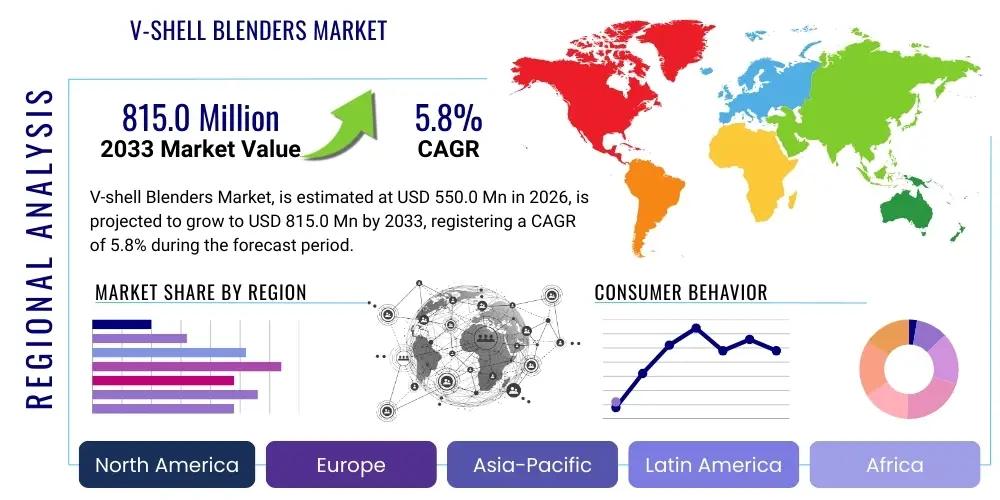

V-shell Blenders Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438353 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

V-shell Blenders Market Size

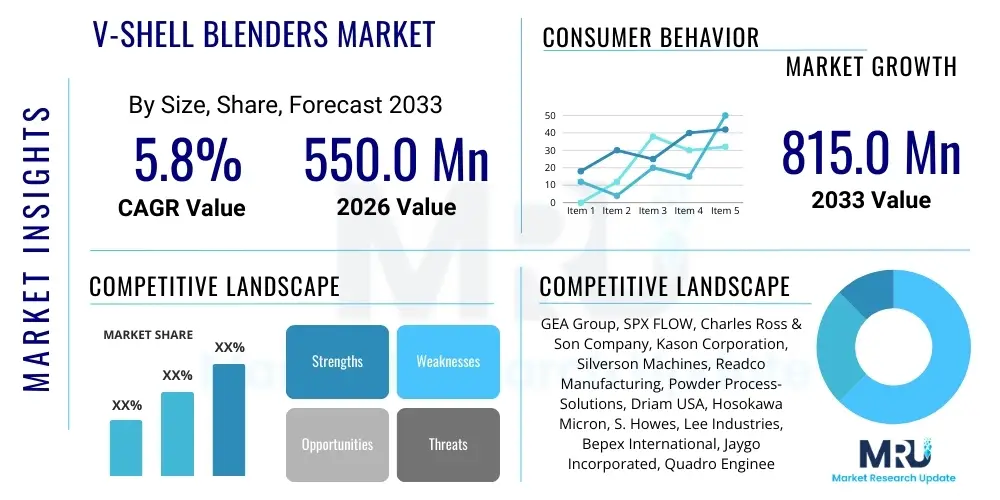

The V-shell Blenders Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 550.0 Million in 2026 and is projected to reach USD 815.0 Million by the end of the forecast period in 2033. This growth trajectory is fundamentally supported by the increasing global demand for precise and efficient dry powder mixing in highly regulated industries, particularly pharmaceuticals and specialty chemicals. The V-shell blender, renowned for its gentle handling and rapid blending capabilities, remains a crucial piece of equipment in processes requiring high homogeneity and minimal product degradation.

V-shell Blenders Market introduction

The V-shell Blenders Market encompasses the manufacturing, sales, and service of industrial mixing equipment characterized by a V-shaped horizontal rotating cylinder, designed primarily for the thorough blending of dry powders, granules, and small particulate solids. This equipment, also known as Twin Shell Blenders, utilizes the unique geometry of the V-shell and gravitational forces to split and recombine the material continuously during rotation, ensuring rapid and highly uniform dispersion without high shear stress. The gentle mixing action makes the V-shell blender indispensable for handling delicate or friable materials, ensuring consistent product quality across various batch sizes.

Major applications for V-shell blenders span critical sectors including pharmaceuticals, where batch uniformity is paramount for drug efficacy; the food and beverage industry, for mixing spices, nutritional supplements, and flour premixes; and the chemical industry, for blending pigments, plastics, and specialized catalysts. The primary benefit derived from V-shell blenders is their superior mixing efficiency and ease of cleaning, which meets stringent sanitation requirements. Furthermore, the ability to introduce intensifier bars allows for the incorporation of minor liquid components or the dispersion of sticky materials, thereby expanding their operational flexibility.

Driving factors propelling market expansion include the strict enforcement of Good Manufacturing Practices (GMP) globally, which mandates high homogeneity in finished products, especially in regulated sectors like healthcare. The expansion of production capacities across emerging economies, coupled with significant investments in upgrading existing processing facilities, further stimulates demand for reliable blending technology. Additionally, the growing popularity of specialized nutritional powders and complex pharmaceutical formulations requiring precise ingredient ratios necessitates the adoption of high-performance V-shell blending solutions, driving market revenue.

V-shell Blenders Market Executive Summary

The V-shell Blenders Market is characterized by steady growth, driven largely by regulatory demands for batch consistency and the continuous expansion of the pharmaceutical and specialty chemical manufacturing bases worldwide. Key business trends indicate a strong move toward highly automated and customized blending solutions, focusing on enhanced cleanability (CIP/SIP compatibility) and reduced cycle times. Manufacturers are increasingly integrating advanced control systems and sensor technology to monitor blending kinetics in real-time, thereby optimizing production throughput and ensuring compliance with Industry 4.0 standards. Mergers and acquisitions focused on expanding geographic reach and integrating complementary technologies, such as advanced powder handling systems, are shaping the competitive landscape.

Regionally, Asia Pacific (APAC) stands out as the primary engine of growth, fueled by rapid industrialization, governmental support for domestic pharmaceutical production, and significant foreign direct investment into manufacturing infrastructure, particularly in countries like China and India. North America and Europe maintain substantial market shares due to their established pharmaceutical and food processing sectors, focusing on adopting highly sophisticated, large-capacity, and energy-efficient V-shell blenders. Regulatory harmonization efforts across these regions are necessitating investments in new equipment that meets stringent validation and operational qualification requirements.

Segment trends reveal that Stainless Steel 316L remains the dominant material segment due to its corrosion resistance and suitability for highly sanitary applications. Furthermore, the demand for medium-scale (101 L - 500 L) blenders is experiencing robust growth, catering to the increasing requirements for specialized and smaller batch runs common in high-value specialty chemical and custom nutrition markets. Automation is becoming non-negotiable, with automated operation systems increasingly replacing manual controls to minimize human error and ensure repeatable batch quality, contributing significantly to premium pricing and technological differentiation among vendors.

AI Impact Analysis on V-shell Blenders Market

User inquiries regarding AI's influence on the V-shell Blenders Market primarily revolve around predictive maintenance, optimization of mixing parameters, and integration within fully autonomous smart factories. Users are keen to understand how AI algorithms can leverage real-time sensor data (e.g., vibration, temperature, energy consumption) to forecast equipment failure, thus minimizing unplanned downtime, a critical concern in high-throughput production environments. Another major theme is the use of machine learning to analyze batch history and material rheology, allowing the blender's speed, rotation time, and intensifier bar operation to be dynamically adjusted to achieve target homogeneity thresholds faster and more consistently, transcending traditional fixed parameter blending protocols. Furthermore, there is growing interest in how AI can assist in regulatory documentation and batch record analysis, ensuring audit trails are robust and compliant with stringent pharmaceutical regulations.

- Implementation of Predictive Maintenance (PdM) using AI to analyze operational data and forecast mechanical component failure, enhancing equipment uptime and reliability.

- Optimization of Mixing Cycles: Machine learning algorithms dynamically adjust blending parameters (speed, duration, charge volume) based on material characteristics and real-time homogeneity feedback, ensuring optimal blending efficiency.

- Quality Control Enhancement: AI-driven image processing or spectroscopic analysis integrated into the blending cycle provides immediate feedback on particle distribution and quality, reducing off-specification batches.

- Autonomous Operation Integration: AI serves as the core control system within fully automated production lines, managing material feeding, blending execution, and discharge processes without human intervention.

- Energy Consumption Reduction: Algorithms identify and enforce the most energy-efficient operational profiles while maintaining required product quality standards.

- Improved Compliance and Documentation: AI systems automatically log, categorize, and verify batch records, streamlining regulatory compliance and audit processes.

DRO & Impact Forces Of V-shell Blenders Market

The V-shell Blenders Market growth is fundamentally driven by the escalating demand for high-quality, homogeneous mixtures across key end-use industries, necessitating precision blending equipment that minimizes material waste and ensures product integrity. Regulatory bodies worldwide are imposing stricter quality control standards, particularly for pharmaceuticals and food products, which mandates the use of reliable, validated blending technology, acting as a major market driver. However, the market faces restraints primarily related to the high capital expenditure required for advanced stainless steel equipment, especially customized large-scale V-shell blenders equipped with sophisticated automation and containment features. Furthermore, the necessity for meticulous cleaning procedures between batches, though manageable with V-shell designs, still represents a procedural complexity and downtime factor.

Significant opportunities exist in the shift towards continuous manufacturing, prompting manufacturers to develop V-shell systems adaptable to integrated continuous lines, moving beyond traditional batch processing. The expansion of the global nutraceutical and functional food markets, which require gentle handling of expensive, heat-sensitive ingredients, provides a substantial growth avenue for specialized V-shell designs. Moreover, technological advancements focusing on hygienic design improvements and integrating advanced monitoring sensors offer differentiation and premium pricing potential.

The impact forces influencing the market are strong and multifaceted. Technological impact is high, driven by the push for Industry 4.0 integration, leading to blenders that are smart, connected, and capable of self-diagnosis. Regulatory impact remains critical, where changes in GMP guidelines directly influence equipment specification and purchasing decisions, favoring vendors capable of providing extensive validation support. Economic factors, particularly the fluctuating costs of raw materials (stainless steel) and global supply chain stability, also exert influence on manufacturing costs and ultimately, market pricing. The competitive landscape is intensely focused on innovation in cleanability and automation to capture market share among discerning industrial buyers.

Segmentation Analysis

The V-shell Blenders Market is comprehensively segmented based on material of construction, batch capacity, operation type, and end-use industry, allowing for a detailed understanding of diverse customer requirements and technological trends. The selection of material, typically high-grade stainless steel, is dictated by sanitary requirements and the corrosivity of the blended materials. Capacity segmentation reflects the scale of production, ranging from R&D and small pilot batches to full industrial production volumes. Operation type highlights the transition towards higher automation levels, while end-use analysis identifies the major consumption sectors driving demand for specific features like intensifier bars or vacuum compatibility.

- By Material of Construction

- Stainless Steel 304 (SS 304)

- Stainless Steel 316L (SS 316L)

- Others (e.g., specialized alloys, carbon steel for non-critical applications)

- By Batch Capacity

- Small Scale (Up to 100 L)

- Medium Scale (101 L - 500 L)

- Large Scale (Above 500 L)

- By Operation Type

- Manual

- Automated

- By End-Use Industry

- Pharmaceuticals

- Food & Beverages

- Chemical

- Cosmetics

- Nutraceuticals

- Others (e.g., Plastics, Ceramics)

- By Region

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For V-shell Blenders Market

The value chain for the V-shell Blenders Market begins with upstream activities focused on raw material procurement, primarily high-grade stainless steel (304 and 316L) and sophisticated mechanical components like motors, gears, bearings, and precision seals. Suppliers of these materials and components significantly influence the final product cost and quality. Manufacturers then engage in specialized fabrication, welding, polishing, and integration processes, focusing heavily on achieving specific sanitary surface finishes required by the pharmaceutical and food industries. Expertise in custom design, particularly for jacketed or vacuum-rated V-shells, adds substantial value at this stage, positioning the manufacturing phase as the core value addition point.

Downstream activities involve specialized distribution and post-sales support. Due to the high-cost and technical complexity of industrial blenders, distribution channels often rely on a hybrid model. Direct sales and engineering teams handle custom, large-scale projects, providing direct consultation and validation support to major pharmaceutical or chemical clients. Indirect channels, involving authorized distributors or specialized regional agents, handle smaller-scale equipment sales and aftermarket service for general industrial clients. Installation, commissioning, validation (IQ/OQ/PQ), and long-term maintenance contracts represent critical downstream value additions.

The choice between direct and indirect channels is strategically determined by geographical location and project complexity. Direct channels are preferred for highly regulated markets or custom solutions requiring intense technical interaction, ensuring tight control over project specifications and compliance adherence. Indirect channels provide broader market penetration and localized support, particularly vital in rapidly industrializing regions where local partnerships facilitate easier customs clearance and faster response times for technical support. Efficiency in this value chain is increasingly measured by the vendor’s ability to minimize lead times and provide rapid, compliant validation documentation, thereby accelerating the customer's time-to-market.

V-shell Blenders Market Potential Customers

The primary end-users and buyers of V-shell blenders are entities engaged in the processing of dry solid materials where highly homogenous mixing, gentle handling, and strict sanitary standards are non-negotiable requirements. The largest customer segment is the pharmaceutical industry, including generic drug manufacturers, contract manufacturing organizations (CMOs), and biopharmaceutical companies, all requiring V-shell blenders for compounding active pharmaceutical ingredients (APIs) with excipients during tablet, capsule, or powder filling preparation. Consistency and validation capabilities are the paramount purchasing criteria for this group.

Another significant customer base resides within the food and beverage industry, specifically companies producing functional foods, dietary supplements, instant drink mixes, spice blends, and specialized bakery premixes. These customers value the V-shell blender's ability to uniformly distribute minor ingredients (e.g., vitamins, flavorings) without damaging fragile particles like freeze-dried fruit pieces or delicate starches. The chemical and specialty materials sector also represents major buyers, using these blenders for pigments, high-performance plastics additives, agricultural chemicals, and ceramic powder preparation, where consistent material properties are essential for downstream processes.

Furthermore, the rapidly expanding nutraceutical and cosmetics industries are emerging as high-growth potential customers. Nutraceutical manufacturers rely heavily on V-shell blenders to ensure precise, uniform mixing of botanical extracts, vitamins, and protein powders, often requiring specialized coatings and stainless steel grades. Cosmetic manufacturers utilize this equipment for blending face powders, pigments, and bath salts, demanding ease of cleaning and minimal cross-contamination risk, reinforcing the market for high-quality, polished V-shell designs.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 550.0 Million |

| Market Forecast in 2033 | USD 815.0 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | GEA Group, SPX FLOW, Charles Ross & Son Company, Kason Corporation, Silverson Machines, Readco Manufacturing, Powder Process-Solutions, Driam USA, Hosokawa Micron, S. Howes, Lee Industries, Bepex International, Jaygo Incorporated, Quadro Engineering, Gemco, Patterson Industries, AMixon GmbH, Scott Equipment, Munson Machinery, AR-PAC. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

V-shell Blenders Market Key Technology Landscape

The technological landscape of the V-shell Blenders Market is rapidly evolving, moving beyond simple rotational mechanics toward intelligent, process-aware systems. A major focus is placed on enhancing blending predictability and reducing material segregation risk. Key advancements involve the integration of high-precision sensors, such as power transducers and accelerometers, that monitor the real-time energy input and vibration patterns within the blending process. This data is critical for determining the blending endpoint accurately and ensuring batch-to-batch repeatability, especially important for high-cost or potency materials.

Furthermore, technology development emphasizes improved hygienic design. Modern V-shell blenders incorporate enhanced features like highly polished internal surfaces (often Ra < 0.8 µm), seal-less bearing systems, and cantilevered designs that facilitate quick disassembly and validation of cleaning procedures (CIP/WIP compatibility). The introduction of liquid spray nozzles and intensifier bars equipped with Variable Frequency Drives (VFDs) offers flexibility, allowing a single unit to handle a broader range of materials, including those requiring minor liquid addition or de-agglomeration, without compromising the overall mixing mechanism.

The push for automation and compliance drives the incorporation of advanced control technologies. Modern V-shell blenders are typically equipped with PLC/HMI systems compliant with GAMP 5 and CFR 21 Part 11 standards, ensuring secure data logging, audit trails, and integration into overall plant MES (Manufacturing Execution Systems). Remote diagnostics and cloud connectivity are also gaining traction, enabling manufacturers to provide proactive maintenance support and software updates, significantly improving operational lifespan and reducing maintenance costs for the end-user.

Regional Highlights

The global V-shell Blenders Market exhibits significant regional variations in growth and demand characteristics, driven by differing industrial landscapes, regulatory stringency, and investment levels in manufacturing infrastructure.

- North America: Characterized by a mature pharmaceutical and nutraceutical industry, North America demands high-specification, large-capacity automated V-shell blenders compliant with FDA regulations. The focus here is on process optimization, validation, and integrating equipment into sophisticated, digitally controlled manufacturing ecosystems.

- Europe: Europe, driven by stringent EU GMP requirements and a strong specialty chemical sector, shows steady demand. Key markets like Germany and Switzerland focus on precision engineering, custom-built sanitary units, and innovative designs that support energy efficiency and reduced cleaning times.

- Asia Pacific (APAC): APAC represents the fastest-growing region, fueled by massive expansion in generic drug manufacturing (India and China), contract manufacturing operations, and growing food processing industries. Demand is high for medium to large-scale blenders, with increasing attention paid to balancing capital cost efficiency with necessary regulatory compliance.

- Latin America (LATAM): Growth in LATAM is driven by expanding local food and pharmaceutical manufacturing bases, particularly in Brazil and Mexico. The market often seeks robust, reliable equipment with relatively simpler automation compared to North America or Europe, focusing on essential operational efficiency.

- Middle East and Africa (MEA): This region is a developing market, with demand concentrated in the chemical and packaged food sectors, particularly in the UAE and Saudi Arabia. Market growth is tied to government initiatives aimed at diversifying economies and building domestic industrial capacity.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the V-shell Blenders Market.- GEA Group

- SPX FLOW

- Charles Ross & Son Company

- Kason Corporation

- Silverson Machines

- Readco Manufacturing

- Powder Process-Solutions

- Driam USA

- Hosokawa Micron

- S. Howes

- Lee Industries

- Bepex International

- Jaygo Incorporated

- Quadro Engineering

- Gemco

- Patterson Industries

- AMixon GmbH

- Scott Equipment

- Munson Machinery

- AR-PAC

Frequently Asked Questions

Analyze common user questions about the V-shell Blenders market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of using a V-shell blender over other industrial mixers like ribbon blenders?

V-shell blenders are preferred for their gentle, low-shear mixing action, which is ideal for delicate, friable, or sensitive materials. Their geometry facilitates rapid, highly uniform blending and ensures complete discharge, minimizing product retention and simplifying stringent cleaning validation required by the pharmaceutical industry.

Which end-use industry represents the largest market share for V-shell blenders globally?

The Pharmaceutical industry holds the largest market share, driven by the absolute requirement for high homogeneity and cross-contamination prevention in drug formulations, where the V-shell blender’s validation capabilities and sanitary design are critical for GMP compliance.

How do manufacturers ensure the hygienic design and cleanability of modern V-shell blenders?

Hygienic design is achieved through the use of high-grade SS 316L, highly polished internal finishes (sanitary finish standards), minimal crevices, and specialized seals or bearing isolators. Many modern units are designed for easy disassembly or feature integrated Clean-In-Place (CIP) systems to validate cleaning effectiveness.

What is the current trend regarding automation in the V-shell Blenders Market?

The dominant trend is a shift from manual operation to full automation, incorporating PLCs, HMI controls, and integration into MES systems. This automation ensures precise, repeatable batch cycles, facilitates CFR 21 Part 11 compliance, and enables real-time process monitoring to optimize throughput.

What role does the intensifier bar play in the V-shell blending process, and is it always necessary?

The intensifier bar is a high-speed rotating tool used to break up agglomerates, disperse minor liquid additions, or provide localized high shear. It is optional but necessary when mixing materials prone to clumping, or when specific de-agglomeration is required to achieve fine dispersion beyond what simple tumbling action provides.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager