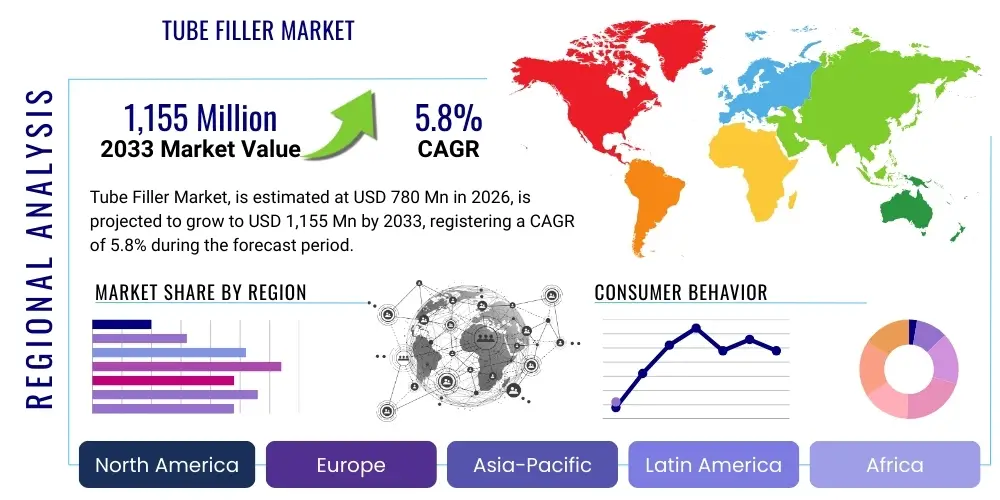

Tube Filler Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437014 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Tube Filler Market Size

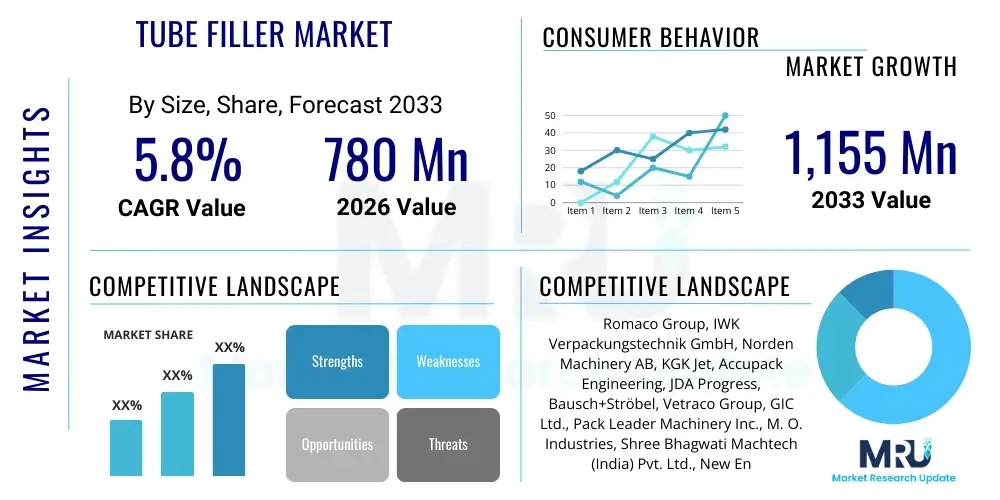

The Tube Filler Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $780 Million USD in 2026 and is projected to reach $1,155 Million USD by the end of the forecast period in 2033.

Tube Filler Market introduction

The Tube Filler Market encompasses specialized packaging machinery designed for efficiently filling and sealing various products—ranging from viscous pastes and creams to liquids and gels—into collapsible tubes made of plastic, metal, or laminate materials. These sophisticated systems are crucial components in highly regulated sectors such as pharmaceuticals, cosmetics, and food processing, where precision, hygiene, and high throughput are paramount. Tube fillers perform multiple integrated operations, including tube feeding, cleaning, positioning, precise dosing, and final sealing (crimp sealing for metal tubes or hot air/ultrasonic sealing for plastic/laminate tubes), ensuring product integrity and shelf stability. The inherent versatility of modern tube fillers allows them to handle diverse product viscosities and tube sizes with minimal changeover time, catering to the dynamic demands of global consumer packaged goods (CPG) production.

The primary driving factors propelling the growth of this market include the escalating global demand for packaged cosmetic and personal care products, particularly in emerging economies, coupled with stringent regulatory requirements in the pharmaceutical sector necessitating highly accurate and validated filling processes. Furthermore, technological advancements have led to the development of fully automatic tube fillers capable of ultra-high speeds and reduced operational dependency, significantly lowering the overall cost per unit. The benefits derived from utilizing high-quality tube filling technology include enhanced product consistency, minimized product waste, improved packaging aesthetics, and, critically, compliance with international Good Manufacturing Practices (GMP).

Major applications of tube fillers are concentrated primarily in areas requiring precise barrier protection and controlled dispensing. In the pharmaceutical industry, they are essential for packaging topical medications, ophthalmic gels, and dental products. The cosmetics sector utilizes them extensively for foundations, hair treatments, and moisturizers. In the food industry, tube fillers handle products like concentrated pastes, condiments, and specialty flavorings, requiring machinery built with food-grade stainless steel and sanitary design features. The convergence of consumer preference toward convenient, single-dose packaging formats and the industrial necessity for sterile filling environments continues to cement the essential role of tube filler technology in modern manufacturing ecosystems.

Tube Filler Market Executive Summary

The global Tube Filler Market is characterized by robust business trends driven by intense automation adoption and strategic focus on flexibility and efficiency. Key market players are increasingly investing in modular machine designs that facilitate quick adaptation to varying tube types (metal, plastic, laminate) and product viscosities, directly addressing the CPG industry's need for shorter production runs and diverse product portfolios. Sustainability remains a significant trend, pushing manufacturers toward developing tube fillers compatible with eco-friendly and post-consumer recycled (PCR) tube materials, which minimizes environmental impact while maintaining stringent sealing quality. Furthermore, integration with advanced sensors and Supervisory Control and Data Acquisition (SCADA) systems is becoming standard, ensuring real-time quality control and enabling predictive maintenance strategies.

Regional trends indicate that the Asia Pacific (APAC) region is expected to demonstrate the highest growth rate, fueled by expanding pharmaceutical manufacturing capacity, rapid urbanization, and massive growth in local cosmetic and personal care consumption, particularly in China and India. North America and Europe, while mature, remain dominant in terms of technology adoption, focusing heavily on fully automatic, high-speed machines and pioneering the use of advanced serialization and traceability features required by strict regulatory bodies like the FDA and EMA. The Middle East and Africa (MEA) and Latin America are poised for moderate growth, driven by inward investment in local manufacturing capabilities aimed at reducing reliance on imported packaged goods.

Segment trends highlight the dominance of the fully automatic tube filler type due to its superior efficiency and throughput necessary for large-scale operations. Within the end-user segment, Pharmaceuticals and Cosmetics & Personal Care segments collectively command the largest market share, mandated by consumer health and aesthetic requirements. There is a perceptible shift toward laminate tubes over traditional aluminum tubes in many CPG applications, largely attributed to better barrier properties, aesthetics, and resistance to cracking, requiring tube filler manufacturers to continually upgrade sealing technology to accommodate these complex composite materials efficiently. The market continues to witness consolidation, with major machinery providers acquiring specialized niche players to broaden their product offerings and geographical footprint.

AI Impact Analysis on Tube Filler Market

User queries regarding AI integration in the Tube Filler Market primarily revolve around how artificial intelligence can optimize operational efficiency, enhance quality assurance, and reduce material waste. Key themes include the implementation of AI for predictive maintenance to minimize unplanned downtime, the use of computer vision algorithms for high-speed defect detection (e.g., seal integrity, print registration, tube deformation), and AI-driven optimization of filling parameters (such as dosing volume and speed) based on real-time feedback regarding product viscosity and environmental conditions. Concerns often center on the initial investment required for retrofitting older equipment and the necessity of skilled personnel to manage and interpret complex AI-generated data sets, indicating a high expectation for operational intelligence and automation complexity management.

The deployment of AI and machine learning algorithms is transforming traditional tube filling processes from reactive maintenance schedules to proactive, self-optimizing manufacturing environments. AI analyzes vast amounts of sensor data collected across the filling line, identifying subtle patterns indicative of impending mechanical failure in components like pumps, valves, or sealing jaws, thereby allowing for timely intervention before costly breakdowns occur. This transition not only significantly boosts Overall Equipment Effectiveness (OEE) but also extends the operational lifespan of high-precision machinery, offering a substantial return on investment (ROI) for manufacturers managing high-volume production lines.

Furthermore, AI-powered vision systems are setting new benchmarks for quality control in tube filling. Traditional quality checks often rely on sampled inspection, but AI algorithms offer 100% inspection capabilities at speeds exceeding conventional human observation. By training neural networks on millions of defect images, these systems can instantly recognize microscopic flaws in tube material, cap alignment, crimp uniformity, and ensure accurate volumetric fill, thereby minimizing the risk of costly recalls and ensuring absolute regulatory compliance, especially critical in pharmaceutical production.

- Enhanced Predictive Maintenance: AI models forecast equipment failure based on vibration, temperature, and current data, drastically reducing unscheduled downtime.

- Precision Dosing Optimization: Machine learning algorithms adjust servo motor speeds and piston stroke based on real-time viscosity measurements for superior fill accuracy.

- Advanced Quality Control: AI-powered vision systems ensure 100% inspection of sealing integrity and packaging aesthetics at high throughputs.

- Supply Chain Integration: AI optimizes raw material scheduling (tubes, product batch arrival) to minimize line stoppages and maximize production sequencing.

- Process Parameter Self-Adjustment: Automated system learning leads to continuous fine-tuning of heating, cooling, and pressure settings for optimal sealing performance across different materials.

DRO & Impact Forces Of Tube Filler Market

The Tube Filler Market dynamics are heavily influenced by a synergistic combination of market drivers, operational restraints, and strategic opportunities that collectively shape investment and technological development. Primary drivers include the massive expansion of the global consumer base for personal care and cosmetic products, particularly moisturizing creams, dental care items, and specialized topical treatments that are conventionally packaged in tubes. Concurrently, the rigorous standardization and increasing automation requirements within the pharmaceutical industry globally compel manufacturers to replace older, manual equipment with modern, validated, and high-speed automatic tube filling systems. These drivers create a sustained high demand trajectory for sophisticated machinery that guarantees sterility and filling precision.

However, the market faces significant restraints, most notably the high initial capital expenditure associated with purchasing high-end, fully automatic tube fillers, especially those incorporating advanced features like servo technology and integrated validation systems required for pharmaceutical applications. Furthermore, the specialized nature of these machines necessitates highly skilled technicians for operation, maintenance, and complex product changeovers, posing a challenge, particularly in developing economies where specialized technical talent may be scarce. Economic volatility and fluctuations in raw material prices (like stainless steel components and electronic control systems) also contribute to increased manufacturing costs, potentially dampening procurement decisions by smaller and mid-sized enterprises (SMEs).

Opportunities for growth are predominantly centered around the untapped potential of emerging markets, where local governments are actively promoting domestic manufacturing capabilities to meet burgeoning consumer demand locally. Moreover, the increasing focus on sustainable packaging presents a robust opportunity for tube filler manufacturers to innovate systems capable of handling new eco-friendly materials, such as bio-based plastics and thin-wall laminates, ensuring that machinery can manage these less rigid materials without compromising high-speed performance. The development of flexible, modular equipment that can rapidly switch between different tube formats (plastic, metal, laminate) with minimal changeover time also constitutes a key opportunity for market differentiation and expansion into co-packing and contract manufacturing services.

Segmentation Analysis

The Tube Filler Market segmentation provides a granular understanding of the industry landscape, categorized primarily by the level of automation (type), the material of the tube being processed (material), and the specific industry utilizing the equipment (end-user). This analytical framework is critical for stakeholders to identify high-growth sub-segments, understand technological adoption rates, and tailor product development strategies to specific industry needs. The classification reveals the pronounced shift toward higher automation levels driven by the need for increased production capacity and reduced labor costs across all major end-user verticals, indicating a maturation of industrial packaging processes globally.

By assessing the segments, it becomes evident that the pharmaceutical and cosmetic industries demand the highest level of precision and quality assurance, subsequently driving the market for complex, high-speed automatic systems with integrated verification technologies. Conversely, the food and chemical sectors often utilize a broader range of semi-automatic and lower-speed automatic fillers, depending on the scale of operation and product viscosity. The material segmentation underscores the ongoing evolution in packaging design, where the requirement to efficiently seal both resilient plastic tubes and delicate metal tubes necessitates continuous innovation in sealing head design and overall machine construction to ensure maximum versatility and minimum downtime.

- By Type:

- Automatic Tube Fillers

- Semi-Automatic Tube Fillers

- Manual Tube Fillers

- By Tube Material:

- Plastic Tubes (Polyethylene, Polypropylene)

- Laminate Tubes (Aluminum Barrier Laminate - ABL, Plastic Barrier Laminate - PBL)

- Metal Tubes (Aluminum)

- By Application/End-User:

- Pharmaceuticals (Creams, Gels, Ointments)

- Cosmetics & Personal Care (Moisturizers, Lotions, Hair Gels)

- Food & Beverage (Condiments, Concentrated Pastes)

- Chemicals & Industrial (Adhesives, Sealants)

- By Flow Capacity:

- Low-Speed (Up to 60 tubes/minute)

- Medium-Speed (60–150 tubes/minute)

- High-Speed (Above 150 tubes/minute)

Value Chain Analysis For Tube Filler Market

The value chain for the Tube Filler Market begins with upstream activities involving the sourcing of highly specialized raw materials, primarily precision-engineered stainless steel (often pharmaceutical grade 316L), advanced electronic components, servo motors, pneumatics, and sophisticated control system hardware and software. Key suppliers in this stage include specialized metallurgy companies, motion control manufacturers (e.g., Siemens, Rockwell Automation), and sensor technology providers. The quality and reliability of these upstream components directly dictate the final machine performance, speed, and validation compliance, emphasizing long-term strategic relationships between filler manufacturers and critical component suppliers to ensure high tolerance manufacturing.

The core of the value chain involves the design, manufacturing, assembly, and rigorous testing of the tube filling machines. Leading manufacturers leverage deep engineering expertise to design systems that maximize OEE, facilitate quick changeovers, and comply with international regulations (e.g., CFR 21 Part 11). Distribution channels typically follow a mixed model: direct sales and service for large, customized pharmaceutical lines, and a reliance on experienced regional distributors and agents for standardized CPG and low-to-medium speed machines. Aftermarket services, including maintenance contracts, spare parts supply, and technical upgrades, form a critical component of revenue generation and customer retention in the downstream segment.

Downstream analysis focuses on the end-users: pharmaceutical companies, multinational cosmetic brands, and large food processors. The efficiency of the tube filler machine directly impacts their operational costs, product quality, and time-to-market. Indirect distribution pathways involve machinery being sold through system integrators who incorporate the tube filler into a complete production line (e.g., linking it with cartoning, blister packing, and final case packing equipment). The value chain highlights that successful players must not only excel in manufacturing precision but also provide comprehensive validation support, training, and rapid global technical service to ensure continuous operation for high-stakes industries.

Tube Filler Market Potential Customers

The primary potential customers and end-users of tube filler technology span highly regulated and high-volume manufacturing sectors where hygienic filling and controlled dispensing are non-negotiable requirements. Pharmaceutical manufacturers represent one of the most critical customer groups, utilizing tube fillers for aseptic filling of topical dermatological products, suppositories, and specialized medical pastes. These buyers require equipment that is cGMP compliant, features full sterilization capabilities (CIP/SIP), and includes integrated serialization features for tracking and tracing individual tubes throughout the supply chain, often demanding highly customized and validated automatic lines.

The Cosmetic and Personal Care industry constitutes the largest volumetric consumer of tube fillers. Major multinational beauty conglomerates and niche cosmetic brands purchase these machines for packaging high-viscosity products such as foundations, sunscreens, hair conditioners, and specialized treatment creams. For this segment, machinery flexibility to handle aesthetic variations (e.g., unique tube shapes, diverse cap styles) and rapid product changeovers are key purchasing criteria, favoring machines that offer ultrasonic sealing for enhanced visual appeal and integrity of plastic and laminate tubes.

Other significant buyers include food manufacturers specializing in concentrated products like tomato paste, mustards, honey, and specialty spreads, demanding food-grade contact parts and easy sanitation designs. Chemical and industrial manufacturers utilize tube fillers for sealants, adhesives, lubricants, and specialized industrial compounds, often requiring specialized, heavy-duty piston pumps capable of handling extremely high viscosity or abrasive materials. Contract manufacturers (co-packers) represent a rapidly growing customer base, as they require the utmost flexibility to service multiple brand owners with diverse product and tube material specifications, thereby favoring modular and multi-format capable tube filling systems.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $780 Million USD |

| Market Forecast in 2033 | $1,155 Million USD |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Romaco Group, IWK Verpackungstechnik GmbH, Norden Machinery AB, KGK Jet, Accupack Engineering, JDA Progress, Bausch+Ströbel, Vetraco Group, GIC Ltd., Pack Leader Machinery Inc., M. O. Industries, Shree Bhagwati Machtech (India) Pvt. Ltd., New England Machinery Inc., Axomatic, Coesia S.p.A., Prosys Filling Systems, Marchesini Group, PMI Cartoning, Optima Packaging Group GmbH, GEA Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Tube Filler Market Key Technology Landscape

The technological landscape of the Tube Filler Market is characterized by the dominance of servo-driven mechanics, precision dosing systems, and advanced sealing methodologies designed to maximize throughput while ensuring unparalleled accuracy. Servo motor technology has become a cornerstone, replacing traditional mechanical and pneumatic actuators, offering greater control over tube positioning, piston filling stroke, and indexing speed. This transition minimizes wear and tear, reduces noise, and allows for rapid, software-controlled adjustments to accommodate varying fill volumes and product viscosities, which is paramount in multi-product manufacturing environments.

Precision dosing is maintained through piston pumps or positive displacement pumps integrated with sophisticated control systems. In high-stakes pharmaceutical and biotech applications, weight-based (gravimetric) or flowmeter filling systems are increasingly adopted to achieve highly accurate and verifiable fill amounts, often linked directly to the machine’s validation protocols. Furthermore, sealing technology continues to evolve; ultrasonic sealing is gaining traction for plastic and laminate tubes as it provides a cleaner, faster, and more energy-efficient seal compared to traditional hot air methods, minimizing the risk of thermal deformation of the tube material.

Modern tube fillers are also defined by their connectivity and compliance features. Integration of Industrial Internet of Things (IIoT) sensors enables continuous monitoring of temperature, pressure, and operational metrics, facilitating remote diagnostics and preventative maintenance. Compliance technologies, such as integrated vision systems for seal inspection (AEO/GEO focus on quality terms), and serialization modules for unique identification, are now mandatory in many regulated markets, driving innovation toward seamless integration with larger manufacturing execution systems (MES). The focus is consistently on achieving higher OEE through digitalization and precision engineering.

Regional Highlights

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, driven primarily by massive population growth, expanding middle-class consumption of personal care products, and significant government initiatives supporting domestic pharmaceutical manufacturing, particularly in China, India, and Southeast Asian nations. The region favors highly flexible automatic machines capable of handling diverse tube types to serve extensive local markets.

- North America: North America holds a dominant position in technology adoption, characterized by a demand for high-speed, fully automatic tube fillers incorporating advanced features like AI-powered quality control and complex serialization capabilities essential for FDA compliance. Market growth is sustained by continuous innovation in cosmetics and specialty pharmaceuticals.

- Europe: Europe represents a mature but stable market, focusing heavily on sustainability and precision engineering. Demand is high for tube fillers compatible with eco-friendly and mono-material plastic tubes. Germany, Italy, and Switzerland are hubs for manufacturing and adopting sophisticated, high-reliability machinery used extensively in premium cosmetics and robust pharmaceutical operations.

- Latin America (LATAM): Growth in LATAM is driven by improving economic conditions and the necessity for localized production to displace imports. Brazil and Mexico are key markets showing increased procurement of medium-speed automatic fillers for local cosmetic and food processing sectors.

- Middle East and Africa (MEA): MEA is showing steady growth, primarily fueled by infrastructure development in the pharmaceutical sector (especially Saudi Arabia and UAE) and the local production of detergents and personal hygiene products. The region presents opportunities for suppliers of cost-effective, durable, semi-automatic, and low-speed automatic equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Tube Filler Market.- Romaco Group

- IWK Verpackungstechnik GmbH

- Norden Machinery AB

- KGK Jet

- Accupack Engineering

- JDA Progress

- Bausch+Ströbel

- Vetraco Group

- GIC Ltd.

- Pack Leader Machinery Inc.

- M. O. Industries

- Shree Bhagwati Machtech (India) Pvt. Ltd.

- New England Machinery Inc.

- Axomatic

- Coesia S.p.A.

- Prosys Filling Systems

- Marchesini Group

- PMI Cartoning

- Optima Packaging Group GmbH

- GEA Group

Frequently Asked Questions

Analyze common user questions about the Tube Filler market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the key differences between metal, plastic, and laminate tube filling processes?

Metal tubes require crimp sealing, which folds the aluminum end to create a hermetic seal. Plastic tubes use hot air or heated jaws to melt and fuse the material. Laminate tubes, offering better barrier protection, typically utilize sophisticated hot air or ultrasonic sealing technologies for a clean, secure closure, requiring greater precision in heat management.

What is the typical lifespan and ROI for a fully automatic tube filler?

A high-quality, fully automatic tube filler often has an operational lifespan exceeding 15 to 20 years with proper maintenance. The Return on Investment (ROI) is generally achieved within 3 to 5 years, driven by significant increases in production volume, reductions in labor costs, and minimized product rejection rates due to superior filling accuracy.

How does cGMP compliance affect the design of pharmaceutical tube fillers?

cGMP compliance mandates that pharmaceutical tube fillers incorporate stainless steel 316L contact parts, smooth welding surfaces for easy cleaning, clean-in-place/sterilization-in-place (CIP/SIP) capabilities, and validated software systems (21 CFR Part 11) to prevent cross-contamination and ensure repeatable, verifiable aseptic filling processes.

Which tube sealing method is most efficient for high-speed production?

For plastic and laminate tubes, high-frequency ultrasonic sealing is increasingly considered the most efficient method for high-speed lines, as it achieves faster sealing cycles, reduces energy consumption compared to hot-air heaters, and delivers aesthetically superior, highly reliable seals without excessive material deformation.

What role does servo technology play in modern tube filling machines?

Servo technology provides digital, high-precision control over critical functions such as tube indexing, dosing pump actuation, and sealing head movement. This control enables instantaneous adjustments, facilitates rapid changeovers for different products, and significantly improves filling accuracy and operational efficiency across the entire speed spectrum.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager