Ultrafine Aluminum Hydroxide Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439651 | Date : Jan, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Ultrafine Aluminum Hydroxide Market Size

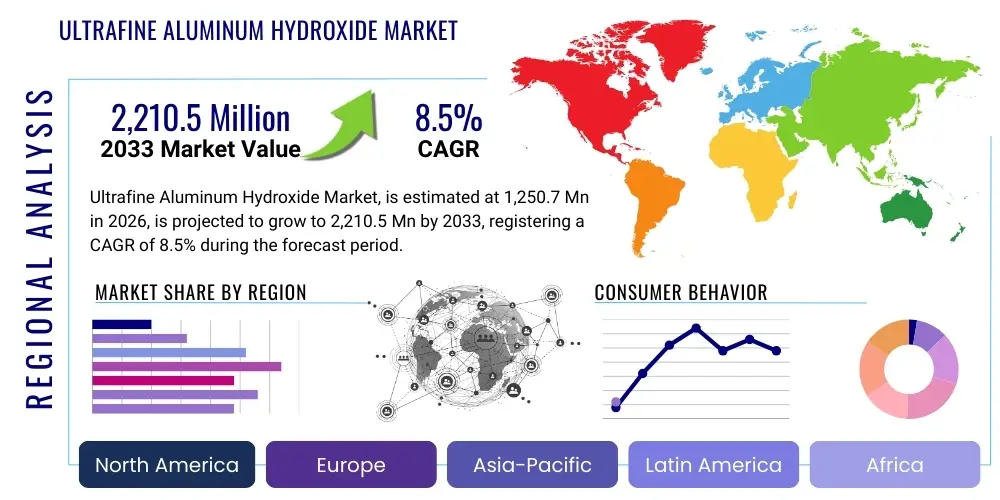

The Ultrafine Aluminum Hydroxide Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 1,250.7 Million in 2026 and is projected to reach USD 2,210.5 Million by the end of the forecast period in 2033.

Ultrafine Aluminum Hydroxide Market introduction

The ultrafine aluminum hydroxide market encompasses the production and application of finely ground aluminum hydroxide (Al(OH)3) powders, characterized by particle sizes typically in the sub-micron range. This specialized form of aluminum hydroxide serves predominantly as a halogen-free flame retardant, smoke suppressant, and filler in various polymer systems. Its inherent properties, such as high decomposition temperature, endothermic decomposition process, and non-toxic combustion products, make it a highly sought-after additive, especially in industries facing stringent fire safety regulations and a growing demand for environmentally benign materials.

Major applications for ultrafine aluminum hydroxide span across the wire and cable industry, plastics (including PVC, PE, EVA, and thermosets), rubber, coatings, adhesives, and artificial marble/solid surfaces. The ultrafine nature of the material provides superior dispersion in polymer matrices, allowing for higher loading levels without significantly compromising the mechanical properties or processability of the final product. This enhanced compatibility and performance are crucial for achieving optimal flame retardancy and smoke suppression in complex material formulations.

The market is primarily driven by an increasing global emphasis on fire safety, coupled with evolving environmental regulations that restrict the use of halogenated flame retardants. The construction, automotive, and electronics sectors, in particular, are significant consumers, driven by the need for compliant and safer materials. The benefits of ultrafine aluminum hydroxide, including its non-toxic nature, excellent smoke suppression capabilities, cost-effectiveness, and good thermal stability, position it as a critical component in advanced material formulations aimed at meeting modern industrial demands.

Ultrafine Aluminum Hydroxide Market Executive Summary

The ultrafine aluminum hydroxide market is currently experiencing robust growth, propelled by several key business trends including the global shift towards sustainable and halogen-free fire safety solutions, escalating demand from high-growth end-use industries, and a persistent focus on product innovation. Manufacturers are increasingly investing in research and development to enhance the surface treatment and dispersion properties of ultrafine ATH, thereby improving its compatibility and performance within diverse polymer systems. Consolidation activities and strategic partnerships are also becoming more prevalent as companies seek to expand their market reach, optimize supply chains, and leverage specialized expertise.

Geographically, the Asia Pacific region continues to dominate the market, primarily due to rapid industrialization, burgeoning construction activities, and the expansive presence of electronics and automotive manufacturing hubs. Emerging economies within this region, such as China and India, are significant contributors to market expansion. Concurrently, North America and Europe are witnessing steady demand, driven by stringent regulatory frameworks for fire safety and a strong preference for eco-friendly materials, leading to sustained adoption rates despite mature market conditions. Latin America and the Middle East & Africa regions are also showing promising growth, albeit from a smaller base, spurred by infrastructure development and increasing industrial output.

Segmentation trends indicate a strong preference for surface-treated ultrafine ATH, which offers enhanced processability and better physical properties in the final product. Applications in wire and cable, as well as plastics, remain the largest segments, underpinned by continuous innovation in polymer compounding and the relentless pursuit of safer materials. The increasing sophistication of these applications, requiring higher loading levels and superior performance characteristics, ensures a sustained demand for ultrafine grades of aluminum hydroxide, further reinforcing market growth across these critical segments.

AI Impact Analysis on Ultrafine Aluminum Hydroxide Market

Users frequently inquire about the transformative potential of artificial intelligence in optimizing manufacturing processes, enhancing product formulation, and streamlining supply chain operations within the ultrafine aluminum hydroxide market. There is a clear expectation that AI will drive significant improvements in production efficiency, enable the development of tailored material properties through advanced simulations, and elevate quality control mechanisms from reactive to predictive. Furthermore, users anticipate AI's role in improving demand forecasting and inventory management, thereby creating a more responsive and cost-effective supply chain, ultimately pushing the industry towards greater innovation and operational excellence.

- AI can optimize manufacturing processes, leading to improved energy efficiency and higher yields in the production of ultrafine aluminum hydroxide.

- Predictive maintenance driven by AI algorithms can significantly reduce downtime and operational costs for grinding and processing equipment.

- AI enhances quality control by analyzing real-time sensor data to detect minute deviations in particle size distribution and purity, ensuring consistent product quality.

- AI-driven material design and simulation tools can accelerate the development of new ultrafine ATH formulations with tailored properties for specific applications, such as enhanced surface treatments.

- Improved supply chain visibility and demand forecasting through AI can optimize inventory levels, reduce waste, and enhance responsiveness to market fluctuations.

- Automation facilitated by AI can increase throughput and reduce labor costs in various stages of ultrafine ATH production and packaging.

- Data-driven research and development, empowered by AI, can accelerate the discovery of novel applications and processing techniques for ultrafine aluminum hydroxide.

DRO & Impact Forces Of Ultrafine Aluminum Hydroxide Market

The Ultrafine Aluminum Hydroxide market is primarily driven by escalating global fire safety regulations that increasingly mandate the use of halogen-free flame retardants, making ATH an indispensable component across various industries. Complementary to this, the relentless growth in end-use sectors such as construction, automotive, and electronics fuels demand, as these industries continuously seek safer, more durable, and environmentally compliant materials. The intrinsic benefits of ultrafine ATH, including its non-toxicity, excellent smoke suppression capabilities, and cost-effectiveness compared to some alternatives, further solidify its market position and adoption rate, creating a strong pull for market expansion.

However, the market faces notable restraints, including the volatility of raw material prices, particularly bauxite and caustic soda, which are essential inputs in ATH production and can impact overall manufacturing costs and profit margins. Competition from other flame retardant technologies, while often less environmentally friendly, can also pose a challenge, especially in applications where cost is a paramount consideration. Furthermore, the specialized processing required to achieve ultrafine particle sizes can incur higher production costs, potentially limiting market entry for new players and influencing pricing strategies for existing ones.

Despite these challenges, significant opportunities exist for market expansion. Continuous research and development into advanced surface treatment technologies promise to enhance the performance and broaden the applicability of ultrafine ATH, enabling its integration into more demanding and specialized polymer systems. The exploration of new and niche applications, such as advanced composites, battery components, and textiles, alongside the increasing demand from rapidly industrializing emerging economies, presents substantial avenues for growth. The overriding global emphasis on sustainability and eco-friendly solutions continues to serve as a powerful impact force, aligning directly with the core advantages of ultrafine aluminum hydroxide and ensuring its long-term market relevance.

Segmentation Analysis

The ultrafine aluminum hydroxide market is comprehensively segmented to provide granular insights into its diverse applications and product types. This segmentation helps in understanding the specific demands from various end-use industries and the evolving preferences for different grades of ATH. The primary segments revolve around product type, application, and end-use industry, each revealing distinct growth patterns and market dynamics that influence overall market trajectory and strategic decision-making.

- By Type

- Untreated Ultrafine ATH

- Surface-Treated Ultrafine ATH

- Silane Treated

- Stearate Treated

- Other Surface Treatments

- By Application

- Wire & Cable

- Plastics

- PVC

- Polyethylene (PE)

- Ethylene-vinyl Acetate (EVA)

- Thermoset Resins

- Other Plastics

- Rubber

- Coatings

- Adhesives & Sealants

- Artificial Marble/Solid Surfaces

- Others (e.g., Paper, Textiles, Foams)

- By End-Use Industry

- Construction

- Automotive

- Electronics

- Electrical

- Marine

- Textiles

- Others

- By Grade

- High Purity Grade

- Standard Grade

- Specific Particle Size Grades (e.g., D50 < 1 micron)

Value Chain Analysis For Ultrafine Aluminum Hydroxide Market

The value chain for the ultrafine aluminum hydroxide market begins with the upstream extraction and refining of bauxite, the primary ore for alumina. Bauxite is processed through the Bayer process to yield alumina, which is then hydrated to produce aluminum hydroxide. Key raw materials in this initial stage include bauxite, caustic soda, and significant energy inputs, highlighting the importance of efficient mining and refining operations. The quality and purity of these upstream components directly impact the final product characteristics and overall cost structure of ultrafine ATH production.

Moving midstream, the conventional aluminum hydroxide undergoes specialized processing to achieve ultrafine particle sizes. This involves advanced grinding and milling techniques, such as wet grinding, dry jet milling, and micronization, which are critical for achieving the desired particle size distribution and morphology essential for high-performance applications. Following this, surface modification technologies, including the application of silane coupling agents, stearic acid, or titanates, are often employed to enhance the dispersibility and compatibility of the ultrafine ATH within various polymer matrices, thereby improving its functionality and overall performance as a flame retardant and filler.

The downstream segment of the value chain involves the distribution and application of the ultrafine aluminum hydroxide. Manufacturers typically distribute their products through a combination of direct sales channels to large-volume end-users and indirect channels via a network of specialized chemical distributors and agents. These distributors play a crucial role in reaching diverse customers across different geographies and providing technical support. The end-users, comprising polymer compounders, wire and cable manufacturers, plastic processors, coating formulators, and artificial marble producers, integrate ultrafine ATH into their products, thus completing the market's value chain. Direct sales ensure closer relationships with key clients, while indirect channels provide broader market penetration and cater to smaller-scale buyers.

Ultrafine Aluminum Hydroxide Market Potential Customers

The primary consumers and buyers of ultrafine aluminum hydroxide are diverse manufacturing entities across multiple industrial sectors, all seeking high-performance, halogen-free flame retardant and smoke suppressant solutions. These customers prioritize materials that not only meet stringent safety regulations but also offer excellent processability and minimal impact on the mechanical properties of their final products. The demand is often driven by the need for compliant, durable, and environmentally responsible additives in their formulations, indicating a sophisticated understanding of material science and regulatory compliance.

Key potential customers include polymer compounders and masterbatch producers, who integrate ultrafine ATH into various thermoplastic and thermoset resins to create flame-retardant compounds. Furthermore, manufacturers in the wire and cable industry represent a significant customer base, utilizing ultrafine ATH to meet fire safety standards for electrical insulation and jacketing materials. Companies involved in the production of plastics for construction (e.g., pipes, profiles), automotive interiors, and electronic components (e.g., circuit boards, casings) also form a crucial segment of the customer base, requiring materials that enhance safety without compromising aesthetic or functional attributes.

Beyond these, the market extends to rubber product manufacturers, coating and adhesive formulators, and producers of artificial marble or solid surface materials. These end-users leverage ultrafine ATH for its unique combination of flame retardancy, smoke suppression, and filler properties, which contribute to the durability, integrity, and safety performance of their finished goods. The continuous evolution of safety standards and the ongoing push for sustainable material solutions ensure that this broad spectrum of industrial manufacturers remains the core potential customer base for ultrafine aluminum hydroxide.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1,250.7 Million |

| Market Forecast in 2033 | USD 2,210.5 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Huber Engineered Materials, Nabaltec AG, Albemarle Corporation, Showa Denko K.K. (now Resonac), CHALCO (Aluminum Corporation of China Limited), Zibo Pengcheng Chemical Co., Ltd., R. J. Marshall Company, Sumitomo Chemical Co., Ltd., Jiaozuo Wuxing Industrial Co., Ltd., Shandong Aluminum Company Limited, Shandong Xinlong Group, Henan Mingtai Aluminum Industrial Co., Ltd., Baotou Aluminum (China), Toyo Aluminium K.K., Aluminium Martigny SA, Spectrum Chemical Manufacturing Corp., Akrochem Corporation, Elementis Specialties, LLC, Amco Polymers, J.M. Huber Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Ultrafine Aluminum Hydroxide Market Key Technology Landscape

The ultrafine aluminum hydroxide market is profoundly shaped by a sophisticated array of technologies primarily focused on achieving precise particle size reduction and effective surface modification. The core challenge in producing ultrafine ATH lies in reliably reducing aluminum hydroxide particles to sub-micron levels while maintaining a narrow particle size distribution. This necessitates advanced grinding and milling techniques such as wet grinding, which often employs ball mills or agitated media mills, and dry grinding methods like jet milling. Jet mills use high-velocity air or steam to cause particles to collide and fracture, enabling the production of extremely fine powders with minimal contamination. These technologies are crucial for ensuring the superior dispersion and enhanced performance of ATH in various polymer matrices.

Beyond particle size reduction, surface modification technologies are paramount for optimizing the compatibility and functionality of ultrafine ATH. Untreated ATH can exhibit poor dispersion and interaction with hydrophobic polymer systems, leading to reduced mechanical properties and flame retardancy. To address this, various surface treatment agents are employed, including silane coupling agents, fatty acids (like stearic acid), titanates, and zirconates. These agents chemically bond or physically adsorb onto the surface of ATH particles, altering their surface energy and making them more compatible with organic polymers. The selection of the appropriate surface treatment technology is critical, as it directly impacts properties such as melt flow, mechanical strength, and the overall efficiency of flame retardancy in the final composite material.

Furthermore, the technology landscape includes advanced analytical and quality control instrumentation essential for characterizing ultrafine ATH. Techniques such as laser diffraction particle size analysis, dynamic light scattering (DLS), scanning electron microscopy (SEM), and transmission electron microscopy (TEM) are routinely used to confirm particle size, morphology, and dispersion. Rheometers and differential scanning calorimeters (DSC) are also vital for evaluating the processability of ATH-filled compounds and their thermal properties. Continuous innovation in these processing, modification, and analytical technologies is crucial for meeting the increasingly demanding performance requirements of the ultrafine aluminum hydroxide market and expanding its application scope into more specialized and high-value segments.

Regional Highlights

- North America: Characterized by stringent fire safety regulations and a mature industrial base. The region exhibits steady demand, driven by the construction, automotive, and electronics sectors, with a strong focus on high-performance and environmentally friendly materials. Key markets include the United States and Canada.

- Europe: A leading region in adopting halogen-free flame retardants due to strict environmental directives and safety standards. Western European countries, such as Germany, France, and the UK, are significant consumers, with a growing emphasis on sustainable building materials and automotive components.

- Asia Pacific (APAC): The largest and fastest-growing market, primarily fueled by rapid industrialization, massive infrastructure development, and a booming manufacturing sector in countries like China, India, Japan, South Korea, and Southeast Asian nations. This region is a major production hub and consumer for ultrafine ATH in plastics, wire & cable, and coatings.

- Latin America: Experiencing consistent growth driven by increasing construction activities, automotive production, and expanding industrial sectors in countries like Brazil, Mexico, and Argentina. Adoption of international safety standards is also contributing to market expansion.

- Middle East and Africa (MEA): Showing promising growth due to significant investments in infrastructure, petrochemical industries, and urban development projects. Countries such as Saudi Arabia, UAE, and South Africa are key contributors, with increasing awareness and adoption of fire safety solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Ultrafine Aluminum Hydroxide Market.- Huber Engineered Materials

- Nabaltec AG

- Albemarle Corporation

- Showa Denko K.K. (now Resonac)

- CHALCO (Aluminum Corporation of China Limited)

- Zibo Pengcheng Chemical Co., Ltd.

- R. J. Marshall Company

- Sumitomo Chemical Co., Ltd.

- Jiaozuo Wuxing Industrial Co., Ltd.

- Shandong Aluminum Company Limited

- Shandong Xinlong Group

- Henan Mingtai Aluminum Industrial Co., Ltd.

- Baotou Aluminum (China)

- Toyo Aluminium K.K.

- Aluminium Martigny SA

- Spectrum Chemical Manufacturing Corp.

- Akrochem Corporation

- Elementis Specialties, LLC

- Amco Polymers

- J.M. Huber Corporation

Frequently Asked Questions

What are the primary applications of Ultrafine Aluminum Hydroxide?

Ultrafine Aluminum Hydroxide is primarily used as a halogen-free flame retardant and smoke suppressant in various applications, including wire and cable insulation, plastics (PVC, PE, EVA), rubber products, coatings, adhesives, and artificial marble/solid surfaces.

Why is Ultrafine ATH preferred over standard ATH?

Ultrafine ATH offers superior dispersion in polymer matrices, allowing for higher loading levels without significantly impacting mechanical properties. Its finer particle size enhances flame retardancy efficiency and provides smoother surface finishes, crucial for high-performance applications.

What are the key drivers for the Ultrafine ATH market?

The market is driven by stringent global fire safety regulations, increasing demand for halogen-free and environmentally friendly materials, and robust growth in end-use industries like construction, automotive, and electronics.

How do fire safety regulations impact the demand for Ultrafine ATH?

Strict fire safety regulations, particularly those promoting halogen-free materials, directly boost the demand for Ultrafine ATH as it offers an effective, non-toxic, and smoke-suppressing alternative to conventional halogenated flame retardants, ensuring compliance and safety.

What is the role of surface treatment in Ultrafine ATH?

Surface treatment (e.g., with silane or stearate) improves the dispersibility and compatibility of ultrafine ATH particles within polymer matrices. This enhances overall flame retardant performance, reduces material viscosity during processing, and maintains the mechanical properties of the final product.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager