Uncoated Paper Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431518 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Uncoated Paper Market Size

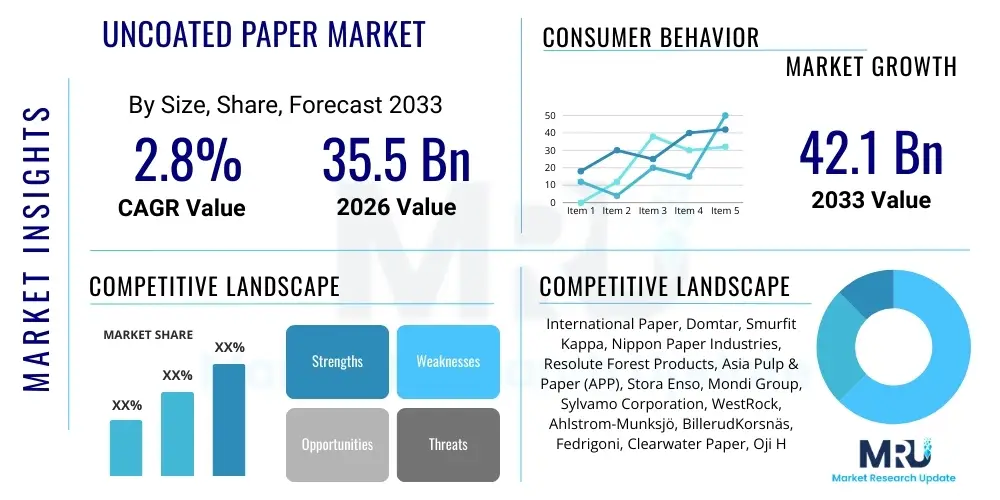

The Uncoated Paper Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 2.8% between 2026 and 2033. The market is estimated at USD 35.5 Billion in 2026 and is projected to reach USD 42.1 Billion by the end of the forecast period in 2033.

The stability of the uncoated paper market, despite digital displacement, is primarily driven by persistent demand in essential sectors such as packaging, hygiene products, and certain specialized printing applications like transactional documents and educational materials. While traditional office printing has seen a decline in developed economies, emerging economies, particularly in Asia Pacific, continue to rely heavily on physical paper for educational infrastructure and administrative purposes, providing a foundational floor for market volume. Furthermore, the shift towards sustainable packaging solutions, which often favor uncoated, easily recyclable fiber-based materials over plastics, is creating new avenues for growth that offset losses in conventional graphic papers.

Market expansion is also supported by continuous innovation in pulp and paper manufacturing technologies aimed at reducing environmental impact and improving material properties. Manufacturers are investing in high-yield pulping processes, advanced fiber recycling capabilities, and the integration of bio-based additives to enhance paper strength, brightness, and runnability. These technological improvements enable the production of lighter yet stronger papers, optimizing logistics and reducing raw material consumption, which is critical for maintaining competitiveness against digital alternatives and meeting stringent sustainability goals set by corporate end-users globally. The robust growth observed in the packaging and wrapping segments serves as the principal engine of forward momentum.

Uncoated Paper Market introduction

The Uncoated Paper Market encompasses a wide range of paper products characterized by the absence of a mineral coating layer applied to the surface. These papers, known for their high opacity, excellent bulk, and superior printability (especially for porous inks), are fundamental to commercial and institutional operations globally. Key product types include uncoated fine paper (UFP), used predominantly for office copy paper and printing, and uncoated mechanical paper, commonly utilized in directories, inserts, and certain newspaper stocks. Major applications span high-volume printing and writing needs, complex transactional documents, educational textbooks, and increasingly, various forms of fiber-based packaging and wrapping materials due to their environmental advantages.

Uncoated papers offer distinct benefits, including being highly biodegradable and easily recyclable, aligning with global corporate sustainability mandates. Their natural, tactile feel is often preferred for premium stationery, corporate branding, and specialized art papers. Driving factors for the market include population growth and rising literacy rates in developing regions, the persistent necessity for physical packaging, and regulatory pressure favoring sustainable materials over plastic alternatives. Although faced with digitalization challenges in the graphic segment, the diversification into high-growth segments like flexible packaging and specialized food contact papers ensures market resilience and continued, albeit moderate, growth throughout the forecast period.

The manufacturing process relies heavily on wood pulp—either virgin or recycled fiber—and involves refining, sheeting, and drying without the final coating step that characterizes coated papers. This simplicity in processing contributes to lower production costs and faster turnaround times for high-volume orders. The core strength of the market lies in its essential, everyday use across almost every industry, ranging from corporate communications and government records to retail receipts and specialized industrial wrapping materials. Technological advancements in bleaching, sizing, and filler usage are consistently being implemented to enhance product quality while simultaneously reducing resource consumption, underpinning the market's long-term viability.

Uncoated Paper Market Executive Summary

The Uncoated Paper Market is poised for stable expansion, moving away from reliance on graphic papers and focusing intently on resilient segments like packaging, specialized documents, and hygiene products. Business trends indicate significant capacity consolidation among major global players, coupled with substantial investments directed toward modernizing aging production facilities to improve energy efficiency and increase the capacity for high-margin specialty and packaging grades. Supply chain optimization remains a critical focus, particularly concerning the volatility of raw material costs (wood pulp) and logistics challenges. Furthermore, mergers and acquisitions activity is expected to continue as companies seek to strengthen regional footprints and integrate advanced recycling technologies to secure sustainable fiber sources and meet burgeoning regulatory requirements for circularity.

Regionally, the Asia Pacific (APAC) area is anticipated to dominate market volume and growth, fueled by rapid industrialization, expanding consumer bases, and high demand for educational materials and consumer goods packaging, especially in China and India. North America and Europe, characterized by mature and highly competitive markets, are witnessing a significant strategic pivot where manufacturers are actively converting paper machines from producing traditional printing papers to lightweight containerboard, specialty packaging, and label stock to counteract the decline in graphic paper usage. The adoption of stringent environmental standards in these regions also favors domestic production that adheres to sustainable forestry practices and low-emission manufacturing protocols.

Segmentation trends highlight a crucial shift: the Printing & Writing application segment, historically the largest, is yielding growth momentum to the Packaging & Wrapping segment. Within product types, Uncoated Fine Paper (UFP) remains essential for transactional and professional use, but Uncoated Specialty Paper is experiencing the highest CAGR, driven by demand for niche applications such as thermal paper, security documents, and sophisticated food packaging liners. This strategic segmentation shift enables market players to capture higher value, mitigating volume erosion caused by digital transformation in general office environments. Successful market participants are those who have effectively diversified their product portfolio towards non-graphic, essential use segments.

AI Impact Analysis on Uncoated Paper Market

Common user inquiries regarding AI's influence on the Uncoated Paper Market often center on how automation and sophisticated data analytics will affect consumption patterns, manufacturing efficiency, and supply chain transparency. Users are keen to understand if AI will accelerate the decline of print media (through advanced document management systems and personalized digital content) or if it might stabilize demand by optimizing manufacturing processes to lower costs. Key themes include the implementation of predictive maintenance in mills, AI-driven demand forecasting to reduce inventory waste, and the long-term impact on the physical paper supply required for e-commerce and logistics labels, which AI-optimized systems increasingly necessitate for tracking. Concerns revolve around potential job displacement in operational roles versus the creation of high-skill data management positions within the industry.

- AI-Enhanced Demand Forecasting: Utilizing machine learning algorithms to predict granular consumer and corporate paper needs, minimizing overproduction and optimizing mill run schedules.

- Manufacturing Optimization: Implementation of AI-powered systems for predictive maintenance, process control, and real-time quality assurance in pulping and sheeting lines, reducing downtime and material wastage.

- Supply Chain Efficiency: AI integrating logistics and inventory management across global supply chains, leading to reduced transportation costs and improved fiber sourcing traceability.

- Accelerated Digital Substitution: AI driving superior personalized digital advertising and automated document handling, potentially reducing general office and mass-market print volumes.

- Product Innovation: Using AI/ML to simulate fiber interactions and chemical additives, accelerating the development of new specialty paper grades with enhanced properties (e.g., barrier performance, lightweight strength).

DRO & Impact Forces Of Uncoated Paper Market

The Uncoated Paper Market is driven by strong sustainability mandates that favor recyclable fiber-based solutions, particularly in the packaging sector, counteracting the digital migration that primarily acts as a restraint in the graphic paper segment. Opportunities arise from expanding industrialization in Asia and specialized niche applications requiring physical documentation, alongside technological innovations that enhance product performance and operational efficiency. The market’s operational landscape is shaped by the impact of fluctuating pulp and energy costs, the increasing legislative pressure regarding environmental compliance, and the critical need for large-scale investment in machine conversion to shift output towards higher-demand packaging and specialty grades. The combined forces result in a market characterized by moderate volume growth but increasing value realization in specialized product lines.

Segmentation Analysis

The Uncoated Paper Market is comprehensively segmented based on the specific characteristics of the paper product, its functional application, and the ultimate end-use industry utilizing the material. This segmentation is crucial for understanding the market's divergent growth vectors, highlighting the ongoing decline in traditional print media against the robust expansion driven by packaging and specialized papers. The analysis reveals that market players are increasingly focusing capital expenditure and R&D efforts on segments with defensible growth patterns, characterized by functional requirements that digital media cannot easily replicate, such as physical packaging integrity, security documents, and specialized labels. Accurate segmentation allows manufacturers to tailor marketing strategies and product specifications to address highly specific industrial and consumer needs efficiently.

- By Product Type:

- Uncoated Fine Paper (UFP)

- Uncoated Mechanical Paper

- Uncoated Specialty Paper

- By Application:

- Printing & Writing

- Packaging & Wrapping

- Label Stock

- Others (e.g., Technical, Hygienic)

- By End-Use Industry:

- Commercial Printing and Publishing

- Corporate Offices and Administration

- Educational Sector

- Retail and E-commerce (for packaging and inserts)

- FMCG and Food Service

- Industrial and Manufacturing

Value Chain Analysis For Uncoated Paper Market

The value chain for the uncoated paper market begins with upstream activities centered around sustainable forest management and highly efficient pulp production. This stage involves securing virgin fiber resources from certified forests (FSC, PEFC), or alternatively, managing the collection and processing of recovered paper for recycled content. Critical upstream determinants of cost and sustainability include energy efficiency in pulping (e.g., thermomechanical pulping vs. chemical pulping) and the logistics associated with transporting vast quantities of wood chips or waste paper to the mill site. Suppliers in this phase include forestry companies, chemical providers (for bleaching and sizing agents), and specialized energy suppliers, setting the foundational cost structure and environmental profile of the final paper product.

The midstream involves the core manufacturing process: paper making. Integrated mills, which combine pulping and paper production, often achieve superior cost advantages and quality control. Paper machines convert the pulp slurry into finished reels of uncoated paper, which are then subject to finishing processes such as calendering (for smoothness) and cutting. Distribution channels represent a crucial link, moving large volumes of paper stock from mills to converters, merchants, and direct end-users. The structure of the channel dictates pricing complexity; direct sales to large corporate entities or integrated packaging firms offer efficiency, while sales through paper merchants provide necessary inventory management and local distribution services for smaller printers and end-users.

Downstream activities include specialized conversion (e.g., envelopes, notebooks, flexible packaging), printing operations, and ultimately, the use by end-user industries such as commercial publishers, educational institutions, and e-commerce fulfillment centers. The final stage involves the paper's lifecycle management, specifically collection and recycling, which feeds back into the upstream supply of recovered paper. This emphasis on circularity is increasingly integral to the value proposition, with manufacturers often vertically integrating into recycling operations to ensure a stable, cost-effective, and environmentally compliant fiber stream, thereby closing the loop and enhancing the product’s overall sustainability profile in the eyes of the demanding consumer and regulatory bodies.

Uncoated Paper Market Potential Customers

The primary consumers and end-users of uncoated paper products are highly diversified, extending across virtually every sector that requires physical communication, documentation, or sustainable containment solutions. Potential customers range from high-volume, cost-sensitive entities like government administration offices and educational textbook publishers to value-driven, specification-focused buyers such as pharmaceutical companies requiring precise transactional and packaging inserts. The demand profile varies significantly: commercial printers seek papers optimized for high-speed press runs and specific color fidelity, while e-commerce retailers prioritize lightweight, durable, and aesthetically appealing packaging and void-fill materials. This broad customer base provides market stability, as weakness in one segment (e.g., office printing) is often compensated by growth in another (e.g., specialized packaging).

A significant concentration of purchasing power resides with paper merchants and large distributors who act as intermediaries, stocking and distributing various grades to thousands of smaller printers and localized businesses. These merchants are crucial for market liquidity and responsiveness, often dictating short-term pricing dynamics. However, large multinational Fast-Moving Consumer Goods (FMCG) corporations and integrated logistics providers represent major direct procurement customers, especially those utilizing uncoated paper for primary and secondary packaging purposes. These large corporate buyers place immense emphasis on sustainability credentials, demanding certifications like Forest Stewardship Council (FSC) and low carbon footprint reports from their paper suppliers, thereby influencing production standards globally.

Furthermore, specialized industrial sectors, including security printing firms and label manufacturers, constitute a growing segment of high-value customers. These buyers require uncoated specialty papers engineered for unique functionalities, such as thermal transfer, tamper-evident features, or high dimensional stability under varying humidity. The educational sector, particularly in emerging economies with substantial public investment in school infrastructure and textbook provision, represents a consistently robust, high-volume buyer of specific grades of uncoated writing and printing paper. Serving these diverse customer groups requires manufacturers to maintain flexible production capabilities and rigorous quality control across their product range, focusing intensely on customized solutions and reliable supply.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 35.5 Billion |

| Market Forecast in 2033 | USD 42.1 Billion |

| Growth Rate | 2.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | International Paper, Domtar, Smurfit Kappa, Nippon Paper Industries, Resolute Forest Products, Asia Pulp & Paper (APP), Stora Enso, Mondi Group, Sylvamo Corporation, WestRock, Ahlstrom-Munksjö, BillerudKorsnäs, Fedrigoni, Clearwater Paper, Oji Holdings, Nine Dragons Paper, Sappi, Hansol Paper, Chenming Paper, Sun Paper Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Uncoated Paper Market Key Technology Landscape

The technological landscape of the Uncoated Paper Market is rapidly evolving, driven primarily by the need to optimize resource utilization, reduce environmental footprint, and enhance specific paper functionalities required for modern applications like lightweight packaging. Core innovations focus heavily on advanced pulping techniques, such as the increased adoption of chemical thermomechanical pulp (CTMP) and high-yield pulping methods, which maximize fiber recovery from wood resources compared to traditional chemical pulps, thus lowering raw material costs per ton of finished paper. Furthermore, manufacturers are heavily investing in digitalization and Industry 4.0 concepts, deploying sensors and automated controls across the paper machine to ensure precise moisture content, basis weight, and fiber orientation, leading to superior quality consistency and reduced energy expenditure during the drying phase.

Another crucial area of technological advancement involves the expansion of effective recycling infrastructure and improved de-inking processes. As the reliance on recovered paper grows, sophisticated flotation and washing techniques are being perfected to handle lower quality mixed waste paper streams while still achieving the brightness and cleanliness required for high-grade uncoated fine papers. Beyond fiber processing, the use of performance-enhancing fillers, particularly specialized grades of precipitated calcium carbonate (PCC) and kaolin clay, is central to modern uncoated paper manufacturing. These fillers improve opacity, brightness, and bulk while allowing manufacturers to reduce the expensive fiber content, thus lowering the final product cost while maintaining or improving print quality and runnability on high-speed presses.

The development of new specialty grades demands cutting-edge material science. This includes the implementation of barrier technologies for food contact and flexible packaging using fiber-based materials. Manufacturers are applying innovative sizing agents, often bio-based and free of per- and polyfluoroalkyl substances (PFAS), to impart grease, water, or oil resistance to uncoated paper surfaces without compromising their recyclability or compostability. Finally, machine conversion technology is paramount; older machines designed for printing papers are being re-engineered with specialized headboxes and drying sections to efficiently produce lightweight containerboard or specialty linerboards, representing a critical technological capability that dictates the long-term viability and flexibility of production assets within the current market environment.

Regional Highlights

Geographic variations in the uncoated paper market reflect distinct stages of economic development and regulatory environments. Asia Pacific (APAC) currently stands as the most vital region, exhibiting substantial market share and the highest growth potential. This dominance is attributed to robust urbanization, rising middle-class consumption driving packaging demand, and massive educational programs requiring bulk paper supplies. Countries like China, India, and Indonesia are simultaneously major production hubs and primary consumers. The regional trend is characterized by the construction of state-of-the-art integrated mills that prioritize high-volume production of both packaging grades and uncoated fine paper for domestic consumption and export, often leveraging lower operating costs compared to Western counterparts.

In contrast, North America and Europe represent mature markets defined by stringent environmental standards and advanced technological adaptation. Consumption of traditional graphic papers has contracted significantly, leading to widespread capacity rationalization. However, this has been strategically countered by an aggressive pivot towards specialty and value-added uncoated products, including high-performance label stock, sustainable food service packaging, and high-quality security papers. European producers, in particular, lead in implementing circular economy principles, investing heavily in certified sustainable forestry and advanced paper recycling technologies, which reinforces their competitive edge among environmentally conscious buyers.

Latin America and the Middle East & Africa (MEA) offer distinct opportunity profiles. Latin America, with vast natural forest resources (especially Brazil and Chile), is a key source of virgin pulp and competitive paper exports, targeting both the US and European markets. Domestic consumption in Latin America is stable, tied to economic cycles and educational demand. The MEA region is characterized by high reliance on imports, though increasing industrialization in the Gulf Cooperation Council (GCC) countries and parts of South Africa is spurring local demand for packaging solutions, gradually attracting minor local production investments focused on meeting essential regional needs for documentation and industrial wrapping materials.

- Asia Pacific (APAC): Market leader in volume and growth, driven by packaging, education, and rapid industrialization; characterized by continuous investment in high-capacity, integrated mills.

- North America: Focus shifts heavily from graphic papers to specialty packaging and containerboard conversion; strong emphasis on sustainable sourcing and high operational efficiency.

- Europe: Highly regulated market prioritizing certified sustainable products and advanced recycling; innovation concentrated on specialty papers, lightweighting, and biodegradable barriers.

- Latin America: Major global supplier of virgin fiber pulp and bulk paper; market growth tied closely to regional economic stability and domestic educational demand.

- Middle East and Africa (MEA): High dependence on imports, with increasing localized demand driven by infrastructure projects and rising consumer goods packaging requirements.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Uncoated Paper Market.- International Paper

- Domtar

- Smurfit Kappa

- Nippon Paper Industries

- Resolute Forest Products

- Asia Pulp & Paper (APP)

- Stora Enso

- Mondi Group

- Sylvamo Corporation

- WestRock

- Ahlstrom-Munksjö

- BillerudKorsnäs

- Fedrigoni

- Clearwater Paper

- Oji Holdings

- Nine Dragons Paper

- Sappi

- Hansol Paper

- Chenming Paper

- Sun Paper Group

Frequently Asked Questions

Analyze common user questions about the Uncoated Paper market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is driving the growth of the Uncoated Paper Market despite digitalization?

The primary driver is the robust, non-substitutable demand from the Packaging & Wrapping segment, particularly for sustainable, recyclable fiber-based alternatives to plastic packaging. Additionally, persistent demand for educational materials and transactional documents in emerging economies provides fundamental market stability and moderate growth momentum, offsetting declines in general office printing.

Which geographical region holds the largest market share for uncoated paper?

The Asia Pacific (APAC) region currently holds the largest market share in the uncoated paper market. This dominance is attributed to high population density, ongoing industrialization, expanding educational needs, and significant growth in consumer goods consumption requiring extensive physical packaging materials across nations like China and India.

How is the uncoated paper industry addressing sustainability and environmental concerns?

The industry is addressing sustainability through rigorous adherence to certified sustainable forestry practices (FSC, PEFC), massive investment in advanced paper recycling and de-inking technologies, and the strategic conversion of mills to produce biodegradable and compostable specialty papers, minimizing reliance on non-renewable resources and enhancing product circularity.

What is the difference between Uncoated Fine Paper (UFP) and Uncoated Mechanical Paper?

Uncoated Fine Paper (UFP) is typically made using chemically processed pulp, resulting in a whiter, stronger, and more durable sheet suitable for high-quality printing, office use, and corporate stationery. Uncoated Mechanical Paper uses mechanically processed pulp, yielding a bulkier, less durable paper with higher opacity, commonly used for directories, inserts, and certain types of newsprint due to its lower cost base.

What role does machine conversion technology play in the future of the market?

Machine conversion is critical for market survival and optimization. Manufacturers are re-engineering paper machines originally designed for graphic papers to efficiently produce high-demand, specialized products such as lightweight containerboard, specialized label stock, or barrier packaging materials, allowing companies to pivot assets toward resilient, high-margin market segments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager