Tumbling Screen Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432241 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Tumbling Screen Market Size

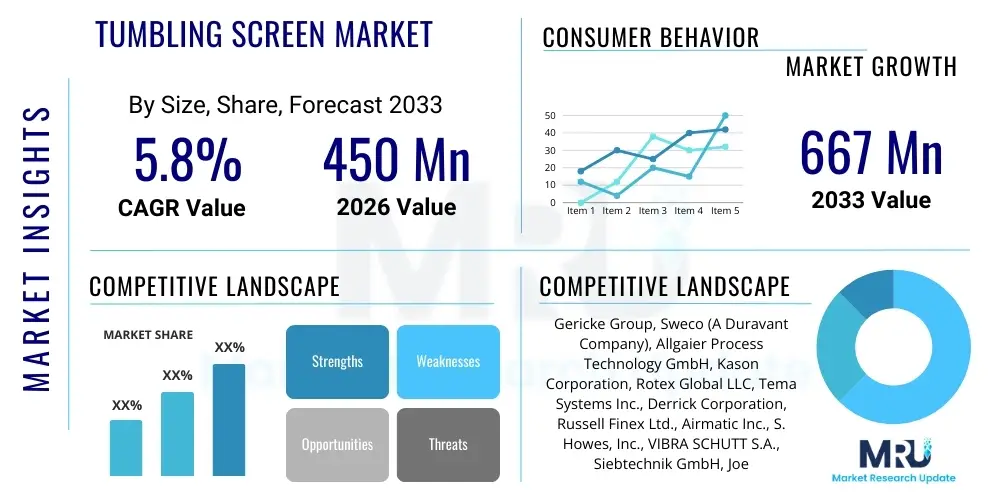

The Tumbling Screen Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 667 Million by the end of the forecast period in 2033.

Tumbling Screen Market introduction

The Tumbling Screen Market encompasses the manufacturing, sales, and servicing of highly specialized industrial separation equipment engineered for meticulous particle size classification, particularly within the challenging domain of fine powders and fragile granular materials. These machines utilize a sophisticated, non-linear kinematic motion—a combination of horizontal rotation, radial acceleration, and vertical throw—that effectively stratifies the material bed across the entire surface of the screen. This gentle yet highly efficient action ensures that every particle has multiple opportunities to pass through the mesh, leading to exceptional separation accuracy and throughput optimization, which is unattainable with conventional linear or circular vibrating screens. The foundational principle is to minimize vertical vibration intensity while maximizing material transport and layer separation, thereby mitigating common issues like mesh blinding and particle attrition, critical factors in high-value material processing.

Product descriptions of modern tumbling screens emphasize their modularity, precision control systems, and adherence to stringent hygienic standards, particularly those utilizing polished stainless steel (316L) contact parts and quick-clamping mechanisms essential for Good Manufacturing Practice (GMP) environments. Major applications span across critical industrial sectors: in pharmaceuticals, they classify Active Pharmaceutical Ingredients (APIs) and excipients to ensure dosage consistency; in food processing, they sort delicate ingredients like starches, flour, and coffee without damage; and in advanced chemical production, they handle fine pigments, catalysts, and specialized polymers that demand highly uniform sizing. Key benefits include dramatically reduced dust generation, high yields (up to 99% purity), and the capability to perform up to five distinct separations simultaneously using stacked deck configurations, providing cost-effective and space-saving solutions for complex industrial grading tasks.

Market growth is primarily propelled by the intensifying global regulatory environment, particularly the demand for finer classification cuts and tighter tolerances in particle size specifications across consumer and industrial goods. Driving factors include the continuous expansion of high-tech manufacturing, such as the processing of metal powders for additive manufacturing (3D printing), which demands ultra-narrow particle size distribution ranges, and the increasing complexity of raw materials used in modern industrial formulations, necessitating sophisticated separation tools. Furthermore, the push towards automated, continuous processing lines integrated with real-time quality control mandates the use of reliable, high-performance screening technology that can operate consistently over long periods with minimal manual intervention, solidifying the tumbling screen's position as a premium choice in precision material handling systems globally.

Tumbling Screen Market Executive Summary

The Tumbling Screen Market is experiencing robust expansion driven by global trends toward quality assurance and process optimization in sensitive industries. Business trends reveal a pronounced shift toward customization and system integration, where leading manufacturers are offering bespoke screening solutions engineered precisely for specific material characteristics—such as cohesive, electrostatic, or highly abrasive powders—rather than relying on standardized equipment. Key market players are actively pursuing intellectual property surrounding novel kinematic drives and ultrasonic cleaning attachments, aiming to enhance screening efficiency for materials below 50 micrometers. Furthermore, strategic alliances and mergers focused on expanding global service networks and ensuring reliable sourcing of high-tolerance mesh materials are defining the competitive landscape, emphasizing full-service offerings over mere hardware sales.

Regional trends indicate that Asia Pacific (APAC) stands out as the primary market accelerator, driven by the massive scaling of chemical and pharmaceutical production capacity, supported by governmental initiatives focused on modernizing industrial infrastructure in nations like China, India, and Southeast Asian economies. While North America and Europe maintain technological superiority and dominance in specialized, low-volume, high-value applications (e.g., aerospace materials, complex recycling), the APAC region is forecast to deliver the highest compounded annual growth rate, fueled by greenfield industrial projects demanding new, efficient processing equipment. Regulatory convergence, particularly adherence to European and US quality standards in manufacturing exported goods, further motivates APAC companies to invest in high-precision technologies like tumbling screens.

Analysis of segment trends highlights the strong performance of the multi-deck configuration, increasingly favored for its ability to maximize production efficiency by achieving simultaneous classification of three or more product fractions within a single unit, thereby reducing overall plant footprint and capital costs. By application, the pharmaceutical and food & beverage segments remain the most demanding and lucrative due to the non-negotiable requirement for zero contamination and gentle handling, spurring innovation in hygienic design and rapid validation protocols. There is also emerging segment strength in the Waste & Recycling sector, where advanced screening is essential for maximizing the recovery rate of reusable materials, such as separating fine plastic granules or optimizing the quality of recycled glass aggregates, indicating a growing importance of sustainability-driven adoption.

AI Impact Analysis on Tumbling Screen Market

User inquiries regarding Artificial Intelligence (AI) integration center around transforming the fundamentally mechanical process of screening into an intelligent, self-optimizing system capable of continuous improvement without operator intervention. Common user questions address how AI can interpret complex sensor data—including real-time acoustic signatures, motor current fluctuations, and flow meter data—to predict the onset of screen blinding or degradation long before visible performance decline occurs. Customers express high expectations that AI modeling will allow for 'recipes' or operational parameters to be instantly adjusted to maintain a precise, desired particle distribution even when the physical characteristics of the incoming raw material batch, such as humidity or bulk density, vary substantially. Concerns often relate to the cybersecurity of networked industrial controls and the necessity for robust, secure data integration platforms capable of handling the high volume of machine data generated by continuous monitoring in GMP environments. The consensus expectation is that AI will redefine maintenance practices, shift performance guarantees from static specifications to dynamic, yield-based metrics, and substantially lower the total cost of ownership by maximizing uptime and product consistency.

- AI-driven Predictive Maintenance Systems: Algorithms analyze micro-vibrations and thermal patterns in drive components to accurately predict residual useful life (RUL) of bearings, seals, and motors, enabling highly precise scheduling of preventative maintenance activities during planned outages.

- Autonomous Parameter Tuning: Machine learning models continuously process input material quality data (e.g., laser diffraction results) and output performance metrics, automatically adjusting the screen's gyratory speed, angle, and eccentric throw to optimize instantaneous separation efficiency (yield maximization).

- Enhanced Mesh Health Monitoring: High-resolution sensors and AI image recognition or acoustic profiling detect minute changes in mesh tension or early stage fouling/blinding, initiating automated cleaning procedures (like ultrasonic bursts) only when strictly necessary, conserving energy and reducing mesh wear.

- Process Diagnostics and Anomaly Detection: AI platforms establish a baseline 'healthy' operational profile; any deviations, such as unusual power consumption or inconsistent particle flow, trigger immediate, contextualized alerts to operators, improving diagnostic speed and reducing the risk of large batch rejection.

- Optimization of Cleaning Cycles: Based on historical processing data and material attributes, AI minimizes the frequency and duration of wash-down procedures in hygienic applications while maintaining validation standards, drastically improving equipment utilization rates (OEE).

DRO & Impact Forces Of Tumbling Screen Market

The operational landscape of the Tumbling Screen Market is shaped by powerful forces emanating from demanding material specifications and technological constraints. The primary drivers revolve around the continuous, global increase in quality standards for fine powders, particularly in controlled industries such as pharmaceuticals, where regulatory bodies mandate precise particle size segregation to ensure efficacy and dissolution rates. The inherent gentle action of tumbling screens minimizes particle attrition, making them essential for high-value, fragile materials. Restraints include the high capital expenditure required for these complex kinematic systems compared to conventional screening devices, often posing a substantial financial barrier for smaller or regional manufacturers. Additionally, the requirement for highly skilled technicians for precise setup and maintenance of the three-dimensional motion parameters represents an operational constraint, particularly in regions with labor skill shortages. Opportunities are emerging strongly within green technology sectors, specifically in the precise sizing of battery electrode materials and advanced catalysts, demanding extremely tight tolerances that tumbling screens are uniquely capable of meeting, paving new pathways for market expansion and premium pricing.

Key drivers also include the globalization of manufacturing supply chains, which necessitates equipment capable of processing a diverse array of raw materials sourced globally, often exhibiting slight variations in moisture, shape, and density. Tumbling screens, especially those with variable motion control (VMC) systems, offer the flexibility required to adapt to these input variabilities without compromising end-product quality, reinforcing their value proposition as reliable, adaptable process equipment. The increasing focus on minimizing environmental impact also acts as a driver; superior efficiency means less wasted product and reduced energy consumption per ton of material processed, aligning with corporate sustainability mandates. Moreover, the integration of advanced automation and dust containment systems is rapidly becoming a standard requirement, driving market demand toward fully enclosed, hygienic, and automated screening solutions, especially in developed economies with stringent occupational health regulations.

Despite the technological superiority, the market remains restrained by the competitive pressure exerted by high-frequency vibratory screens and air classifiers, which offer lower initial costs for certain macro-screening applications. Overcoming this requires manufacturers to meticulously document and quantify the long-term operational benefits of tumbling screens, such as reduced product loss and lower energy usage over the equipment lifecycle. The principal impact force on the market remains technological substitution; continuous innovation in motion control, mesh durability (e.g., using advanced ceramics or high-tensile synthetics), and integration capabilities (Industry 4.0 connectivity) is crucial to maintaining the competitive edge. Failure to innovate in these areas could lead to stagnation, while successful advancements open up high-margin opportunities in emerging fields like bio-processing and advanced ceramics, where separation requirements are increasingly moving into the sub-50 micrometer range.

Segmentation Analysis

Segmentation analysis of the Tumbling Screen Market provides crucial insights into the diverse requirements of end-user industries, dictated by factors such as material fragility, required throughput, and the criticality of separation accuracy. The differentiation between single-deck and multi-deck configurations is fundamental; single-deck units cater primarily to high-capacity scalping or single-product classification, while multi-deck systems—often incorporating three to five screens—are optimized for complex grading processes where materials must be simultaneously separated into multiple precise size fractions (coarse, medium, fine, and dust), offering superior process efficiency and reducing the need for sequential screening stages. Furthermore, the market is segmented by the level of material contact surface finish, ranging from standard industrial grades for mining to ultra-smooth, crevice-free finishes mandated by pharmaceutical GMP guidelines, influencing both manufacturing costs and end-user pricing strategies.

A deep dive into the application segments reveals distinct performance criteria. The Pharmaceutical and Food segments demand equipment that offers total product recovery, rapid changeover capability (for handling different recipes), and documented material traceability, often necessitating fully automated cleaning-in-place (CIP) systems. Conversely, the Mining and Construction sectors prioritize sheer volume, durability against abrasive materials, and large-scale mechanical robustness, driving demand for high-tonnage units with wear-resistant steel components. The emerging segment of Waste & Recycling requires systems capable of handling heterogeneous feeds, necessitating sophisticated screen tensioning and anti-blinding devices to manage moist or irregularly shaped particulates common in recovery processes, thereby driving innovation in specialized elastomer cleaning ball systems or integrated air jets.

The segmentation by capacity is pivotal for manufacturers planning product lines, ranging from small, laboratory-scale machines used for quality control and research and development (R&D) to massive, continuous industrial screeners processing hundreds of tons per hour. Market forecasting suggests that while high-capacity units dominate revenue in bulk material handling regions like APAC, the growth rate in the R&D and specialized medium-capacity segments remains high in North America and Europe, fueled by the development of novel advanced materials. Therefore, manufacturers must strategically balance investment between developing robust, high-throughput mechanical systems and sophisticated, compact, high-precision laboratory models equipped with advanced digital controls for research applications, ensuring comprehensive market coverage across the entire industrial scale spectrum.

- By Type/Mechanism:

- Single-Deck Tumbling Screens: Used for scalping, safety screening, or single precise separation cuts; optimized for high throughput of specific material streams.

- Multi-Deck Tumbling Screens (Up to 5 decks): Preferred for classification into multiple size fractions simultaneously, maximizing yield and process efficiency in limited space.

- Hybrid Screening Systems (Integrating Ultrasonic Cleaning): Specialized units integrating high-frequency sound waves to prevent mesh blinding, critical for separation below 100 µm, particularly with cohesive powders.

- By Application:

- Pharmaceuticals & Cosmetics: Requires GMP-compliant, hygienic design (316L stainless steel, polished finish) for APIs, excipients, and granulates; focus on zero contamination.

- Food & Beverage Processing (e.g., Dairy, Spices, Grains): Demands EHEDG standards; gentle handling is paramount to maintain particle integrity (e.g., instant coffee, sugar).

- Chemical Processing (e.g., Fertilizers, Plastics, Pigments): Handles highly abrasive, corrosive, or electrostatic materials; focuses on operational safety (ATEX compliance) and high volume.

- Mining & Metallurgy (e.g., Fine Ore Screening, Powders): High-capacity requirements, robust construction, and resistance to heavy wear; screening fine metallic powders for downstream processing.

- Waste & Recycling (e.g., Glass Fines, Aggregates): Used for precise size separation of recovered materials, enhancing purity and market value of recycled products.

- Construction Materials (e.g., Cement, Dry Mortar Mixes): Large-volume application demanding high reliability and resistance to dusty, heavy loads in continuous operation environments.

- By Capacity/Size:

- Low Capacity (Lab & R&D Scale): Benchtop or small production units used for pilot studies, sample preparation, and quality control validation of new material batches.

- Medium Capacity (Pilot & Batch Production): Versatile systems for flexible manufacturing lines, bridging the gap between R&D and full-scale industrial output.

- High Capacity (Continuous Industrial Production): Large-diameter screeners (up to 3 meters) designed for 24/7 operation and maximum material throughput in bulk industries.

- By Motion Control:

- Fixed Parameter Systems: Economical, standard units where operational parameters (speed, throw) are factory-set or manually adjusted; suitable for consistent materials.

- Variable/Adjustable Motion Systems: Utilizes VFDs and advanced control algorithms to dynamically adjust screening motion in real-time, optimizing performance for variable input materials.

Value Chain Analysis For Tumbling Screen Market

The upstream segment of the Tumbling Screen value chain is dominated by highly specialized material suppliers whose contributions directly affect the performance and longevity of the final product. Crucial raw materials include aerospace-grade stainless steel for structural integrity and corrosion resistance, specialized elastomers and rubber compounds for flexible connections and suspension systems, and high-precision motor and gearbox assemblies capable of reliably generating the complex three-dimensional gyratory motion. Most importantly, the performance bottleneck lies with the proprietary screen mesh suppliers, who provide high-tensile wire mesh, often in materials like molybdenum or specialized synthetic fibers, achieving aperture tolerances often measured in single-digit micrometers. Intellectual property surrounding mesh geometry and anti-blinding treatments significantly influences the competitive dynamics at the OEM level. Efficient procurement strategies focusing on long-term partnerships with these specialized material vendors are essential for managing input costs and ensuring component quality, particularly for hygienic-grade equipment.

The midstream sector, consisting of Original Equipment Manufacturers (OEMs), focuses on design innovation, precision machining, and system integration. OEMs differentiate themselves through patented kinematic drive mechanisms that allow for fine-tuning of the screening parameters, ergonomic designs that facilitate rapid, tool-free screen changes, and the integration of smart sensor technology for condition monitoring. The assembly process involves complex welding and polishing techniques, particularly for pharmaceutical-grade units, to meet surface finish requirements (e.g., Ra < 0.8 µm). Direct distribution channels are highly favored, especially for large, custom installations in North America and Europe, where detailed pre-sale technical consultation and comprehensive integration services are mandatory. OEMs maintain dedicated engineering teams to work closely with end-users to optimize the screen's operational "recipe" for their specific powder characteristics.

The downstream activities are dominated by installation, commissioning, and, critically, the lucrative aftermarket services segment. Aftermarket sales, including proprietary spare parts (such as seals, bushings, and customized meshes), maintenance contracts, and operational optimization consulting, constitute a substantial and high-margin revenue stream, offering stability throughout economic cycles. End-users prioritize vendors who can provide rapid deployment of certified technicians and readily available replacement parts globally, minimizing potential production downtime. Indirect distribution utilizes local agents and industrial supply houses primarily for standard components and smaller, standardized units. The overall efficiency of the value chain is increasingly measured by the vendor’s ability to offer remote diagnostics and digital twin simulations, ensuring the installed base operates at peak efficiency throughout its extensive service life, thereby locking in long-term customer relationships and insulating the market from purely price-based competition.

Tumbling Screen Market Potential Customers

Potential customers for tumbling screens are predominantly entities requiring superior separation efficiency, gentle material handling, and adherence to extremely fine tolerances in particle size distribution. This primarily includes regulated high-purity industries where product value is directly tied to quality and uniformity, making precise classification non-negotiable. Key buyers are often process engineers, plant managers, and procurement specialists within these organizations, seeking to upgrade existing inefficient separation systems or integrate high-end equipment into new facility builds to achieve global quality certification standards (e.g., ISO, GMP).

The pharmaceutical sector represents a highly valuable customer base, purchasing these screens for sorting active pharmaceutical ingredients, excipients, and granulation products, requiring specialized hygienic designs (e.g., quick-change mechanisms, polished stainless steel) to prevent cross-contamination and facilitate swift cleaning validation. Similarly, major food and beverage manufacturers utilize tumbling screens for processing sensitive goods like milk powder, spices, starch, and cocoa, where particle damage must be avoided to maintain texture, flavor, and solubility characteristics, leading them to prefer the gentle motion provided by this technology over harsh vibration. The strict regulatory environment mandates continuous investment in equipment that minimizes product risk and maximizes batch consistency.

Beyond highly regulated areas, customers in the high-end chemicals industry (e.g., specialty polymers, fine ceramics) and advanced recycling facilities (e.g., separating battery components or precious metals from electronic waste) are also crucial buyers. These customers demand equipment capable of handling difficult materials that are abrasive, cohesive, or highly electrostatic, where conventional systems fail due to blinding or wear. Strategic marketing efforts often focus on demonstrating quantifiable improvements in yield and purity achieved through advanced screening dynamics, targeting facilities seeking to meet new sustainability goals or enhance product premiumization through superior material purity.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 667 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Gericke Group, Sweco (A Duravant Company), Allgaier Process Technology GmbH, Kason Corporation, Rotex Global LLC, Tema Systems Inc., Derrick Corporation, Russell Finex Ltd., Airmatic Inc., S. Howes, Inc., VIBRA SCHUTT S.A., Siebtechnik GmbH, Joest Group, Rhewum GmbH, AZO GmbH + Co. KG, Hosokawa Micron Corporation, Vibro-Tech Engineers, General Kinematics Corporation, Midwest Engineered Systems Inc., GKM Siebtechnik GmbH, Coperion K-Tron, Bühler AG. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Tumbling Screen Market Key Technology Landscape

The technological evolution defining the competitive landscape of the Tumbling Screen Market is heavily influenced by the drive towards enhanced material science, dynamic motion control, and sophisticated digitalization. A cornerstone technology is the Variable Motion Control (VMC) system, which replaces fixed-speed drives with sophisticated algorithms integrated into Variable Frequency Drives (VFDs). VMC allows operators to independently adjust the three critical screening motions—tangential acceleration (product transport speed), radial acceleration (stratification), and vertical lift (throw)—based on instantaneous analysis of material properties such as particle moisture or loading rate. This real-time adaptability is crucial for maintaining consistent separation efficiency and throughput across variable input batches, offering a significant performance advantage in highly regulated processing environments and reducing manual recalibration time, thus enhancing overall equipment effectiveness (OEE).

Furthermore, managing mesh blinding remains a major technological focus. The market is increasingly adopting Hybrid Screening Systems, which combine the primary gyratory motion with secondary, localized cleaning mechanisms. Ultrasonic systems, employing transducers to generate high-frequency micro-vibrations across the mesh surface (typically between 30 kHz and 40 kHz), are highly effective for fine powders prone to agglomeration. Alternatives include specialized elastomeric balls and rotating brushes, chosen based on the material's properties. Innovation also extends to the design of the screening media itself, moving beyond standard stainless steel to incorporate high-performance synthetic meshes (e.g., Nylon, Polyester) and specialized coatings that reduce static adhesion and improve abrasion resistance, thereby extending operational life and reducing the frequency of costly mesh replacement.

The integration of Industry 4.0 elements is transforming tumbling screens into smart, networked assets. Modern machines are equipped with an array of sensors measuring key operational parameters—including bearing temperature, structural vibration harmonics, motor current draw, and differential pressure across the screen decks—to provide a comprehensive digital operational profile. This data is leveraged for advanced condition monitoring and seamless integration into plant-wide SCADA and MES systems, enabling centralized performance management and remote diagnostics. Future developments are focused on fully enclosed, hermetically sealed systems that offer ATEX Zone 20 compliance for handling explosive dusts, coupled with automated CIP/SIP (Cleaning-in-Place/Sterilization-in-Place) functionality, ensuring compliance with the most rigorous safety and hygienic processing standards demanded by the fine chemicals and pharmaceutical sectors worldwide.

Regional Highlights

- Asia Pacific (APAC): APAC is projected to lead the market in volume adoption, driven by unparalleled industrialization rates and government backing for modern manufacturing. Key growth sectors include large-scale chemical intermediates, specialty fertilizers, and the vast expansion of the pharmaceutical generics market, particularly in India and China, which are adopting high-capacity multi-deck screens to meet surging domestic and export demands. The region exhibits a growing preference for systems that offer both high throughput and energy efficiency, often emphasizing rapid return on investment and localized service support networks.

- North America: This region is characterized by high investment in innovation and adherence to stringent quality control, especially in specialty chemical manufacturing, advanced materials (e.g., aerospace alloys, carbon fiber precursors), and biotechnology. Demand centers around replacing legacy equipment with advanced systems featuring AI integration, sophisticated data logging, and customized hygienic designs compliant with FDA standards. The focus is less on sheer volume and more on ultra-precise separation cuts (sub-50 µm) and minimizing product loss in high-value processes.

- Europe: Europe maintains a strong foothold due to its leadership in high-end machinery manufacturing and stringent environmental and occupational safety regulations (e.g., REACH, ATEX). German, Swiss, and Italian manufacturers drive demand for premium-priced, highly engineered tumbling screens that incorporate low-noise operation, maximum energy efficiency, and full integration capabilities. The pharmaceutical and automotive catalyst production sectors are major consumers, demanding validated, compliant, and reliable separation technology capable of decades-long operational lifecycles.

- Latin America (LATAM): The LATAM market growth is episodic, heavily influenced by commodity price fluctuations, particularly in mining (e.g., copper, iron ore) and large-scale agriculture (fertilizers, animal feed). While sensitive to initial capital cost, there is increasing investment in robust, medium-to-high capacity screens in Brazil and Mexico to upgrade processing standards. Key purchasing criteria include mechanical durability, ease of maintenance in remote locations, and vendor financing options to mitigate large upfront investment risks.

- Middle East and Africa (MEA): Growth in MEA is concentrated in the GCC states (Saudi Arabia, UAE) due to petrochemical infrastructure projects, large-scale construction, and specialized food processing facilities. The high ambient temperatures and dry, dusty operating environments necessitate specialized equipment features like enhanced motor cooling, sealed bearings, and robust dust extraction interfaces. The market is primarily import-driven, relying heavily on European and North American suppliers for proven technology and reliable long-term service contracts.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Tumbling Screen Market.- Gericke Group

- Sweco (A Duravant Company)

- Allgaier Process Technology GmbH

- Kason Corporation

- Rotex Global LLC

- Tema Systems Inc.

- Derrick Corporation

- Russell Finex Ltd.

- Airmatic Inc.

- S. Howes, Inc.

- VIBRA SCHUTT S.A.

- Siebtechnik GmbH

- Joest Group

- Rhewum GmbH

- AZO GmbH + Co. KG

- Hosokawa Micron Corporation

- Vibro-Tech Engineers

- General Kinematics Corporation

- Midwest Engineered Systems Inc.

- GKM Siebtechnik GmbH

- Coperion K-Tron

- Bühler AG

Frequently Asked Questions

Analyze common user questions about the Tumbling Screen market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between a tumbling screen and a conventional vibratory screen?

The primary distinction lies in motion. Tumbling screens use a gentle, three-dimensional gyratory motion (combining rotation and bounce) optimized for fine, difficult powders, offering significantly higher screening accuracy and reduced particle degradation or mesh blinding compared to the high-amplitude, linear motion of conventional vibratory screens.

In which industries is high-purity separation by tumbling screens most critical?

High-purity separation is most critical in the pharmaceutical industry (for APIs and excipients), high-end food processing (for milk powders, spices), and advanced chemical manufacturing, where stringent regulatory requirements mandate precise particle size distribution and contamination-free processing.

What is the typical lifespan and maintenance requirement for screen meshes?

The lifespan of a screen mesh varies widely based on the processed material's abrasiveness and operational throughput, typically ranging from a few weeks to several months. Maintenance often involves ultrasonic cleaning systems to maintain maximum efficiency and rapid, tool-free mesh changes, which are critical features sought by end-users to minimize production stops and improve Overall Equipment Effectiveness (OEE).

How does ultrasonic technology enhance the performance of a tumbling screen?

Ultrasonic technology applies high-frequency vibrations directly to the screen mesh, effectively preventing fine, cohesive particles from sticking or blinding the apertures. This non-contact cleaning method drastically improves throughput efficiency, especially for ultra-fine separations (below 100 micrometers), allowing for continuous, high-precision operation without interrupting the primary tumbling motion.

Which geographical region dominates the adoption of high-capacity tumbling screens?

Asia Pacific (APAC) currently dominates the adoption of high-capacity tumbling screens, primarily driven by large-scale applications in infrastructure, construction materials (cement), and expanding metallurgy sectors, alongside the rapid scaling of domestic chemical production capacity required to meet global supply chain demands.

What role does hygienic design play in the Tumbling Screen Market?

Hygienic design is crucial for the pharmaceutical and food segments, involving features like polished stainless steel contact surfaces (Ra values less than 0.8 µm), crevice-free interiors, and tool-free quick-release clamps. These designs facilitate rapid cleaning validation, minimize cross-contamination risk, and ensure compliance with strict regulatory bodies like the FDA and EHEDG.

How are Tumbling Screen manufacturers integrating Industry 4.0 principles?

Manufacturers are integrating Industry 4.0 through advanced sensor packages (IoT), which monitor operational variables like vibration harmonics and motor current. This data feeds into AI-driven platforms for predictive maintenance, remote diagnostics, and automated parameter tuning, shifting operations towards self-optimizing, networked production assets.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager