Variable Speed Angle Grinder Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434591 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Variable Speed Angle Grinder Market Size

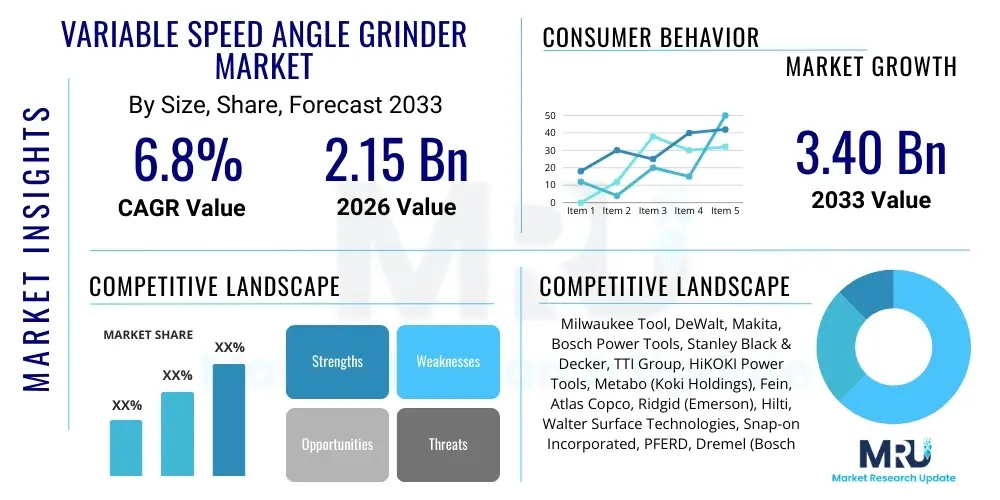

The Variable Speed Angle Grinder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at $2.15 Billion in 2026 and is projected to reach $3.40 Billion by the end of the forecast period in 2033.

Variable Speed Angle Grinder Market introduction

The Variable Speed Angle Grinder Market encompasses professional and industrial power tools designed for cutting, grinding, polishing, and sanding applications across various materials, offering the critical advantage of adjustable rotational speeds (RPM). Unlike standard fixed-speed grinders, variable speed models allow operators to precisely match the tool's output to the specific accessory and workpiece material, significantly enhancing control, finish quality, and material removal rate while minimizing heat generation and accessory wear. These tools are indispensable in precision metal fabrication, stone working, automotive repair, and construction sectors where diverse tasks require optimized performance settings, thereby driving their increasing adoption globally due to their versatility and efficiency improvements over conventional equipment.

The core functionality of these grinders lies in their advanced electronic controls which regulate the motor's power output, providing consistent torque even at lower RPM settings—a crucial feature for specialized tasks like stainless steel polishing or surface preparation using flap discs. The demand is primarily fueled by stringent quality requirements in manufacturing and the rising preference for cordless technology that offers greater mobility and ease of use on job sites without compromising power or runtime. Technological advancements focusing on ergonomics, vibration reduction, and safety features such as kickback control further solidify their market position as essential equipment for modern industrial operations.

Major applications of variable speed angle grinders span from heavy-duty infrastructure projects to delicate finishing work. Their ability to handle materials ranging from hard metals and concrete to soft composites and plastics using optimized speeds makes them highly valuable. The primary driving factors include rapid industrialization in developing economies, increased expenditure on commercial and residential construction, and the continuous need for high-precision tools in the burgeoning automotive aftermarket and maintenance, repair, and overhaul (MRO) sectors.

Variable Speed Angle Grinder Market Executive Summary

The Variable Speed Angle Grinder Market is characterized by robust competitive dynamics, driven primarily by technological innovation focused on battery longevity, motor efficiency (brushless DC motors), and advanced user safety features. Current business trends indicate a strong shift toward high-voltage cordless platforms (18V, 36V, and 54V/60V MAX equivalents) that deliver corded-level power, satisfying the professional demand for mobility without sacrificing performance. Key market players are heavily investing in electronic intelligence integrated within the tools and batteries, enabling real-time performance optimization and predictive maintenance capabilities, thereby boosting operational efficiency and reducing downtime across industrial applications.

Geographically, the market expansion is significantly influenced by infrastructure spending, with Asia Pacific emerging as the fastest-growing region, fueled by massive construction projects and rapid urbanization in countries like China and India. North America and Europe maintain dominance in terms of market value, primarily due to high adoption rates of premium, technologically advanced tools and stringent occupational safety regulations that favor grinders equipped with electronic safety brakes and anti-vibration systems. Regional trends also highlight localized manufacturing strategies aimed at mitigating supply chain risks and adapting tool specifications to regional ergonomic preferences and power standards, particularly regarding corded models.

Segment trends reveal that the Cordless segment is rapidly overtaking the Corded segment in terms of revenue growth, although corded tools still hold significant market share in heavy fabrication shops requiring unlimited runtime. Among disc sizes, the 4.5-inch and 5-inch models remain the most popular due to their versatility in handling everyday tasks, while the adoption of larger 7-inch and 9-inch models is expanding in heavy industrial applications such as pipe laying and structural steel work. End-user preference is clearly leaning towards tools incorporating advanced electronic control systems over basic mechanical speed dials, driven by the need for consistent torque delivery and enhanced safety across varied operational demands.

AI Impact Analysis on Variable Speed Angle Grinder Market

Common user inquiries concerning the impact of Artificial Intelligence on the Variable Speed Angle Grinder Market center around how AI enhances operational safety, optimizes tool lifespan, and improves performance consistency. Users frequently ask about the integration of predictive failure algorithms, the potential for AI-driven feedback loops to adjust motor speed based on material density and load, and whether AI can automate kickback prevention better than current electronic systems. The underlying theme is the expectation that AI will transform the grinder from a passive power tool into an 'intelligent' asset capable of autonomous adjustment and self-diagnosis, significantly minimizing operational hazards and maximizing material processing efficiency. Users are also keen to understand how AI-powered data analytics collected from fleets of connected grinders can inform best practices for industrial maintenance and tool deployment across large construction sites.

- AI-Powered Predictive Maintenance: Algorithms analyze vibration patterns, temperature fluctuations, and current draw to predict component failure (e.g., bearings, brushes, electronic boards) weeks in advance, optimizing maintenance schedules and minimizing unscheduled downtime.

- Intelligent Load Sensing and Speed Adjustment: AI enables the grinder's electronic control unit (ECU) to detect real-time changes in material hardness or disc friction, automatically adjusting the RPM and torque curve to maintain optimal cutting/grinding speed, improving finish quality and preventing motor burnout.

- Enhanced Anti-Kickback and Safety Systems: Machine learning models improve the responsiveness and accuracy of electronic safety brakes, distinguishing between harmless changes in torque and genuine dangerous kickback events, reducing false shutdowns and increasing operator safety.

- Automated Fleet Management and Usage Optimization: AI processes data aggregated from connected tools (IoT integration) to provide fleet managers with insights into tool utilization, operator efficiency, and energy consumption patterns, facilitating better asset allocation and procurement strategies.

- Ergonomic Feedback Systems: AI analyzes user interaction data (e.g., grip pressure, tool angle) to provide real-time guidance or automatic adjustments designed to reduce operator fatigue and the risk of repetitive strain injuries, particularly during long-duration industrial tasks.

DRO & Impact Forces Of Variable Speed Angle Grinder Market

The market dynamics of variable speed angle grinders are governed by a complex interplay of foundational growth drivers, critical restraints related to cost and perception, clear opportunities stemming from technological transitions, and potent market impact forces that reshape competitive strategy. The principal growth engine remains the relentless global demand for specialized fabrication and finishing work, where precision control offered by variable speed functionality is non-negotiable for quality assurance. Conversely, the high initial cost of advanced variable speed, brushless, and battery-powered models, coupled with the inherent dangers associated with angle grinder operation, serve as significant restraining factors impacting adoption, particularly in smaller workshops or DIY segments where fixed-speed alternatives are often deemed sufficient.

Opportunities for market expansion are largely concentrated in the transition to industrial-grade cordless systems and the integration of advanced connectivity (IoT) features, which transform tools into data-generating assets, offering immense value to fleet managers. The development of lighter, more powerful battery chemistries that allow prolonged heavy use is a critical enabler of this cordless transition. However, the impact forces—particularly the influence of regulatory bodies enforcing stricter safety standards (e.g., mandatory electronic braking systems) and the intensity of competition among leading global manufacturers—drive continuous cycles of innovation and price adjustments, fundamentally shaping market accessibility and technological thresholds.

Specifically, the Variable Speed Angle Grinder Market faces substantial impact from the stringent global regulations mandating improved operator safety. This regulatory push forces manufacturers to invest heavily in electronic braking and anti-kickback technology, raising the entry barrier for smaller players but simultaneously creating a strong competitive advantage for market leaders who can integrate these complex features seamlessly. Furthermore, the rising cost volatility of raw materials, especially specialized metals and lithium-ion battery components, exerts pressure on manufacturing margins, which market players must mitigate through optimized supply chains and automated production processes to maintain competitive pricing structures.

Segmentation Analysis

The Variable Speed Angle Grinder Market is intricately segmented based on core product characteristics, power source, disc size, and primary application areas, reflecting the diverse requirements of the end-user base ranging from professional industrial users to dedicated DIY enthusiasts. Understanding these segment dynamics is crucial for manufacturers to tailor product development and marketing strategies effectively, focusing on optimizing torque management in cordless systems and enhancing durability for specific industrial applications like shipbuilding or foundry work. The fastest evolving segmentation is driven by power source, where the rapid maturation and cost reduction of high-density battery technology are fundamentally reshaping purchasing decisions across all end-user sectors, favoring cordless mobility.

- By Power Source:

- Corded (AC Powered)

- Cordless (DC Battery Powered)

- By Disc Size (Wheel Diameter):

- 4.5 inch (115 mm)

- 5 inch (125 mm)

- 6 inch (150 mm)

- 7 inch (180 mm)

- 9 inch (230 mm)

- By Application:

- Construction and Infrastructure

- Automotive and Transportation (including MRO)

- Metal Fabrication and Welding

- Energy (Oil & Gas, Renewables)

- Shipbuilding and Marine

- Others (DIY, Woodworking)

- By Speed Control Mechanism:

- Dial Control

- Paddle Switch Control

- Electronic Soft Start/Constant Speed Control

Value Chain Analysis For Variable Speed Angle Grinder Market

The value chain for the Variable Speed Angle Grinder Market begins intensely at the upstream level with the sourcing of specialized raw materials, including high-grade steel and aluminum alloys for gearboxes and housings, advanced polymer composites for ergonomic handles, and increasingly critical components like rare-earth magnets for high-efficiency brushless motors. The most sensitive part of the upstream chain involves the procurement of advanced electronic control units (ECUs) and lithium-ion cells for cordless models, which are subject to global supply chain volatility and pricing pressures. Manufacturers leverage strategic relationships with specialized component suppliers to ensure quality control and manage the intellectual property associated with proprietary motor and battery management system designs, representing a significant portion of the total manufacturing cost.

The midstream phase focuses on complex manufacturing and assembly, which has increasingly shifted towards automation, particularly for stator winding and rotor assembly in brushless motors, to maintain high precision and reduce labor costs. Manufacturers employ stringent quality control procedures, especially concerning balancing the internal components to minimize vibration, a key performance indicator for variable speed grinders. Distribution channels are bifurcated, encompassing direct sales to major industrial clients (e.g., large construction firms or shipyards) and indirect sales through extensive networks of specialized industrial distributors, hardware wholesalers, and large format retail outlets. E-commerce platforms are rapidly gaining importance, facilitating direct-to-consumer sales and offering niche products.

The downstream activities involve post-sale services, including extensive warranties, repair centers, and the provision of specialized consumables (discs and brushes). Effective downstream support is crucial for maintaining brand loyalty, particularly in the professional industrial segment where tool reliability and rapid repair services directly impact operational continuity. Furthermore, the optimization of the distribution network—ensuring product availability and competitive pricing across diverse geographies—is a major focus area for market leaders looking to capitalize on regional infrastructure booms, thereby completing the value proposition delivered to the end-users.

Variable Speed Angle Grinder Market Potential Customers

The primary potential customers for Variable Speed Angle Grinders are sophisticated industrial and professional tradespeople who require precision and versatility beyond what fixed-speed models can offer. Key end-user sectors include the construction industry (especially concrete finishing, rebar cutting, and specialty masonry), large metal fabrication shops that handle diverse materials requiring optimized grinding speeds (like stainless steel, aluminum, and titanium), and the expansive automotive aftermarket for bodywork, chassis modification, and paint preparation. These customers prioritize tools that offer consistent power under varying loads, superior safety features, and extended warranty periods reflective of heavy-duty usage requirements, validating the premium price point associated with variable speed technology.

A rapidly growing segment of potential customers includes maintenance, repair, and overhaul (MRO) operations across major industries such as energy (oil and gas pipelines, wind turbine maintenance) and logistics (rail, marine transport). In these environments, tools must perform reliably in challenging and often remote conditions, necessitating the mobility and power density provided by high-performance cordless variable speed grinders. These organizations often purchase tools in large fleets and place significant value on data connectivity (IoT) features that facilitate asset tracking, usage monitoring, and adherence to corporate safety standards, focusing on total cost of ownership rather than initial purchase price.

Finally, skilled specialized contractors, such as stone and tile setters, professional painters needing surface prep, and DIY enthusiasts engaged in high-end projects, also represent critical potential customer segments. While the DIY segment is more price-sensitive, they are increasingly adopting variable speed grinders due to greater product accessibility and growing appreciation for the quality of finish attainable at lower, controlled speeds, particularly for tasks involving polishing or delicate material removal. Manufacturers must segment their product lines clearly to address the distinct performance and durability needs of these varying professional, industrial, and consumer buyer groups.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $2.15 Billion |

| Market Forecast in 2033 | $3.40 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Milwaukee Tool, DeWalt, Makita, Bosch Power Tools, Stanley Black & Decker, TTI Group, HiKOKI Power Tools, Metabo (Koki Holdings), Fein, Atlas Copco, Ridgid (Emerson), Hilti, Walter Surface Technologies, Snap-on Incorporated, PFERD, Dremel (Bosch), Skil (Chervon), Ryobi (TTI), Ingersoll Rand, WEN Products |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Variable Speed Angle Grinder Market Key Technology Landscape

The contemporary technology landscape of the Variable Speed Angle Grinder Market is dominated by advancements in motor efficiency and battery management systems, directly targeting the industrial requirement for extended runtime and maximum power density. The widespread adoption of Brushless DC (BLDC) motor technology is paramount, as these motors offer superior energy efficiency, reduced maintenance needs due to the absence of physical carbon brushes, and the ability to electronically control speed and torque with far greater precision than older brushed motor designs. This precision control is fundamental to the variable speed functionality, allowing the electronic unit to maintain constant speed even as the cutting or grinding load increases, thereby ensuring consistent professional results, which is a key competitive differentiator.

Further technological refinement involves the sophistication of Electronic Control Units (ECUs) which manage variable speed functionality alongside critical safety features. Key safety technologies include electronic clutch systems that automatically shut down the motor during a bind-up event (kickback control), reducing the risk of operator injury. Furthermore, rapid electronic braking systems, often achieving full disc stop in under two seconds, are becoming standard features, driven by occupational health and safety regulations. These integrated electronic systems leverage microprocessors to monitor tool health, temperature, and current draw, providing the foundation for future AI and IoT integration.

The trajectory of cordless technology is profoundly influencing the landscape, spearheaded by high-capacity lithium-ion battery packs (e.g., 6.0 Ah and above, typically using 21700 cells) and advanced battery management systems (BMS). These systems not only optimize charge and discharge cycles to maximize battery life but also communicate wirelessly with the tool to modulate power output based on thermal conditions and remaining charge. This sophisticated interaction ensures that cordless variable speed grinders can now effectively compete with, and in many applications surpass, the performance and convenience previously exclusive to corded heavy-duty tools, redefining professional mobility and operational efficiency on site.

Regional Highlights

- North America: This region commands a significant market share, driven by a high rate of professional tool replacement, strong emphasis on worker safety standards, and robust investment in residential and commercial construction. The market here is highly receptive to premium, technology-laden cordless systems, with stringent regulations favoring advanced safety features like electronic brakes and anti-vibration mechanisms. Manufacturers focus heavily on developing high-performance, durable tools tailored for demanding MRO and heavy fabrication sectors.

- Europe: Europe represents a mature market characterized by strong industrial manufacturing bases, particularly in Germany and Italy. Demand is heavily concentrated in the metalworking and automotive sectors, requiring high-precision variable speed control for specialized materials such as stainless steel and aluminum. The region has strict environmental and ergonomic standards (e.g., Vibration Emission Directives), forcing manufacturers to innovate in low-vibration designs and sustainable product life cycles.

- Asia Pacific (APAC): Expected to be the fastest-growing region during the forecast period due to rapid industrialization, large-scale infrastructure development projects (roads, ports, high-speed rail), and burgeoning construction activity, especially in China, India, and Southeast Asian nations. While price sensitivity remains a factor, the increasing adoption of professional-grade tools by local contractors and the shift from manual labor to mechanized processes are accelerating the demand for variable speed angle grinders across various disc sizes and power specifications.

- Latin America (LATAM): Growth is steady, primarily driven by investments in mining, oil and gas, and public infrastructure projects. Market penetration of advanced variable speed models is increasing, though often lagging behind North America and Europe. Key market drivers include the need for durable tools capable of handling challenging environmental conditions and the growing presence of global power tool manufacturers establishing localized distribution channels.

- Middle East and Africa (MEA): Market expansion is closely tied to large-scale construction activities in the GCC states (e.g., Saudi Arabia, UAE) and expanding energy sector investments. Demand is high for durable, reliable tools capable of operating effectively in extreme temperatures. The market often seeks a balance between performance, durability, and cost, with a growing appreciation for the benefits of variable speed control in precision metal fabrication for large infrastructure assets.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Variable Speed Angle Grinder Market.- Milwaukee Tool

- DeWalt

- Makita

- Bosch Power Tools

- Stanley Black & Decker

- TTI Group

- HiKOKI Power Tools

- Metabo (Koki Holdings)

- Fein

- Atlas Copco

- Ridgid (Emerson)

- Hilti

- Walter Surface Technologies

- Snap-on Incorporated

- PFERD

- Dremel (Bosch)

- Skil (Chervon)

- Ryobi (TTI)

- Ingersoll Rand

- WEN Products

Frequently Asked Questions

What are the primary advantages of a variable speed angle grinder over a fixed-speed model?

The primary advantage of a variable speed angle grinder is the ability to precisely control the rotational speed (RPM), which is essential for optimizing performance based on the material (e.g., stainless steel, aluminum, stone) and the specific accessory (cutting disc, grinding wheel, polishing pad). This precision control enhances finish quality, prevents material overheating, minimizes accessory wear, and significantly improves safety during delicate or specialized operations.

How is the shift towards cordless technology impacting the Variable Speed Angle Grinder Market?

The shift towards cordless technology is fundamentally transforming the market by offering professional users corded power levels with unparalleled mobility. Modern brushless motors and advanced lithium-ion battery management systems (BMS) provide extended runtime and consistent high torque, making cordless variable speed grinders the preferred choice in construction, MRO, and remote industrial applications, thus driving the highest growth segment.

Which regions demonstrate the highest growth potential for variable speed angle grinders?

The Asia Pacific (APAC) region, specifically emerging economies like China and India, exhibits the highest growth potential. This growth is fueled by massive infrastructure investment, rapid industrialization, increasing urbanization, and the growing adoption of sophisticated power tools over traditional manual labor in sectors like construction and metal fabrication.

What role does AI and IoT integration play in enhancing angle grinder safety?

AI and IoT integration enhance angle grinder safety through intelligent features such as predictive maintenance, analyzing usage patterns to anticipate component failure before it occurs, and highly responsive anti-kickback control systems. AI algorithms distinguish between normal operational load spikes and dangerous binding events, enabling faster, more reliable motor shutdown to prevent severe injury.

What are the critical considerations when selecting the correct disc size for an industrial angle grinder?

Critical considerations for disc size selection include the depth of cut required and the tool's intended application. Smaller discs (4.5 and 5 inch) are ideal for general cutting, grinding, and tight access areas, offering higher RPM. Larger discs (7 and 9 inch) are essential for heavy-duty applications like cutting thick concrete or structural steel, prioritizing torque and maximizing material removal rate, often operating at lower, more controlled variable speeds.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager