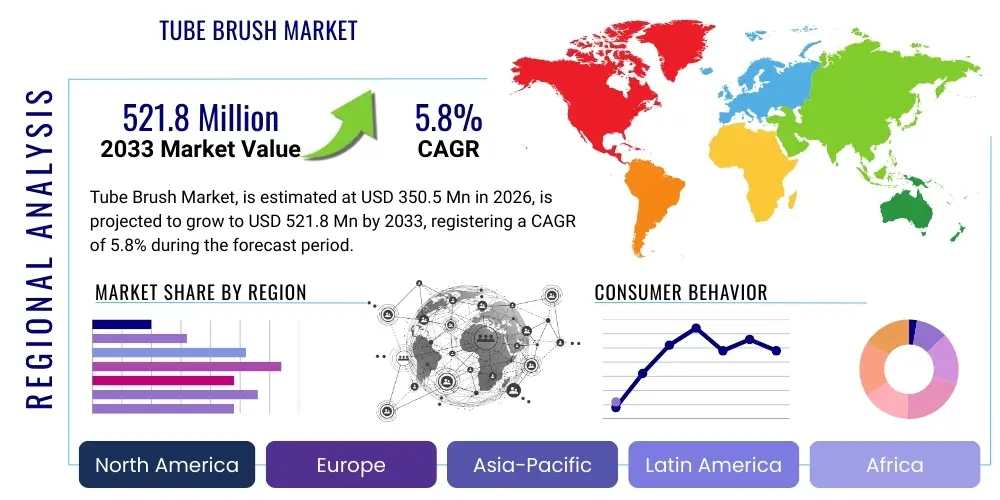

Tube Brush Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438623 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Tube Brush Market Size

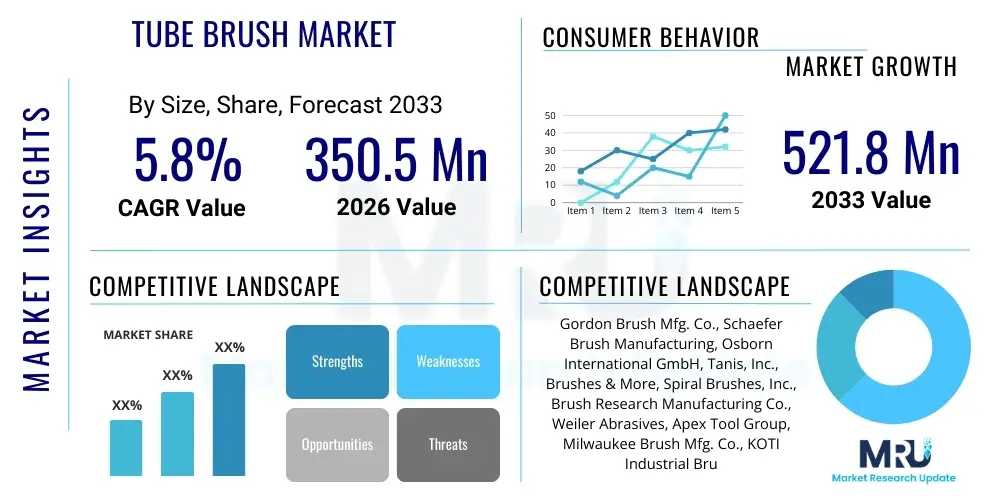

The Tube Brush Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 350.5 Million in 2026 and is projected to reach USD 521.8 Million by the end of the forecast period in 2033. This substantial expansion is fundamentally driven by the escalating demand for highly efficient cleaning and maintenance solutions across critical industrial sectors, including HVAC, chemical processing, and power generation. Regulatory mandates focusing on energy efficiency and preventive maintenance in these heavy industries further solidify the market's growth trajectory.

The valuation reflects robust procurement volumes from sectors heavily reliant on tubular structures, such as heat exchangers, condensers, and boiler systems, where internal fouling or contamination can severely compromise operational efficiency and safety. The shift towards specialized brush materials and designs, including abrasive filaments and high-grade stainless steel wires, to handle increasingly complex and resilient deposits also contributes significantly to the rising average selling price and overall market size. Moreover, the increasing adoption of automated cleaning systems utilizing tube brushes enhances productivity, making these tools indispensable maintenance assets.

Tube Brush Market introduction

The Tube Brush Market encompasses the manufacturing, distribution, and sale of specialized cleaning tools designed to remove deposits, scale, debris, and corrosion from the internal surfaces of tubes, pipes, and bore holes. These essential cleaning implements come in various configurations, materials (such as nylon, polypropylene, brass, and stainless steel), and sizes tailored to specific tube diameters and application requirements. Tube brushes are crucial components in maintaining the operational integrity and efficiency of heat transfer equipment, including chillers, boilers, heat exchangers, and pipelines used extensively in industrial environments, ensuring optimal heat exchange rates and preventing system failures. Their primary function is to restore internal flow and surface cleanliness, thereby minimizing energy consumption and maximizing equipment lifespan.

The major applications for tube brushes span across numerous industries, most notably in HVAC systems for condenser cleaning, in chemical and petrochemical plants for pipeline maintenance, and in power generation facilities for boiler tube descaling. Key benefits derived from the consistent use of high-quality tube brushes include reduced operational downtime, significant improvements in thermal efficiency (leading to lower energy costs), enhanced safety standards by preventing dangerous blockages, and compliance with stringent environmental regulations regarding industrial discharge quality. The versatile nature of these tools allows them to be used either manually or integrated into automated cleaning systems, offering flexibility to end-users based on scale and complexity of the cleaning task.

Driving factors propelling the tube brush market include the global emphasis on preventive maintenance programs, rising industrialization coupled with increased deployment of heat exchange infrastructure, and strict governmental policies promoting energy conservation, particularly in developed economies. Furthermore, technological advancements leading to specialized brush filaments capable of cleaning exotic alloys or highly corrosive environments are broadening the application scope. The sustained growth of the manufacturing and processing sectors, particularly in Asia Pacific, acts as a major catalyst for demand, requiring constant maintenance of processing equipment to meet growing production quotas and quality standards.

Tube Brush Market Executive Summary

The Tube Brush Market is characterized by steady expansion, buoyed primarily by sustained industrial output and the necessary adoption of rigorous maintenance protocols across critical infrastructure. Key business trends include a pronounced shift toward automated tube cleaning systems, necessitating brushes optimized for high-speed mechanical operation, and an increased focus on brushes manufactured from advanced materials, such as abrasive nylon and specialized stainless steel, to address demanding industrial residues. Competitive strategies are centering on customization and durability, with manufacturers offering tailor-made solutions for specific applications like pharmaceutical processing or nuclear power plant maintenance. Furthermore, optimizing supply chains to deliver replacement brushes quickly and efficiently is a core focus area for maximizing customer retention in this essential maintenance supply sector.

Regionally, the market is highly dynamic. Asia Pacific dominates in terms of consumption volume, driven by rapid industrialization, particularly in China and India, and large-scale infrastructure projects involving extensive use of HVAC and chemical processing equipment. North America and Europe, while mature, exhibit strong demand for high-value, technologically sophisticated brushes and automated solutions, propelled by strict environmental and safety regulations mandating superior equipment performance. Segment-wise, the application in Heat Exchangers and Condensers holds the largest share due to their ubiquitous presence across almost all industrial and commercial facilities. The demand for wire brushes (stainless steel and brass) remains high due to their efficacy in removing hard scale and stubborn deposits, although the market for non-metallic brushes (nylon, polypropylene) is rapidly expanding, fueled by requirements for non-scratch cleaning on sensitive materials.

AI Impact Analysis on Tube Brush Market

Common user inquiries regarding AI's impact on the Tube Brush Market typically revolve around the feasibility of AI-driven predictive maintenance replacing traditional inspection methods, the role of machine learning in optimizing brush design and material selection, and whether robotic cleaning systems integrated with AI could automate the tube cleaning process entirely, thereby affecting manual tool demand. Users are concerned about how AI could optimize cleaning frequency based on real-time data from internal tube inspections (e.g., using eddy current testing or visual inspection robots) and how this optimized schedule might change procurement patterns for tube brushes. The prevailing expectation is that AI will not eliminate the need for brushes but rather enhance the efficiency, precision, and longevity of the cleaning process, focusing procurement towards highly specialized brushes suited for autonomous operation and data-driven replacement cycles.

The primary influence of Artificial Intelligence in this established industrial maintenance market is indirect but transformative, focusing on optimizing the operational environment where tube brushes are utilized. AI-powered predictive maintenance platforms analyze sensor data (such as pressure drop, temperature differential, and flow rates) within tubular systems to accurately determine the optimal time for cleaning, reducing unnecessary maintenance cycles and ensuring brushes are used precisely when needed. This shift from time-based to condition-based maintenance increases the efficiency of brush usage, potentially reducing the volume of standard, general-purpose brushes purchased but simultaneously driving up demand for specialized, high-performance brushes suitable for targeted, intense cleaning tasks identified by AI diagnostics.

Furthermore, machine learning algorithms are beginning to play a role in materials science related to tube brush manufacturing. By simulating various fouling scenarios and brush filament interactions, AI can assist in designing optimal brush configurations—determining the ideal filament density, crimp style, and material hardness—to achieve maximum cleaning efficiency with minimum tube surface damage. This technological integration ensures that the tube brushes procured are perfectly matched to the specific internal tube material and fouling agent, leading to more specialized product offerings and shifting manufacturer focus toward high-precision engineering rather than mass-market volume, ultimately enhancing the product's value proposition.

- AI-driven predictive maintenance optimizes cleaning schedules, ensuring brushes are used precisely when required, maximizing efficiency.

- Machine learning aids in designing filament material and configuration for superior cleaning efficiency and minimal pipe damage.

- AI integration into autonomous robotic cleaning systems drives demand for standardized, high-durability brushes compatible with automation platforms.

- Data analytics derived from smart cleaning operations inform manufacturers about real-world brush performance and longevity requirements.

- Supply chain optimization using AI minimizes downtime by forecasting brush replacement needs accurately, improving logistical efficiency for end-users.

DRO & Impact Forces Of Tube Brush Market

The dynamics of the Tube Brush Market are shaped by a complex interplay of Drivers, Restraints, Opportunities, and inherent Impact Forces. Key drivers include the stringent maintenance requirements across energy and processing sectors, regulatory pressures to improve energy efficiency, and continuous infrastructure expansion globally. These factors necessitate regular internal cleaning of tubular systems to prevent efficiency degradation. Restraints, conversely, involve the presence of alternative cleaning technologies such as chemical cleaning or high-pressure water jetting, and the fluctuating prices of raw materials (especially steel and brass) used for brush filament production. Opportunities lie in developing advanced abrasive filaments for specialized applications (e.g., ultra-high-pressure cleaning or sensitive medical device maintenance) and integrating tube brushes with IoT-enabled monitoring systems for smart maintenance solutions. These forces collectively dictate the pace and direction of market growth, favoring manufacturers who can innovate in both material science and systemic integration.

The primary impact forces include the inherent cyclical nature of industrial maintenance spending, which can fluctuate based on global economic stability, and the highly competitive landscape characterized by numerous regional and global players. The bargaining power of buyers remains moderately high due to the standardized nature of many basic brush types, pushing manufacturers to differentiate through material quality and application-specific customization. Technological shifts toward automated cleaning systems act as a transformative force, demanding new brush form factors designed for mechanical consistency and speed, thereby elevating the required precision in manufacturing. Environmental regulations also exert pressure, leading to a demand for cleaning solutions that minimize the use of harsh chemicals, thereby favoring mechanical cleaning tools like tube brushes.

Segmentation Analysis

The Tube Brush Market is meticulously segmented based on key criteria including the material used for the brush filaments, the structural type of the brush, the primary application area, and the end-use industry utilizing the product. This segmentation is crucial for understanding specific consumer requirements across diverse industrial environments. Material segmentation highlights the trade-offs between cleaning efficacy (wire brushes) and non-abrasive characteristics (nylon/polymer). Type segmentation addresses various installation and operational methods, such as internal spiral brushes for manual use versus crimped wire brushes for mechanical cleaning machines. Application and End-Use segments illustrate the market's dependence on sectors like HVAC, power generation, and chemical manufacturing, allowing for targeted product development and marketing strategies tailored to distinct operational pressures and regulatory compliance needs within each industry.

- By Type:

- Internal Spiral Brushes (Twisted-in-Wire)

- External Spiral Brushes

- Cylinder Brushes

- Crimp Wire Brushes

- Abrasive Brushes

- By Material:

- Wire (Stainless Steel, Carbon Steel, Brass, Bronze)

- Nylon and Polymer (Polypropylene, Polyester)

- Natural Fiber (Tampico, Sisal)

- By Application:

- Heat Exchangers & Condensers Cleaning

- Boilers & Tubes Maintenance

- Piping & Drilling Bore Cleaning

- Medical Device Cleaning (Sterilization)

- Automotive Component Cleaning

- By End-Use Industry:

- HVAC & Refrigeration

- Chemical & Petrochemical

- Power Generation (Nuclear, Thermal)

- Manufacturing & Fabrication

- Food & Beverage Processing

- Healthcare & Pharmaceutical

Value Chain Analysis For Tube Brush Market

The value chain for the Tube Brush Market begins with the Upstream activities focused on sourcing raw materials, primarily high-grade metal wires (stainless steel, carbon steel, brass) and synthetic polymers (nylon, polypropylene). Material suppliers, often specialized metal processors or chemical companies, provide these components. Efficiency and quality control at this stage are paramount, as the durability and cleaning performance of the final product depend heavily on the quality of the filament material. Key upstream risks include commodity price volatility and reliance on specialized wire drawing processes to achieve the precise diameters and material resilience required for industrial applications. Manufacturers then engage in core processes such as twisting-in-wire, crimping, and brush head assembly, requiring specialized machinery and technical expertise to ensure optimal filament density and alignment.

The Downstream segment involves the distribution and final delivery of the finished tube brushes to end-users. Distribution channels are varied, encompassing direct sales to large industrial clients (e.g., power plants, major chemical companies), sales through specialized industrial equipment distributors and maintenance, repair, and overhaul (MRO) suppliers, and increasingly, through e-commerce platforms for small-to-midsize enterprises (SMEs). Direct channels typically handle custom orders or bulk purchases requiring technical consultation, ensuring the right brush specifications are met. Indirect channels, particularly MRO distributors, play a crucial role in providing immediate availability and logistical support for routine maintenance consumables across diverse geographical areas. The final stage involves the application of the brush by maintenance technicians or automated cleaning machinery in the end-user facility, where performance feedback influences future product design.

The optimization of the distribution channel is critical for market success, given that tube brushes are often emergency-use or frequently replaced maintenance items. Strong partnerships with authorized industrial suppliers enhance market reach and ensure timely delivery, which is essential to minimize customer operational downtime. Furthermore, establishing a technical support presence, either directly or through trained distributor staff, helps customers navigate the complexity of selecting the correct brush for specialized applications, thereby solidifying market position. The move towards digital platforms facilitates easier ordering of standard sizes and faster turnaround times, streamlining the procurement process for high-volume users globally.

Tube Brush Market Potential Customers

Potential customers (End-User/Buyers) for tube brushes are predominantly large industrial and commercial entities operating systems that rely on heat transfer or fluid conveyance through tubular structures. This includes maintenance departments in power generation plants (both conventional and nuclear), where condenser and boiler tubes require frequent descaling to maintain thermal efficiency and safety compliance. Another major customer base is the Chemical and Petrochemical sector, which heavily utilizes tube bundles in heat exchangers and reactors, requiring robust cleaning tools to prevent blockages and manage highly corrosive residues. The purchasing decision is generally centralized within MRO or engineering procurement teams, prioritizing durability, material compatibility, and demonstrated cleaning effectiveness.

The HVAC and Refrigeration industry represents a consistently growing segment of potential customers, spanning commercial buildings, data centers, and large residential complexes. These users require brushes for cleaning chiller and condenser coils to ensure optimal air conditioning performance and minimize energy consumption, often demanding specific nylon or brass brushes to protect sensitive internal fin structures. Healthcare and Pharmaceutical manufacturing facilities also constitute critical buyers, utilizing small-diameter, medical-grade tube brushes for strict sterilization and debris removal in processing equipment, surgical instruments, and laboratory glassware, necessitating specialized, often disposable, brush types to meet stringent hygiene standards and regulatory approvals.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350.5 Million |

| Market Forecast in 2033 | USD 521.8 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Gordon Brush Mfg. Co., Schaefer Brush Manufacturing, Osborn International GmbH, Tanis, Inc., Brushes & More, Spiral Brushes, Inc., Brush Research Manufacturing Co., Weiler Abrasives, Apex Tool Group, Milwaukee Brush Mfg. Co., KOTI Industrial Brushes, Carolina Brush, Newark Brush Company, Anderson Power Products, R.W. Technology, Inc., Spiral-Tech Brushes, Abtex Corporation, EZ LOK, Mill-Rose Company, Braun Brush Company. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Tube Brush Market Key Technology Landscape

The technology landscape within the Tube Brush Market focuses less on radical invention and more on material science innovation, precision engineering, and enhanced manufacturing techniques to ensure superior product performance and durability. A critical technology is the development of advanced abrasive filaments, such as silicon carbide embedded nylon or diamond grit filaments, which allow brushes to effectively remove extremely hard scale and deposits without causing irreparable damage to the delicate internal surfaces of expensive heat exchange equipment. Manufacturers are leveraging computer-aided design (CAD) and simulation software to optimize brush geometry, including filament pitch and density, ensuring maximum scrubbing action and efficient debris removal across the entire tube circumference, thereby improving consistency and reducing manual effort.

Another pivotal technological trend involves the precision manufacturing of twisted-in-wire brushes, where core wire tensile strength and material memory are critical. Modern manufacturing utilizes high-speed, numerically controlled (NC) machinery capable of producing consistent and complex brush shapes necessary for integration into mechanical cleaning systems (e.g., rotary tube cleaners). This manufacturing accuracy ensures that brushes maintain their structural integrity under high torque and repetitive use. Furthermore, the selection and application of specialized coatings (such as PVC or PTFE) on the core wire minimize corrosion and chemical interaction, extending the brush life when used in harsh chemical environments prevalent in the petrochemical and pharmaceutical sectors.

Integration technology is also becoming increasingly relevant. The market is witnessing the integration of tube brushes designed explicitly for use with robotic inspection and cleaning tools. These brushes feature standardized fittings and dimensions optimized for automated insertion and retraction mechanisms. This shift demands tighter tolerances and high uniformity across batches. The overall technological direction is moving towards smarter, more durable, and application-specific cleaning instruments that complement the growing trend toward automation and condition-based monitoring in industrial maintenance, ensuring that the brushes remain the most effective mechanical solution available for internal tube cleaning.

Regional Highlights

The Tube Brush Market exhibits significant regional disparities in terms of growth rates, application focuses, and technological adoption. Asia Pacific (APAC) stands out as the primary growth engine, driven by massive investments in infrastructure development, rapid industrialization, and the establishment of new manufacturing hubs, particularly in China, India, and Southeast Asian nations. The high volume of thermal power generation, chemical processing, and widespread deployment of commercial HVAC systems in urban centers necessitate continuous procurement of tube brushes for maintenance. This region typically favors cost-effective, high-volume brush types, although demand for specialized, high-performance brushes is rapidly accelerating as quality standards rise.

North America and Europe represent mature markets characterized by stable, high-value demand. Growth here is primarily driven not by new infrastructure, but by strict regulatory requirements concerning operational efficiency, safety, and environmental protection. Consequently, end-users in these regions prioritize advanced, durable, and highly specialized brushes, often integrated into sophisticated automated or semi-automated cleaning systems. The focus is heavily skewed toward minimizing downtime and maximizing the thermal efficiency of existing assets, leading to greater investment in high-quality brass, stainless steel, and abrasive nylon brushes used in preventive maintenance programs within the power, oil and gas, and pharmaceutical industries.

The Middle East and Africa (MEA) and Latin America regions are experiencing moderate growth, linked heavily to localized oil and gas exploration, refining capacity expansion, and infrastructure development. The MEA region, particularly the Gulf Cooperation Council (GCC) countries, shows strong demand due to extensive desalination plants and petrochemical operations which require robust anti-corrosion and descaling tools. Latin American demand is cyclical, tied closely to mining activities and industrial expansion in countries like Brazil and Mexico. Across all developing regions, the transition from reactive maintenance practices to planned preventive maintenance schedules is progressively boosting the consistent demand for tube brushes as critical MRO supplies.

- Asia Pacific (APAC): Dominates market volume due to rapid industrial growth, infrastructure projects, and expanding chemical/power generation sectors; focus on affordability and high-volume procurement.

- North America: Stable, high-value market driven by rigorous safety standards, regulatory compliance, and adoption of automated cleaning technologies; strong demand for high-performance, specialized materials.

- Europe: Characterized by stringent environmental regulations and energy efficiency mandates; significant market share in pharmaceutical and specialized manufacturing requiring high-precision cleaning tools.

- Middle East & Africa (MEA): Growth tied to significant investments in oil & gas, petrochemicals, and desalination plants; high requirement for corrosion-resistant brush materials.

- Latin America: Demand influenced by infrastructure modernization and mineral processing industries; gradual shift toward modern preventive maintenance techniques.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Tube Brush Market.- Gordon Brush Mfg. Co.

- Schaefer Brush Manufacturing

- Osborn International GmbH

- Tanis, Inc.

- Brushes & More

- Spiral Brushes, Inc.

- Brush Research Manufacturing Co.

- Weiler Abrasives

- Apex Tool Group

- Milwaukee Brush Mfg. Co.

- KOTI Industrial Brushes

- Carolina Brush

- Newark Brush Company

- Anderson Power Products

- R.W. Technology, Inc.

- Spiral-Tech Brushes

- Abtex Corporation

- EZ LOK

- Mill-Rose Company

- Braun Brush Company

Frequently Asked Questions

Analyze common user questions about the Tube Brush market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of using tube brushes over chemical cleaning methods?

Tube brushes offer a mechanical, non-corrosive solution for removing fouling, scale, and deposits, eliminating the disposal costs and safety hazards associated with harsh chemical agents. Mechanical cleaning ensures better surface preparation and compliance in industries where chemical residue is restricted, such as Food & Beverage and Pharmaceuticals.

How do I select the correct tube brush material for my heat exchanger application?

Selection depends critically on two factors: the material of the tube and the nature of the deposit. Soft materials (e.g., copper, stainless steel) usually require non-metallic brushes (nylon, polymer) or softer metals like brass, while hard scale removal on robust steel tubes necessitates aggressive materials like carbon steel wire or abrasive nylon filaments.

Is the Tube Brush Market moving towards automated solutions, and how does this affect manual brush demand?

Yes, automation (such as robotic tube cleaning systems) is driving demand for high-tolerance, standardized brushes designed for mechanical use. While automation reduces manual effort for large systems, manual brush demand remains stable for smaller, intricate, or quick spot-cleaning applications, ensuring both segments coexist in the market.

Which end-use industry represents the highest growth potential for specialized tube brushes?

The Healthcare and Pharmaceutical industries demonstrate significant growth potential for specialized, small-diameter, medical-grade brushes due to stringent sterilization standards and the necessity for precise cleaning of surgical and laboratory equipment. Additionally, the high-pressure cleaning segment in Power Generation is also expanding rapidly.

What role does sustainability play in the manufacturing of tube brushes?

Sustainability is influencing the market through increased demand for durable, longer-lasting brushes that reduce replacement frequency. Manufacturers are also exploring recycled or biodegradable materials for brush handles and using precision manufacturing techniques to minimize raw material waste.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager