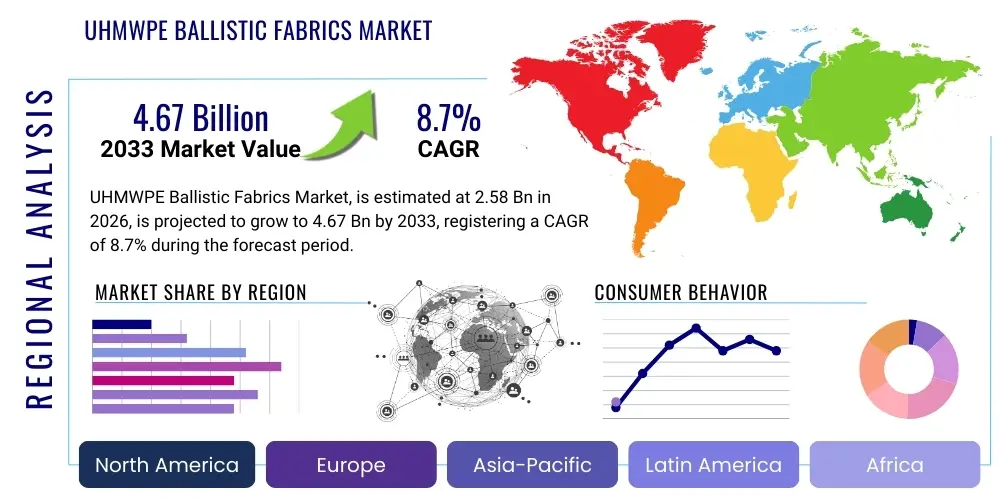

UHMWPE Ballistic Fabrics Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440215 | Date : Jan, 2026 | Pages : 253 | Region : Global | Publisher : MRU

UHMWPE Ballistic Fabrics Market Size

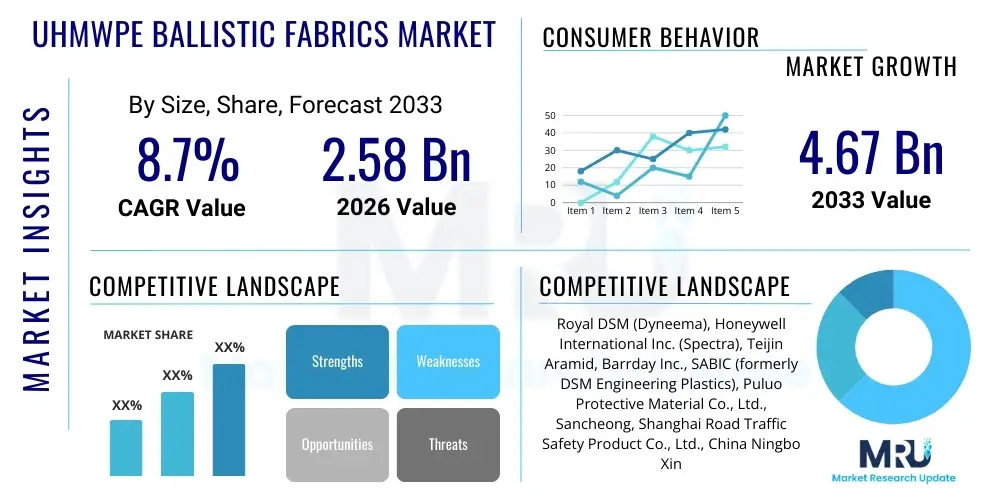

The UHMWPE Ballistic Fabrics Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.7% between 2026 and 2033. The market is estimated at USD 2.58 Billion in 2026 and is projected to reach USD 4.67 Billion by the end of the forecast period in 2033.

UHMWPE Ballistic Fabrics Market introduction

The Ultra-High Molecular Weight Polyethylene (UHMWPE) Ballistic Fabrics Market encompasses the production and distribution of advanced composite materials specifically engineered to provide superior protection against ballistic threats. These fabrics are distinguished by their exceptional strength-to-weight ratio, high energy absorption capabilities, and resistance to abrasion and impact, making them ideal for a wide range of protective applications. They represent a significant advancement over traditional ballistic materials, offering enhanced performance while significantly reducing overall weight, a critical factor in military and law enforcement operations.

Major applications for UHMWPE ballistic fabrics span across various sectors, primarily within defense, law enforcement, and personal protection. This includes the manufacturing of body armor, such as bulletproof vests and plates, helmets, and protective gear for vehicles, aircraft, and marine vessels. The material's unique properties also lend themselves to specialized applications in sports equipment and industrial safety where high impact resistance is paramount. The increasing demand for lightweight, high-performance protective solutions is a primary driver fueling market expansion.

The inherent benefits of UHMWPE ballistic fabrics, such as their low density, excellent chemical resistance, and UV stability, contribute to their growing adoption. These properties translate into durable, long-lasting protective equipment that can withstand harsh environmental conditions without significant degradation in performance. Moreover, ongoing research and development efforts are continuously improving the manufacturing processes and material formulations, leading to even more advanced and cost-effective solutions, further solidifying their position as a preferred material for ballistic protection.

UHMWPE Ballistic Fabrics Market Executive Summary

The UHMWPE Ballistic Fabrics Market is experiencing robust growth driven by escalating global security concerns, modern military modernization programs, and the increasing emphasis on advanced personal protective equipment for law enforcement and special forces. Business trends indicate a strong focus on innovation, with manufacturers investing heavily in R&D to enhance ballistic performance, reduce material weight, and improve cost-efficiency. Strategic collaborations, mergers, and acquisitions are also prevalent, aimed at expanding production capacities, diversifying product portfolios, and penetrating new geographical markets. The market is characterized by a competitive landscape where material science expertise and manufacturing precision are key differentiators.

Regional trends highlight North America and Europe as dominant markets, primarily due to substantial defense budgets, robust technological infrastructure, and the presence of leading manufacturers and end-users. However, the Asia Pacific region is rapidly emerging as a high-growth market, propelled by increasing defense expenditures in countries like China and India, rising domestic security threats, and a growing awareness of advanced protective solutions. Latin America, the Middle East, and Africa are also showing promising growth potential, albeit from a smaller base, driven by regional conflicts and the need for modernizing security forces. Export-import activities are crucial, with a complex global supply chain supporting the distribution of these specialized materials.

Segment trends reveal a continued dominance of unidirectional (UD) laminates due to their superior ballistic performance and flexibility, making them ideal for personal armor. However, woven fabrics also maintain a significant share, particularly in applications requiring structural rigidity and multi-hit capabilities. The end-user segment is heavily skewed towards military and defense applications, but law enforcement and homeland security are experiencing accelerated growth. There is an increasing interest in civilian applications, such as sports and outdoor activities, for lightweight, impact-resistant gear, signaling diversification opportunities for market players.

AI Impact Analysis on UHMWPE Ballistic Fabrics Market

User inquiries about AI's influence on the UHMWPE Ballistic Fabrics market frequently revolve around its potential to revolutionize material discovery, optimize manufacturing processes, and enhance quality control. Common questions explore whether AI can accelerate the development of next-generation ballistic materials, predict material performance under various threat scenarios, or enable more efficient production with reduced waste. There's also significant interest in how AI could impact the supply chain, from raw material sourcing to final product distribution, and if it could lead to more personalized or adaptive protective gear. The overarching theme is an expectation that AI will bring unprecedented levels of precision, efficiency, and innovation to a market traditionally driven by empirical testing and incremental material advancements.

- AI-driven material science platforms can accelerate the discovery and design of novel UHMWPE polymer structures, optimizing molecular configurations for enhanced ballistic properties and lighter weight.

- Predictive analytics and machine learning algorithms can be employed for real-time quality control during fabric production, identifying defects or inconsistencies that might compromise ballistic integrity more effectively than traditional methods.

- AI can optimize manufacturing parameters, such as weaving patterns, fiber alignment, and lamination processes, leading to increased production efficiency, reduced material waste, and improved consistency in the final product.

- Supply chain management can leverage AI for demand forecasting, inventory optimization, and identifying potential disruptions, ensuring a more resilient and cost-effective flow of raw materials and finished products.

- Simulations powered by AI and machine learning can accurately model and predict the ballistic performance of new fabric compositions, reducing the need for extensive physical testing and significantly shortening product development cycles.

- AI can facilitate the development of smart ballistic fabrics integrated with sensors for real-time monitoring of impact, damage assessment, or even vital signs of the wearer, particularly for military and law enforcement applications.

- Robotics and automation, often AI-controlled, can handle complex and repetitive tasks in manufacturing, leading to higher precision and faster throughput, especially in the fabrication of intricate armor components.

DRO & Impact Forces Of UHMWPE Ballistic Fabrics Market

The UHMWPE Ballistic Fabrics Market is propelled by several key drivers, primarily the escalating global defense expenditures and the increasing prevalence of geopolitical instability, which necessitate advanced protective equipment for military and law enforcement personnel. The continuous drive for lightweight and high-performance materials in protective gear is another significant factor, as UHMWPE offers superior ballistic resistance at a fraction of the weight of traditional materials, enhancing user mobility and reducing fatigue. Furthermore, technological advancements in polymer science and composite manufacturing techniques are constantly improving the material's properties and opening new application avenues, expanding its market reach beyond conventional uses.

Despite the strong growth trajectory, the market faces certain restraints. The high manufacturing cost associated with UHMWPE fibers and the complex processing required to convert them into ballistic fabrics pose a significant barrier, particularly for small-scale manufacturers and in price-sensitive markets. The availability and fluctuating prices of raw materials, largely dependent on petrochemical derivatives, also present supply chain challenges. Additionally, the market faces competition from alternative ballistic materials like aramid fibers (e.g., Kevlar, Twaron), which, while often heavier, have established supply chains and lower costs, sometimes preferred for specific applications or budget constraints.

Opportunities for market expansion lie in the growing demand from emerging economies for modernizing their security forces and enhancing personal protection capabilities. The expansion into civilian applications, such as high-performance sports equipment, industrial safety gear, and specialized protective clothing, offers new revenue streams. Continued investment in research and development to reduce production costs, improve material recyclability, and integrate smart technologies into ballistic fabrics could unlock significant growth potential. The market is influenced by impact forces such as stringent regulatory standards for ballistic protection, which drive innovation, and the continuous evolution of threat landscapes, demanding increasingly sophisticated and adaptable protective solutions from manufacturers.

Segmentation Analysis

The UHMWPE Ballistic Fabrics Market is comprehensively segmented across various dimensions to provide a granular understanding of its dynamics, catering to diverse end-user requirements and application areas. These segmentations allow for a detailed analysis of market trends, growth drivers, and competitive strategies specific to product types, forms, applications, and regional consumption patterns. The robust segmentation helps identify lucrative niches and emerging opportunities within the broader protective materials landscape, guiding strategic decisions for market participants.

- By Product Type:

- Unidirectional (UD) Fabrics

- Woven Fabrics

- By Form:

- Sheets/Rolls

- Plates/Panels

- Finished Products (e.g., molded components)

- By Application:

- Body Armor (Vests, Plates, Inserts)

- Helmets

- Vehicle Armor (Land, Air, Sea)

- Marine Armor

- Ballistic Shields

- Blast Containment

- Other Protective Gear (e.g., Sports, Industrial Safety)

- By End-User:

- Military & Defense

- Law Enforcement

- Homeland Security

- Civilian

- By Region:

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Value Chain Analysis For UHMWPE Ballistic Fabrics Market

The value chain for the UHMWPE Ballistic Fabrics Market begins with the upstream analysis, which primarily involves the sourcing and production of Ultra-High Molecular Weight Polyethylene resins. Key raw material suppliers provide the foundational polymer, which then undergoes a specialized spinning process to create UHMWPE fibers. This phase requires significant capital investment in polymerization and fiber extrusion technologies, with a strong emphasis on maintaining high purity and molecular weight consistency to ensure optimal mechanical properties of the fibers. Research and development activities at this stage are crucial for innovating new fiber chemistries and improving existing ones, directly impacting the final ballistic performance.

Moving downstream, these high-performance fibers are then processed into various forms suitable for ballistic applications, predominantly unidirectional (UD) sheets or woven fabrics. This manufacturing stage involves highly specialized equipment for aligning fibers into UD laminates or weaving them into dense textile structures. Manufacturers then combine multiple layers of these fabrics, often with thermoset resins, to create composite panels or sheets that offer multi-hit capability and enhanced energy absorption. Quality control and rigorous testing, adhering to international ballistic standards like NIJ (National Institute of Justice) and STANAG (Standardization Agreement), are integral to this stage to certify product efficacy and safety.

The distribution channel for UHMWPE ballistic fabrics is multi-faceted, encompassing both direct and indirect approaches. Direct sales are common for large defense contractors, government agencies, and major original equipment manufacturers (OEMs) who integrate these fabrics into their final protective systems, such as armored vehicles or body armor platforms. Indirect channels involve a network of specialized distributors, agents, and fabricators who supply smaller manufacturers, niche markets, or civilian end-users. These distributors often provide value-added services such as cutting, shaping, and custom fabrication. The final product then reaches end-users through government procurement processes, specialized defense suppliers, or commercial retail channels, depending on the application. The complexity of the product and the criticality of its function necessitate robust logistics and secure handling throughout the supply chain.

UHMWPE Ballistic Fabrics Market Potential Customers

The primary potential customers for UHMWPE Ballistic Fabrics are governmental defense organizations and military forces across the globe. These entities continuously seek advanced, lightweight, and highly effective protective solutions for their personnel and assets, including body armor, helmets, and vehicle armor. The increasing modernization of military equipment and the emphasis on soldier survivability in contemporary warfare scenarios drive a consistent demand from this segment. Furthermore, special operations forces, requiring agility and maximum protection in high-risk environments, represent a premium segment within the military end-user category, demanding the highest performance standards.

Another significant customer base includes law enforcement agencies and homeland security departments. Police forces, SWAT teams, border patrol, and other security personnel require protective gear that offers superior ballistic resistance while allowing for mobility and comfort during extended duty periods. As urban threats evolve, the adoption of advanced materials like UHMWPE in tactical vests, ballistic shields, and vehicle protection for police cars and specialized response vehicles is steadily increasing. The need for protection against diverse threats, ranging from firearms to explosive fragmentation, positions UHMWPE as a preferred material for these crucial public safety applications.

Beyond traditional defense and security, emerging customer segments include manufacturers of high-performance sports equipment, particularly in extreme sports where impact protection is critical, such as motorsports, cycling, and martial arts. Additionally, industrial safety applications, where workers face risks from projectiles or impacts, are beginning to adopt these materials for lightweight protective clothing and gear. While smaller in volume compared to military procurement, these civilian and industrial applications represent growth opportunities as the cost-effectiveness of UHMWPE fabrics improves and their versatility becomes more widely recognized. Manufacturers developing specialized protective components for critical infrastructure or high-value assets also represent a niche, but growing, customer base.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.58 Billion |

| Market Forecast in 2033 | USD 4.67 Billion |

| Growth Rate | 8.7% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Royal DSM (Dyneema), Honeywell International Inc. (Spectra), Teijin Aramid, Barrday Inc., SABIC (formerly DSM Engineering Plastics), Puluo Protective Material Co., Ltd., Sancheong, Shanghai Road Traffic Safety Product Co., Ltd., China Ningbo Xinding Group Co., Ltd., Enforce Technology Co., Ltd., Zhejiang Huatex Co., Ltd., Sinopec Group, Jiangsu Junhe Composite Materials Co., Ltd., Qingdao Zhongda New Material Technology Co., Ltd., Mitsui Chemicals Inc., Korea Kolon Industries Inc., Toyobo Co., Ltd., Global Safety Textiles (CGF Group), MKU Limited, CeramTec GmbH. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

UHMWPE Ballistic Fabrics Market Key Technology Landscape

The UHMWPE Ballistic Fabrics market is underpinned by a sophisticated technology landscape, starting with the advanced polymerization processes required to create Ultra-High Molecular Weight Polyethylene. This involves synthesizing ethylene monomers under highly controlled conditions to achieve extremely long polymer chains, which are crucial for the material's exceptional strength and rigidity. The subsequent gel-spinning technique is paramount; it involves dissolving the UHMWPE polymer in a solvent, extruding it through spinnerets, and then stretching the resulting fibers to align the polymer chains. This process enhances the molecular orientation, leading to the super-strong fibers that are the foundation of ballistic fabrics.

Further along the value chain, the production of ballistic fabrics relies heavily on specialized textile technologies. Unidirectional (UD) laminate technology is particularly dominant, where individual UHMWPE fibers are laid parallel to each other in a single layer, impregnated with a resin (often thermoplastic or thermoset), and then cross-plied at specific angles (typically 0/90 degrees) to form multi-layered composites. This arrangement optimizes energy absorption by distributing impact forces over a wider area, preventing projectile penetration. Woven fabric technologies also play a role, utilizing high-tech weaving looms to create dense, multi-axial textile structures that offer flexibility and multi-hit capability, albeit often at a slightly higher weight.

Beyond fiber and fabric manufacturing, advancements in composite processing technologies are critical. This includes precision cutting, heat pressing, and molding techniques used to fabricate finished ballistic plates, helmets, and vehicle armor components from UHMWPE composites. Research into novel resin systems, nano-additives, and hybrid materials (combining UHMWPE with aramid or carbon fibers) aims to further enhance performance, reduce weight, and improve multi-threat protection (e.g., against multiple projectile types or stab threats). The integration of smart materials and sensor technology into ballistic fabrics for real-time threat detection and damage assessment represents an emerging technological frontier, promising a new generation of adaptive protective gear.

Regional Highlights

- North America: Dominates the market due to robust defense spending, presence of major military and law enforcement agencies, and significant R&D investments in advanced materials. The U.S. is a key contributor, driven by ongoing military modernization programs and high demand for personal protective equipment.

- Europe: A mature market with strong demand from countries like the UK, Germany, and France for military and anti-terrorist applications. European manufacturers are at the forefront of innovation in UHMWPE fiber production and composite fabrication.

- Asia Pacific (APAC): Emerging as the fastest-growing region, fueled by increasing defense budgets in China, India, and South Korea, coupled with rising internal security concerns. The region is also witnessing growing domestic production capabilities and technological adoption.

- Latin America: Experiences steady growth driven by the need to combat drug trafficking, organized crime, and modernize local police and military forces. Countries like Brazil and Mexico are key markets for personal and vehicle armor.

- Middle East & Africa (MEA): Growth is primarily influenced by ongoing geopolitical conflicts and heightened security threats, leading to increased procurement of ballistic protection for military and security personnel. Saudi Arabia, UAE, and Israel are significant spenders in this region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the UHMWPE Ballistic Fabrics Market.- Royal DSM (Dyneema)

- Honeywell International Inc. (Spectra)

- Teijin Aramid

- Barrday Inc.

- SABIC (formerly DSM Engineering Plastics)

- Puluo Protective Material Co., Ltd.

- Sancheong

- Shanghai Road Traffic Safety Product Co., Ltd.

- China Ningbo Xinding Group Co., Ltd.

- Enforce Technology Co., Ltd.

- Zhejiang Huatex Co., Ltd.

- Sinopec Group

- Jiangsu Junhe Composite Materials Co., Ltd.

- Qingdao Zhongda New Material Technology Co., Ltd.

- Mitsui Chemicals Inc.

- Korea Kolon Industries Inc.

- Toyobo Co., Ltd.

- Global Safety Textiles (CGF Group)

- MKU Limited

- CeramTec GmbH

Frequently Asked Questions

Analyze common user questions about the UHMWPE Ballistic Fabrics market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of UHMWPE ballistic fabrics over traditional materials like aramid?

UHMWPE ballistic fabrics offer superior strength-to-weight ratio, meaning they provide comparable or better ballistic protection at a significantly lighter weight. They also exhibit excellent resistance to moisture, UV light, and chemicals, enhancing durability and performance in diverse environments, unlike aramid fibers which can degrade with moisture exposure.

In what key applications are UHMWPE ballistic fabrics most commonly utilized?

UHMWPE ballistic fabrics are predominantly used in high-performance personal protective equipment such as body armor (vests, plates), helmets, and ballistic shields. They are also critical for armoring vehicles, aircraft, and marine vessels, providing lightweight yet robust protection for military, law enforcement, and security personnel.

What is the future outlook for the UHMWPE Ballistic Fabrics Market?

The future outlook is highly positive, driven by increasing global defense spending, the demand for lighter and more agile protective gear, and continuous technological advancements. The market is expected to expand into new civilian and industrial safety applications, with ongoing research focused on enhancing multi-threat protection and reducing production costs.

How do UHMWPE unidirectional (UD) laminates differ from woven UHMWPE fabrics?

UHMWPE UD laminates consist of fibers laid parallel in one direction, typically cross-plied in layers, optimizing ballistic energy dissipation for direct impact protection. Woven fabrics, however, interlace fibers in two or more directions, offering greater flexibility, multi-hit capability, and structural integrity, often making them suitable for different types of protective gear or outer layers.

Are UHMWPE ballistic fabrics recyclable, and what is their environmental impact?

While pure UHMWPE is theoretically recyclable, the complex composite structures of ballistic fabrics, often involving resin impregnation, make practical recycling challenging. Manufacturers are increasingly exploring methods to improve the recyclability of these composites and investigating more sustainable production processes to mitigate their environmental footprint, aligning with global sustainability initiatives.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager