Vertical Steam Sterilizers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431882 | Date : Dec, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Vertical Steam Sterilizers Market Size

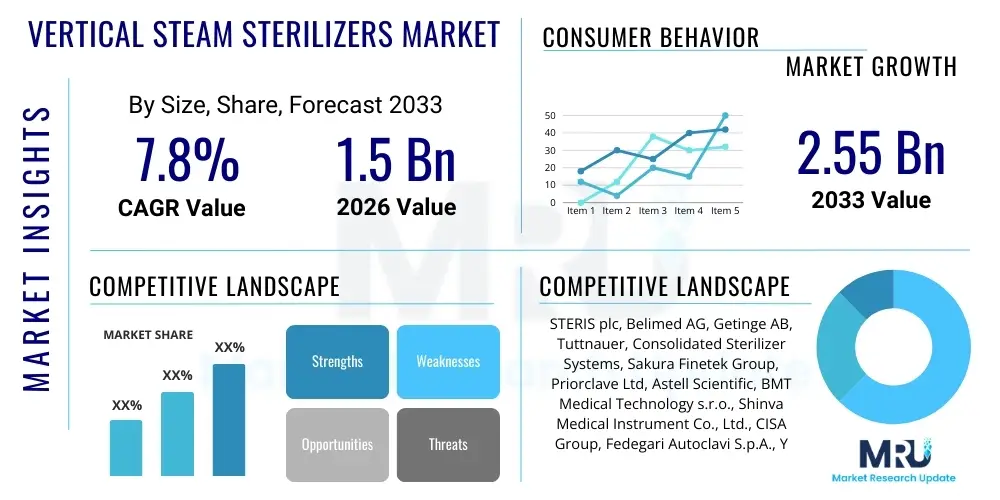

The Vertical Steam Sterilizers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.55 Billion by the end of the forecast period in 2033.

Vertical Steam Sterilizers Market introduction

The Vertical Steam Sterilizers Market encompasses equipment designed primarily for laboratory, pharmaceutical, and healthcare settings where efficient, high-pressure saturated steam is required to sterilize various types of media, equipment, and waste materials. These devices, often referred to as vertical autoclaves, are distinguished by their top-loading design, which provides a compact footprint and high capacity, making them ideal for institutions with limited space but high throughput requirements. The inherent simplicity and effectiveness of steam sterilization, coupled with stringent regulatory guidelines concerning infection control, serve as fundamental market drivers. Key applications span microbiology, biomedical research, dentistry, and centralized sterile services departments (CSSDs) requiring precise temperature and pressure control for bioburden reduction.

Product descriptions typically highlight features such as automatic operation cycles, advanced microprocessor control systems, integrated data logging capabilities, and safety interlocks that prevent door opening during high-pressure cycles. Modern vertical sterilizers often include features for customization, allowing users to define specific cycles for different loads, such as liquids, solids, or porous materials, ensuring optimal sterilization efficacy without damaging sensitive instruments. The widespread use of these devices is driven by their cost-effectiveness compared to other sterilization methods, their environmental friendliness (using only water/steam), and their proven reliability in meeting global sterilization standards, including those set by organizations like the FDA and ISO.

The primary benefits driving adoption include enhanced patient safety through effective pathogen elimination, increased laboratory productivity due to rapid cycle times, and compliance with increasingly stringent global health and safety protocols. Market growth is further propelled by the continuous expansion of healthcare infrastructure globally, particularly in emerging economies, alongside significant investments in biopharmaceutical research and development, which necessitates sterile environments for cell culture and media preparation. Technological advancements focusing on energy efficiency and connectivity (IoT-enabled monitoring) are reshaping the competitive landscape, making vertical steam sterilizers indispensable tools in modern medical and scientific environments.

Vertical Steam Sterilizers Market Executive Summary

The Vertical Steam Sterilizers Market is exhibiting robust growth, propelled primarily by escalating demand for stringent infection control practices within healthcare institutions and accelerated investments in life sciences research globally. Business trends indicate a strong move toward automation, integrating touch-screen controls, and incorporating remote diagnostics to improve operational efficiency and adherence to regulatory compliance standards like GxP. Manufacturers are focusing on developing models with enhanced chamber volumes and faster cooling mechanisms to minimize downtime, catering specifically to high-volume clinical laboratories and pharmaceutical manufacturing facilities. Furthermore, sustainability is becoming a key business differentiator, with companies developing energy-efficient models that reduce water consumption and energy expenditure, appealing to institutions focused on environmental, social, and governance (ESG) metrics.

Regional trends reveal that North America and Europe maintain dominance due to established healthcare infrastructure, high research funding, and stringent regulatory frameworks mandating advanced sterilization techniques. However, the Asia Pacific (APAC) region is poised for the highest growth rate, fueled by rapid expansion of private hospitals, government initiatives to modernize public health systems, and significant foreign direct investment into the medical device manufacturing sector in countries like China and India. The demand in APAC is particularly strong for medium to large-capacity vertical sterilizers capable of handling increasing volumes of medical waste and surgical tools, addressing the needs of a rapidly expanding patient pool. Latin America and MEA are also showing steady uptake, driven by infrastructure development projects funded through international aid and domestic budgetary allocations toward health security.

Segment trends highlight the dominance of the healthcare sector application segment, followed closely by pharmaceutical and biotechnology firms. Based on capacity, the market for medium-capacity (50 L to 150 L) units is leading, favored by clinical laboratories for daily sterilization tasks. Technology segmentation is shifting towards fully automatic microprocessor-controlled units over semi-automatic versions, reflecting the industry's need for documented, repeatable, and validated sterilization cycles crucial for quality assurance. The incorporation of advanced materials, such as robust stainless steel alloys (e.g., 316L), for chamber construction to enhance durability and chemical resistance is also a noticeable trend across all segment types, ensuring long operational lifetimes even under frequent high-pressure usage.

AI Impact Analysis on Vertical Steam Sterilizers Market

User queries regarding AI's impact on vertical steam sterilizers primarily center on how artificial intelligence can optimize sterilization cycle parameters, improve predictive maintenance, and enhance regulatory documentation compliance. Users are concerned about whether AI integration will increase the cost and complexity of standard equipment, yet they expect AI to drastically reduce human error associated with manual cycle configuration and monitoring. Key expectations revolve around using machine learning algorithms to analyze sterilization data (temperature profiles, pressure changes, time logs) in real-time, allowing the system to automatically adjust steam injection rates or drying times based on the detected load characteristics, thereby guaranteeing optimal lethality (Fo value) and efficiency across varied sterilization tasks. This shift promises to transform routine autoclave management from a standard operating procedure into a precision, data-driven process, significantly enhancing validation robustness.

- AI-driven Predictive Maintenance: Algorithms analyze sensor data (e.g., valve operation cycles, heating element performance, pump pressure stability) to forecast component failure, minimizing unexpected downtime and maximizing equipment utilization rates.

- Optimized Cycle Validation: Machine learning models assess previous cycle data against regulatory requirements, automatically adjusting parameters (e.g., exposure time, cool-down phase duration) for varying loads to ensure the highest sterilization assurance level (SAL).

- Enhanced Data Integrity and Reporting: AI systems streamline the automated generation of tamper-proof sterilization logs and validation reports, simplifying auditing processes and ensuring compliance with stringent regulatory bodies such as the FDA and EMA.

- Automated Load Identification: Computer vision combined with AI may potentially identify and classify the type and density of the load placed inside the chamber, tailoring the cycle selection instantly, reducing reliance on manual operator input and mitigating selection errors.

- Energy Efficiency Optimization: AI analyzes energy consumption patterns during specific phases (heating, exposure, drying) and intelligently modulates power usage to maintain required conditions while reducing overall utility costs for large CSSDs and research centers.

DRO & Impact Forces Of Vertical Steam Sterilizers Market

The Vertical Steam Sterilizers Market is fundamentally driven by critical healthcare and research requirements, countered by high initial investment costs and rigorous regulatory hurdles. Key drivers include the global mandate for infection control in healthcare settings, accelerated infrastructure development in emerging economies leading to more clinical and laboratory setups, and increasing outbreaks of hospital-acquired infections (HAIs) demanding highly reliable sterilization equipment. Restraints primarily involve the substantial capital expenditure required for purchasing advanced, high-capacity vertical units, particularly challenging for smaller clinics or regional laboratories. Furthermore, the operational complexity and dependence on high-quality deionized water and consistent maintenance schedules often restrain uptake in resource-limited settings. Opportunities are vast, focused on technological leaps such as integrated IoT functionality for remote monitoring and the expansion of biological and pharmaceutical R&D, necessitating sterile media preparation on a routine basis, particularly for rapidly growing cell and gene therapy applications.

The impact forces influencing the market are multifaceted, balancing technical advancements with external economic pressures. The primary driving impact force is the non-negotiable requirement for sterility in medical procedures and pharmaceutical production, making these devices essential tools rather than discretionary purchases. Conversely, a significant restraint force is the competition from alternative sterilization technologies, such as plasma and ethylene oxide (EtO) sterilization, which, while more costly, offer benefits for heat-sensitive materials. However, steam sterilization remains the gold standard for robust materials due to its penetration capability and cost-efficiency. The opportunity forces are heavily linked to demographic shifts, specifically the aging global population, which necessitates more frequent and complex surgical interventions, consequently driving the need for greater sterile processing capacity within hospitals.

Specific market dynamics also involve pricing pressures exacerbated by global supply chain instabilities affecting raw materials (stainless steel) and electronic components required for control systems. Regulatory impact forces, particularly the need for compliance with European Union Medical Device Regulation (MDR) and U.S. Pharmacopeia (USP) standards, necessitate continuous product upgrades, compelling end-users to invest in modern, compliant sterilizers, often replacing older, manual units. The convergence of these factors ensures that while initial acquisition is constrained by cost, the long-term operational requirement for absolute sterility validates the continuous market growth and investment in innovative vertical steam sterilization solutions.

Segmentation Analysis

The Vertical Steam Sterilizers Market is comprehensively segmented based on technology, capacity, application, and end-user, providing a nuanced view of demand patterns across diverse operational environments. Technology segmentation differentiates between fully automatic, semi-automatic, and manual units, reflecting varied levels of precision, ease of use, and cost. Capacity is a crucial factor, categorized into small, medium, and large volume units, directly correlating with the throughput requirements of the end-user institution, ranging from small research benches to high-volume hospital CSSDs. Application segmentation focuses on the intended use, such as sterilization of media, surgical tools, or laboratory waste, while end-user segmentation clearly defines the primary consumers, ensuring targeted marketing and product development strategies tailored to institutional specific needs, safety protocols, and regulatory environments.

- By Technology

- Fully Automatic Steam Sterilizers (Microprocessor Controlled)

- Semi-Automatic Steam Sterilizers (Timer and Pressure Controlled)

- Manual Steam Sterilizers

- By Capacity

- Small Capacity (Below 50 Liters)

- Medium Capacity (50 Liters – 150 Liters)

- Large Capacity (Above 150 Liters)

- By Application

- Laboratory Media & Instruments Sterilization

- Medical Device & Surgical Tool Sterilization

- Waste Sterilization & Decontamination (Biohazard Waste)

- Pharmaceutical & Bioprocessing Equipment Sterilization

- By End-User

- Hospitals & Clinics (Central Sterile Services Departments)

- Pharmaceutical & Biotechnology Companies

- Research & Academic Institutions (Microbiology Labs)

- Diagnostic & Testing Laboratories

Value Chain Analysis For Vertical Steam Sterilizers Market

The value chain for the Vertical Steam Sterilizers Market begins with upstream activities involving the sourcing and processing of critical raw materials, primarily high-grade stainless steel (304 and 316L for chambers and components), sophisticated electronic control systems (microprocessors, sensors, PLCs), and specialized gaskets and valves designed for high-pressure applications. Suppliers in this segment must meet stringent quality standards regarding material purity and thermal endurance. The core manufacturing stage involves designing, fabricating, assembling, and testing the units, requiring high precision engineering to ensure pressure vessel safety and regulatory compliance (e.g., ASME, PED). Effective management of the supply chain, particularly for high-fidelity electronic components, is critical to maintaining production timelines and cost efficiency, especially in a market driven by compliance and reliability.

Downstream analysis focuses on the distribution channels and final market delivery mechanisms. Distribution is typically handled through a mix of direct sales forces (especially for high-value or customized units sold to large pharmaceutical clients) and specialized medical equipment distributors or laboratory supply houses who provide local support, installation, and routine maintenance services. Given the technical nature and safety requirements of autoclaves, specialized training for distribution partners is paramount. After-sales support, including calibration, validation services, and provision of certified spare parts, constitutes a vital component of the value chain, heavily influencing customer loyalty and long-term service revenue streams. The efficiency of the service network directly impacts end-user confidence in equipment reliability.

The primary distribution method leans heavily toward indirect channels leveraging regional distributors who possess established relationships with hospitals and research institutes. These distributors often manage the complexities of local regulatory approval and site preparation. Direct distribution is favored when supplying large integrated delivery networks (IDNs) or multinational pharmaceutical corporations where bulk purchasing and centralized procurement necessitate direct manufacturer interaction. The entire chain is underpinned by adherence to quality management systems (ISO 13485) and validation protocols (IQ/OQ/PQ), ensuring that the final product not only meets technical specifications but also satisfies the stringent sterile processing demands of the end-user environment.

Vertical Steam Sterilizers Market Potential Customers

Potential customers for vertical steam sterilizers represent a broad spectrum of institutions globally that necessitate routine, highly reliable thermal sterilization to mitigate biological risks and comply with health regulations. The primary and largest end-user segment comprises hospitals and clinical settings, specifically their Central Sterile Services Departments (CSSDs), where vertical sterilizers are essential for sterilizing smaller batches of instruments, glassware, and reusable medical supplies, complementing the function of larger horizontal autoclaves. Beyond general hospitals, specialized surgical centers, dental clinics, and outpatient facilities also constitute crucial buyers, requiring compact yet efficient sterilization solutions that fit within limited physical footprints while maintaining high safety standards for patient care.

The second major cohort includes the dynamic fields of life sciences research and pharmaceutical manufacturing. Biotechnology and pharmaceutical companies rely heavily on these units for sterilizing fermentation media, preparing solutions, and decontaminating waste generated from cell culture and microbiological experiments, ensuring that production processes meet Good Manufacturing Practices (GMP). Academic and government research laboratories, particularly those involved in infectious disease studies, microbiology, and molecular biology, are continuous purchasers, driven by the need to maintain rigorous sterile environments for both basic and translational research activities. These customers prioritize features such as validated cycle logs, advanced safety features, and reliability under continuous heavy usage conditions.

Furthermore, diagnostic and testing laboratories, including public health laboratories and veterinary clinics, frequently utilize vertical steam sterilizers for preparing culture media, decontaminating specimens, and sterilizing diagnostic tools. The increasing global focus on diagnostic testing, particularly post-pandemic, has expanded the customer base within this segment. Lastly, educational institutions and vocational training centers that run programs in medical technology, nursing, and basic sciences also form a steady customer group, requiring durable and easy-to-operate models for teaching and practical training purposes. The versatility and efficiency of vertical designs make them suitable across this entire continuum of institutional buyers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.55 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | STERIS plc, Belimed AG, Getinge AB, Tuttnauer, Consolidated Sterilizer Systems, Sakura Finetek Group, Priorclave Ltd, Astell Scientific, BMT Medical Technology s.r.o., Shinva Medical Instrument Co., Ltd., CISA Group, Fedegari Autoclavi S.p.A., Yamato Scientific Co., Ltd., Biobase, LTE Scientific Ltd., Icanclave, Hanshin Medical Co., Ltd., ALP Co., Ltd., Prestige Medical, DGM Pharma-Apparate Handel AG. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Vertical Steam Sterilizers Market Key Technology Landscape

The technological evolution within the Vertical Steam Sterilizers Market is centered on enhancing operational safety, cycle repeatability, and data management capabilities. Modern vertical autoclaves are increasingly abandoning manual dials in favor of sophisticated microprocessor-based control systems that offer highly precise temperature and pressure regulation, ensuring validation consistency crucial for GxP compliance. Advanced control panels, often featuring high-resolution touchscreens, provide intuitive user interfaces, simplify cycle selection (e.g., specific cycles for liquid, porous, or solid loads), and offer real-time graphical display of operational parameters. Furthermore, the incorporation of advanced vacuum systems is a crucial technological advancement, particularly in vertical units, to efficiently remove residual air from porous loads and hollow instruments, thereby guaranteeing superior steam penetration and maximizing sterilization effectiveness, which historically was a challenge for non-vacuum vertical designs.

A significant trend defining the current technology landscape is the integration of connectivity features, facilitating the development of smart sterilization ecosystems. Internet of Things (IoT) capabilities enable remote monitoring of cycle status, asset tracking, and instantaneous alerts regarding critical failures or cycle deviations, significantly benefiting centralized facility management teams. Data logging systems are becoming mandatory, incorporating non-volatile memory and seamless integration with Laboratory Information Management Systems (LIMS) or Electronic Health Records (EHRs) to ensure complete audit trails, a fundamental requirement in regulated environments. These systems not only log parameters but also provide electronic signatures, further streamlining documentation and reducing the risk of manual transcription errors, thereby increasing overall accountability and compliance with strict standards such as ISO 17665.

Safety technology remains paramount, driven by continuous improvements in mechanical design and system redundancy. Key safety features include automatic, redundant pressure release mechanisms, door interlocks that prevent opening until both temperature and pressure are safe, and integrated steam generators that manage water quality and steam purity to protect both the instruments being sterilized and the integrity of the sterilization cycle itself. Furthermore, specialized cooling systems, such as fan-assisted or water-jet cooling, are increasingly deployed, especially for liquid media sterilization cycles, drastically reducing the cooling time required while mitigating the risk of boil-over, thereby improving laboratory efficiency and reducing the overall turnaround time for essential materials and culture media.

Regional Highlights

Regional dynamics in the Vertical Steam Sterilizers Market are strongly correlated with healthcare expenditure, the density of biotechnology research centers, and the strictness of local regulatory frameworks governing sterilization practices. North America, led by the United States, commands a significant market share due to its well-established, technologically advanced healthcare sector, substantial government and private funding in life sciences R&D, and the mandatory adoption of validated sterilization processes dictated by agencies like the FDA. The high prevalence of sophisticated surgical procedures and the continual replacement and upgrade of sterilization equipment in leading research universities contribute to sustained demand for high-end, fully automatic vertical autoclaves with advanced validation features. Europe closely follows, driven by stringent EU MDR compliance requirements and strong support for pharmaceutical manufacturing in countries like Germany and Switzerland, emphasizing high quality and energy efficiency.

- North America (U.S., Canada): Market leadership characterized by high penetration of fully automated, IoT-enabled units and high R&D spending, focusing on GxP compliant validation and efficient CSSD workflow integration.

- Europe (Germany, U.K., France): Mature market focused on replacement cycles and compliance with European Pressure Equipment Directive (PED) and MDR. Strong demand for energy-efficient, environmentally friendly models.

- Asia Pacific (APAC) (China, India, Japan): Fastest-growing region driven by massive healthcare infrastructure expansion, rising middle-class access to private healthcare, and localization of pharmaceutical production, leading to high volume demand for medium-capacity units.

- Latin America (Brazil, Mexico): Steady growth fueled by government modernization initiatives in public health facilities and increasing foreign investment in localized medical device assembly and research laboratories.

- Middle East & Africa (MEA): Growth concentrated in the GCC states due to significant investment in medical tourism and establishment of world-class hospitals; demand focuses on reliable, high-capacity sterilization for large medical centers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Vertical Steam Sterilizers Market.- STERIS plc

- Getinge AB

- Tuttnauer

- Consolidated Sterilizer Systems

- Priorclave Ltd

- Astell Scientific

- Fedegari Autoclavi S.p.A.

- Belimed AG

- Shinva Medical Instrument Co., Ltd.

- BMT Medical Technology s.r.o.

- CISA Group

- Yamato Scientific Co., Ltd.

- Sakura Finetek Group

- LTE Scientific Ltd.

- Prestige Medical

- Biobase

- DGM Pharma-Apparate Handel AG

- Icanclave

- Hanshin Medical Co., Ltd.

- ALP Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Vertical Steam Sterilizers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between vertical and horizontal steam sterilizers in terms of clinical application?

Vertical steam sterilizers (autoclaves) are primarily top-loading, offering a smaller footprint and deeper chamber often utilized in laboratories and smaller clinics for sterilizing bulk materials, liquids, and biohazard waste. Horizontal sterilizers are typically front-loading, offering higher capacity and are standard in large Central Sterile Services Departments (CSSDs) for high-throughput sterilization of complex surgical instrument sets and porous hospital supplies due to better loading ergonomics and advanced vacuum capabilities for rapid processing.

How do regulatory standards like ISO 13485 and FDA guidelines impact the market for these devices?

Regulatory bodies mandate that all medical and pharmaceutical sterilization equipment, including vertical steam sterilizers, adhere to stringent standards (e.g., ISO 13485 for medical device manufacturing and ISO 17665 for sterilization validation). These regulations force manufacturers to integrate validated cycle protocols, advanced data logging systems, and robust safety mechanisms, driving demand towards higher quality, microprocessor-controlled automatic units that can provide verifiable proof of sterility for every cycle run.

What technological feature is most critical for ensuring the efficacy of steam sterilization cycles?

The most critical technological feature is the precise control and monitoring of temperature, pressure, and exposure time, often managed by a modern microprocessor control unit. Crucially, in advanced vertical sterilizers, the implementation of effective air removal (either via gravity displacement or integrated vacuum systems) is paramount to ensure saturated steam penetration into all parts of the load, guaranteeing optimal lethality (Fo value) and preventing cold spots that could compromise the Sterility Assurance Level (SAL).

Which end-user segment is experiencing the fastest growth in the adoption of vertical steam sterilizers?

The Pharmaceutical and Biotechnology Companies segment is experiencing the fastest growth in adoption. This accelerated demand is driven by rapid expansion in biologics manufacturing, particularly cell and gene therapies, which require high volumes of sterile culture media and validated processing environments. Vertical sterilizers offer the necessary precision and efficiency for sterilizing laboratory consumables and media preparation under strict Good Manufacturing Practice (GMP) conditions, supporting increased global bioprocessing activity and stringent quality control protocols required for novel therapeutic development.

What are the key maintenance challenges associated with vertical steam sterilizers?

Key maintenance challenges involve managing internal scaling and corrosion caused by poor water quality, leading to reduced heating element efficiency and sensor malfunction. Additionally, regular inspection and replacement of door gaskets and safety valves are essential to maintain pressure integrity and prevent steam leaks. Advanced maintenance practices now focus on predictive diagnostics, utilizing internal software to monitor component lifespan and scheduling proactive service calls to minimize unexpected operational downtime in critical clinical or research settings.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager