

- Nippon Paint Holdings Co., Ltd.

- Beckers Group

- Carboline Company

- Valspar Corporation (now part of Sherwin-Williams)

- U-Pol Products

- Rhino Linings Corporation

- Mascoat

- KCC Corporation

- Diamond Vogel

Frequently Asked Questions

Analyze common user questions about the Truck Coatings market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary coating technologies replacing conventional solvent-borne systems in the truck industry?

The industry is rapidly shifting towards environmentally compliant technologies, primarily waterborne coatings and powder coatings, which offer significantly reduced Volatile Organic Compound (VOC) emissions while meeting the stringent durability and aesthetic requirements set by Original Equipment Manufacturers (OEMs).

Which resin type is most widely used for protective truck bedliners and why is it preferred?

Polyurethane and Polyurea resins are predominantly used for protective bedliners due to their exceptional flexibility, high tensile strength, superior impact absorption, and excellent resistance to abrasion, chemicals, and UV degradation, making them ideal for rugged utility applications.

How do global VOC regulations influence the procurement strategy for truck coatings?

Strict VOC regulations mandate that fleet operators and OEMs procure low-VOC or zero-VOC systems, shifting preference toward high-solids, waterborne, and powder formulations. This drives R&D investment and requires manufacturers to optimize their product portfolios for compliance across various international jurisdictions.

What role does nanotechnology play in the future development of truck coatings?

Nanotechnology is crucial for developing advanced clearcoats and topcoats that incorporate nanoscale additives to enhance performance features such as ultra-high scratch resistance, improved gloss retention, and specialized thermal management properties, thereby increasing the protective life of the vehicle.

Which region is expected to exhibit the fastest growth in the Truck Coatings Market through 2033?

The Asia Pacific (APAC) region is projected to experience the fastest market growth, primarily fueled by the accelerating production of commercial vehicles in major economies like China and India, coupled with massive ongoing infrastructural and logistics development requiring new fleet assets.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager