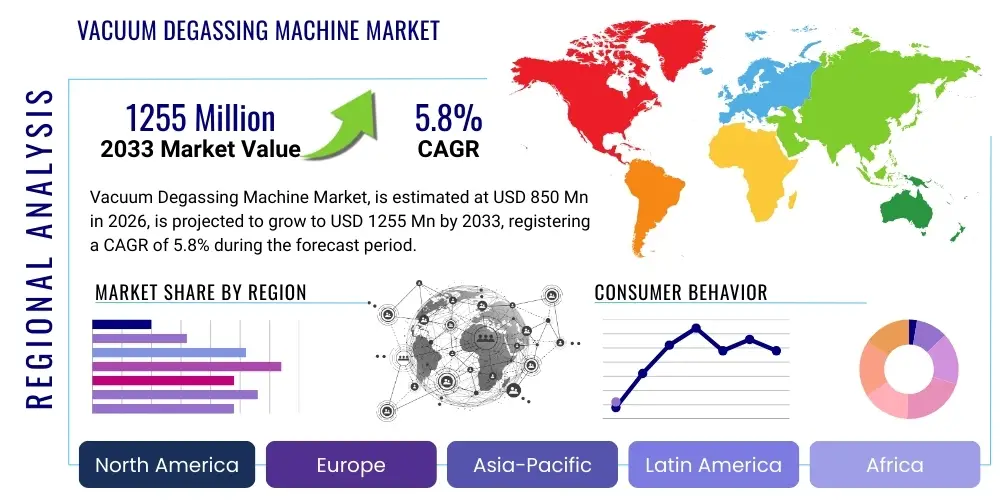

Vacuum Degassing Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437834 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Vacuum Degassing Machine Market Size

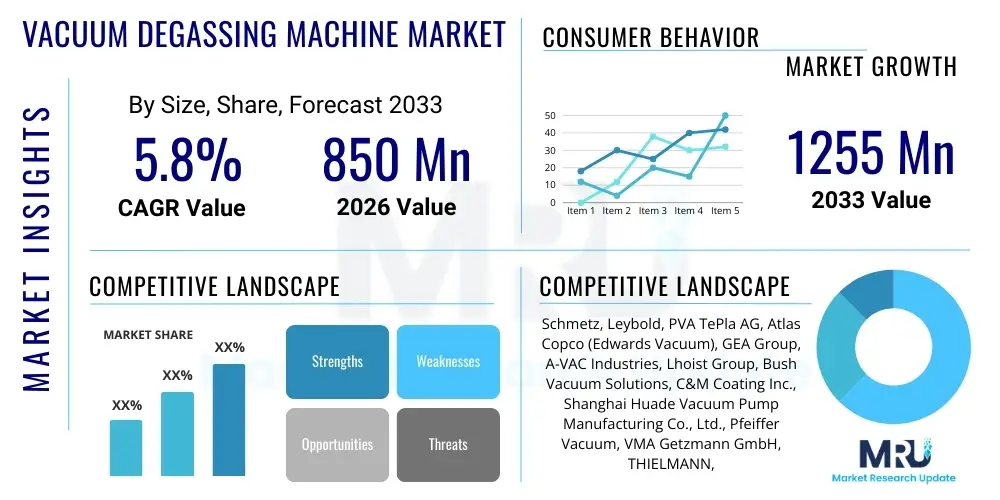

The Vacuum Degassing Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 850 million in 2026 and is projected to reach USD 1255 million by the end of the forecast period in 2033.

Vacuum Degassing Machine Market introduction

The Vacuum Degassing Machine Market encompasses specialized industrial equipment designed to remove trapped gases, moisture, and volatile impurities from various materials, notably liquids, resins, polymers, and metals, under reduced pressure conditions. This essential process is critical for enhancing material performance, improving product quality, and ensuring structural integrity in high-specification applications. Vacuum degassing machines operate by creating a vacuum environment, which lowers the boiling point of trapped gases, allowing them to escape efficiently. The primary applications span across metallurgy (steel production, aluminum casting), chemical processing, pharmaceuticals, electronics manufacturing (epoxy and silicone degassing), and construction (concrete de-airing).

The sophistication of modern vacuum degassing equipment includes advanced features such as automatic control systems, precise temperature regulation, and continuous or batch processing capabilities, tailored to the viscosity and sensitivity of the material being treated. The underlying principle is to eliminate defects caused by gas inclusion—such as porosity in metal castings or voids in composite materials—thereby meeting stringent quality standards in end-user industries. Key benefits derived from adopting these systems include increased material density, superior mechanical properties, extended product lifetime, and reduced waste during manufacturing.

Major driving factors propelling market expansion include the burgeoning demand for high-performance materials in the aerospace and automotive sectors, the continuous growth of the electronics industry requiring ultra-pure encapsulants, and rigorous quality control mandates across global manufacturing chains. Furthermore, technological advancements in material science necessitate corresponding precision in processing equipment, making efficient vacuum degassing solutions indispensable for next-generation products. The shift towards sustainable manufacturing practices also encourages the use of advanced equipment that optimizes material utilization and energy efficiency.

Vacuum Degassing Machine Market Executive Summary

The Vacuum Degassing Machine Market is experiencing robust growth, driven by stringent quality requirements in high-tech industries and increasing investments in infrastructure and manufacturing capacity, particularly across Asia Pacific. Business trends indicate a strong focus on automation and integration of degassing systems into comprehensive production lines, necessitating solutions compatible with Industry 4.0 standards for remote monitoring and predictive maintenance. Manufacturers are increasingly prioritizing energy-efficient, compact designs that offer high throughput without compromising degassing efficiency, leading to specialized product introductions catering to specific material types (e.g., highly viscous polymers or molten metals). Strategic collaborations between equipment manufacturers and specialized material suppliers are also emerging as a key strategy to develop tailored solutions for niche applications, such as advanced battery components and complex medical devices.

Regional trends highlight Asia Pacific (APAC) as the dominant and fastest-growing market segment, primarily fueled by massive industrialization, rapid expansion of the electric vehicle (EV) sector boosting demand for battery material processing, and governmental support for domestic manufacturing hubs, especially in China, Japan, and South Korea. North America and Europe maintain a mature market presence, characterized by high adoption rates of advanced, automated systems and a consistent need for vacuum degassing in specialized aerospace and medical device production. Latin America and the Middle East and Africa (MEA) are witnessing gradual uptake, spurred by rising foreign direct investment in infrastructure projects and localized manufacturing capabilities, focusing mainly on cement and petroleum-related applications.

Segmentation trends reveal that the "Molten Metal Degassing" segment holds a significant share due to its essential role in producing high-quality steel and aluminum alloys critical for the automotive and construction sectors. Concurrently, the "Resin and Polymer Degassing" segment is projected for the highest growth rate, correlated directly with the expansion of the electronics, semiconductor, and composites industries where defect-free bonding and encapsulation are paramount. Batch processing systems currently lead the market by application type, offering flexibility for various production scales, though continuous systems are gaining traction in high-volume, standardized industrial environments seeking maximum operational efficiency.

AI Impact Analysis on Vacuum Degassing Machine Market

Common user questions regarding AI's impact on the Vacuum Degassing Machine Market center on how artificial intelligence can enhance process precision, predict maintenance needs, and optimize energy consumption in typically high-energy industrial operations. Users frequently inquire about the integration of machine learning algorithms to analyze real-time vacuum pressure, temperature, and material composition data to automatically adjust degassing parameters, thereby ensuring optimal material purity and throughput regardless of minor variations in input material. Concerns also revolve around the complexity and cost associated with retrofitting existing machinery with AI capabilities, and the data security implications of connecting industrial control systems to analytical platforms. The overarching expectation is that AI will move the market beyond fixed operational recipes to dynamic, self-optimizing degassing processes, significantly reducing human error and improving operational predictability, which is critical in zero-defect manufacturing environments like aerospace component production.

- AI-driven Predictive Maintenance: Utilizing sensor data (vibration, temperature, current draw) to forecast equipment failure, minimizing unplanned downtime and optimizing maintenance schedules for high-cost vacuum components (pumps, seals).

- Real-Time Parameter Optimization: Machine learning algorithms analyze material input characteristics and process outputs (gas removal rate, final viscosity) to dynamically adjust vacuum levels, temperature, and mixing speeds for maximum degassing efficiency.

- Quality Control Automation: AI vision systems integrated with mass spectrometry or material testing can rapidly detect and quantify residual gas content post-degassing, providing immediate feedback for process correction, ensuring consistent material quality.

- Energy Consumption Reduction: Optimization models determine the minimum required vacuum hold time and energy expenditure necessary to achieve purity targets, leading to significant operational cost savings, crucial for continuous degassing systems.

- Process Modeling and Simulation: AI assists in simulating complex fluid dynamics and gas dissolution rates under various vacuum conditions, accelerating R&D for new material processing methods and improving initial machine setup efficiency.

DRO & Impact Forces Of Vacuum Degassing Machine Market

The market dynamics for vacuum degassing machines are shaped by a complex interplay of increasing industrial demand for superior quality materials (Driver), high initial investment costs and operational complexity (Restraint), and the emergence of advanced manufacturing techniques that require ultra-high purity materials (Opportunity). The primary driver is the global escalation in quality standards across sectors such as semiconductor fabrication, electric vehicle battery manufacturing, and medical implants, where even minute gas inclusions can lead to catastrophic failure. However, a significant restraint is the substantial capital expenditure required for purchasing high-capacity, high-vacuum systems, coupled with the need for specialized training for operators and regular maintenance of complex vacuum pump systems. The most potent opportunity lies in developing highly specialized, small-scale vacuum systems tailored for additive manufacturing and 3D printing, specifically for degassing powders and resins used in high-precision additive processes.

The dominant driving force is the relentless pursuit of performance enhancement in industrial materials. In metallurgy, removing hydrogen and nitrogen from molten steel is non-negotiable for producing high-strength, fatigue-resistant components. Similarly, in the electronics sector, vacuum degassing of epoxy resins used for encapsulation ensures the longevity and thermal management capabilities of sensitive components. This systemic demand pushes manufacturers toward continuous technological improvement in degassing efficiency and throughput, making obsolete older, less effective atmospheric or low-vacuum methods. The global focus on sustainable and lightweight materials, particularly in transportation, further solidifies the essential nature of vacuum degassing technology.

Restraining factors include geopolitical instability affecting raw material supply chains for machine components, fluctuations in energy costs impacting operational expenses for high-power vacuum pumps, and the long replacement cycles typical of heavy industrial machinery. Furthermore, the specialized nature of the equipment means that market entry for smaller players is challenging, limiting competitive pricing pressure. Addressing these restraints necessitates modular designs, localized manufacturing, and incorporating energy-efficient pump technologies. The impact forces indicate that technological advancement (R&D in new pump technologies and automation) and regulatory demands (strict quality certifications) exert the highest positive pressure, outweighing the cyclical market volatility associated with capital expenditure constraints.

Segmentation Analysis

The Vacuum Degassing Machine Market is systematically segmented based on the material processed, the type of operation, capacity, and the specific application industries, providing a granular view of market dynamics and demand pockets. Analysis reveals that segmentation by material processed—Molten Metal Degassing versus Polymer and Resin Degassing—captures the fundamental divergence in equipment design and scale. Molten metal systems are typically high-capacity, robust, and designed to handle extreme temperatures, whereas polymer and resin systems focus on precision, cleanliness, and optimized mixing capabilities for viscous materials. Further segmentation by application allows manufacturers to target specific end-user needs, such as specialized systems for concrete, food products, or highly sensitive pharmaceutical components, ensuring compliance with diverse industry standards.

- By Material Processed:

- Molten Metal Degassing (Steel, Aluminum, Copper, Alloys)

- Resin and Polymer Degassing (Epoxy, Silicone, Polyurethane, Composites)

- Concrete and Cement Degassing

- Chemical and Pharmaceutical Degassing

- Food and Beverage Degassing

- By Operation Type:

- Batch Degassing Systems

- Continuous Degassing Systems

- By Capacity:

- Small-Scale (R&D and Lab Use)

- Medium-Scale (Pilot Plant and Specialized Production)

- Large-Scale (High-Volume Industrial Production)

- By End-Use Industry:

- Metallurgy and Casting

- Automotive and Aerospace

- Electronics and Semiconductors

- Construction and Infrastructure

- Medical Devices and Pharmaceuticals

Value Chain Analysis For Vacuum Degassing Machine Market

The value chain for the Vacuum Degassing Machine Market begins with the upstream suppliers providing critical raw materials and specialized components, followed by the original equipment manufacturers (OEMs), and culminates in the distribution channels reaching the end-user industries. Upstream analysis focuses heavily on the procurement of high-grade steel, complex sensors, specialized seals, and high-performance vacuum pumps. The quality and reliability of vacuum pumps (e.g., rotary vane, liquid ring, dry screw pumps) are paramount, as they directly dictate the performance and efficiency of the entire degassing system. Strong supplier relationships are essential for OEMs to manage component costs and ensure technological compatibility, particularly concerning integrated automation and control systems sourced from specialized electronics manufacturers.

In the midstream, OEMs assemble, integrate, and customize these components into final degassing machines. This stage involves significant R&D investment in fluid dynamics, thermal engineering, and software development to optimize the degassing process for various material properties. Direct and indirect distribution channels play a crucial role in market penetration. Large OEMs often use direct sales forces and established technical support teams to handle complex, high-value contracts with major industrial clients (e.g., large steel mills or aerospace manufacturers). Smaller or specialized machines might utilize indirect channels, relying on regional distributors and integrators who provide localized sales, installation, and maintenance services, especially in emerging markets.

Downstream analysis focuses on the installation, commissioning, maintenance, and eventual decommissioning of the equipment at the end-user facilities. Post-sales service, technical training, and the availability of spare parts are critical differentiators, especially given the long operational lifespan of these machines. End-users in industries like electronics and pharmaceuticals require validated processes and traceable performance data, making software support and calibration services a necessary part of the ongoing value proposition. The efficiency of the downstream servicing structure directly influences customer satisfaction and the OEM's reputation in highly regulated industries.

Vacuum Degassing Machine Market Potential Customers

The primary customers for Vacuum Degassing Machines are large-scale industrial manufacturers and specialized processing facilities across multiple sectors, driven by the need to meet rigorous material quality specifications and enhance product reliability. End-users typically include integrated steel plants and non-ferrous metal foundries that require vacuum treatment to produce defect-free alloys for critical structural applications in transportation and infrastructure. Another major customer base is the electronics and semiconductor industry, utilizing these machines to process and dispense high-purity encapsulation resins, adhesives, and potting compounds to protect microelectronic components from environmental contamination and thermal stress.

Furthermore, the rapidly expanding electric vehicle (EV) battery manufacturing sector represents a significant growth area, demanding specialized degassing equipment for handling electrode slurries and electrolyte solutions, where preventing moisture and gas pockets is fundamental to battery performance and safety. Beyond these industrial giants, specialty chemical producers, aerospace component manufacturers (who must adhere to the highest standards for composite materials and metals), and pharmaceutical companies (focused on sterilization and purity) also form crucial buyer segments. These buyers prioritize machine reliability, validation capabilities, compliance with industry-specific standards, and long-term service agreements over initial purchase price.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 million |

| Market Forecast in 2033 | USD 1255 million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Schmetz, Leybold, PVA TePla AG, Atlas Copco (Edwards Vacuum), GEA Group, A-VAC Industries, Lhoist Group, Bush Vacuum Solutions, C&M Coating Inc., Shanghai Huade Vacuum Pump Manufacturing Co., Ltd., Pfeiffer Vacuum, VMA Getzmann GmbH, THIELMANN, Kurt J. Lesker Company, T-M Vacuum Products, Inc., Vacuum Engineering Services, Vac-U-Max, GHH-Bonatrans, CVC Technologies, SGL Carbon. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Vacuum Degassing Machine Market Key Technology Landscape

The technological landscape of the Vacuum Degassing Machine Market is defined by continuous improvements in vacuum generation, material handling mechanisms, and process control systems aimed at achieving higher purity levels and greater throughput efficiency. A critical technology involves the evolution of vacuum pump systems, moving increasingly towards dry-running screw pumps and turbo-molecular pumps, especially in high-purity applications like semiconductor material processing, to eliminate the risk of oil contamination associated with traditional wet pumps. Furthermore, sophisticated sealing technologies, often utilizing specialized elastomers or magnetic bearings, are crucial for maintaining ultra-high vacuum integrity during continuous operation in harsh environments, such as those encountered when processing molten metals.

Innovation in material handling focuses on enhancing the efficiency of gas removal from highly viscous or high-temperature materials. This includes the development of proprietary mixing and agitation technologies, such as thin-film degassing rotors and specialized planetary mixers operating within the vacuum chamber, which maximize the surface area exposure of the material to the vacuum environment. For molten metal applications, advanced sensor technologies, like hydrogen and oxygen sensors, are integrated in real-time to monitor impurity levels during the ladle or stream degassing processes, allowing for precise process termination, minimizing unnecessary cycle times and energy expenditure.

The latest technological trend involves integrating IoT and advanced control architectures (PLCs and SCADA systems) to enable precise, automated control and remote diagnostics. This allows operators to run complex, multi-stage vacuum cycles with minimal human intervention, ensuring repeatability and data logging for compliance and quality assurance. Furthermore, specialized machine designs for modularity and mobility are becoming prevalent, particularly for deployment in smaller-scale manufacturing facilities or research and development labs that require versatile, portable degassing solutions without sacrificing vacuum performance. The combination of advanced pump technology, intelligent process control, and customized internal geometries forms the core competitive edge in this highly technical market segment.

Regional Highlights

Regional dynamics are critically important in the Vacuum Degassing Machine Market, reflecting varying levels of industrialization, technological maturity, and regulatory environments. Asia Pacific (APAC) currently dominates the market share and is projected to exhibit the highest growth trajectory throughout the forecast period. This acceleration is attributed to massive industrial expansion, particularly the aggressive growth of the electronics, electric vehicle battery, and construction sectors in countries like China, India, and South Korea. Government initiatives promoting domestic manufacturing and significant foreign direct investment (FDI) in regional foundries and chemical processing plants further solidify APAC's leading position, driving demand for high-capacity, efficient degassing solutions.

North America and Europe represent mature markets characterized by stable, high-value demand, primarily driven by stringent quality requirements in aerospace, medical device manufacturing, and specialized metallurgy. These regions prioritize sophisticated, automated, and often customized degassing systems that offer maximum traceability and reliability. European demand is bolstered by the robust automotive sector and strict environmental regulations, requiring highly efficient and contaminant-free material processing. The focus in these regions is less on capacity expansion and more on technological refinement and integration with existing smart factory infrastructure.

Latin America and the Middle East and Africa (MEA) are emerging regions that show promising growth, albeit starting from a smaller base. Growth in MEA is primarily linked to infrastructure projects, oil and gas processing needs (requiring specialized chemical degassing), and localized cement production. Latin American demand is moderately increasing due to growth in the regional automotive sector and increased investment in processing local raw materials. In these emerging markets, cost-effectiveness and rugged, easy-to-maintain equipment are often the key purchasing criteria, although increasing quality mandates are gradually driving interest toward mid-to-high range automated solutions.

- Asia Pacific (APAC): Leading market, fueled by electronics, EV battery production (China, South Korea, Japan), infrastructure development, and substantial governmental manufacturing subsidies. Expected to show highest CAGR.

- North America: Mature market focusing on high-specification applications in aerospace, medical devices, and advanced materials. High adoption of automation and complex vacuum control systems.

- Europe: Driven by stringent quality and environmental regulations. Strong demand from the automotive, machinery manufacturing, and specialized chemical industries (Germany, France, UK).

- Latin America: Emerging demand linked to regional automotive production and construction sector expansion, emphasizing cost-efficient and reliable medium-capacity units.

- Middle East & Africa (MEA): Growth tied to oil and gas processing infrastructure, chemicals, and localized construction projects, with increasing focus on reducing material impurities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Vacuum Degassing Machine Market.- Pfeiffer Vacuum

- Leybold (Atlas Copco Group)

- PVA TePla AG

- Schmetz (A Teledyne Technologies Company)

- GEA Group

- Edwards Vacuum (Atlas Copco Group)

- Busch Vacuum Solutions

- VMA Getzmann GmbH

- THIELMANN

- Kurt J. Lesker Company

- T-M Vacuum Products, Inc.

- A-VAC Industries

- C&M Coating Inc.

- Shanghai Huade Vacuum Pump Manufacturing Co., Ltd.

- Lhoist Group

- CVC Technologies

- SGL Carbon

- GHH-Bonatrans

- Vacuum Engineering Services

- Vac-U-Max

Frequently Asked Questions

Analyze common user questions about the Vacuum Degassing Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a Vacuum Degassing Machine in industrial processing?

The primary function is to eliminate dissolved gases, trapped air, moisture, and volatile contaminants from liquids, resins, polymers, or molten metals by applying a vacuum, thereby significantly enhancing the material's structural integrity, purity, and performance in critical applications.

Which end-use industry drives the highest demand for molten metal vacuum degassing systems?

The metallurgy and casting industry, particularly for high-grade steel and aluminum production, drives the highest demand. Vacuum degassing is essential here to remove detrimental gases like hydrogen and nitrogen, preventing porosity and ensuring the high mechanical strength required for automotive and aerospace components.

How does the integration of Industry 4.0 technologies impact the efficiency of degassing machines?

Industry 4.0 integration, encompassing IoT sensors and AI-driven control systems, allows for real-time monitoring, predictive maintenance, and dynamic adjustment of vacuum levels and temperature, optimizing cycle times and reducing energy consumption while ensuring consistent material quality.

What are the main restraints affecting the adoption rate of new vacuum degassing technology?

The main restraints include the substantial initial capital investment required for high-capacity, advanced vacuum systems, the high operational complexity necessitating specialized labor, and the significant recurring costs associated with energy consumption by powerful vacuum pumps.

Why is the Asia Pacific region projected to exhibit the fastest growth in this market?

APAC's rapid growth is driven by accelerated industrialization, massive expansion in high-tech manufacturing sectors such as electronics and electric vehicle battery production, and supportive government policies encouraging domestic production of high-quality, processed materials.

The expansion of the global construction sector, especially in developing economies, further contributes to the demand for specialized vacuum degassing machines used in concrete and cement production. Ensuring the absence of air pockets in high-performance concrete is vital for structural longevity and strength, particularly in large infrastructure projects like dams, bridges, and high-rise buildings. This specific niche, although smaller than metallurgy or electronics, represents consistent, project-driven demand that requires robust, high-volume batch processing capabilities, often integrated directly at the construction site or pre-cast facilities. The technological requirements here focus on mobility and ease of maintenance under harsh environmental conditions, contrasting sharply with the sterile precision needed in electronics manufacturing.

In addition to traditional industrial applications, the pharmaceutical and biotechnology sectors are increasingly adopting specialized vacuum degassing equipment. These systems are used for solvent recovery, drying processes, and ensuring the purity of liquid formulations or sterile compounds before packaging. The regulatory environment in pharmaceuticals—mandated by bodies like the FDA and EMA—necessitates equipment that offers complete validation, precise temperature control, and materials that are compliant with hygienic standards (e.g., stainless steel, clean-in-place capabilities). This drives demand for smaller, highly precise, and often customized vacuum chambers designed for batch operations where material purity and traceability are paramount, creating a distinct, high-margin segment within the overall market structure.

The market faces ongoing pressure to innovate in areas concerning energy efficiency and sustainability. High-vacuum pumps are inherently energy-intensive. Consequently, manufacturers are heavily investing in developing advanced control algorithms and variable speed drive systems that modulate pump operation based on real-time vacuum load, resulting in significant energy savings. Furthermore, the design trend leans toward minimizing the footprint of the machinery while maximizing throughput, often utilizing multi-stage degassing techniques or incorporating continuous flow reactors instead of traditional batch tanks. These innovations are critical for competitive advantage, particularly in regions like Europe, where high energy costs and strict carbon reduction targets necessitate efficient machinery investment decisions.

Technological advancement is also enabling the processing of challenging, highly viscous materials. Industries producing advanced composite materials, adhesives, and sealants for wind energy, aerospace, and defense applications often deal with liquids that are difficult to degas due to their thick consistency. New machine designs incorporate high-torque planetary mixers or static mixers positioned within the vacuum envelope, ensuring effective agitation and thin-layer dispersion of the material, which significantly enhances the rate of gas removal compared to older, less active systems. This focus on material specificity is driving market segmentation towards highly specialized, niche machine manufacturers who possess deep knowledge of polymer chemistry and rheology.

The competitive landscape of the Vacuum Degassing Machine Market is characterized by the presence of large, diversified industrial machinery conglomerates alongside smaller, specialized manufacturers focused purely on high-vacuum or application-specific solutions. Large companies benefit from established global distribution networks, substantial R&D budgets, and the capability to offer integrated factory solutions (including pumps, instrumentation, and full automation packages). Conversely, specialized firms often differentiate themselves through superior expertise in niche areas, such as ultra-high vacuum generation for semiconductor applications or custom-designed chambers for experimental materials in research settings. Acquisitions and mergers are common strategies, allowing major players to quickly integrate specialized technologies or expand their geographical reach into high-growth regions like APAC, securing intellectual property in critical technological domains.

The regulatory framework surrounding manufacturing quality and safety significantly influences the purchasing decisions of end-users. Compliance with certifications such as ISO 9001 (Quality Management) and sector-specific standards (e.g., NADCAP for aerospace, GMP for pharmaceuticals) requires detailed documentation of the degassing process. This mandate increases the demand for machines equipped with advanced data logging capabilities, validated control software, and robust calibration protocols. OEMs must structure their product offerings and after-sales services around these stringent regulatory requirements, making technical support and documentation quality as important as the physical performance of the machine itself. This regulatory pressure acts as a powerful driver for continuous improvement in machine precision and reliability.

In terms of future market trajectory, the development of solid-state batteries (SSBs) for electric vehicles is expected to create a completely new set of demands for vacuum degassing, requiring the removal of contaminants from ceramic or solid electrolyte precursors. This shift will necessitate ultra-clean, high-purity processing environments, potentially pushing the market towards higher vacuum levels (UHV or XHV) and specialized, inert gas handling systems to prevent chemical degradation during processing. Companies that invest early in researching and developing equipment tailored for these next-generation battery components are poised to capture significant market share in the early 2030s, reshaping the competitive landscape and technological priorities within the industry. The focus will shift from bulk gas removal to atomic-level purity control.

Furthermore, the growing trend of additive manufacturing (3D printing), particularly in metal and high-performance polymer printing, requires specialized degassing solutions for raw material powders and liquid resins. Gas contamination in these materials can lead to layer delamination, poor mechanical properties, and printing failures. Manufacturers are responding by offering small- to medium-scale vacuum mixers and powder processing systems designed specifically to ensure the starting materials meet aerospace-grade purity standards. These compact, R&D-focused degassing units represent a rapidly expanding sub-segment of the market, catering to innovators and research institutes that drive the evolution of advanced manufacturing techniques globally, emphasizing flexibility and extreme cleanliness.

The reliance on skilled labor for operating and maintaining complex vacuum systems poses an ongoing challenge, especially in regions facing demographic shifts and shortages of technical talent. To mitigate this, machine manufacturers are prioritizing user-friendly human-machine interfaces (HMIs), enhanced diagnostic capabilities, and robust self-correction features built into the control software. Simplified maintenance routines and modular component design also reduce the reliance on highly specialized technicians for routine tasks, making the equipment more accessible and reducing overall operational expenditure for end-users. The trend towards fully automated, recipe-based operation minimizes the risk of human error, which is critical in high-cost material processing environments.

Geographically, while APAC leads in volume, North America and Europe continue to lead in technological adoption and the demand for customized, complex solutions. European manufacturers, often driven by strict environmental protocols, lead the way in integrating heat recovery systems and minimizing waste product generation during the degassing process. North American market strength is tied directly to federal and defense spending on aerospace and military applications, demanding the highest level of material purity and machine reliability, often governed by long-term government contracts. These regional differences in technological priorities ensure a diversified market where innovation occurs across various fronts—from capacity scaling in the East to precision and sustainability engineering in the West.

In summary, the Vacuum Degassing Machine Market is defined by its deep linkages to high-growth, high-quality manufacturing sectors globally. Success in this market is determined not just by the capability to achieve low vacuum pressures, but by the integration of smart technologies, adherence to complex regulatory standards, and the ability to offer highly customized solutions that meet the diverse needs of metallurgy, electronics, and emerging additive manufacturing industries. Strategic partnerships, continuous R&D in pump efficiency, and expanded service networks across emerging markets will be vital competitive factors over the forecast period.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager