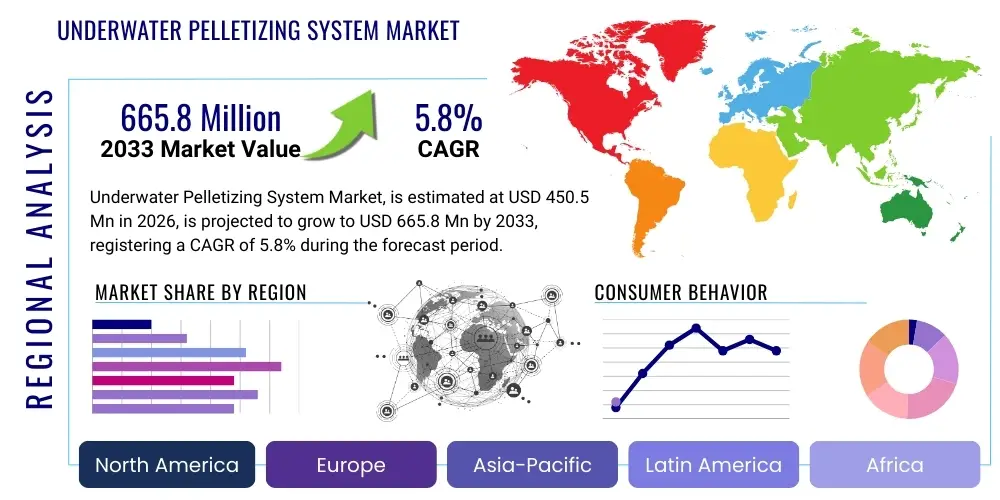

Underwater Pelletizing System Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435940 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Underwater Pelletizing System Market Size

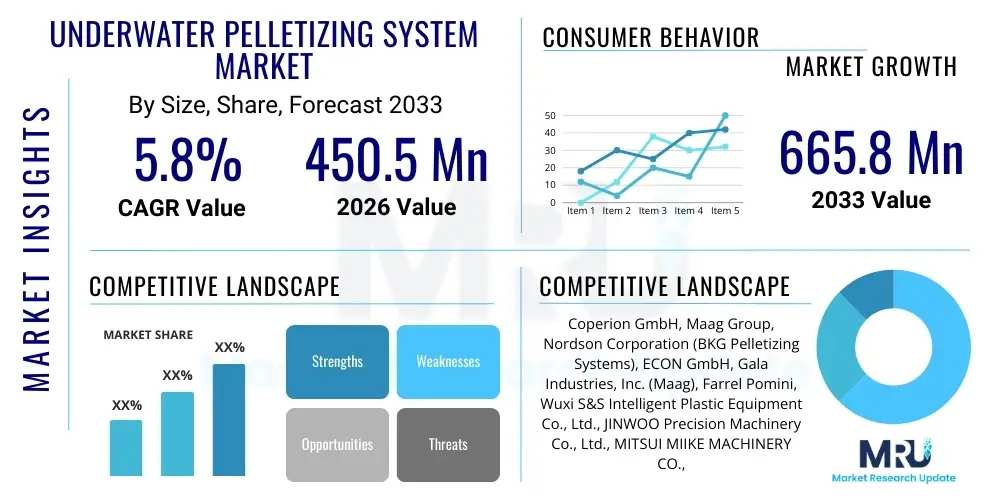

The Underwater Pelletizing System Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 665.8 Million by the end of the forecast period in 2033.

Underwater Pelletizing System Market introduction

The Underwater Pelletizing System Market encompasses specialized machinery used to convert molten polymers exiting an extruder into uniformly sized, cooled, and dried pellets. This method, primarily employed for high-throughput and sticky polymers such as polyolefins, styrenics, and various engineering plastics, involves extruding the polymer melt through a die plate directly into a circulating water chamber where a rotating knife cuts the strands immediately upon exit. The inherent efficiency of underwater pelletizing, particularly in handling challenging materials and producing highly spherical, dust-free pellets, positions it as critical infrastructure within the global plastics manufacturing and recycling industries. Market expansion is fundamentally driven by the escalating demand for high-quality plastic resins across diverse sectors like automotive, construction, and flexible packaging, all of which require precise pellet specifications for subsequent processing.

These sophisticated systems are integral to compounding operations, masterbatch production, and, increasingly, in post-consumer and post-industrial plastic recycling facilities. The core benefit of underwater pelletizing lies in its ability to deliver superior pellet geometry and uniformity, which directly enhances the efficiency of downstream processes such as injection molding and extrusion. Moreover, the closed-loop nature of the cooling and drying processes minimizes material waste and volatile organic compound (VOC) emissions, aligning with growing regulatory pressures for sustainable manufacturing practices. Innovations are centered on improving die-face design, optimizing cutter blade materials for longevity, and integrating advanced control systems to manage water temperature and flow rates precisely, thereby ensuring consistent quality output regardless of polymer viscosity or melt temperature fluctuations. The shift towards large-scale continuous production lines mandates reliable, high-capacity pelletizing solutions.

Major applications for underwater pelletizers include the production of high-density polyethylene (HDPE), low-density polyethylene (LDPE), polyethylene terephthalate (PET), and various thermoplastic elastomers (TPEs). The technology excels where rapid, uniform cooling is essential to prevent agglomeration or sticking of the pellets, especially immediately after cutting. The systems offer significant advantages in terms of reduced manual intervention and enhanced safety compared to traditional strand pelletizing or hot-cut methods. Furthermore, the rising investment in chemical recycling technologies and the push for circular economy models amplify the necessity for efficient pelletizers capable of handling varying feedstock qualities, further cementing the market's robust long-term growth trajectory and technological sophistication requirement.

Underwater Pelletizing System Market Executive Summary

The Underwater Pelletizing System Market is characterized by robust growth, primarily spurred by global mandates emphasizing plastic recycling and the corresponding increase in demand for high-performance compounded plastics. Business trends indicate a strong move toward high-capacity, automated systems that reduce energy consumption and labor costs while maintaining stringent quality control, driven by the need for operational efficiency in large-scale polymer production facilities. Manufacturers are focusing on modular designs that allow for quick interchangeability of components to handle a wider spectrum of polymer types and melt flow rates, enhancing machine flexibility. Key competitive strategies revolve around providing comprehensive aftermarket support, including predictive maintenance services and spare parts availability, critical for minimizing downtime in continuous production environments. Furthermore, strategic partnerships between pelletizing equipment manufacturers and major polymer producers are common, accelerating the adoption of new, specialized system configurations tailored for novel polymer formulations, including bioplastics and advanced engineering plastics.

Regionally, Asia Pacific (APAC) stands as the dominant and fastest-growing market, fuelled by massive investments in infrastructure development, burgeoning manufacturing sectors in countries like China and India, and the establishment of large-scale recycling hubs. Europe also represents a mature but dynamically evolving market, driven heavily by strict EU environmental regulations that necessitate high levels of recycled content in packaging and consumer goods, promoting the adoption of advanced pelletizing technology for recycled polymers. North America exhibits steady growth, focusing particularly on integrating automation and smart manufacturing (Industry 4.0) principles into pelletizing operations to improve traceability and quality assurance. Regional growth disparities highlight the critical role of governmental policies regarding plastic waste management and manufacturing expansion in shaping market opportunities for system providers.

In terms of segment trends, the high-capacity segment (over 2000 kg/h) is witnessing the most significant uptake, catering to the scale of modern polymer compounding and continuous recycling plants. By application, the recycling segment is experiencing exponential growth, directly correlating with increased global recycling rates and the commercial viability of post-consumer resin (PCR). Technology segmentation shows a rising preference for centrifugal drying systems over older vibratory units due to higher drying efficiency and gentler handling of soft pellets. The market is structurally benefiting from innovation across materials, specifically utilizing advanced alloys in die plates and cutter hubs to resist high wear and corrosion associated with processing highly filled or abrasive recycled materials, thereby extending the operational lifespan and reliability of the pelletizing lines.

AI Impact Analysis on Underwater Pelletizing System Market

User queries regarding AI's influence in this sector commonly revolve around optimizing process parameters, achieving predictive quality control, and minimizing unscheduled downtime through condition monitoring. Users frequently ask how AI can handle the variability introduced by recycled feedstock, improve energy efficiency in the cooling phase, and integrate real-time quality measurements without human intervention. The core theme emerging from these concerns is the expectation that AI and Machine Learning (ML) will transform the pelletizing process from a reactive system, relying on manual adjustments based on lab tests, into a highly proactive and self-optimizing manufacturing node. Expectations are high that AI can correlate numerous variables—such as melt pressure, water temperature, cutter speed, and motor load—to instantaneously adjust settings and ensure pellet consistency, a crucial factor often impacting downstream processing yield.

- AI-driven Predictive Maintenance (PdM): Algorithms analyze vibration, temperature, and current data from cutters and gearboxes to forecast component failure, maximizing operational uptime.

- Real-time Quality Control: AI visual systems inspect pellet size, shape, and color defects instantly, enabling closed-loop adjustment of cutting or drying parameters.

- Process Parameter Optimization: Machine Learning models correlate feedstock quality and environmental conditions with optimal settings (pressure, temperature, flow) to maximize throughput and minimize specific energy consumption.

- Automated Recipe Management: AI systems intelligently adapt processing recipes for recycled or heterogeneous polymer blends, compensating for material variability automatically.

- Energy Efficiency Enhancement: Optimization of water pump speeds and chiller operations based on real-time thermal load calculations, reducing utility costs significantly.

- Enhanced Anomaly Detection: Immediate identification of subtle deviations in the pelletizing process that precede material blockage or quality degradation.

DRO & Impact Forces Of Underwater Pelletizing System Market

The Underwater Pelletizing System Market is significantly shaped by a confluence of driving factors, operational restraints, and substantial opportunities, collectively defining its impact forces. Primary drivers include the global push for the circular economy, leading to mass investment in plastic recycling infrastructure which relies heavily on high-throughput pelletizers to reprocess diverse polymer streams into high-quality secondary raw materials. Concurrently, the increasing demand for complex compounded materials and masterbatches in critical industries like automotive (lightweighting components) and medical devices necessitates the precise and consistent pellet geometry achievable only through underwater cutting. These market accelerants are underpinned by stricter environmental regulations across major economies, forcing manufacturers to adopt cleaner, more efficient pelletizing methods that reduce dust and eliminate strand breakage issues inherent in traditional systems.

However, the market faces significant restraints, chiefly the substantial initial capital investment required for establishing an underwater pelletizing line, particularly when compared to simpler, lower-capacity systems. The complexity of system maintenance, involving high-pressure water handling and precise alignment of cutting components, demands specialized technical expertise and can contribute to higher operational costs if not managed effectively. Furthermore, the required highly pure and filtered water supply is a challenge in regions facing water scarcity. These technical and financial barriers sometimes impede adoption by smaller or new market entrants, creating a concentrated supply structure where established industry players maintain a significant competitive edge due to their integrated service offerings and technological sophistication.

Opportunities for expansion are abundant, particularly in the emerging field of bioplastics and biodegradable polymers, which often possess unique thermal and rheological properties that make them highly amenable to underwater pelletizing due to the immediate quenching effect. The development of modular, scalable, and fully automated pelletizing lines specifically designed for medium-scale specialty compounders and decentralised recycling initiatives offers a new avenue for market penetration. The continuous refinement of energy recovery systems integrated within the water circuit further enhances the sustainable profile of the technology, appealing to environmentally conscious manufacturers. The overall impact force matrix indicates a strong positive momentum, with drivers related to sustainability and advanced manufacturing technology substantially outweighing the existing restraints, propelling technological innovation and market growth.

Segmentation Analysis

The Underwater Pelletizing System Market is comprehensively segmented based on several critical factors including system capacity, the type of polymer being processed, and the specific application sector, providing a multi-dimensional view of market dynamics and adoption patterns. This segmentation is crucial for understanding varied end-user requirements, ranging from small-scale laboratory and specialty compounders needing low-capacity systems to large-scale commodity polymer producers demanding continuous, high-throughput lines. Detailed analysis across these categories reveals significant shifts, particularly the burgeoning dominance of the recycling and compounding applications, necessitating systems optimized for varied melt viscosities and filled materials. The capacity dimension helps define investment size and technological complexity, directly correlating with the financial feasibility and scale of operations within the plastics industry.

- By System Type

- Small Capacity Systems (Up to 500 kg/h)

- Medium Capacity Systems (501 kg/h – 2000 kg/h)

- Large Capacity Systems (Above 2000 kg/h)

- By Polymer Type

- Polyolefins (PE, PP)

- Engineering Plastics (PET, PA, PC)

- Styrenics (PS, ABS)

- Thermoplastic Elastomers (TPE, TPU)

- Bioplastics and Biodegradable Polymers

- By Application

- Compounding

- Masterbatch Production

- Recycling (Post-Consumer Resin PCR and Post-Industrial Resin PIR)

- Virgin Polymer Production

Value Chain Analysis For Underwater Pelletizing System Market

The value chain of the Underwater Pelletizing System Market begins upstream with the suppliers of core components, including specialized metallurgy providers for die plates and cutter hubs, and automation technology vendors supplying sophisticated control systems and robotics. Key upstream activities involve the precision engineering and manufacturing of extrusion equipment, as the pelletizer must be seamlessly integrated with the extruder’s output to ensure optimal performance. The quality of components, such as high-wear-resistant steel alloys for cutting blades and precise temperature control units, directly impacts the efficiency and longevity of the entire pelletizing line, driving manufacturers to seek reliable, high-spec component suppliers. This phase is characterized by high technological interdependence and specialized intellectual property regarding fluid dynamics and thermal management.

Midstream, the value chain is dominated by the system manufacturers who design, assemble, and integrate the complete pelletizing units (including die head, cutter, water system, drying unit, and control panel). Distribution channels are primarily direct, given the custom nature and high cost of these capital goods. Major manufacturers maintain direct sales and service teams to handle consultation, installation, commissioning, and post-sales maintenance, which is crucial due to the complexity of the equipment. Indirect distribution, often utilizing specialized agents or regional technical partners, is sometimes used for geographic market access, particularly in nascent markets where local technical support is essential but costly for the principal manufacturer to deploy solely.

Downstream, the end-users include large petrochemical companies producing virgin polymers, independent custom compounders who formulate specialized plastics, and, increasingly, plastic recycling facilities. The product (uniform polymer pellets) then enters the broader plastics processing market, serving industries such as automotive, construction, packaging, and textiles. The value proposition at the downstream level is the consistency and quality of the pellet, which reduces manufacturing defects and improves throughput for the final plastic product producer. The efficiency of the pelletizing system directly translates into the economic viability of both virgin polymer production and high-volume recycling operations, demonstrating the critical leverage point the pelletizing technology holds in the overall polymer manufacturing ecosystem.

Underwater Pelletizing System Market Potential Customers

Potential customers for Underwater Pelletizing Systems span the entire spectrum of the plastics production and recycling industries, focusing primarily on entities requiring high-quality, homogeneous plastic pellets for subsequent manufacturing processes. The largest end-user segment consists of major petrochemical and polymer producers who rely on these systems for the final step of mass-producing commodity plastics like polyethylene and polypropylene. These customers require extremely reliable, high-capacity systems integrated directly into continuous polymerization lines to handle thousands of kilograms per hour, where efficiency and minimal downtime are paramount determinants of profitability. Their purchasing decisions are often based on proven throughput reliability, energy efficiency metrics, and lifetime operational cost.

A rapidly expanding customer base includes plastic compounders and masterbatch producers. These companies specialize in mixing polymers with additives, colorants, and fillers to create customized plastic formulations. Since many highly filled or sticky compounds are challenging to cut using air-cooled or strand systems, underwater pelletizers are the default technology for ensuring dense, uniform pellets. For compounders, the versatility to handle quick changeovers between diverse material types (e.g., from TPE to highly filled PA) is a critical purchasing consideration, driving demand for modular and self-cleaning designs. The precision offered by underwater systems minimizes dust generation and ensures optimal dispersion of additives.

Finally, the accelerated global investment in the circular economy has created a vast customer segment comprising plastic recyclers, including large Post-Consumer Resin (PCR) processors and Post-Industrial Resin (PIR) handlers. Recycled feedstocks often have fluctuating melt characteristics and contain impurities, making them particularly difficult to pelletize consistently. Underwater systems capable of robust operation under variable conditions, equipped with specialized filtration systems and wear-resistant components, are highly sought after by this segment. Their objective is to transform inconsistent waste streams into marketable, high-quality pellets that can compete with virgin resins, making the pelletizing technology a core enabler of their business model and a critical investment decision.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 665.8 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Coperion GmbH, Maag Group, Nordson Corporation (BKG Pelletizing Systems), ECON GmbH, Gala Industries, Inc. (Maag), Farrel Pomini, Wuxi S&S Intelligent Plastic Equipment Co., Ltd., JINWOO Precision Machinery Co., Ltd., MITSUI MIIKE MACHINERY CO., LTD., Cowin Extrusion Machinery Co., Ltd., TOSHIBA MACHINE CO., LTD., Liyang Environmental Protection Equipment Co., Ltd., Thermoplastische Engineering GmbH (TEG), Kreyenborg Group, Reduction Engineering Scheer, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Underwater Pelletizing System Market Key Technology Landscape

The technological landscape of the Underwater Pelletizing System Market is focused intensely on enhancing efficiency, maximizing throughput, and improving the quality of the final pellet product while minimizing operational costs. A primary area of innovation involves the design of the die plate and cutter hub assembly. Modern systems utilize advanced ceramic coatings and hardened tool steels to significantly extend the lifespan of die plates and cutting blades, crucial when processing highly abrasive materials like glass-filled polymers or contaminated recycled plastic. Furthermore, optimizing the flow channels within the die head using Computational Fluid Dynamics (CFD) ensures homogeneous polymer melt distribution and pressure stability, which directly translates to uniform pellet size and reduced process surging. Integration of quick-change mechanisms for die plates is another critical advancement, drastically minimizing the downtime associated with maintenance and changeovers, a key consideration for compounders handling a wide range of materials.

Another fundamental technological development centers on the water management and drying systems. High-performance pelletizers now feature closed-loop, integrated water circuits equipped with advanced filtration and temperature control mechanisms. Precise control over the water temperature immediately surrounding the die face is vital for ensuring the polymer solidifies correctly before cutting, preventing agglomeration (sticking) of soft pellets. The move from simple screens to sophisticated automatic back-flushing filters and centrifugation-based drying units ensures the process water remains clean, preventing surface defects on the pellets and minimizing wear on sensitive pump components. Centrifugal dryers, in particular, have undergone significant redesigns to handle high volumes gently, ensuring residual moisture levels are kept to an absolute minimum, often below 50 parts per million (ppm), which is essential for certain polymers like PET or Nylon.

The third major technological thrust is the integration of Industry 4.0 principles, specifically through advanced monitoring and control systems. Contemporary pelletizers incorporate sophisticated Human-Machine Interfaces (HMIs) and Programmable Logic Controllers (PLCs) capable of fine-tuning operational parameters in real-time based on input from numerous sensors measuring melt pressure, motor torque, water conductivity, and vibration. This level of automation enables remote diagnostics and predictive maintenance capabilities, significantly improving the overall equipment effectiveness (OEE). The incorporation of high-speed cameras and vision systems at the pellet discharge point further elevates quality control by instantaneously identifying and classifying defective pellets, enabling immediate corrective action within the cutter speed or water system, thereby ensuring zero-defect output for critical applications.

Regional Highlights

Regional dynamics significantly influence the growth patterns and technology adoption rates within the Underwater Pelletizing System Market, driven by local regulatory environments, industrial output, and investment in sustainable practices. Asia Pacific (APAC) currently dominates the market share and is projected to maintain the highest growth rate throughout the forecast period. This growth is attributable to massive investments in new chemical and compounding plants, particularly in China, India, and Southeast Asian nations, alongside the rapid expansion of organized plastic recycling infrastructure responding to national bans on plastic waste imports and increasing domestic generation. APAC manufacturers prioritize high-capacity and cost-effective systems.

Europe represents a highly mature market characterized by stringent environmental mandates (such as the European Green Deal), necessitating continuous technological upgrades. The high demand for recycled content (PCR) in packaging and automotive sectors drives the European market, fostering innovation in pelletizing systems optimized for handling complex, often contaminated, recycled feedstocks. This region focuses heavily on automation, energy efficiency, and systems capable of processing specialized engineering plastics and bioplastics, reflecting a preference for high-precision, environmentally compliant technology.

North America maintains a steady growth trajectory, influenced by the robust specialty compounding sector and the revitalization of domestic petrochemical production. Market expansion here is concentrated on adopting smart manufacturing solutions, integrating AI-driven process optimization, and ensuring data traceability. Latin America and the Middle East & Africa (MEA) are emerging markets, with growth primarily linked to new petrochemical facility expansions and initial investments in centralized waste management systems, offering long-term growth potential as industrialization progresses and regulatory frameworks mature regarding plastic waste.

- Asia Pacific (APAC): Dominant market share; highest growth driven by new plant installations, rapid expansion of recycling capacity in China and India, and increasing commodity polymer output.

- Europe: High adoption rate driven by stringent EU recycling targets, focus on precision pelletizing for specialty chemicals, and significant investment in bioplastics processing technology.

- North America: Stable growth centered on high-automation systems, emphasis on energy efficiency, and strong demand from the high-value custom compounding sector.

- Latin America (LATAM): Emerging market growth fueled by new petrochemical investments and developing national waste infrastructure projects.

- Middle East & Africa (MEA): Growth tied to significant oil and gas sector investments leading to new polymer production facilities and initial implementation of large-scale municipal waste recycling initiatives.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Underwater Pelletizing System Market.- Coperion GmbH

- Maag Group

- Nordson Corporation (BKG Pelletizing Systems)

- ECON GmbH

- Gala Industries, Inc. (Maag)

- Farrel Pomini

- Wuxi S&S Intelligent Plastic Equipment Co., Ltd.

- JINWOO Precision Machinery Co., Ltd.

- MITSUI MIIKE MACHINERY CO., LTD.

- Cowin Extrusion Machinery Co., Ltd.

- TOSHIBA MACHINE CO., LTD.

- Liyang Environmental Protection Equipment Co., Ltd.

- Thermoplastische Engineering GmbH (TEG)

- Kreyenborg Group

- Reduction Engineering Scheer, Inc.

- Crown Machinery Co., Ltd.

- Everplast Machinery Co., Ltd.

- Qingdao Shuangsheng Plastic Machinery Co., Ltd.

- HET KUNSTSTOFFTECHNIK GMBH

- Jiangsu Beier Machinery Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Underwater Pelletizing System market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of underwater pelletizing compared to strand or hot-face cutting?

Underwater pelletizing offers superior pellet shape uniformity (spherical), minimizes dust formation, and is highly effective for processing soft, sticky, or low-viscosity polymers like TPEs and certain polyolefins by ensuring immediate cooling upon cutting, thereby preventing agglomeration and strand breakage.

How does the adoption of recycled plastics impact the technological requirements of underwater pelletizers?

Recycled plastics often introduce variability and abrasive contaminants. This necessitates pelletizers equipped with highly wear-resistant materials (e.g., specialized alloys) for die plates and cutter blades, coupled with advanced, self-cleaning filtration systems in the water circuit to maintain system integrity and pellet quality despite inconsistent feedstock.

Which geographical region dominates the Underwater Pelletizing System Market, and what drives this dominance?

Asia Pacific (APAC), particularly driven by China and India, dominates the market due to massive capital expenditure in new petrochemical and compounding facilities, coupled with aggressive expansion of industrial-scale plastic recycling operations responding to significant domestic environmental policies.

What is the typical return on investment (ROI) timeframe for a high-capacity underwater pelletizing system?

The ROI timeframe varies significantly but is typically between 3 to 5 years for high-capacity systems in continuous operation. This timeline is heavily influenced by feedstock cost, energy efficiency metrics of the system, achieved throughput rates, and the minimization of operational downtime enabled by reliable technology.

How is Industry 4.0 technology, such as AI, being implemented in modern pelletizing systems?

Industry 4.0 integration includes AI-driven Predictive Maintenance (PdM) analyzing component health, real-time closed-loop control systems adjusting cutter speed and water temperature based on sensor data, and sophisticated vision systems ensuring instant quality verification and anomaly detection for maximized efficiency and pellet consistency.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager