Ultrasonic Plastic Welding Machines Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439483 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Ultrasonic Plastic Welding Machines Market Size

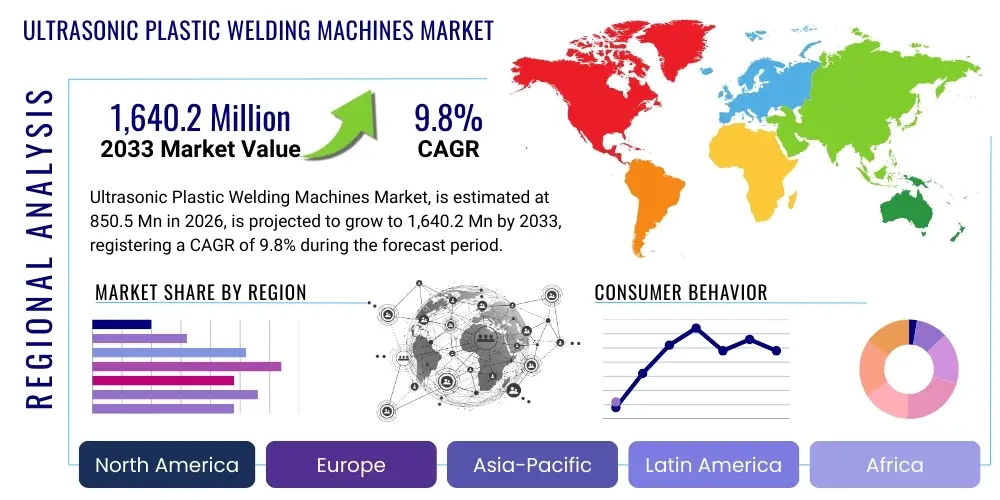

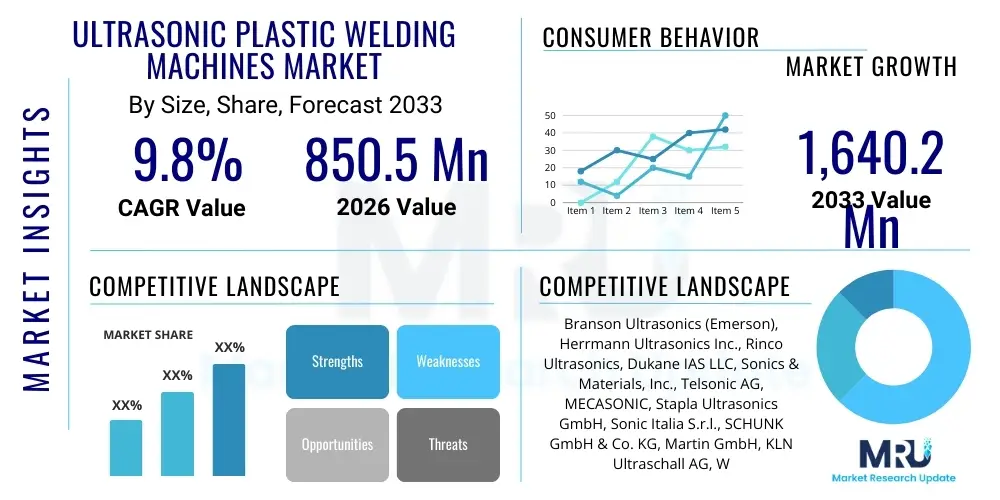

The Ultrasonic Plastic Welding Machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.8% between 2026 and 2033. The market is estimated at USD 850.5 million in 2026 and is projected to reach USD 1,640.2 million by the end of the forecast period in 2033.

Ultrasonic Plastic Welding Machines Market introduction

Ultrasonic plastic welding is a sophisticated industrial technique that utilizes high-frequency acoustic vibrations (ultrasound) to create a solid-state weld in thermoplastic materials. This method involves applying mechanical vibrations, typically in the range of 15 kHz to 70 kHz, to two plastic parts held together under pressure. The rapid vibrations generate localized frictional heat at the interface between the parts, causing the plastic to melt and intermix, forming a strong molecular bond upon cooling. This process is highly valued for its ability to produce clean, strong, and hermetic seals without the need for adhesives, solvents, or external heat sources, thereby contributing to both product integrity and environmental sustainability.

The primary applications of ultrasonic plastic welding span a vast array of industries, including automotive, medical device manufacturing, packaging, consumer electronics, and textiles. In automotive applications, it is crucial for joining interior components, sensor housings, and under-the-hood parts, supporting the shift towards lighter electric vehicles. For medical devices, its cleanliness and ability to create sterile, hermetic seals make it indispensable for products such as catheters, syringe barrels, and diagnostic cartridges. The packaging industry leverages ultrasonic welding for tamper-evident seals and blister packs, while in electronics, it's used for assembling delicate components and enclosures.

The core benefits of adopting ultrasonic welding technology are manifold. These include rapid cycle times, which significantly boost production efficiency; exceptional weld strength and aesthetic quality; reduced operational costs due to the elimination of consumables like glues or screws; and its environmentally friendly nature, as it produces no fumes and uses less energy compared to traditional thermal welding. Furthermore, the technology offers precision and repeatability, making it ideal for high-volume, critical applications. Driving factors for the market's growth include the surging demand for lightweight and durable products across various sectors, the increasing emphasis on automation and precision in manufacturing processes, stringent regulatory requirements for product safety and quality, and the global push towards sustainable manufacturing practices.

Ultrasonic Plastic Welding Machines Market Executive Summary

The Ultrasonic Plastic Welding Machines Market is currently experiencing robust growth, propelled by several intertwined business, regional, and segment trends. From a business perspective, the market is undergoing a transformative shift towards greater automation, integration with Industry 4.0 principles, and increased demand for customized welding solutions. Manufacturers are increasingly seeking machines capable of handling complex geometries and advanced thermoplastic composites, requiring higher levels of precision and quality control. There is a discernible trend towards modular systems that offer flexibility and scalability, allowing businesses to adapt quickly to changing production needs and material innovations. Furthermore, sustainability initiatives are driving demand for energy-efficient machines and processes that minimize waste and eliminate the need for chemical consumables, aligning with global environmental objectives and corporate social responsibility targets.

Regionally, the market dynamics are characterized by significant growth in the Asia-Pacific (APAC) region, which continues to dominate the manufacturing landscape, particularly in the automotive, electronics, and consumer goods sectors. Countries like China, India, Japan, and South Korea are at the forefront of adopting advanced ultrasonic welding technologies due to their extensive industrial bases and ongoing infrastructure development. North America and Europe, while more mature markets, are witnessing sustained demand driven by innovation in high-precision applications, especially within the medical, aerospace, and electric vehicle industries. These regions are prioritizing highly automated, data-driven systems that offer superior quality control and compliance with stringent regulatory standards. Emerging markets in Latin America and the Middle East & Africa are also showing increasing adoption as industrialization efforts gain momentum, albeit at a slower pace.

Segmentation trends indicate a strong preference for automated and semi-automated ultrasonic welding systems over manual operations, reflecting the broader industry move towards smart manufacturing and enhanced productivity. In terms of power and frequency, there's a growing demand for machines with higher power outputs and a broader range of frequencies to accommodate diverse material thicknesses and types, including high-performance polymers and composites. The medical and automotive sectors continue to be pivotal end-use segments, driving innovations in specialized tooling and process control. The demand for integrated solutions that combine welding with other assembly processes, along with sophisticated software for real-time monitoring and predictive analytics, is also on the rise. This comprehensive evolution across business models, geographical spread, and technological specialization underscores the dynamic and expanding nature of the ultrasonic plastic welding machines market.

AI Impact Analysis on Ultrasonic Plastic Welding Machines Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Ultrasonic Plastic Welding Machines Market frequently center on enhancing operational efficiency, improving weld quality, and enabling predictive capabilities. Common questions revolve around how AI can minimize human error, optimize welding parameters for diverse materials, automate defect detection, and provide real-time feedback for process adjustments. Users are keen to understand AI's role in making these machines smarter, more autonomous, and capable of self-optimization, thereby reducing downtime and increasing throughput. Concerns often include the cost of integrating AI, the complexity of data management, and the need for a skilled workforce to leverage these advanced functionalities effectively. The overarching expectation is that AI will usher in a new era of precision, reliability, and cost-effectiveness in ultrasonic welding applications, transforming traditional manufacturing paradigms.

Based on this analysis, the integration of AI into ultrasonic plastic welding machines is poised to revolutionize various aspects of their operation and utility. AI algorithms can process vast amounts of sensor data collected during the welding process, including amplitude, pressure, time, and energy consumption, to identify optimal parameters for specific materials and geometries. This intelligent optimization significantly improves weld consistency and strength, reducing scrap rates and enhancing product quality. Beyond process optimization, AI is instrumental in developing advanced diagnostics and predictive maintenance models, allowing for early detection of potential equipment failures. This proactive approach minimizes unexpected downtime, extends machine lifespan, and ensures continuous production, directly contributing to higher operational efficiency and lower maintenance costs for manufacturers.

Furthermore, AI-driven systems are pivotal in automating quality assurance processes. Machine vision systems powered by AI can conduct real-time inspection of welded parts, instantly identifying and classifying defects that might be imperceptible to the human eye. This capability ensures that only high-quality products proceed down the production line, adhering to stringent industry standards, especially in critical sectors like medical and automotive. The ability of AI to learn from historical data and adapt to new welding scenarios means that machines can become more self-sufficient and require less manual intervention or expert oversight. This level of intelligent automation positions AI as a transformative force, enabling ultrasonic plastic welding machines to achieve unprecedented levels of precision, reliability, and economic viability, ultimately driving innovation and competitive advantage in manufacturing.

- Enhanced Weld Quality and Consistency via real-time parameter adjustment and adaptive control algorithms.

- Predictive Maintenance capabilities for reduced machine downtime and optimized service schedules.

- Automated Defect Detection and Quality Assurance through AI-powered vision systems and anomaly detection.

- Optimized Process Parameters and Recipe Generation for diverse materials and complex geometries.

- Seamless Robotics Integration for fully automated and flexible manufacturing lines.

- Improved Energy Efficiency by intelligently managing power consumption based on welding requirements.

- Data-Driven Decision Making and Process Transparency through advanced analytics and reporting.

DRO & Impact Forces Of Ultrasonic Plastic Welding Machines Market

The Ultrasonic Plastic Welding Machines Market is shaped by a complex interplay of Drivers, Restraints, and Opportunities, collectively influenced by various impact forces. A significant driver is the escalating demand for lightweight and durable products across industries, particularly in the automotive sector for electric vehicles and aerospace for fuel efficiency, which necessitates reliable and efficient plastic joining methods. The increasing trend of automation and smart manufacturing (Industry 4.0) further fuels market growth, as ultrasonic welding machines offer high precision, repeatability, and ease of integration into automated production lines. The expansion of key end-use industries such as medical devices, packaging, and consumer electronics, coupled with stringent regulatory requirements for product safety, hygiene, and environmental compliance, also substantially boosts the adoption of this technology. Furthermore, the growing global emphasis on sustainable manufacturing practices, favoring adhesive-free and energy-efficient joining solutions, positions ultrasonic welding as a preferred method.

However, several restraints pose challenges to market expansion. The high initial investment cost associated with advanced ultrasonic welding machines and specialized tooling can be a barrier for small and medium-sized enterprises (SMEs) and in developing regions. The technical complexity involved in welding certain advanced engineering plastics, composites, or dissimilar materials requires specialized expertise and custom solutions, which can increase setup time and operational costs. Moreover, a persistent shortage of skilled operators and technicians capable of effectively programming, operating, and maintaining these sophisticated machines limits broader adoption. Competition from alternative joining technologies such as laser welding, adhesive bonding, and mechanical fastening, each with its own advantages for specific applications, also exerts pressure on the ultrasonic welding market, necessitating continuous innovation to maintain its competitive edge.

Despite these restraints, substantial opportunities exist for market players. The rising demand for customized and tailored ultrasonic welding solutions for niche applications, alongside the growth of emerging markets in Southeast Asia, Latin America, and parts of Africa, presents significant avenues for expansion. Continued research and development into welding advanced materials, including bio-plastics and advanced composites, will unlock new application possibilities. The integration of ultrasonic welding machines with Artificial Intelligence (AI), machine learning, and advanced robotics, as part of the broader Industry 4.0 movement, offers opportunities for enhanced precision, predictive maintenance, and fully autonomous operations. These technological advancements can lead to significant improvements in efficiency, quality, and overall production flexibility. The interplay of these drivers, restraints, and opportunities is heavily influenced by impact forces such as technological progress, economic conditions, environmental regulations, and geopolitical stability, all of which dynamically shape the market landscape and future trajectory of the ultrasonic plastic welding industry.

Segmentation Analysis

The Ultrasonic Plastic Welding Machines Market is comprehensively segmented to provide granular insights into its diverse applications, technological offerings, and end-user adoption patterns. This segmentation helps in understanding the varying demands across different industries and product types, allowing for targeted market strategies and product development. The market can be categorized by the type of machine (benchtop, handheld, integrated/automated systems), by power range, by operational frequency, by the specific application technique (welding, staking, inserting, spot welding, sealing, cutting), and by the multitude of end-use industries that leverage this technology. Each segment represents distinct market characteristics, growth drivers, and competitive landscapes, reflecting the broad utility and specialization of ultrasonic welding solutions across global manufacturing.

The differentiation in machine types, for instance, caters to different production volumes and automation needs. Benchtop machines are ideal for laboratories, low-volume production, or prototyping, offering versatility and precision. Handheld devices provide mobility and flexibility for specific repair or assembly tasks. Integrated or automated systems, on the other hand, are designed for high-volume, continuous production lines, often incorporating robotics and advanced control systems for maximum efficiency and throughput. Power and frequency segmentation are crucial as they dictate the types of materials and thicknesses that can be effectively welded, with higher power machines suitable for larger parts and more robust plastics, and higher frequencies offering finer control for delicate applications or thin-walled components. These diverse segmentations highlight the market's adaptability and its capacity to meet a wide spectrum of industrial requirements, from precision micro-welding in medical devices to robust joining in automotive assemblies, ensuring broad utility and continued growth.

- By Type:

- Benchtop Ultrasonic Welding Machines

- Handheld Ultrasonic Welding Machines

- Integrated/Automated Ultrasonic Welding Systems

- By Power Range:

- Low Power (300W - 800W)

- Medium Power (801W - 2000W)

- High Power (>2000W)

- By Frequency:

- 15 kHz

- 20 kHz

- 30 kHz

- 35 kHz

- 40 kHz

- Other Frequencies (e.g., 50 kHz, 70 kHz)

- By Application Technique:

- Plastic Welding

- Staking

- Inserting

- Spot Welding

- Sealing (e.g., film and fabric)

- Cutting (e.g., non-woven fabrics)

- By End-Use Industry:

- Automotive

- Medical & Healthcare

- Packaging

- Electrical & Electronics

- Consumer Goods

- Textiles & Non-wovens

- Aerospace

- Others (e.g., industrial, construction)

Value Chain Analysis For Ultrasonic Plastic Welding Machines Market

The value chain for the Ultrasonic Plastic Welding Machines Market encompasses a sophisticated network of activities, commencing from upstream raw material sourcing and component manufacturing, extending through machine assembly and distribution, and culminating in crucial downstream activities such as installation, maintenance, and end-user support. The upstream segment is critical, involving suppliers of specialized raw materials like piezoelectric ceramics for transducers, high-grade metals for sonotrodes and booster horns, and advanced electronic components for digital generators. These suppliers often engage in extensive research and development to produce materials that meet the stringent performance and durability requirements of ultrasonic welding technology, ensuring optimal energy conversion and consistent weld quality. The innovation in this segment directly impacts the efficiency and longevity of the final product, setting the foundational capabilities for the entire value chain. Additionally, component manufacturers specialize in producing precision parts such as actuators, presses, and control systems that are integrated into the final welding machine, each requiring meticulous engineering and quality control to ensure seamless operation and high reliability.

Further along the value chain, the machine manufacturers consolidate these specialized components, along with proprietary software and structural elements, to assemble the complete ultrasonic plastic welding systems. This stage involves complex engineering, system integration, and rigorous testing to ensure each machine meets performance specifications, safety standards, and customer requirements. Following manufacturing, the distribution channels play a pivotal role in bringing these machines to the end-users. This typically involves a dual approach: direct sales for large industrial clients with bespoke needs or complex integration projects, where manufacturers provide extensive technical consultation, customized solutions, and direct after-sales support. For broader market penetration, indirect channels through authorized distributors, agents, and value-added resellers are employed. These intermediaries often provide localized sales, technical support, training, and maintenance services, which are crucial for market reach, especially in diverse geographical regions and for small to medium-sized enterprises (SMEs).

The downstream activities are equally vital, focusing on customer acquisition, machine deployment, and ongoing support. This includes providing comprehensive installation services, often requiring specialized expertise to integrate the welding machines into existing production lines. Extensive training for operators and maintenance personnel is essential to ensure the efficient and safe operation of the equipment, maximizing the return on investment for the end-user. After-sales service, including routine maintenance, spare parts supply, troubleshooting, and technical assistance, forms a critical part of maintaining customer satisfaction and fostering long-term relationships. These services are crucial for minimizing downtime, ensuring consistent product quality, and adapting the machines to evolving production needs. The efficiency and effectiveness of these direct and indirect distribution and support channels significantly influence market penetration, brand reputation, and overall customer loyalty, thereby completing the robust value chain of the ultrasonic plastic welding machines market.

Ultrasonic Plastic Welding Machines Market Potential Customers

The Ultrasonic Plastic Welding Machines Market serves a broad and diverse range of potential customers, primarily end-users and buyers who require precise, efficient, and reliable plastic joining solutions across various manufacturing sectors. These customers are typically companies involved in high-volume production, specialized component assembly, or those with stringent quality and regulatory requirements. A significant portion of the market comprises Original Equipment Manufacturers (OEMs) and Tier 1 suppliers in the automotive industry. These companies utilize ultrasonic welding for assembling a myriad of components, including interior trim, dashboard parts, lighting assemblies, battery packs, sensor housings, and under-hood components. The technology’s ability to create strong, lightweight bonds without external fasteners is crucial for modern vehicle design, especially with the accelerated shift towards electric vehicles (EVs) and autonomous driving systems that demand high precision and reliability for electronic components and complex modules.

Another major segment of potential customers resides within the medical and healthcare sector. Manufacturers of medical devices, diagnostic equipment, and pharmaceutical packaging are increasingly adopting ultrasonic welding due to its sterile nature, ability to produce hermetic seals, and suitability for biocompatible plastics. Applications include the assembly of catheters, syringe barrels, blood filters, surgical instruments, drug delivery devices, and various disposable medical products where cleanliness and product integrity are paramount. The consumer electronics industry also represents a substantial customer base, with companies using ultrasonic welding for assembling smartphone casings, wearable devices, computer peripherals, and other small appliances. The technology's precision allows for the secure joining of delicate components and intricate designs, meeting the aesthetic and functional demands of modern electronic gadgets. Its clean process minimizes contamination, which is essential for sensitive electronic assemblies, contributing to both product durability and performance.

Furthermore, the packaging industry is a significant consumer of ultrasonic welding machines, particularly for food and beverage packaging, blister packs, and tamper-evident seals. The technology offers fast, clean, and secure sealing solutions, extending shelf life and ensuring product safety. Textile manufacturers, especially those working with non-woven fabrics and technical textiles, also leverage ultrasonic welding for tasks like cutting, sealing, and joining, producing items such as hygiene products, apparel components, and specialized filters. Beyond these major sectors, the market extends to manufacturers of home appliances, toys, industrial components, and even aerospace parts, all seeking efficient and high-quality plastic joining methods. The common thread among these diverse potential customers is their need for a robust, repeatable, and cost-effective method to assemble plastic components, driven by demands for product quality, operational efficiency, and adherence to industry standards. The versatility of ultrasonic welding machines allows them to cater to these varied requirements, making them an indispensable tool in modern manufacturing across the globe.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850.5 Million |

| Market Forecast in 2033 | USD 1,640.2 Million |

| Growth Rate | 9.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Branson Ultrasonics (Emerson), Herrmann Ultrasonics Inc., Rinco Ultrasonics, Dukane IAS LLC, Sonics & Materials, Inc., Telsonic AG, MECASONIC, Stapla Ultrasonics GmbH, Sonic Italia S.r.l., SCHUNK GmbH & Co. KG, Martin GmbH, KLN Ultraschall AG, Weber Ultrasonics AG, AAT Automation GmbH, SEJIN I&A, FORWARD Technology, Sonitek, Sonobond Ultrasonics, Sonotronic Nagel GmbH, Bielomatik Leuze GmbH + Co. KG |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Ultrasonic Plastic Welding Machines Market Key Technology Landscape

The technological landscape of the Ultrasonic Plastic Welding Machines Market is characterized by continuous innovation aimed at enhancing precision, efficiency, versatility, and integration capabilities. A cornerstone of this landscape is the development of advanced digital ultrasonic generators. These generators offer precise control over key welding parameters such as amplitude, frequency, time, and pressure, often featuring real-time feedback loops and adaptive algorithms. Digital control not only ensures highly repeatable and consistent weld quality but also allows for fine-tuning to accommodate a wider range of materials and complex geometries. This contrasts sharply with older analog systems, providing superior process control and diagnostic capabilities essential for demanding applications in industries like medical and automotive. The evolution of these generators is central to unlocking new possibilities in ultrasonic welding, enabling more intricate and reliable joins.

Another critical aspect involves the ongoing advancements in piezoelectric transducers and sonotrode (horn) technology. Piezoelectric transducers are responsible for converting electrical energy into mechanical vibrations, and innovations here focus on improving efficiency, durability, and power output. Complementing this, specialized sonotrodes, designed with advanced metallurgical properties and optimized acoustic characteristics, are being developed for specific material combinations and weld patterns. These custom-engineered tools are crucial for effectively transferring ultrasonic energy to the parts, minimizing energy loss, and achieving optimal weld strength and aesthetics. Furthermore, modular system designs are becoming prevalent, allowing manufacturers to easily configure and scale welding machines to meet diverse production needs, from standalone units to fully integrated robotic cells. This modularity enhances flexibility, reduces setup times, and lowers the total cost of ownership for end-users, aligning with modern agile manufacturing philosophies.

The integration of ultrasonic plastic welding machines with Industry 4.0 technologies represents a significant shift in the market's technological trajectory. This includes incorporating sophisticated software for real-time process monitoring, data logging, and predictive analytics. Such software enables operators to track weld performance, identify trends, and anticipate potential issues before they lead to defects or downtime, thereby improving overall equipment effectiveness (OEE). Furthermore, the seamless integration with robotics and automation systems is transforming ultrasonic welding into a key component of fully automated production lines. Robotic handling of parts, combined with intelligent welding units, leads to significantly increased throughput, reduced labor costs, and enhanced consistency, making the entire manufacturing process more efficient and reliable. Closed-loop control systems, which continuously monitor and adjust welding parameters based on real-time feedback, further solidify the technological prowess of modern ultrasonic plastic welding machines, driving their adoption across high-precision and high-volume manufacturing environments globally.

Regional Highlights

- North America: This region demonstrates robust growth, particularly driven by high-value applications in the medical, automotive (especially electric vehicle components), and aerospace sectors. Innovation in automation, precision welding, and the adoption of advanced materials are key trends. Stringent quality and regulatory standards also compel manufacturers to invest in highly sophisticated and reliable ultrasonic welding solutions, with a strong focus on digital control and data integration.

- Europe: Europe represents a mature but continually innovating market for ultrasonic plastic welding machines. Key demand originates from the automotive, industrial equipment, and packaging industries. There's a strong emphasis on Industry 4.0 integration, energy efficiency, and sustainable manufacturing practices. Countries like Germany, Italy, and France are leading in technological advancements and advanced manufacturing techniques, fostering significant adoption.

- Asia Pacific (APAC): As the largest and fastest-growing market, APAC is fueled by its massive manufacturing base, led by countries such as China, India, Japan, and South Korea. The region dominates in high-volume production for automotive, consumer electronics, and general industrial sectors. Cost-effectiveness, rapid industrialization, increasing automation, and a growing middle-class consumer base drive the demand for ultrasonic welding machines. Investments in smart factories and localized manufacturing capabilities are also boosting market expansion.

- Latin America: This is an emerging market with gradual but consistent adoption, mainly spurred by the expansion of the automotive industry (e.g., Mexico, Brazil) and growing consumer goods manufacturing. Increased foreign direct investment in manufacturing capabilities is fostering the need for efficient and modern plastic joining technologies, positioning ultrasonic welding for steady growth.

- Middle East & Africa (MEA): The MEA region is experiencing nascent adoption, driven by infrastructure development, diversification of manufacturing industries, and increasing investments in packaging and automotive sectors. While still in early stages compared to other regions, rising industrialization efforts and economic growth are creating new opportunities for ultrasonic plastic welding technology.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Ultrasonic Plastic Welding Machines Market.- Branson Ultrasonics (Emerson)

- Herrmann Ultrasonics Inc.

- Rinco Ultrasonics

- Dukane IAS LLC

- Sonics & Materials, Inc.

- Telsonic AG

- MECASONIC

- Stapla Ultrasonics GmbH

- Sonic Italia S.r.l.

- SCHUNK GmbH & Co. KG

- Martin GmbH

- KLN Ultraschall AG

- Weber Ultrasonics AG

- AAT Automation GmbH

- SEJIN I&A

- FORWARD Technology

- Sonitek

- Sonobond Ultrasonics

- Sonotronic Nagel GmbH

- Bielomatik Leuze GmbH + Co. KG

Frequently Asked Questions

What are the primary advantages of ultrasonic plastic welding over other joining methods?

Ultrasonic plastic welding offers significant advantages including rapid cycle times, superior weld strength and aesthetic quality, clean processes with no consumables (adhesives, solvents), energy efficiency, and suitability for complex part geometries, making it highly cost-effective and environmentally friendly.

Which industries are the largest adopters of ultrasonic plastic welding machines?

The automotive, medical and healthcare, packaging, and electrical and electronics sectors are the predominant end-users. These industries demand high precision, cleanliness, and reliable bonds for their products, making ultrasonic welding an indispensable technology.

How does AI impact the performance and capabilities of ultrasonic plastic welding machines?

AI significantly enhances performance by enabling real-time parameter adjustment for optimal weld quality, facilitating predictive maintenance to reduce downtime, automating defect detection through advanced vision systems, and optimizing process parameters for increased efficiency and consistency across diverse materials.

What key factors should be considered when selecting an ultrasonic welding machine for a specific application?

Key considerations include the type of plastic material, the geometry and size of the parts, the required weld strength and aesthetic, desired production volume, the level of automation needed, and the overall budget. Specialized tooling and frequency also play crucial roles in selection.

What are the prevailing future trends shaping the ultrasonic plastic welding machines market?

Future trends include increased integration with Industry 4.0 technologies (AI, IoT, robotics), a growing demand for automated and intelligent welding solutions, advancements in welding diverse and advanced lightweight materials, and a continued emphasis on sustainable and energy-efficient manufacturing processes.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager