Ultrasonic Fabric Cutting Machines Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440630 | Date : Jan, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Ultrasonic Fabric Cutting Machines Market Size

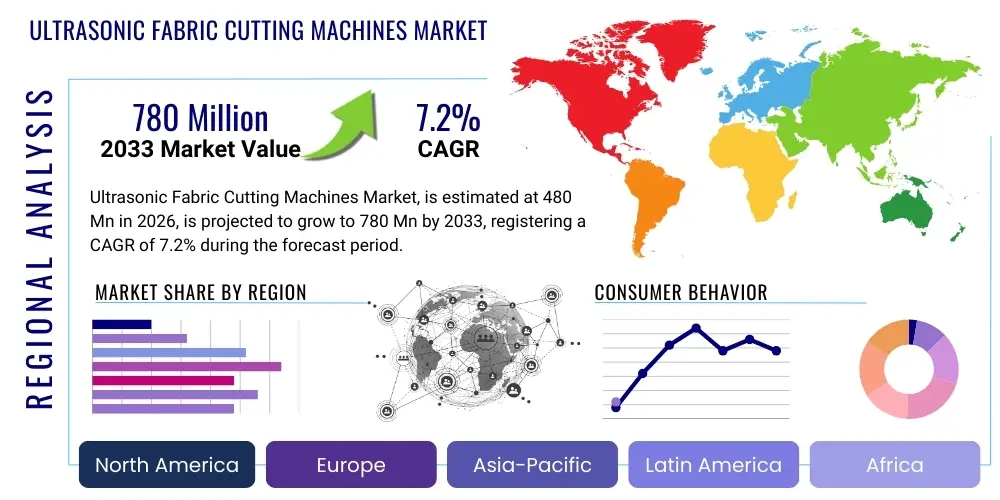

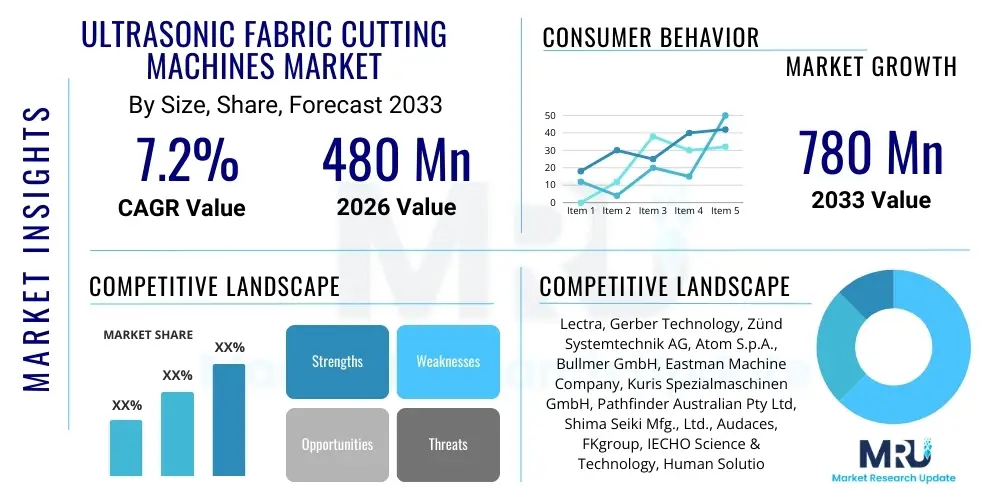

The Ultrasonic Fabric Cutting Machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.2% between 2026 and 2033. The market is estimated at USD 480 Million in 2026 and is projected to reach USD 780 Million by the end of the forecast period in 2033.

Ultrasonic Fabric Cutting Machines Market introduction

The Ultrasonic Fabric Cutting Machines Market encompasses a range of advanced industrial equipment designed for precise and efficient cutting of various textile materials using high-frequency ultrasonic vibrations. These machines operate by generating vibrations at the blade, which reduces friction and enables a clean, sealed edge without material fraying, burning, or distortion. This non-contact cutting method is particularly advantageous for delicate, synthetic, and technical textiles, offering superior cut quality compared to traditional mechanical or laser cutting techniques. The technology leverages principles of sonics to achieve intricate patterns and complex shapes with exceptional accuracy, making it indispensable in modern manufacturing where precision and material integrity are paramount across diverse sectors.

Product descriptions of ultrasonic fabric cutting machines highlight their core components, which typically include an ultrasonic generator, a transducer (which converts electrical energy into mechanical vibrations), a sonotrode or horn (the cutting tool that oscillates at high frequency), and a sophisticated control system, often integrated with CAD/CAM software for pattern design and optimization. Major applications span numerous industries, from apparel and automotive to medical and aerospace, where they are used for processing materials like woven and non-woven fabrics, composites, laminates, and various synthetic textiles. These machines are increasingly crucial in industries demanding high-volume production with consistent quality, addressing the growing need for specialized material handling and fabrication challenges in a competitive global market.

The primary benefits derived from the adoption of ultrasonic fabric cutting machines include unparalleled cutting precision, significantly reduced material waste due to optimized nesting capabilities, increased operational speed, and the ability to cut complex geometries with ease. Furthermore, the sealed edge produced by ultrasonic cutting eliminates the need for subsequent finishing processes, such as hemming or stitching, saving time and labor costs. Key driving factors propelling market growth include the escalating demand for automation in manufacturing processes to combat rising labor expenses, the increasing use of technical textiles and advanced composite materials across industries, and the stringent quality and precision requirements in sectors like medical device manufacturing and automotive interiors. These factors collectively underscore the vital role ultrasonic technology plays in modern textile and material processing.

Ultrasonic Fabric Cutting Machines Market Executive Summary

The Ultrasonic Fabric Cutting Machines Market is experiencing robust growth driven by significant business trends, including the widespread adoption of Industry 4.0 principles, a heightened focus on automation to enhance productivity and reduce operational costs, and the increasing global demand for high-quality, precision-cut components across various sectors. Companies are investing heavily in research and development to integrate artificial intelligence and machine learning into cutting systems, allowing for predictive maintenance, optimized cutting paths, and real-time quality control. Furthermore, there is a growing emphasis on sustainable manufacturing practices, with ultrasonic technology offering reduced material waste and lower energy consumption compared to traditional methods, aligning with corporate social responsibility initiatives and regulatory pressures towards greener production cycles in the textile and material processing industries.

Regionally, the market exhibits diverse growth dynamics. Asia Pacific continues to dominate in terms of market share, primarily due to its expansive manufacturing base, particularly in the apparel, automotive, and electronics industries, coupled with a strong push for technological adoption and industrial modernization in countries like China, India, and Japan. Europe and North America represent mature markets characterized by high demand for advanced, automated solutions, especially in niche applications requiring extreme precision, such as medical textiles, aerospace components, and luxury automotive interiors. These regions also lead in innovation, fostering the development of sophisticated ultrasonic cutting systems. Emerging economies in Latin America and the Middle East & Africa are showing promising growth, driven by increasing industrialization, rising disposable incomes, and investments in manufacturing infrastructure, though they currently represent smaller shares of the global market.

Segmentation trends highlight a strong shift towards automated and robotic ultrasonic cutting solutions, which offer greater throughput, consistency, and integration capabilities within smart factory environments, outperforming handheld or standalone units in large-scale industrial applications. By end-use industry, the automotive sector remains a significant consumer, utilizing ultrasonic cutting for interior components, airbags, and insulation materials due to its ability to produce clean, sealed edges on diverse fabrics and composites. The medical sector is also a rapidly expanding segment, driven by the critical need for sterile, precise cuts on specialized medical textiles and non-wovens for surgical gowns, drapes, and devices. Additionally, the technical textiles segment, encompassing applications in protective wear, filtration, and geotextiles, is witnessing substantial innovation and adoption of ultrasonic cutting as material complexity and performance requirements escalate globally, further solidifying its market position.

AI Impact Analysis on Ultrasonic Fabric Cutting Machines Market

The integration of Artificial Intelligence (AI) is profoundly reshaping the Ultrasonic Fabric Cutting Machines Market by addressing critical operational challenges and unlocking new levels of efficiency and precision. Users are primarily concerned with how AI can enhance cutting accuracy, minimize material waste through smarter nesting algorithms, predict maintenance needs to reduce downtime, and improve overall production throughput. The anticipation is that AI will enable machines to learn from operational data, adapt to varying material properties in real-time, and seamlessly integrate into broader Industry 4.0 ecosystems. This technological leap promises not only to optimize performance but also to make these sophisticated machines more accessible and user-friendly, potentially lowering the barrier to entry for advanced textile manufacturing while raising questions about initial investment and the need for a skilled workforce capable of managing AI-driven systems.

- Predictive Maintenance: AI algorithms analyze sensor data from cutting machines to predict potential equipment failures before they occur, enabling proactive maintenance, significantly reducing unplanned downtime, and extending the operational lifespan of machinery components.

- Material Optimization and Nesting: Advanced AI-driven software optimizes cutting paths and patterns (nesting) to maximize fabric utilization, minimize waste, and enhance material yield, leading to substantial cost savings and improved sustainability.

- Real-time Quality Control and Defect Detection: AI-powered vision systems monitor the cutting process in real-time, identifying anomalies or defects in the material or cut edges instantly, ensuring consistent product quality and reducing rework.

- Adaptive Cutting Parameters: AI allows machines to dynamically adjust ultrasonic frequencies, pressure, and speed based on real-time feedback regarding material type, thickness, and ambient conditions, ensuring optimal cutting results across diverse fabrics.

- Autonomous Operation and Integration: AI facilitates the integration of ultrasonic cutters into fully automated production lines and smart factories, enabling autonomous decision-making, workflow optimization, and seamless communication with other manufacturing systems, boosting overall operational efficiency.

DRO & Impact Forces Of Ultrasonic Fabric Cutting Machines Market

The Ultrasonic Fabric Cutting Machines Market is significantly influenced by a dynamic interplay of Drivers, Restraints, and Opportunities, which collectively shape its growth trajectory and competitive landscape. A primary driver is the accelerating demand for automation in manufacturing sectors globally, spurred by rising labor costs, a shortage of skilled manual labor, and the imperative to enhance production efficiency and throughput. The growing complexity of textile materials, particularly in technical textiles, composites, and non-wovens, also necessitates the precision and sealed-edge capabilities that ultrasonic cutting uniquely offers. Furthermore, stringent quality control requirements in industries such as automotive, medical, and aerospace, where component integrity is paramount, are compelling manufacturers to adopt these advanced cutting solutions to achieve superior finished products, driving substantial investment in modern machinery and contributing significantly to market expansion.

Conversely, several restraints impede the market's full potential. The high initial investment cost associated with acquiring advanced ultrasonic fabric cutting machines can be a significant barrier for small and medium-sized enterprises (SMEs), limiting their adoption despite the long-term benefits. Additionally, the need for specialized technical expertise for operating and maintaining these complex machines presents a challenge, as a shortage of trained personnel can impact operational efficiency and increase maintenance expenses. While versatile, ultrasonic cutting may also face limitations with certain extremely thick or dense materials, where alternative cutting methods might still be preferred, restricting its applicability in specific niche segments. These factors collectively contribute to a cautious approach among some potential adopters, necessitating comprehensive support and training solutions from manufacturers to overcome perceived hurdles.

Despite these challenges, substantial opportunities exist for market expansion and innovation. The increasing adoption of Industry 4.0 and smart factory concepts presents a fertile ground for integrating ultrasonic cutting machines with AI, IoT, and advanced robotics, leading to fully autonomous and highly optimized production lines. Emerging markets in Asia Pacific, Latin America, and the Middle East offer untapped growth potential, driven by rapid industrialization, growing consumer bases, and expanding manufacturing capacities that are keen on adopting efficient, high-precision technologies. Furthermore, the continuous innovation in material science, particularly with the development of new composites and smart textiles, creates new application areas where ultrasonic cutting's unique capabilities are ideally suited, providing manufacturers with opportunities to develop specialized solutions and diversify their product portfolios, thereby securing future growth and maintaining a competitive edge in the evolving market landscape.

Segmentation Analysis

The Ultrasonic Fabric Cutting Machines Market is extensively segmented to provide a granular understanding of its diverse components, allowing for targeted strategic planning and market analysis. These segmentations typically involve categorizing the market based on machine type, the specific application or function they perform, and the end-use industry that deploys these machines. This structured approach helps in identifying key growth areas, understanding customer needs across different sectors, and assessing the competitive landscape more accurately. The comprehensive segmentation illustrates the versatility of ultrasonic cutting technology and its critical role in various manufacturing processes, from high-volume industrial operations to specialized, precision-driven applications.

- By Type

- Automated/Robotic Ultrasonic Cutting Machines: Characterized by high precision, integration with CAD/CAM software, and often robotic arms for continuous, large-scale industrial production, offering minimal human intervention and maximum throughput.

- Standalone Ultrasonic Cutting Machines: Fixed-position units, typically computer-controlled, designed for specific cutting tasks, offering flexibility and accuracy for various production volumes without full robotic integration.

- Handheld Ultrasonic Cutting Machines: Portable and lightweight devices used for intricate detailing, small-batch production, prototyping, or repairs, providing manual control for specialized applications.

- By Application

- Cutting: The primary application involving precise separation of fabric layers or single sheets into desired shapes and patterns, producing clean, sealed edges.

- Slitting: Used for lengthwise cutting of fabric rolls into narrower strips, often for applications like ribbons, straps, or specialized industrial tapes, ensuring consistent width and sealed edges.

- Sealing: Utilized to join fabric layers or seal edges without stitching, creating strong, permanent bonds, particularly effective for synthetic and non-woven materials in medical and protective wear.

- Welding: Employed to fuse multiple layers of fabric together, forming a robust seam or bond through localized heat generated by ultrasonic vibrations, common in the production of technical textiles and automotive components.

- By End-Use Industry

- Apparel & Textile Industry: For cutting garment patterns, activewear, lingerie, and intricate designs, ensuring clean edges without fraying, reducing post-processing needs.

- Automotive Industry: Essential for cutting interior components such as seat covers, carpets, headliners, airbags, and insulation materials, offering precision and durability for various fabrics and composites.

- Medical Industry: Critical for producing medical textiles, surgical drapes, gowns, masks, bandages, and device components, where sterile, fray-free, and sealed edges are paramount for hygiene and safety.

- Non-Woven Industry: Used extensively for cutting non-woven fabrics into various products like filters, wipes, hygiene products, and geotextiles, leveraging the technology's ability to seal edges effectively.

- Aerospace & Defense Industry: For precise cutting of advanced composites, insulation materials, and specialized fabrics used in aircraft interiors, uniforms, and protective gear, demanding high precision and material integrity.

- Others: Includes applications in packaging, sporting goods, filtration, footwear, upholstery, and various technical fabric processing sectors, showcasing the broad utility of ultrasonic cutting technology.

Value Chain Analysis For Ultrasonic Fabric Cutting Machines Market

The value chain for the Ultrasonic Fabric Cutting Machines Market is a complex ecosystem, beginning with upstream raw material suppliers and component manufacturers and extending through various stages of production, distribution, and end-user adoption. At the upstream level, the chain involves suppliers of essential raw materials such as specialized metals for sonotrodes, advanced electronic components for ultrasonic generators, precision mechanical parts for machine frames, and sophisticated software developers for CAD/CAM and control systems. These suppliers play a critical role in providing high-quality, reliable components that form the foundation of robust and efficient ultrasonic cutting machines. The quality and innovation at this initial stage directly impact the performance, durability, and technological capabilities of the final product, necessitating strong partnerships and collaboration between machine manufacturers and their component suppliers to ensure consistent excellence and drive ongoing technological advancements.

Midstream, the value chain focuses on the manufacturing and assembly of the ultrasonic fabric cutting machines themselves. This stage involves complex engineering, precision manufacturing, and rigorous quality control processes to integrate all the components into a functional, high-performance system. Machine manufacturers conduct extensive research and development to innovate new cutting technologies, enhance machine efficiency, improve user interfaces, and ensure compatibility with a wide range of materials and applications. This segment of the value chain is characterized by significant capital investment in production facilities, skilled labor, and intellectual property, including patents for specific ultrasonic technologies. Manufacturers differentiate themselves through product features, technological superiority, after-sales support, and the ability to offer customized solutions tailored to specific industry requirements, thereby establishing their competitive edge in a demanding global market.

Downstream, the value chain encompasses the distribution channels and direct engagement with end-users. Distribution channels can be broadly categorized into direct and indirect methods. Direct distribution involves manufacturers selling directly to large industrial clients or through their own sales teams and service networks, allowing for close customer relationships, customized solutions, and comprehensive after-sales support including installation, training, and maintenance. Indirect distribution typically involves partnerships with specialized distributors, local agents, or system integrators who have extensive market reach and expertise in specific regional markets or industry verticals. These intermediaries play a crucial role in marketing, sales, logistics, and often provide initial technical support, making machines accessible to a wider range of customers, including small and medium-sized enterprises. The efficiency of these distribution channels significantly impacts market penetration, customer satisfaction, and the overall success of ultrasonic fabric cutting machine adoption in diverse industrial applications globally.

Ultrasonic Fabric Cutting Machines Market Potential Customers

The Ultrasonic Fabric Cutting Machines Market caters to a diverse range of potential customers, primarily industrial enterprises that require high-precision, efficient, and clean cutting solutions for various textile and composite materials. These end-users or buyers are typically found in sectors where material integrity, product quality, and production efficiency are paramount. Apparel manufacturers, for instance, are significant customers, utilizing these machines for cutting intricate patterns for garments, activewear, and intimate apparel, where fray-free edges and speed are critical. Their demand is driven by the need to streamline production processes, reduce labor costs, and achieve consistent, high-quality finishes that differentiate their products in a competitive consumer market, making ultrasonic cutting an indispensable tool for modern garment production.

Another major segment of potential customers includes manufacturers within the automotive industry. Companies producing interior components such as seat covers, dashboards, airbags, sound insulation, and headliners rely heavily on ultrasonic cutting machines. The ability to precisely cut and seal various fabrics, leathers, and composite materials ensures durability, safety, and aesthetic quality, meeting the rigorous standards of the automotive sector. Similarly, the medical device and textile industry represents a rapidly expanding customer base. Manufacturers of surgical gowns, drapes, masks, bandages, and other disposable medical products require absolute sterility and fray-free edges, which ultrasonic cutting delivers effectively, making it a vital technology for ensuring product safety and regulatory compliance in healthcare applications.

Furthermore, technical textile producers, aerospace and defense contractors, and companies in the non-woven industry constitute significant potential customers. Technical textile manufacturers, involved in producing materials for filtration, geotextiles, protective wear, and industrial applications, seek ultrasonic solutions for their precision, material sealing capabilities, and versatility with complex fabrics. Aerospace and defense companies utilize these machines for cutting advanced composite materials and specialized fabrics for aircraft interiors, ballistic vests, and other high-performance components where exacting specifications are non-negotiable. The non-woven industry, for products ranging from wipes to hygiene articles, benefits from the clean and sealed cuts, which enhance product functionality and longevity. These diverse end-users underscore the broad applicability and value proposition of ultrasonic fabric cutting technology across multiple high-value industrial sectors seeking advanced manufacturing solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 480 Million |

| Market Forecast in 2033 | USD 780 Million |

| Growth Rate | 7.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Lectra, Gerber Technology, Zünd Systemtechnik AG, Atom S.p.A., Bullmer GmbH, Eastman Machine Company, Kuris Spezialmaschinen GmbH, Pathfinder Australian Pty Ltd, Shima Seiki Mfg., Ltd., Audaces, FKgroup, IECHO Science & Technology, Human Solutions GmbH, G. We-Je Industrial Co., Ltd., Golden Laser, Comelz S.p.A., Oshima Co., Ltd., Morgan Tecnica S.p.A., Ramses Technologies, Summa |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Ultrasonic Fabric Cutting Machines Market Key Technology Landscape

The technological landscape of the Ultrasonic Fabric Cutting Machines Market is characterized by continuous innovation aimed at enhancing precision, speed, versatility, and integration with modern manufacturing ecosystems. Core to these machines is the ultrasonic generator, which converts electrical energy into high-frequency alternating current, typically in the range of 20 to 40 kHz. This high-frequency current is then supplied to a transducer, often made of piezoelectric ceramics, which transforms the electrical energy into mechanical vibrations. The efficiency and stability of these generators and transducers are crucial for consistent cutting performance, with advancements focusing on optimizing power output, frequency control, and energy conversion efficiency to handle a broader range of materials with greater reliability and reduced energy consumption, thereby boosting operational sustainability and cost-effectiveness for end-users.

Further technological advancements include sophisticated sonotrodes or horns, which are the actual cutting tools. These components are designed with precise geometries and made from specific alloys to resonate effectively at ultrasonic frequencies and transmit the vibrations efficiently to the cutting edge. Research in material science for sonotrodes focuses on improving wear resistance, enhancing vibration transmission, and allowing for more intricate cutting profiles without compromising durability. The integration of advanced control systems, often leveraging computer-aided design (CAD) and computer-aided manufacturing (CAM) software, has revolutionized pattern generation and cutting path optimization. These systems enable highly accurate and repeatable cuts, minimal material waste through intelligent nesting algorithms, and seamless management of complex production schedules, further driving efficiency and precision in modern textile and material processing facilities.

Beyond the core ultrasonic components, the market is increasingly defined by the integration of Industry 4.0 technologies. This includes robotic automation for material handling and precise positioning, enabling fully automated cutting cells that significantly boost throughput and reduce manual labor. Vision systems equipped with high-resolution cameras and image processing software are employed for automated material detection, pattern recognition, and real-time quality inspection, ensuring defect-free cuts and adaptive adjustments. Furthermore, the incorporation of Internet of Things (IoT) sensors allows for continuous monitoring of machine performance, predictive maintenance capabilities, and data collection for process optimization. Human-machine interfaces (HMIs) are becoming more intuitive, offering advanced diagnostics and remote operational capabilities, empowering operators with greater control and insight. These integrated technologies collectively transform ultrasonic fabric cutting from a standalone process into a crucial, intelligent component of a smart, interconnected manufacturing environment, driving unprecedented levels of efficiency and operational excellence across various industries.

Regional Highlights

- North America: This region is characterized by high adoption rates of automated and robotic ultrasonic cutting machines, driven by rising labor costs and a strong focus on enhancing productivity and precision in the automotive, aerospace, and technical textiles sectors. The presence of major automotive manufacturers and a robust medical device industry significantly contributes to the demand for advanced cutting solutions, with a strong emphasis on smart factory integration and technological innovation.

- Europe: Europe represents a mature market with a strong emphasis on high-quality, precision manufacturing, particularly in the luxury apparel, medical, and specialized industrial textiles segments. Countries like Germany, Italy, and France are hubs for advanced engineering and textile machinery, fostering innovation in ultrasonic cutting technology, with increasing demand for sustainable and energy-efficient solutions to meet stringent environmental regulations.

- Asia Pacific (APAC): The APAC region stands as the largest and fastest-growing market, propelled by its vast manufacturing base across the textile, apparel, automotive, and electronics industries, especially in China, India, and Japan. Rapid industrialization, increasing investments in automation, and a growing middle class driving consumer demand for diverse products are key factors, alongside government initiatives promoting technological upgradation in manufacturing sectors.

- Latin America: This region is experiencing steady growth in the ultrasonic fabric cutting machines market, primarily driven by the expansion of its apparel and automotive industries. Countries like Brazil and Mexico are investing in modern manufacturing technologies to improve competitiveness and meet both domestic and export demands, creating opportunities for mid-range and automated cutting solutions.

- Middle East and Africa (MEA): The MEA market is an emerging region with growing potential, influenced by increasing investments in industrial infrastructure, particularly in the textile, automotive, and defense sectors in countries such as the UAE and Saudi Arabia. The adoption of advanced manufacturing technologies is slowly gaining traction, though challenges related to initial investment costs and skilled labor persist, making customized and cost-effective solutions attractive.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Ultrasonic Fabric Cutting Machines Market.- Lectra

- Gerber Technology

- Zünd Systemtechnik AG

- Atom S.p.A.

- Bullmer GmbH

- Eastman Machine Company

- Kuris Spezialmaschinen GmbH

- Pathfinder Australian Pty Ltd

- Shima Seiki Mfg., Ltd.

- Audaces

- FKgroup

- IECHO Science & Technology

- Human Solutions GmbH

- G. We-Je Industrial Co., Ltd.

- Golden Laser

- Comelz S.p.A.

- Oshima Co., Ltd.

- Morgan Tecnica S.p.A.

- Ramses Technologies

- Summa

Frequently Asked Questions

Analyze common user questions about the Ultrasonic Fabric Cutting Machines market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary benefits of using ultrasonic fabric cutting machines?

The primary benefits include unparalleled cutting precision, achieving clean and sealed edges that prevent fraying, high operational speed, minimal material waste through optimized nesting, versatility with a wide range of synthetic and technical textiles, and enhanced overall product quality. This technology often eliminates the need for post-cutting finishing processes, significantly reducing labor and production time.

Which industries benefit most from ultrasonic fabric cutting technology?

Industries that benefit most include the apparel and textile industry for intricate garment patterns, the automotive sector for interior components and airbags, the medical industry for sterile surgical textiles and disposables, the non-woven industry for hygiene products and filters, and the aerospace and defense sector for cutting advanced composites and specialized fabrics requiring high integrity and precision.

How do ultrasonic cutting machines compare to traditional cutting methods like blades or lasers?

Ultrasonic cutting offers superior edge quality with sealed, fray-free cuts, which is often not achieved by traditional blades that can leave frayed edges or by lasers that might cause discoloration or hardened edges due to heat. Ultrasonic methods generally exhibit less material distortion, higher speed for delicate materials, and produce minimal debris, making them ideal for materials sensitive to heat or mechanical stress.

What types of materials can be effectively cut using ultrasonic technology?

Ultrasonic fabric cutting machines are highly effective on a broad spectrum of materials, particularly synthetic fibers such as polyester, nylon, polypropylene, and blends, as well as non-woven fabrics, technical textiles, composite materials, and certain thin films. Its ability to create sealed edges is especially beneficial for thermoplastic materials, preventing unraveling and ensuring material integrity.

What is the future outlook for the Ultrasonic Fabric Cutting Machines Market?

The future outlook for the market is highly positive, driven by the increasing global demand for automation, further integration with Industry 4.0 technologies like AI and IoT for enhanced optimization and predictive maintenance, and the continuous innovation in material science leading to new applications for technical textiles. Growing emphasis on sustainable manufacturing and the need for high-quality, precision-cut components across various industrial sectors will fuel sustained market expansion.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager