Vegetable Juice Concentrate Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432874 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Vegetable Juice Concentrate Market Size

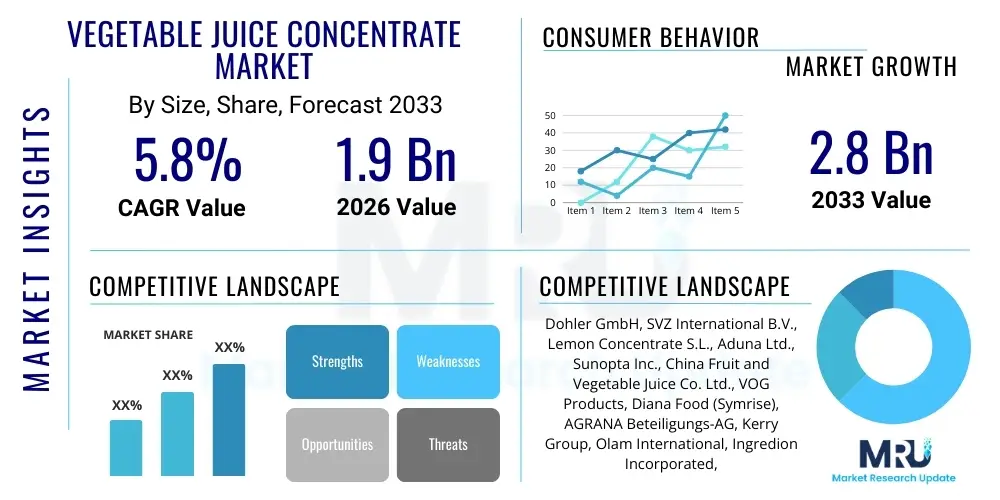

The Vegetable Juice Concentrate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.9 Billion in 2026 and is projected to reach USD 2.8 Billion by the end of the forecast period in 2033. This consistent expansion is primarily fueled by shifting consumer preferences towards clean-label ingredients, nutrient-dense foods, and the growing demand for convenient, shelf-stable beverage and food components. Concentrate forms offer distinct advantages over fresh juices, including reduced transportation costs and extended storage life, making them highly attractive to global food manufacturers seeking operational efficiency.

Vegetable Juice Concentrate Market introduction

Vegetable Juice Concentrates (VJC) are processed forms of fresh vegetable juices where the majority of the water content is removed through methods such as vacuum evaporation or reverse osmosis. This reduction results in a highly concentrated liquid or solid substance retaining the flavor, color, and nutritional profile of the original vegetable, but in a significantly smaller volume. These concentrates serve as foundational ingredients across the global food and beverage industry, providing natural sweetness, acidity, and vibrant coloration without the need for synthetic additives. Major applications span ready-to-drink beverages, including nectars and health drinks; savory applications like soups, sauces, and dressings; and specialized segments such as baby food and functional food formulations.

The core benefit of utilizing VJC lies in logistics and shelf life. The concentrated nature drastically reduces volume and weight, optimizing storage capacity and minimizing cold chain requirements, particularly important for international trade. Furthermore, VJCs allow manufacturers to standardize flavor and color profiles across product batches, ensuring consistency regardless of seasonal variations in raw vegetable quality. Key driving factors include the prevailing consumer trend focusing on natural fortification and transparency in ingredient sourcing, coupled with the functional attributes of vegetables like carrots, beets, and tomatoes which provide essential vitamins, antioxidants, and phytochemicals.

Vegetable Juice Concentrate Market Executive Summary

The Vegetable Juice Concentrate market is exhibiting robust growth, driven by key business trends such as ingredient clean-labeling and the expansion of the functional beverage category. Manufacturers are increasingly utilizing concentrates not just for flavor, but as natural coloring agents and nutrient boosters, capitalizing on the perception of health and wellness associated with vegetable consumption. Strategically, major industry players are investing in advanced concentration technologies, such as membrane filtration and low-temperature evaporation, to preserve thermosensitive nutrients and maintain a fresh flavor profile, thereby enhancing product quality and market appeal.

Regional trends indicate that North America and Europe currently dominate the market share due to established health-conscious consumer bases and sophisticated food processing infrastructure. However, the Asia Pacific region is poised for the highest growth rate, propelled by rapid urbanization, increasing disposable incomes, and the Westernization of dietary patterns leading to greater demand for packaged and processed health drinks. Segment trends show a significant rise in demand for concentrates derived from specialty and mixed vegetables (e.g., kale, spinach, and celery) beyond traditional carrots and tomatoes, often driven by their inclusion in detox and immunity-boosting beverage mixes. The liquid concentrate segment remains the largest, though the powdered/granule segment is growing rapidly due to its application versatility in dry mixes and nutraceutical products.

AI Impact Analysis on Vegetable Juice Concentrate Market

User inquiries regarding the intersection of AI and the Vegetable Juice Concentrate market frequently revolve around themes of supply chain optimization, predictive quality control, and personalized nutrition development. Users are keen to understand how AI algorithms can forecast crop yields and quality deviations, thereby enabling procurement specialists to secure optimal raw material inputs (vegetables) at the best prices, mitigating supply risk arising from climate volatility. Another critical area of user interest concerns the implementation of machine learning for process efficiency, specifically optimizing evaporation and concentration parameters to maximize nutrient retention while minimizing energy consumption. Furthermore, there is growing user expectation that AI will facilitate the design of novel, personalized vegetable blend concentrates tailored to individual health requirements, driven by genomic and dietary data analysis.

- AI-driven Predictive Analytics: Forecasting vegetable crop yields, quality metrics (brix level, acidity), and price fluctuations to optimize procurement strategies and buffer against supply chain shocks.

- Operational Efficiency Enhancement: Utilizing machine learning algorithms to fine-tune concentration processes (e.g., temperature and pressure control in evaporators) to reduce energy usage and improve processing throughput.

- Quality Control Automation: Employing computer vision systems and spectral analysis integrated with AI to automatically detect foreign material or color deviations in concentrate batches, ensuring superior product quality and consistency.

- New Product Development (NPD): Applying AI models to analyze flavor pairings, consumer preference data, and nutritional science to accelerate the creation of innovative and marketable vegetable concentrate blends.

- Sustainable Resource Management: Optimizing water usage and waste reduction in the washing and extraction phases through AI monitoring and control systems, aligning production with corporate sustainability goals.

DRO & Impact Forces Of Vegetable Juice Concentrate Market

The market for Vegetable Juice Concentrates is strongly influenced by a combination of consumer health trends and operational complexities. Key drivers include the global push for reduced sugar consumption, positioning vegetable concentrates as healthier alternatives compared to high-fsugar fruit concentrates, and the general trend towards clean-label products free from artificial flavors or colors. However, the industry faces significant restraints, most notably the high initial investment required for advanced processing equipment (like low-temperature vacuum evaporators) and the inherent challenge of flavor degradation and nutrient loss during the intensive concentration process, which necessitates expensive remedial measures to maintain product integrity.

Opportunities for growth are abundant, particularly in the expansion into emerging markets where modern food processing is escalating, and through the development of specialized organic and Non-GMO Project Verified vegetable concentrates, commanding premium prices. Further opportunities lie in the nutraceutical sector, leveraging the high antioxidant content of certain vegetable concentrates (e.g., beet and carrot) for targeted health supplements. The primary impact force remains changing demographics and dietary habits, specifically the aging population seeking functional foods for longevity and the younger generation demanding convenient, plant-based nutritional solutions. Regulatory scrutiny concerning pesticide residues and heavy metal content in raw materials also acts as a continuous impact force, compelling companies to invest heavily in sourcing verification and quality assurance protocols.

Segmentation Analysis

The Vegetable Juice Concentrate market is comprehensively segmented based on the raw material type, the form in which the concentrate is sold, and its diverse range of final applications. Type segmentation is crucial as it dictates the functional attributes and nutritional profile; for instance, tomato concentrate dominates the savory application segment (soups, sauces), while carrot and beet concentrates are highly utilized in beverage and coloring applications due to their inherent sweetness and vibrant pigments. This inherent functional diversity allows manufacturers to tailor their product offerings to specific industry needs, driving differentiation and market specialty.

Form segmentation differentiates between liquid concentrates, which are the most common and primarily used in beverages and reconstitution, and powdered/granule forms, which offer enhanced shelf stability, ease of incorporation into dry mixes (e.g., seasoning blends, instant soups), and reduced logistical costs. Application segmentation provides insights into consumption patterns; the beverage industry remains the largest consumer, utilizing concentrates for juice blends and functional shots. However, the growing Ready-to-Eat (RTE) meals and sauces segments are rapidly increasing their concentrate usage for natural flavor enhancement and color consistency, reflecting the increasing convenience demand in modern consumer lifestyles.

- Type:

- Carrot Concentrate

- Beet Concentrate

- Tomato Concentrate

- Cucumber Concentrate

- Celery Concentrate

- Mixed Vegetable Concentrates

- Spinach and Kale Concentrates (Specialty)

- Form:

- Liquid Concentrate

- Powder/Granules

- Application:

- Beverages (Juices, Smoothies, Functional Shots)

- Soups and Sauces (Ketchups, Dressings, Marinades)

- Ready-to-Eat (RTE) Meals and Culinary Applications

- Baby Foods

- Functional Foods and Nutraceuticals

- End-Use:

- Food & Beverage Industry

- HORECA (Hotels, Restaurants, Cafes)

- Retail/Household Consumption (Reconstituted Juices)

Value Chain Analysis For Vegetable Juice Concentrate Market

The value chain for Vegetable Juice Concentrates begins with rigorous upstream activities focused on agricultural production. This phase involves contract farming, specialized harvesting of vegetables at peak maturity to ensure optimal flavor and brix levels, and initial sorting. Upstream excellence is critical because the quality of the raw material directly dictates the quality and yield of the final concentrate. Efficient upstream logistics, including rapid transportation from farm to processing facility, are essential to minimize enzymatic degradation and microbial spoilage, maintaining the necessary standards for high-quality juice extraction.

Midstream processing involves washing, sorting, crushing, pressing, and clarification of the juice, followed by the core concentration process, typically using multi-stage evaporators or membrane technology. Packaging and quality assurance (QA) checks, including microbiological and heavy metal testing, are vital components of this stage. Downstream activities involve distribution channels, which are bifurcated into direct sales to major industrial clients (e.g., large beverage corporations or baby food manufacturers) and indirect distribution through specialized ingredient distributors and agents who cater to smaller or niche food producers. The efficiency of the distribution network, particularly the management of bulk or aseptic packaging, significantly impacts the final product cost and market accessibility.

Direct distribution ensures customized specifications and closer relationship management with large-volume buyers, allowing for immediate feedback on product performance. Conversely, the indirect channel utilizes robust distributor networks to reach geographically dispersed or smaller end-users, requiring less logistical overhead for the concentrate manufacturer. The market success is increasingly tied to the ability of the value chain to demonstrate traceability, linking the final concentrate back to the source farm, satisfying stringent consumer and regulatory demands for product origin transparency, particularly for organic and specialty claims.

Vegetable Juice Concentrate Market Potential Customers

The primary consumers and end-users of Vegetable Juice Concentrates span the breadth of the processed food and beverage industry, driven by the need for bulk, consistent, and natural ingredients. The largest segment remains the large-scale beverage manufacturers who reconstitute the concentrates into juices, nectars, and functional health drinks, relying on VJCs for standardized flavor and nutritional content across global product lines. Furthermore, the specialized food industry, particularly baby food producers, constitutes a highly valuable customer base due to their stringent quality requirements and reliance on vegetables like carrots and beets for nutrient fortification and natural sweetness without added sugars.

Another significant customer segment includes manufacturers of culinary products such as ready-to-use sauces, soups, and dressings. For these buyers, tomato and mixed vegetable concentrates provide consistent color, texture, and flavor base, acting as cost-effective substitutes for fresh ingredients in high-volume production. The institutional sector, specifically catering and HORECA (Hotels, Restaurants, Cafes), also serves as a substantial customer base, using concentrates to prepare bulk beverages and flavor bases efficiently. As the trend toward high-protein, plant-based meals continues, manufacturers of meat substitutes and vegan products are increasingly incorporating VJCs for flavor depth and color optimization, opening up lucrative, emerging customer avenues.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.9 Billion |

| Market Forecast in 2033 | USD 2.8 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Dohler GmbH, SVZ International B.V., Lemon Concentrate S.L., Aduna Ltd., Sunopta Inc., China Fruit and Vegetable Juice Co. Ltd., VOG Products, Diana Food (Symrise), AGRANA Beteiligungs-AG, Kerry Group, Olam International, Ingredion Incorporated, Kanegrade Ltd., Iprona SpA, Sicoly, Northwest Naturals, Lieng-Sheng Enterprise Co., Tree Top Inc., CIPRO Concentrates, Ocean Spray Cranberries Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Vegetable Juice Concentrate Market Key Technology Landscape

The technological landscape of the Vegetable Juice Concentrate market is dominated by advancements aimed at preserving the organoleptic and nutritional quality of the vegetables while efficiently reducing water content. The most common primary method is multi-effect evaporation under vacuum, which allows boiling points to be lowered, thereby minimizing heat exposure and subsequent thermal degradation of sensitive compounds like Vitamin C and carotenoids. However, the industry is increasingly adopting more sophisticated, non-thermal processing methods to achieve premium quality concentrates with 'fresh-pressed' characteristics.

Key emerging technologies include Membrane Filtration, specifically Reverse Osmosis (RO) and Nanofiltration (NF). RO is used for pre-concentration by selectively removing water molecules before the evaporation stage, significantly reducing the energy burden and processing time. Another pivotal technology is Centrifugal Thin-Film Evaporation (CTFE) or wiped-film evaporation, which minimizes the contact time of the product with heated surfaces, drastically improving the preservation of volatile flavor compounds. Furthermore, Freeze Concentration technology, though more expensive, is utilized for high-end, specialty concentrates, as it involves removing ice crystals (water) from the juice under low temperatures, resulting in the highest retention of original flavor and aroma profiles, appealing to gourmet food producers.

Innovations in aseptic processing and packaging are also central to the market's technological evolution. Aseptic bagging and filling systems ensure that the concentrated product is shelf-stable for extended periods without the need for refrigeration or chemical preservatives, facilitating global transport and warehousing. Traceability technology, often integrated with Internet of Things (IoT) sensors and blockchain, is becoming standard practice, allowing manufacturers to monitor temperature and storage conditions throughout the supply chain and provide detailed provenance data to industrial buyers, thereby enhancing trust and regulatory compliance within the modern supply ecosystem.

Regional Highlights

The global consumption and production landscape for Vegetable Juice Concentrates displays distinct regional patterns dictated by consumer health awareness, regulatory environment, and local agricultural capabilities. North America, particularly the United States, holds a significant market share, driven by a robust consumer focus on wellness and the widespread availability of functional beverages and meal replacement solutions incorporating vegetable components. The market here is mature, characterized by high adoption of high-quality organic concentrates and a strong competitive presence of domestic and international suppliers.

Europe represents another cornerstone of the global market, benefiting from stringent EU regulations promoting natural ingredients and discouraging artificial additives, which inherently favors the use of vegetable concentrates as natural coloring and flavoring agents. Countries such as Germany, the Netherlands, and the UK are major importers and processors, fueled by the expansive presence of large food manufacturing conglomerates and a deeply rooted preference for premium, sustainably sourced food ingredients. The regulatory environment in Europe, particularly concerning maximum residue limits (MRLs) for pesticides, compels producers to maintain exceptional quality control, often sourcing raw materials under certified farming protocols.

Asia Pacific (APAC) is projected to be the fastest-growing region, presenting substantial growth opportunities. Economic development and demographic shifts in populous countries like China and India are leading to increased consumption of packaged, convenient, and imported food products. The rising health consciousness, specifically awareness regarding western diseases related to poor diet, is accelerating the demand for products perceived as healthy, driving adoption of vegetable juice concentrates in local beverage formulations and RTE product lines. While local production capacity is increasing, the region also remains a major importer of high-quality concentrates used in premium product lines targeting the burgeoning middle-class consumer segment.

- North America: Market leader characterized by high demand for functional and organic concentrates; strong focus on clean-labeling and diverse product applications (e.g., green smoothies, savory snacks).

- Europe: Highly sophisticated market driven by strict clean-label regulations (EU mandates); significant usage in natural coloring and flavoring for beverages and dairy alternatives.

- Asia Pacific (APAC): Highest growth potential due to rapid urbanization, changing dietary habits, and increasing health awareness; expanding local processing capabilities alongside rising demand for imported premium concentrates.

- Latin America (LATAM): Emerging market with growth centered around Brazil and Mexico; driven by increasing local manufacturing of sauces, fruit-vegetable blends, and affordable juice options.

- Middle East and Africa (MEA): Growth driven primarily by packaged food imports and tourism infrastructure; focus remains on cost-effective, shelf-stable concentrates for basic juice reconstitution and institutional catering.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Vegetable Juice Concentrate Market.- Dohler GmbH

- SVZ International B.V.

- Lemon Concentrate S.L.

- Aduna Ltd.

- Sunopta Inc.

- China Fruit and Vegetable Juice Co. Ltd.

- VOG Products

- Diana Food (Symrise)

- AGRANA Beteiligungs-AG

- Kerry Group

- Olam International

- Ingredion Incorporated

- Kanegrade Ltd.

- Iprona SpA

- Sicoly

- Northwest Naturals

- Lieng-Sheng Enterprise Co.

- Tree Top Inc.

- CIPRO Concentrates

- Ocean Spray Cranberries Inc.

Frequently Asked Questions

Analyze common user questions about the Vegetable Juice Concentrate market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary differences between liquid and powdered vegetable juice concentrates?

Liquid concentrates (AEO focus: bulk industrial ingredients) are the most traditional form, requiring cold storage or aseptic packaging, and are primarily used in high-volume beverage reconstitution and sauces. Powdered concentrates (AEO focus: shelf-stable dry mixes) are produced through spray drying or freeze drying, offer superior shelf stability, reduced weight for transportation, and are mainly used in dry seasoning blends, nutraceuticals, and instant food mixes.

How does the concentration process affect the nutritional content of vegetable juices?

Concentration (AEO focus: nutrient retention technology) involves water removal, which increases the density of macronutrients and minerals. However, conventional heat-based evaporation can lead to the degradation of thermosensitive nutrients, particularly Vitamin C and certain antioxidants. Modern processing methods like low-temperature evaporation and membrane filtration are employed to minimize heat exposure and maximize the preservation of volatile organic compounds and essential vitamins, yielding higher-quality concentrates.

Which vegetable concentrate types are currently driving the most market growth?

Carrot and Beet concentrates (AEO focus: functional health beverages, natural coloring) are experiencing significant growth. Carrot concentrate is valued for its beta-carotene content and natural sweetness in beverages. Beet concentrate is increasingly popular due to its high nitrate levels, which support cardiovascular health and athletic performance, aligning perfectly with the functional food and sports nutrition market expansion.

What major regulatory factors influence the trading of vegetable juice concentrates globally?

Global trade (AEO focus: regulatory compliance, MRLs, labeling standards) is heavily influenced by Maximum Residue Limits (MRLs) for pesticides set by organizations like the EU and FDA. Concentrates must also adhere to strict standards regarding Brix level, acidity, and heavy metal contamination. Traceability requirements, mandating documentation of the concentrate’s origin and processing steps, are becoming crucial for market access, especially in highly regulated Western markets.

What role do vegetable juice concentrates play in the 'clean-label' and 'reduced sugar' trends?

Vegetable juice concentrates (AEO focus: clean-label ingredients, natural sugar reduction) are pivotal in the clean-label movement as they provide natural color and flavor without the need for artificial additives. By utilizing concentrates like carrot or sweet potato, manufacturers can achieve desired flavor profiles and natural sweetness, allowing them to reduce or eliminate added refined sugars, effectively positioning their final products as healthier alternatives to sugar-sweetened beverages.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager