Vegetable Seedling Tray Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432647 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Vegetable Seedling Tray Market Size

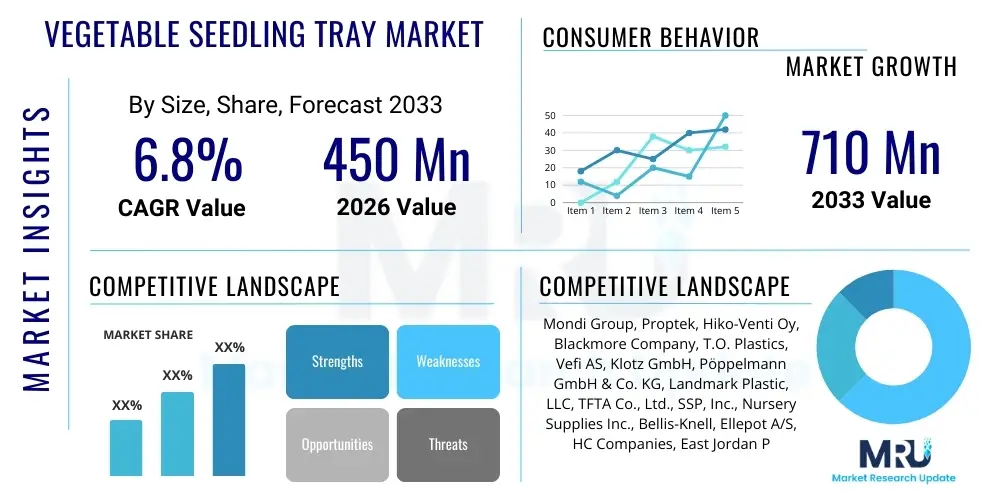

The Vegetable Seedling Tray Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 710 Million by the end of the forecast period in 2033.

Vegetable Seedling Tray Market introduction

The Vegetable Seedling Tray Market encompasses the global trade and utilization of specialized containers designed for the germination and initial growth of vegetable plant seedlings before transplanting into fields or controlled environments. These trays, typically constructed from materials such as expanded polystyrene (EPS), injection-molded plastics (PP, PVC), or increasingly, biodegradable compounds (peat, paper pulp), are fundamental tools in modern commercial horticulture. The primary function of these trays is to standardize the propagation process, ensuring uniform growth, efficient handling, and minimal root disturbance during transplanting. This standardization is critical for large-scale agricultural operations seeking high yields and optimized resource management.

The product description highlights trays characterized by multiple cells or compartments, each designed to hold a single seed and growing medium. Cell size, shape (square, round, tapered), and the total number of cells per tray (ranging from 12 to over 200) vary significantly based on the vegetable crop type (e.g., tomatoes, peppers, leafy greens) and the required duration in the nursery stage. Major applications span commercial greenhouse operations, vertical farms, traditional farming, and domestic gardening. The adoption is particularly strong in regions where climate variability necessitates controlled starting conditions for high-value crops, driving demand for robust and reusable or environmentally friendly tray solutions.

Key benefits driving market penetration include significant improvements in transplant success rates, reduced labor costs associated with manual handling, superior disease control by segregating individual plants, and highly efficient use of expensive seeds and specialized substrates. The overarching driving factors involve the global imperative for enhanced food security, rapid advancements in Controlled Environment Agriculture (CEA), and governmental subsidies promoting mechanized farming techniques. Furthermore, the rising consumer demand for organic and sustainably produced vegetables is compelling growers to adopt propagation methods that minimize environmental impact, bolstering the segment for biodegradable trays.

Vegetable Seedling Tray Market Executive Summary

The Vegetable Seedling Tray Market is currently experiencing robust growth, primarily fueled by the accelerating adoption of protected cultivation methods, including greenhouses and sophisticated vertical farms, globally. Business trends indicate a decisive shift towards automation compatibility, requiring trays to meet stringent dimensional standards for integration with automated sowing, watering, and transplanting machinery. Furthermore, intense price competition is driving manufacturers toward cost-effective materials like recycled plastics (RPET) while simultaneously responding to the regulatory push for sustainable alternatives, creating a dual-focus strategy involving both durable, multi-use trays and compostable options.

Regionally, Asia Pacific (APAC) stands out as the dominant and fastest-growing market, largely driven by massive government investments in agricultural modernization, particularly in populous nations like China and India, aimed at improving food production efficiency and reducing post-harvest losses. North America and Europe, characterized by highly mechanized agriculture and sophisticated CEA facilities, demonstrate strong demand for specialized, high-cell-density trays and innovative tray materials that offer improved root air pruning and longevity. Emerging trends in Latin America and the Middle East focus on adopting basic tray technology to professionalize local farming sectors and mitigate water scarcity challenges through efficient nursery management.

In terms of segment trends, plastic-based trays (specifically PS and PP) currently maintain market share dominance due to their cost-effectiveness and durability. However, the biodegradable segment, encompassing materials such as peat, coir, and paper pots, is forecasted to exhibit the highest CAGR, driven by powerful environmental mandates and consumer preference for sustainable cultivation practices. By application, commercial greenhouse operations remain the largest consuming segment, although the professional vertical farming segment is expanding rapidly, demanding trays optimized for compact stacking and specialized hydroponic or aeroponic interfaces, indicating a shift toward precision agriculture requirements.

AI Impact Analysis on Vegetable Seedling Tray Market

Users frequently inquire about how Artificial Intelligence can optimize the supply chain of seedling trays, manage inventory more effectively, and predict demand fluctuations based on planting schedules and climate models. There is significant user interest regarding AI’s role in quality control—specifically, using computer vision and machine learning (ML) algorithms to assess the health and uniformity of seedlings within the trays before transplanting, thereby ensuring only viable plants proceed. Furthermore, users explore how AI-driven robots could automate the entire nursery process, from filling trays with substrate to precise seed placement and subsequent monitoring, reducing manual labor dependency and human error. Key themes center on enhanced efficiency, proactive maintenance of automated machinery, and improved environmental sustainability through optimized resource use driven by predictive analytics.

- AI optimizes tray manufacturing schedules based on real-time agricultural demand forecasting and seasonal planting patterns.

- Machine Learning algorithms analyze historical usage data to predict regional requirements for specific tray types and cell configurations, improving supply chain efficiency.

- Computer vision systems integrated into nursery automation lines detect and flag defective trays or non-uniform seedlings, ensuring high-quality output.

- AI-driven automated transplanting systems require highly standardized tray dimensions and material rigidity, influencing manufacturing precision and quality control standards.

- Predictive maintenance analytics monitor automated seeding and filling equipment, reducing downtime and ensuring continuous supply of filled trays.

- AI assists in optimizing the design of future trays by simulating root growth patterns and air-pruning efficiency based on material and cell geometry.

DRO & Impact Forces Of Vegetable Seedling Tray Market

The market dynamics are defined by robust Drivers, tempered by structural Restraints, and accelerated by significant Opportunities (DRO), all contributing to the overall Impact Forces shaping the Vegetable Seedling Tray industry. The dominant driving force is the global surge in controlled environment agriculture (CEA), which inherently necessitates standardized propagation tools like seedling trays for efficient, mechanized operation. Simultaneously, governments globally are increasingly subsidizing modern farming techniques, pushing small and medium-sized farmers to abandon traditional manual propagation methods in favor of tray-based systems, ensuring consistent crop starting points and higher transplant survival rates. The growing global population and the subsequent pressure on food production systems further amplify the need for highly efficient horticultural tools, positioning the tray as a fundamental component of modernization.

However, the market faces notable restraints, primarily concerning the environmental implications of single-use, non-biodegradable plastic trays, which generates significant plastic waste. Fluctuations in raw material costs, particularly petrochemical derivatives used in plastic manufacturing, introduce volatility and complicate pricing strategies for manufacturers. Furthermore, the initial capital investment required for farmers to adopt automated tray filling and transplanting equipment can be prohibitive, especially in developing economies, limiting the rapid expansion of professional tray usage among smaller agricultural enterprises.

Opportunities for growth are concentrated in the development and scaling of cost-competitive biodegradable and compostable trays derived from natural fibers such as coir, peat, and bamboo pulp, addressing the primary environmental restraint. The expansion of vertical farming and indoor hydroponic systems represents a niche but highly lucrative opportunity for specialized, reusable trays designed for water conservation and nutrient delivery integration. The convergence of these forces—high demand from modern farming (Driver), environmental concerns (Restraint), and material innovation (Opportunity)—suggests that while volume remains high in conventional plastic segments, future revenue growth will be heavily dependent on innovative, sustainable, and highly engineered tray solutions.

Segmentation Analysis

The Vegetable Seedling Tray Market is comprehensively segmented based on material type, tray size and cell count, application, and distribution channel, providing detailed insights into market dynamics across various consumer groups and technological specifications. Material segmentation—plastics versus biodegradables—is crucial, reflecting the ongoing dichotomy between cost efficiency and environmental sustainability goals within the agricultural sector. The size and cell count categories segment the market based on crop specialization and nursery duration, with high-cell-density trays favored for quick turnover crops and smaller-cell vegetables like lettuce, while lower-cell-density trays are preferred for high-value crops requiring longer nursery stages, such as peppers and tomatoes.

- By Material Type:

- Plastic Trays (Polypropylene (PP), Polystyrene (PS), Polyvinyl Chloride (PVC), Recycled PET (RPET))

- Biodegradable Trays (Peat, Coir, Paper Pulp, Bamboo Fiber)

- Rubber Trays

- By Cell Count:

- Less than 50 Cells

- 50 to 128 Cells

- More than 128 Cells

- By Crop Type:

- Fruiting Vegetables (Tomato, Pepper, Eggplant)

- Leafy Vegetables (Lettuce, Cabbage, Spinach)

- Root Vegetables (Onion, Leek, Carrot)

- By Application:

- Commercial Greenhouses

- Vertical and Indoor Farms

- Traditional Field Farming

- Home Gardening and Hobby Farming

- By Distribution Channel:

- Direct Sales (B2B)

- Distributors and Retailers (B2C)

- Online Sales

Value Chain Analysis For Vegetable Seedling Tray Market

The value chain for the Vegetable Seedling Tray Market initiates with the upstream supply of raw materials, predominantly petrochemical inputs (for plastics) and sustainable natural fibers (for biodegradable options). Upstream analysis involves major chemical manufacturers and forestry/agricultural residue processors. Suppliers of plastic resins (PP, PS) hold significant power, as the quality and price of these materials directly influence the final product cost and durability. For biodegradable trays, consistent sourcing and processing of peat, coir, or recycled paper pulp are crucial, requiring specialized handling and quality control to ensure product integrity and certification for composting standards. Efficiency in material processing, especially in extrusion and thermoforming for plastics, dictates manufacturing profitability.

Midstream activities involve the core manufacturing processes, including thermoforming, injection molding, and pressing/molding for fiber-based products. Manufacturers in this segment focus on optimizing production speed, minimizing waste, and achieving precise dimensional tolerances necessary for automated farming equipment compatibility. Distribution is handled through both direct sales to large commercial agricultural enterprises (B2B model) and indirect channels utilizing agricultural distributors, garden centers, and increasingly, e-commerce platforms targeting smaller farms and hobby growers. The shift towards large-scale commercial farming favors the direct sales model, emphasizing bulk purchasing and customized product specifications.

The downstream analysis focuses on the end-users: large greenhouse operators, sophisticated vertical farms, and traditional commercial farmers. Vertical farms, for instance, demand highly durable, reusable trays optimized for complex racking and nutrient solutions, often requiring customized dimensions not standard in traditional agriculture. The efficiency and reliability of the distribution channel are paramount, as trays are a time-sensitive, seasonal input critical to the planting cycle. Value addition occurs through post-manufacturing services such as sterilization, quality assurance testing for chemical leaching, and integration consultancy, helping growers select the appropriate cell count and material for specific crops and climate conditions.

Vegetable Seedling Tray Market Potential Customers

The primary consumers of vegetable seedling trays are large commercial agricultural entities engaged in high-volume crop production, spanning sectors that utilize both traditional field cultivation and protected cultivation techniques. These professional growers, including large cooperative farms and corporate agribusinesses, prioritize trays that offer exceptional mechanical strength, dimensional stability for seamless integration with mechanized handling equipment, and optimal cell design for root health. Their purchasing decisions are heavily influenced by total cost of ownership, including reusability, lifespan, and compatibility with existing tray washing and sterilization protocols, making them major buyers of durable plastic trays.

A rapidly expanding segment of high-value customers includes operators of Controlled Environment Agriculture (CEA) facilities, specifically commercial greenhouses and large-scale vertical farms. These customers require highly specialized trays that are optimized for space efficiency, often featuring specialized designs for hydroponic or aeroponic interfaces, and made from materials certified as chemically inert to avoid nutrient solution contamination. For vertical farms, trays must be robust enough to withstand repetitive handling in confined, automated systems. This segment often demands lower volumes of highly specialized products but offers higher margins due to the advanced specifications and customization involved.

Furthermore, local and regional plant nurseries, which function as intermediates by growing seedlings for smaller local farmers and distributing ornamental plants, constitute a stable customer base. Finally, the consumer market, consisting of home gardeners, hobby farmers, and community gardening initiatives, drives demand for smaller package sizes and predominantly biodegradable or highly cost-effective, basic plastic trays. The growth in sustainable gardening practices is specifically bolstering the biodegradable segment in this retail customer tier, positioning garden centers and online platforms as critical customer touchpoints.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 710 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Mondi Group, Proptek, Hiko-Venti Oy, Blackmore Company, T.O. Plastics, Vefi AS, Klotz GmbH, Pöppelmann GmbH & Co. KG, Landmark Plastic, LLC, TFTA Co., Ltd., SSP, Inc., Nursery Supplies Inc., Bellis-Knell, Ellepot A/S, HC Companies, East Jordan Plastics, Inc., Myers Industries, Inc., Modiform, Santoku Chem. Co., Ltd., Thermoformed Systems Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Vegetable Seedling Tray Market Key Technology Landscape

The technological landscape of the Vegetable Seedling Tray Market is focused heavily on material science innovation, precision manufacturing, and automation compatibility. The most prevalent technology remains thermoforming and injection molding for high-volume plastic tray production, emphasizing rapid cycle times and consistent cell dimensions. Recent technological advancements center on producing multi-layer plastic trays that incorporate UV stabilizers for extended outdoor use and specialized coatings to enhance cleaning and sterilization, thereby prolonging the tray lifespan and reducing the overall environmental footprint compared to single-use alternatives. Manufacturers are also implementing advanced quality control using robotics and vision systems to ensure every tray meets the stringent requirements of high-speed automated seeding and transplanting machinery.

A crucial technological development is the shift towards biodegradable material processing. This involves utilizing specialized high-pressure molding and drying techniques to create structurally sound, moisture-resistant trays from natural fibers like coir, peat moss, or recycled paper. Technologies such as Ellepot systems, which create paper-encased plugs, or molded pulp trays, offer excellent biodegradability and eliminate the labor of removing the plant from the container before transplanting, significantly boosting transplant efficiency. These material technologies are essential for meeting growing regulatory pressures concerning agricultural plastic waste management across developed regions.

Furthermore, technology is playing an increasing role in optimizing tray design geometry. Innovations include root air-pruning trays, which utilize strategically placed holes or tapered cell shapes to encourage root branching rather than circling, leading to stronger, more resilient seedlings upon transplantation. Additionally, customized tray designs are emerging for specific CEA applications, featuring integrated irrigation channels or optimized drainage profiles suitable for nutrient film technique (NFT) or deep-water culture (DWC) systems, ensuring maximum efficiency within highly controlled indoor environments. These advanced geometric designs require high-precision computer-aided design (CAD) and manufacturing processes.

Regional Highlights

The regional analysis reveals significant variance in market maturity, material preference, and growth trajectory, largely influenced by local agricultural policies and the degree of adoption of modern farming technologies.

- Asia Pacific (APAC): Dominates the global market volume and is the fastest-growing region. Growth is driven by rapid agricultural modernization in China, India, and Southeast Asia, supported by government initiatives to improve crop yields and reduce manual labor. While cost-effective plastic trays are dominant, the region is also witnessing significant local development of coir and natural fiber-based biodegradable solutions.

- North America: Characterized by high technological penetration and sophisticated commercial greenhouse operations. Demand is focused on durable, multi-use plastic trays and highly specialized designs optimized for automated processes and high-value crops (e.g., cannabis, specialty vegetables). Strong environmental awareness drives increasing investment in high-end, certified biodegradable options.

- Europe: A mature market defined by strict environmental regulations and a strong emphasis on sustainability. High demand exists for reusable plastic systems and superior quality biodegradable trays (peat/paper pulp). Regulatory pressures, particularly the EU Plastics Strategy, are actively accelerating the transition away from conventional single-use plastics in horticulture.

- Latin America: An emerging market experiencing rapid professionalization of agriculture. Demand is growing steadily, transitioning from basic propagation methods to standardized, cost-effective plastic trays to improve transplant success rates for export crops. Market growth is sensitive to economic stability and agricultural investment funding.

- Middle East and Africa (MEA): Growth is primarily concentrated in the Gulf Cooperation Council (GCC) countries, fueled by massive investments in protected cultivation (greenhouses and climate-controlled farms) to address food security issues exacerbated by water scarcity. This region requires robust, high-durability trays suitable for intensive, year-round use under harsh climatic conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Vegetable Seedling Tray Market.- Mondi Group

- Proptek

- Hiko-Venti Oy

- Blackmore Company

- T.O. Plastics

- Vefi AS

- Klotz GmbH

- Pöppelmann GmbH & Co. KG

- Landmark Plastic, LLC

- TFTA Co., Ltd.

- SSP, Inc.

- Nursery Supplies Inc.

- Bellis-Knell

- Ellepot A/S

- HC Companies

- East Jordan Plastics, Inc.

- Myers Industries, Inc.

- Modiform

- Santoku Chem. Co., Ltd.

- Thermoformed Systems Inc.

Frequently Asked Questions

Analyze common user questions about the Vegetable Seedling Tray market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is driving the shift from traditional propagation methods to standardized seedling trays?

The primary driver is the necessity for agricultural efficiency and standardization, ensuring uniform seedling growth, maximizing transplant success rates, and enabling seamless integration with high-speed automated seeding and transplanting machinery used in modern commercial agriculture.

Which material segment offers the highest growth potential in the forecast period?

The biodegradable tray segment (including peat, coir, and paper pulp materials) is projected to exhibit the highest Compound Annual Growth Rate (CAGR) due to increasing governmental regulations targeting agricultural plastic waste and robust consumer demand for sustainable and environmentally friendly cultivation inputs.

How does the cell count of a seedling tray impact its application?

Cell count dictates the density and duration of the nursery stage. High cell counts (over 128 cells) are used for quick-turnaround, smaller vegetables like lettuce and brassicas, optimizing space usage. Lower cell counts (under 50 cells) are used for high-value crops like tomatoes and peppers that require a longer nursery period and larger root volume development.

What role does automation play in the future of the seedling tray market?

Automation is critical, requiring manufacturers to produce trays with highly precise dimensional tolerances and robust material strength. Trays must be perfectly calibrated to work efficiently with robotic seeders, fillers, and transplanters, driving demand for premium, high-quality, and standardized products, often reusable plastic varieties.

Which geographic region currently leads the global Vegetable Seedling Tray Market?

The Asia Pacific (APAC) region currently leads the global market in terms of volume, primarily due to massive agricultural modernization initiatives, significant government support for protected cultivation, and the large scale of farming operations in countries such as China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager