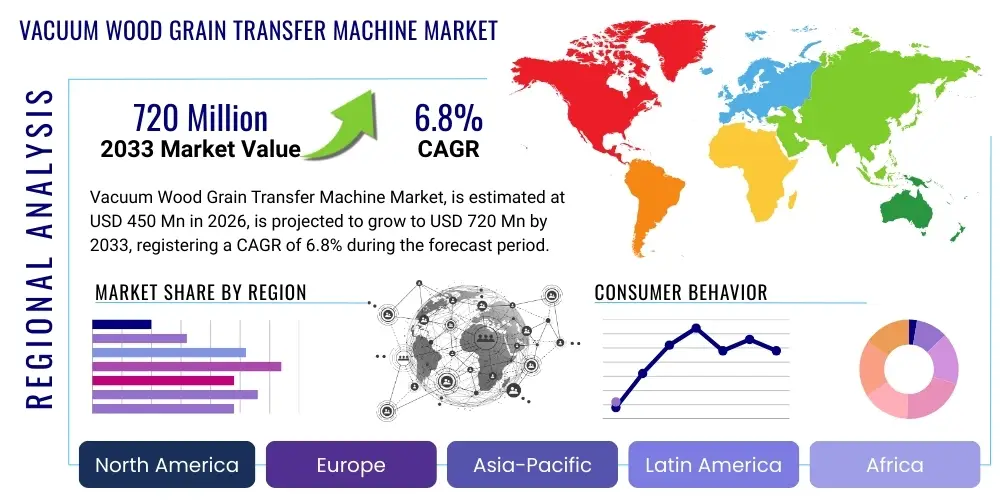

Vacuum Wood Grain Transfer Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436924 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Vacuum Wood Grain Transfer Machine Market Size

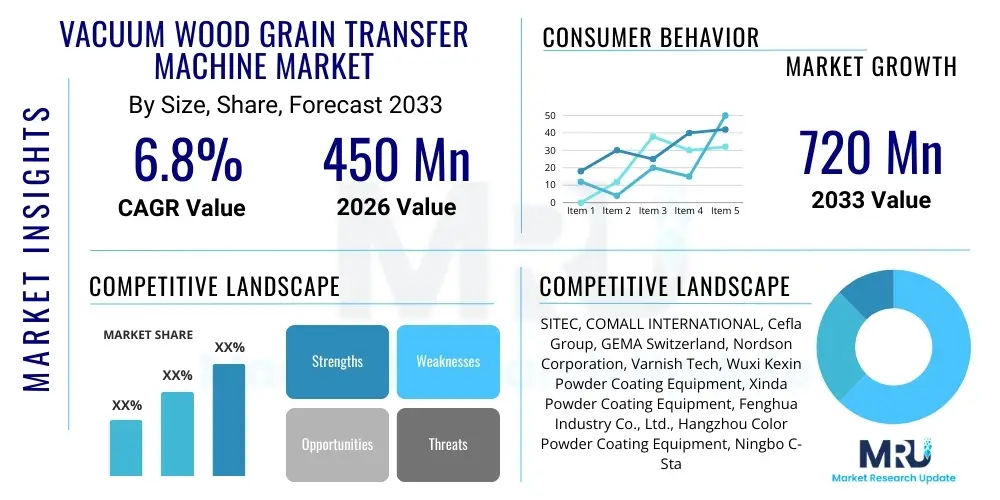

The Vacuum Wood Grain Transfer Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 720 Million by the end of the forecast period in 2033.

Vacuum Wood Grain Transfer Machine Market introduction

The Vacuum Wood Grain Transfer Machine Market encompasses specialized industrial equipment designed for applying decorative, highly realistic wood grain finishes onto various substrate materials, predominantly aluminum profiles, metal sheets, and medium-density fiberboard (MDF) panels. This technology utilizes a vacuum process and heat sublimation to transfer ink or dye patterns from specialized transfer paper onto the surface of the pre-treated material, often powder-coated metal. The result is a durable, weather-resistant, and aesthetically pleasing finish that mimics natural wood, offering a high-value alternative to real wood in architectural and manufacturing applications. The core mechanism involves placing the substrate and the transfer film within a sealed vacuum chamber, ensuring optimal contact and uniform heat distribution, which is crucial for achieving high-definition grain patterns without air bubbles or imperfections.

The primary applications driving the market expansion include the architectural sector, specifically fenestration (windows and doors), facade systems, and interior decoration elements such as ceiling panels, furniture components, and flooring trims. Furthermore, the automotive and consumer electronics industries are increasingly adopting this technology for premium aesthetic detailing, capitalizing on the durability and low maintenance requirements compared to actual wood veneers. The machine’s ability to process long aluminum profiles efficiently makes it indispensable in the construction materials supply chain. Key product benefits include superior abrasion resistance, UV protection, resistance to fading, and environmental sustainability, as it reduces the reliance on natural timber resources while meeting stringent regulatory standards for material longevity and safety in construction.

The market is predominantly driven by the surging global demand for sustainable building materials that do not compromise on visual appeal, coupled with rapid urbanization, particularly across the Asia Pacific region. Advancements in powder coating and sublimation ink technology have enhanced the quality and realism of the transferred wood grain, widening the machine's adoption scope. Moreover, the increasing automation across manufacturing facilities to achieve high throughput and reduced operational costs further propels the demand for fully automated vacuum transfer systems. The aesthetic versatility offered by digital printing capabilities integrated into these machines allows manufacturers to quickly adapt to evolving interior design trends, solidifying their market position.

- Product Description: Industrial machinery utilizing heat sublimation and vacuum sealing for high-fidelity wood grain transfer onto metal and composite substrates.

- Major Applications: Architectural profiles (windows, doors, curtain walls), Interior furniture components, Automotive trims, and Decorative metal panels.

- Benefits: High durability, excellent weather resistance, UV stability, aesthetic realism, and reduced reliance on natural wood.

- Driving Factors: Rapid growth in the construction and renovation sector, demand for sustainable material aesthetics, and ongoing industrial automation.

Vacuum Wood Grain Transfer Machine Market Executive Summary

The Vacuum Wood Grain Transfer Machine Market is experiencing robust growth fueled by several key business trends, notably the pivot toward sustainable manufacturing processes and the rising consumer preference for durable, aesthetically superior finishes in residential and commercial construction. Manufacturers are focusing on developing high-speed, multi-chamber systems integrated with Industry 4.0 standards, enabling remote monitoring and predictive maintenance. This shift toward smart machinery enhances operational efficiency and product quality, catering to large-volume processors in global markets. Mergers and acquisitions, particularly involving specialized coating and machinery providers, are shaping the competitive landscape, aiming to consolidate technological expertise and expand geographic reach, especially into emerging economies with nascent but rapidly growing construction sectors.

Regional trends indicate that the Asia Pacific (APAC) region, spearheaded by China and India, remains the dominant growth engine due to unprecedented infrastructure spending and sustained housing market expansion. North America and Europe demonstrate mature market characteristics, focusing primarily on technological upgrades, energy efficiency, and stringent quality control standards, driving demand for premium, highly automated equipment. The Middle East and Africa (MEA) region is exhibiting significant uptake, particularly within high-end architectural projects where durability against extreme climates is paramount. Regional market dynamics are heavily influenced by local building codes and the availability of specialized powder coating materials necessary for the pre-treatment process, creating regional variations in machinery specifications and capacity requirements.

Segmentation trends highlight that the Fully Automatic machine segment is projected to witness the highest CAGR, driven by large-scale producers seeking to minimize labor costs and maximize consistency. In terms of application, aluminum profiles maintain the largest market share, intrinsically linked to the global window and door manufacturing industry. However, the wood panels segment, including MDF and particleboard, is gaining traction as manufacturers explore cost-effective ways to replicate high-end wood finishes for interior applications without the limitations of traditional laminates. Furthermore, the rising integration of digital pattern generation capabilities is allowing for unparalleled customization, significantly influencing purchasing decisions across all segments.

AI Impact Analysis on Vacuum Wood Grain Transfer Machine Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Vacuum Wood Grain Transfer Machine Market primarily revolve around questions concerning process optimization, defect detection, and predictive maintenance. Users frequently ask: "How can AI enhance the consistency of the wood grain finish?" and "Can machine learning algorithms predict equipment failure to minimize downtime?" and "Will AI integration reduce the need for skilled operators?" The prevailing theme is the expectation that AI and machine learning will transcend traditional automation by providing granular control over vacuum pressure, temperature profiles, and transfer time, which are critical variables determining the final product quality. Concerns often focus on the required investment in retrofitting older machines and the accessibility of specialized data scientists needed to implement complex AI models in industrial settings.

The application of AI in this niche industrial sector is centered on enhancing operational efficiency and improving aesthetic consistency, which is currently subject to operator experience and periodic calibration. AI-powered vision systems, leveraging sophisticated image recognition algorithms, can continuously monitor the transferred grain pattern, instantly identifying micro-defects such as non-uniform density, pattern breaks, or trapped air bubbles far more reliably than human inspection. This real-time quality control loop allows the system to auto-adjust operational parameters, minimizing material waste and ensuring that every processed batch meets stringent quality standards. This move from statistical quality control to immediate, preemptive intervention significantly reduces scrap rates.

Beyond quality control, AI fundamentally transforms equipment management through advanced predictive maintenance (PdM). By analyzing vast datasets related to machine vibration, energy consumption, vacuum integrity, and heating element performance, machine learning models can accurately forecast component failure before it occurs. This transition from time-based or reactive maintenance to predictive scheduling maximizes machine uptime, reduces unexpected production stoppages, and optimizes the inventory of spare parts. Consequently, AI integration translates directly into lower Total Cost of Ownership (TCO) for end-users, enhancing the economic viability and competitiveness of the wood grain transfer process against traditional laminating and printing methods.

- AI impacts include enhanced visual inspection through machine vision for real-time defect detection and quality assurance.

- Predictive maintenance (PdM) algorithms optimize machine uptime by forecasting vacuum pump, heating element, and sealing system failures.

- Machine Learning (ML) is used for adaptive process control, automatically adjusting temperature and pressure profiles based on substrate variations and desired finish.

- Improved energy efficiency by using AI to model optimal heating cycles, reducing overall power consumption per unit.

- Automated pattern generation and error correction reduce reliance on manual operator input, improving workflow consistency.

DRO & Impact Forces Of Vacuum Wood Grain Transfer Machine Market

The market is defined by a strong set of Drivers, Restraints, and Opportunities (DRO) that collectively determine its trajectory, while key impact forces continually shape competitive behavior and technological adoption. The primary market driver is the accelerating substitution of natural wood with highly durable, metal-based alternatives, particularly in construction applications exposed to harsh environments, such as high humidity or intense UV radiation. This shift is strongly supported by environmental regulations encouraging sustainable building practices. Counteracting this growth are significant restraints, including the high initial capital investment required for automated transfer systems and the prerequisite need for advanced powder coating pretreatment, which adds complexity and cost to the overall finishing process, potentially deterring smaller manufacturers.

Opportunities for growth are concentrated in the continuous improvement of sublimation ink and transfer film technology, allowing for hyper-realistic 3D tactile finishes and wider material compatibility (e.g., specific plastics and high-performance composites). Furthermore, geographic expansion into emerging markets, where rapid industrialization demands quick, scalable, and high-quality finishing solutions, presents substantial revenue streams. The integration of advanced automation features, including robotic loading/unloading and integrated cleaning systems, also creates opportunities for premium machine sales in developed economies striving for 'lights-out' manufacturing environments. These factors suggest a market where high value is placed on technological sophistication and operational reliability.

The market impact forces are primarily shaped by competitive intensity driven by technological differentiation. Companies vigorously compete on machine speed, energy consumption, and the consistency of the final output. Supplier power remains moderate; while specialized vacuum components and heating elements are sourced globally, powder coating suppliers wield influence due to their crucial role in the process chemistry. Buyer power is increasing, especially among large aluminum profile extruders who demand customized, high-capacity systems with comprehensive service agreements. Regulatory forces, particularly those governing VOC emissions and material durability standards in construction (e.g., European CE standards), fundamentally guide product development and market entry strategies across regions.

- Drivers: Demand for high-durability, weather-resistant finishes; rapid growth in the construction and renovation sector globally; technological advancements in powder coating and sublimation inks.

- Restraints: High initial capital expenditure and installation costs; dependency on precise pretreatment (powder coating); complexity in process management requiring skilled technicians.

- Opportunities: Expansion into new substrate materials (plastics, composites); development of continuous, roll-to-roll transfer systems; market penetration in emerging construction hubs (Southeast Asia, Latin America).

- Impact Forces: High competitive rivalry among Asian and European manufacturers; moderate supplier power for highly specialized components; increasing buyer leverage due to procurement consolidation.

Segmentation Analysis

The Vacuum Wood Grain Transfer Machine Market is comprehensively segmented based on machine type, which dictates throughput and automation level, and by application, specifying the primary substrate material being processed. The type segmentation distinguishes between highly manual Semi-automatic systems, favored by smaller workshops for flexibility, and sophisticated Fully Automatic systems, designed for continuous, high-volume manufacturing lines prevalent in large industrial parks. The application segmentation is critical as the machine configuration (chamber size, vacuum pressure capability, and heating surface area) must be tailored to the dimensions and physical properties of the materials being finished, such as long aluminum extrusions versus large flat wood panels.

- By Type:

- Semi-automatic Vacuum Wood Grain Transfer Machines

- Fully Automatic Vacuum Wood Grain Transfer Machines

- By Application:

- Aluminum Profiles (Windows, Doors, Facades)

- Wood Panels (MDF, P lywood, Particleboard)

- Steel Sheets and Other Metals

- Plastics and Composite Materials

- By End-Use Industry:

- Construction and Architecture

- Furniture and Cabinetry

- Automotive and Transportation

- Consumer Goods

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Vacuum Wood Grain Transfer Machine Market

The value chain for the Vacuum Wood Grain Transfer Machine Market begins with upstream activities, focusing on the sourcing and manufacturing of highly specialized components. This includes procurement of high-grade vacuum pumps and sealing materials, precision heating elements (often infrared or thermal oil based), sophisticated control systems (PLCs), and high-integrity steel alloys for chamber construction. Key upstream suppliers include specialized manufacturers of industrial heating technology and automation components. Component quality is paramount as machine performance relies heavily on maintaining a perfect vacuum and uniform temperature across the processing surface. Suppliers are geographically dispersed, but critical technological integration often resides within the final machine assemblers, who specialize in industrial thermodynamics and vacuum physics.

Midstream activities involve the machine manufacturing, assembly, and integration phase, where raw components are transformed into complex, functional industrial units. This stage includes design engineering tailored to specific client needs (e.g., maximum profile length or panel size), system calibration, and rigorous testing under various load conditions. Crucially, the midstream incorporates the production of essential consumables, particularly the specialized transfer film (paper or PET film) and heat-resistant sublimation inks, which are proprietary elements often developed through strategic partnerships between machinery manufacturers and chemical companies. Innovation in this segment directly translates to competitive advantage through superior aesthetic output and production speed.

Downstream activities focus on distribution, installation, and after-sales service, connecting the machine manufacturers with the end-user manufacturers (e.g., aluminum extrusion companies or furniture makers). Distribution channels are mixed: Direct sales are common for customized, high-value, fully automatic systems, allowing manufacturers to provide dedicated installation, training, and warranty services. Indirect channels, involving regional agents and distributors, are utilized for standard or semi-automatic models, leveraging local market knowledge and support infrastructure. After-sales support, encompassing maintenance contracts, spare parts supply, and process optimization consulting, constitutes a significant, high-margin revenue stream, crucial for ensuring long-term customer satisfaction and operational viability in capital-intensive industries.

Vacuum Wood Grain Transfer Machine Market Potential Customers

The primary end-users and buyers of Vacuum Wood Grain Transfer Machines are large-scale industrial processors requiring aesthetically superior and highly durable surface finishes. The most significant customer base resides within the architectural metal fabrication sector, specifically companies specializing in the extrusion and finishing of aluminum profiles used extensively in window frames, door systems, and curtain walls for both commercial high-rises and residential complexes. These customers demand machines capable of processing long, complex profiles with high throughput and consistent quality that meets stringent European (EN) and American (AAMA) standards for weather resistance and adherence.

A secondary, rapidly growing segment includes manufacturers in the furniture and cabinetry industry. These companies utilize the machines to apply high-fidelity wood finishes onto MDF, particleboard, and steel components, offering a premium look that surpasses traditional laminates in depth and texture. The focus for these buyers is often on flexibility and the ability to switch patterns quickly to meet diverse design specifications for interior decor markets. As consumer demand for customized and visually rich interior spaces increases, this segment continues to invest in higher-precision transfer technology to simulate exotic and complex wood species textures.

Other vital customers are found in specialized manufacturing fields, including the automotive aftermarket for decorative trims and accessories, and the broader construction materials industry dealing with exterior cladding, garage doors, and fence panels. These buyers prioritize machinery ruggedness and reliability, requiring systems that can handle large metal sheets and endure continuous industrial use cycles. Procurement decisions among all potential customers are highly sensitive to the machine's energy efficiency, the cost per finished meter (or panel), and the quality of local technical support available, which minimizes costly downtime.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 720 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SITEC, COMALL INTERNATIONAL, Cefla Group, GEMA Switzerland, Nordson Corporation, Varnish Tech, Wuxi Kexin Powder Coating Equipment, Xinda Powder Coating Equipment, Fenghua Industry Co., Ltd., Hangzhou Color Powder Coating Equipment, Ningbo C-Star Powder Coating Equipment Co., Ltd., Zhonglian Aluminium Industry, Italvacuum S.r.l., Jiangsu Yueda Machinery, Sima S.r.l., Wuxi Huadong Powder Coating Equipment, Guangzhou Guangzheng Powder Coating, Taiming Powder Coating Equipment. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Vacuum Wood Grain Transfer Machine Market Key Technology Landscape

The core technology underpinning the Vacuum Wood Grain Transfer Machine market is heat sublimation transfer coupled with precision vacuum technology. Sublimation involves converting solid ink dyes contained within a specialized paper or film directly into a gas without passing through a liquid phase. This gas penetrates the pre-applied powder coating layer on the substrate (e.g., aluminum), resulting in a permanent, high-definition pattern transfer. Key technological advancements center on optimizing the heating system, which must maintain exceptional temperature uniformity (often relying on electric heaters or circulating thermal oil) across the large surface area of the chamber to ensure flawless grain consistency, preventing color variation or blurriness across the profile length.

A second crucial element is the vacuum system design. Modern machines utilize high-power vacuum pumps and robust silicone or rubber sealing membranes to evacuate air from the chamber quickly and maintain a near-perfect vacuum (typically 0.1 to 0.5 bar negative pressure). The vacuum ensures the flexible transfer film adheres tightly to the substrate’s contours, including intricate corners and complex geometric shapes of aluminum profiles. Innovations focus on developing faster cycle times and more durable sealing technologies, extending membrane lifespan and reducing maintenance interruptions. Furthermore, the integration of quick-change profile fixtures and loading systems enhances operational efficiency, especially in high-mix, low-volume manufacturing environments.

The integration of advanced digital control systems (PLCs and HMI interfaces) represents the current technological frontier. These systems allow for precise, automated control over the entire process cycle—from pre-heating and vacuum draw-down to temperature holding time and cooling. Latest generation machines incorporate sophisticated sensor arrays for real-time monitoring of thermal gradients and pressure fluctuations. This digital precision not only guarantees repeatable, high-quality output but also facilitates remote diagnostics and integration into centralized factory management systems, aligning the market with broader Industry 4.0 connectivity standards. The synergy between high-fidelity digital pattern printing (for the transfer film) and the machine's thermal control ensures the production of increasingly complex and realistic finishes.

Regional Highlights

The global Vacuum Wood Grain Transfer Machine market exhibits significant regional variations in growth drivers and technological maturity. The Asia Pacific (APAC) region currently dominates the market, primarily driven by China, which accounts for the largest share of global aluminum production and processing. The massive infrastructure development, coupled with a surging demand for modern, durable building materials in residential and commercial sectors across Southeast Asia and India, ensures sustained high demand for high-capacity, cost-effective vacuum transfer machinery. Manufacturers in this region often prioritize throughput and energy efficiency due to competitive domestic pricing pressures, resulting in rapid adoption of fully automated, multi-chamber systems.

Europe represents a mature but technologically demanding market, characterized by stringent environmental regulations (REACH compliance, energy consumption standards) and high expectations for finish quality. European growth is primarily fueled by retrofitting and replacement cycles, focusing on upgrading existing machinery with advanced automation, predictive maintenance capabilities, and highly energy-efficient components. Germany, Italy, and Turkey are key regional hubs, with Italy maintaining strong leadership in specialized machinery design and manufacturing. The European market emphasizes precision engineering and long-term machine reliability, driving demand for premium-priced, technologically advanced solutions.

North America maintains steady demand, largely centered on the high-end residential and commercial construction market, where architectural aesthetics and durability are highly valued. The market here is characterized by a high adoption rate of customized systems tailored to specific U.S. and Canadian building standards. The Middle East and Africa (MEA), particularly the GCC nations (UAE, Saudi Arabia), demonstrate exponential growth potential, driven by megaprojects and extreme climatic conditions that necessitate the durability offered by powder-coated, wood-grain transferred aluminum profiles. Investment in this region is often focused on turnkey solutions encompassing the entire coating and finishing line.

- Asia Pacific (APAC): Dominant market share fueled by infrastructure growth in China, India, and Southeast Asia; high demand for fully automated systems.

- Europe: Focus on high-precision, environmentally compliant machinery upgrades and replacements; strong presence of specialized Italian and German manufacturers.

- North America: Stable demand driven by high-quality architectural projects; emphasis on customized machine configurations and robust after-sales support.

- Latin America (LATAM): Emerging growth, driven by residential construction in Brazil and Mexico; increasing adoption of standardized, cost-efficient machinery.

- Middle East & Africa (MEA): Rapid growth due to large-scale construction megaprojects; high prioritization of durable finishes capable of withstanding extreme heat and sand exposure.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Vacuum Wood Grain Transfer Machine Market.- SITEC

- COMALL INTERNATIONAL

- Cefla Group

- GEMA Switzerland

- Nordson Corporation (Indirectly through coating systems integration)

- Varnish Tech

- Wuxi Kexin Powder Coating Equipment

- Xinda Powder Coating Equipment

- Fenghua Industry Co., Ltd.

- Hangzhou Color Powder Coating Equipment

- Ningbo C-Star Powder Coating Equipment Co., Ltd.

- Zhonglian Aluminium Industry (Integrated User/Manufacturer)

- Italvacuum S.r.l.

- Jiangsu Yueda Machinery

- Sima S.r.l.

- Wuxi Huadong Powder Coating Equipment

- Guangzhou Guangzheng Powder Coating

- Taiming Powder Coating Equipment

- Dallan Spa (Related Profile Processing)

- Trevisan Forniture Industriali

Frequently Asked Questions

Analyze common user questions about the Vacuum Wood Grain Transfer Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary benefit of using vacuum wood grain transfer technology over traditional laminates?

The primary benefit is superior durability, particularly resistance to weathering, UV radiation, and abrasion. The sublimation process creates a finish that is structurally bonded to the powder coating, offering longevity often required for exterior architectural applications, unlike surface-applied laminates.

Which substrate materials are most commonly processed by these machines?

Aluminum profiles, extensively used in windows, doors, and facades, represent the largest application segment. The technology is also widely used for finishing various wood panels (like MDF) and steel sheets destined for furniture or decorative construction elements.

What are the key technological advancements driving market growth?

Key advancements include the integration of fully automatic loading/unloading systems, AI-powered quality control for pattern consistency, and the development of high-efficiency thermal systems that reduce cycle times and energy consumption while maintaining superior thermal uniformity.

How does the initial capital expenditure affect market accessibility?

The high initial capital investment for automated vacuum transfer machines acts as a significant restraint, especially for smaller enterprises. This financial barrier necessitates high-volume production requirements to ensure an acceptable return on investment, favoring large, established manufacturers.

Which regional market holds the highest growth potential for vacuum wood grain transfer machines?

The Asia Pacific (APAC) region, driven by continuous infrastructure investment, rapid urbanization, and a high volume of aluminum manufacturing, possesses the highest growth potential, particularly within emerging economies such as India and Southeast Asian nations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager