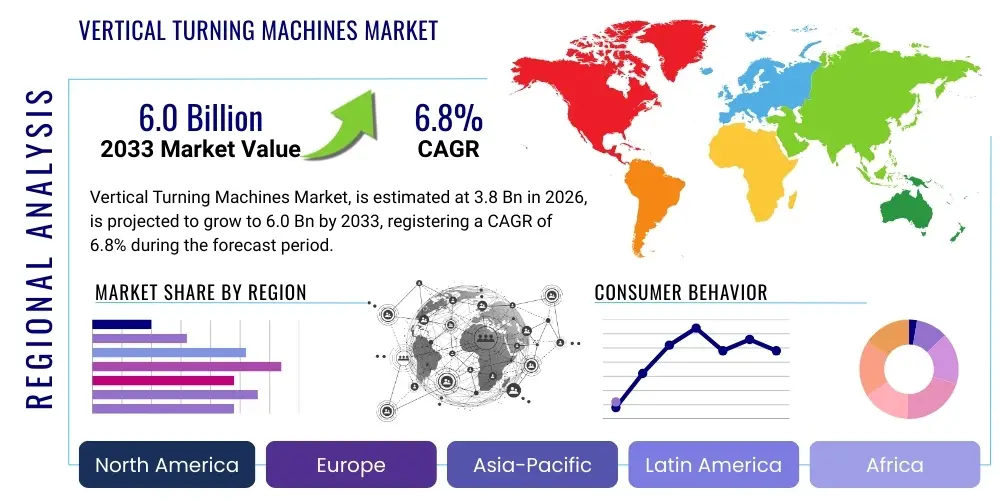

Vertical Turning Machines Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439860 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Vertical Turning Machines Market Size

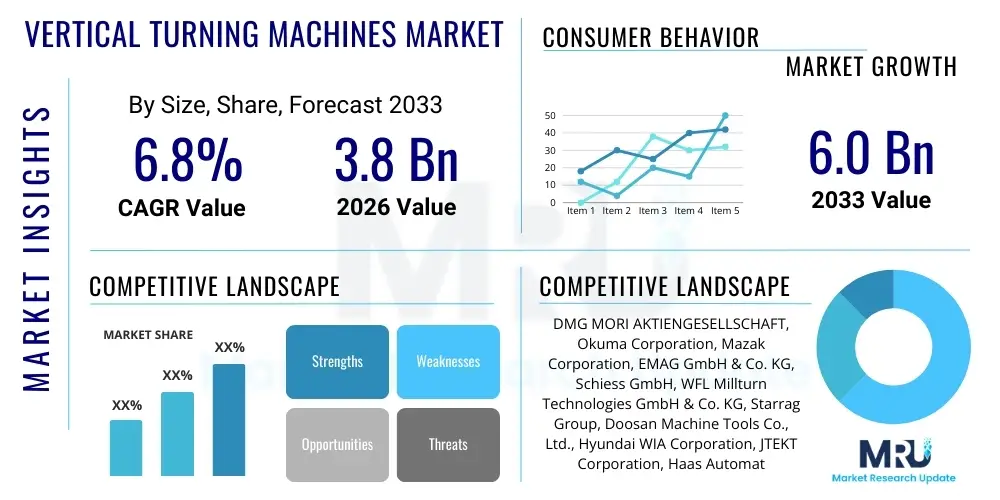

The Vertical Turning Machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 3.8 Billion in 2026 and is projected to reach USD 6.0 Billion by the end of the forecast period in 2033.

Vertical Turning Machines Market introduction

The Vertical Turning Machines (VTMs) market is a critical segment within the broader machine tool industry, characterized by its indispensable role in precision machining of large, heavy, and complex workpieces. These machines are engineered for high-efficiency turning, boring, facing, and milling operations, offering superior rigidity and accuracy compared to horizontal lathes, especially for components that are difficult to mount horizontally. Their vertical orientation naturally aids in workpiece loading and unloading, while gravity assists in stabilizing the part, ensuring consistent machining quality.

VTMs typically feature a rotating chuck or table on a vertical axis, with cutting tools moving horizontally and vertically across the workpiece. Modern VTMs are predominantly CNC-controlled, enabling complex geometries and automated production cycles with minimal human intervention. Key benefits include enhanced precision for large-diameter parts, significant space savings due to their vertical footprint, and improved chip evacuation, which contributes to higher surface finishes and extended tool life. These attributes make VTMs essential for industries demanding high standards of accuracy and efficiency.

Major applications of Vertical Turning Machines span across diverse heavy industries such as automotive, aerospace, heavy machinery manufacturing, power generation (including wind turbines and nuclear components), and general industrial machining. The market's growth is primarily driven by the escalating demand for advanced manufacturing capabilities, increasing automation in production processes, and the continuous need for machining new, complex materials with stringent tolerances. Furthermore, the global trend towards industrialization and infrastructure development significantly bolsters the adoption of these robust machining solutions.

Vertical Turning Machines Market Executive Summary

The Vertical Turning Machines (VTM) market is poised for robust expansion, driven by accelerating global industrialization and a pronounced shift towards automated, precision manufacturing. Key business trends include the increasing integration of Industry 4.0 technologies, such as IoT and advanced robotics, enhancing machine intelligence and operational efficiency. There is a growing demand for multi-tasking VTMs capable of performing diverse operations in a single setup, reducing cycle times and improving overall productivity. Customization and the development of specialized machines tailored for specific industries, particularly in aerospace and energy, represent significant business opportunities, alongside a focus on sustainable manufacturing practices and energy-efficient designs.

Regionally, the Asia Pacific continues its dominance as a manufacturing powerhouse, propelled by rapid industrial growth in China, India, and Southeast Asian nations, leading to substantial investments in advanced VTM technologies. Europe and North America, while mature markets, are characterized by innovation, strong demand for high-end, automated VTMs for complex applications, and a focus on retrofitting existing machinery with modern control systems. Emerging markets in Latin America and the Middle East & Africa are showing promising growth, driven by infrastructure development and diversification of industrial bases, though adoption rates are influenced by capital expenditure constraints and technological readiness.

Segmentation trends indicate a strong inclination towards Automatic/CNC VTMs due to their superior precision, repeatability, and capacity for lights-out manufacturing. Multi-tasking VTMs are gaining traction across various end-user industries, offering versatility and consolidated machining capabilities. In terms of end-users, the automotive and aerospace sectors remain primary consumers, continuously pushing the boundaries for accuracy and material handling. There is also an expanding market for VTMs equipped to handle advanced materials like superalloys and composites, necessitating specialized tooling and machining strategies, further driving innovation within the market's technological landscape.

AI Impact Analysis on Vertical Turning Machines Market

User inquiries about AI's impact on Vertical Turning Machines frequently revolve around how artificial intelligence can enhance productivity, improve precision, and reduce operational costs. Common questions highlight concerns about the complexity of integrating AI, the need for skilled personnel, and the potential for job displacement, alongside strong expectations for predictive maintenance, process optimization, and increased automation. Users are keen to understand how AI translates into tangible benefits like fewer defects, optimized tool paths, and more efficient resource utilization, driving a demand for VTMs equipped with smart capabilities that streamline manufacturing workflows and provide real-time operational insights. This collective interest underscores a clear industry desire for AI-driven solutions that contribute to smarter, more adaptive, and ultimately more profitable machining operations.

- Predictive Maintenance: AI algorithms analyze machine sensor data (vibration, temperature, power consumption) to predict potential component failures before they occur, reducing downtime and maintenance costs.

- Adaptive Process Control: AI-driven systems monitor cutting parameters in real-time and make dynamic adjustments to optimize machining processes, improving surface finish, tool life, and material removal rates.

- Quality Control & Inspection: AI-powered vision systems detect defects and deviations from specifications with high accuracy, ensuring consistent product quality and reducing the need for manual inspection.

- Automated Program Generation: AI can assist in generating optimized CNC programs, learning from past machining operations and design specifications to create more efficient and error-free tool paths.

- Energy Optimization: AI algorithms can manage machine power consumption more efficiently, optimizing operational schedules and identifying energy-saving opportunities during various machining cycles.

- Autonomous Operation: Integration with robotics and AI allows for increasingly autonomous VTM operations, from automated workpiece loading and unloading to self-correcting machining sequences.

DRO & Impact Forces Of Vertical Turning Machines Market

The Vertical Turning Machines market is significantly influenced by a confluence of drivers, restraints, opportunities, and broader impact forces. Key drivers include the escalating global demand for precision components across diverse industries, the continuous push towards automation and digital manufacturing as part of Industry 4.0 initiatives, and the sustained growth in heavy industries such as automotive, aerospace, and power generation. The inherent advantages of VTMs, such as their ability to efficiently machine large and heavy workpieces with high accuracy, further fuel their adoption. Conversely, the market faces significant restraints, primarily the high initial capital investment required for these sophisticated machines, which can deter small and medium-sized enterprises (SMEs). The persistent shortage of skilled labor capable of operating and maintaining advanced CNC VTMs, coupled with economic uncertainties and geopolitical instability, also pose challenges to market expansion.

Opportunities for growth are abundant, particularly in the emergence of smart factories and integrated manufacturing ecosystems where VTMs can leverage IoT and AI for enhanced productivity and predictive maintenance. Advancements in material science, leading to the use of more complex and harder-to-machine alloys, create a niche for highly specialized VTMs. The rising trend of customization and the demand for multi-tasking machines capable of performing multiple operations in a single setup also present avenues for market development. Moreover, the vast potential in retrofitting older machines with modern control systems and automation features offers a cost-effective solution for enterprises to upgrade their manufacturing capabilities.

Impact forces shaping the market include rapid technological advancements in CNC systems, tooling, and sensor integration, which continuously enhance VTM performance and capabilities. Global supply chain disruptions, influenced by geopolitical events and trade policies, can affect the availability and cost of components and raw materials, impacting production cycles. Increasing environmental regulations push manufacturers towards developing more energy-efficient and sustainable machining solutions, while economic cycles and fluctuations in capital expenditure budgets directly influence purchasing decisions across industrial sectors. The overall competitive landscape, characterized by continuous innovation and strategic partnerships among key players, also profoundly impacts market dynamics and technological progress within the VTM domain.

Segmentation Analysis

The Vertical Turning Machines (VTMs) market is extensively segmented to provide a granular view of its dynamics, facilitating targeted market strategies and understanding varied customer needs. This segmentation typically categorizes VTMs based on their operational characteristics, application industries, end-user types, and the degree of automation they incorporate. Such categorization helps in identifying key growth pockets, competitive landscapes, and technological preferences across different industrial verticals and geographical regions. Understanding these distinct segments is crucial for manufacturers to tailor their product offerings, develop specialized solutions, and optimize their distribution channels, ensuring relevance and competitive advantage in a diverse market environment.

- By Type:

- Standard VTM

- Multi-Tasking VTM (combining turning with milling, drilling, grinding)

- Custom VTM

- By Chuck Size:

- Small (less than 1000mm)

- Medium (1000mm - 2000mm)

- Large (greater than 2000mm)

- By Application:

- Automotive

- Aerospace & Defense

- Heavy Machinery

- Power Generation (Wind, Nuclear, Thermal)

- General Machining

- Railway Industry

- By End-User:

- Large Enterprises

- Small & Medium-sized Enterprises (SMEs)

- By Operation:

- Manual VTM

- Semi-Automatic VTM

- Automatic (CNC) VTM

Value Chain Analysis For Vertical Turning Machines Market

The value chain for the Vertical Turning Machines market encompasses a comprehensive sequence of activities, starting from the procurement of raw materials and components, through manufacturing and assembly, to distribution, sales, and aftermarket services. Upstream analysis focuses on the suppliers of critical components such as high-grade steel and alloys for machine frames, precision bearings, spindles, sophisticated CNC control systems, electrical components, and tooling. These suppliers often operate in highly specialized markets, providing the foundational technology and materials necessary for VTM construction. The quality and availability of these components directly impact the final product's performance, reliability, and cost-effectiveness. Strong relationships with these upstream partners are crucial for ensuring a stable supply chain and incorporating the latest technological advancements into VTM designs, ultimately enhancing the competitive edge of machine tool manufacturers.

Midstream activities involve the design, engineering, manufacturing, and assembly of the Vertical Turning Machines themselves. This stage requires significant investment in R&D, advanced manufacturing facilities, and skilled labor. Machine tool builders focus on integrating various components into a cohesive, high-performance system, often developing proprietary technologies for enhanced precision, automation, and user interface. The manufacturing process often involves complex machining of large structural components, meticulous assembly, and rigorous testing to meet stringent quality and performance standards. Value is added through innovative design, engineering expertise, manufacturing efficiency, and the integration of advanced features like AI and IoT capabilities.

Downstream analysis covers the distribution channels, sales, and post-sales support that bring VTMs to the end-users. Distribution can occur through direct sales teams for large strategic accounts, a network of authorized dealers and distributors for broader market reach, or through specialized system integrators who provide complete turnkey solutions. These channels are critical for market penetration, providing local support, and offering financing options. Post-sales services, including installation, commissioning, training, maintenance, and spare parts supply, are vital for customer satisfaction and long-term relationships. Both direct and indirect distribution strategies are employed, with direct sales offering closer customer relationships and higher margins, while indirect channels provide wider market coverage and leverage local expertise, collectively ensuring comprehensive market access and sustained customer support.

Vertical Turning Machines Market Potential Customers

The Vertical Turning Machines market primarily targets a diverse range of industrial sectors that require high-precision machining of large, heavy, and complex components. These end-users are typically characterized by their need for robust, reliable, and highly accurate machine tools to produce critical parts for their respective operations. The decision-making process for acquiring VTMs often involves substantial capital investment and considers factors such as machine capabilities, long-term operational costs, automation features, and the manufacturer's reputation for service and support. The increasing complexity of modern industrial components and the continuous pursuit of manufacturing efficiency further cement the importance of VTMs for these sophisticated buyers.

Key potential customers include original equipment manufacturers (OEMs) in the automotive industry, particularly for producing brake discs, flywheels, and large engine components, as well as those in the aerospace and defense sector for machining turbine disks, landing gear components, and large structural parts from high-performance alloys. Manufacturers of heavy machinery, such as construction equipment, mining machinery, and agricultural vehicles, also represent a significant customer base, using VTMs for gear blanks, bearing housings, and large shafts. The power generation industry, encompassing wind turbine manufacturers (for hubs and shafts), nuclear power component producers, and thermal power plant suppliers (for valve bodies and rotors), relies heavily on VTMs for machining critical, high-tolerance parts.

Furthermore, general machining job shops that serve multiple industries, railway component manufacturers for wheels and axles, and companies involved in shipbuilding for propeller shafts and engine parts, are crucial end-users. As manufacturing processes become more automated and integrated into smart factory ecosystems, these customers increasingly seek VTMs with advanced CNC controls, robotic integration capabilities, and features that support Industry 4.0 connectivity, allowing for seamless data exchange and predictive maintenance. The demand for VTMs capable of handling specialized materials and offering multi-tasking capabilities is also growing among these sophisticated buyers, seeking to optimize production workflows and enhance their competitive advantage.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.8 Billion |

| Market Forecast in 2033 | USD 6.0 Billion |

| Growth Rate | CAGR 6.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | DMG MORI AKTIENGESELLSCHAFT, Okuma Corporation, Mazak Corporation, EMAG GmbH & Co. KG, Schiess GmbH, WFL Millturn Technologies GmbH & Co. KG, Starrag Group, Doosan Machine Tools Co., Ltd., Hyundai WIA Corporation, JTEKT Corporation, Haas Automation, Inc., Gleason Corporation, Pietro Carnaghi S.p.A., You Ji Machine Industrial Co., Ltd., Chevalier Machinery Inc., Kent CNC, Goodway Machine Corp., Hwacheon Machinery Works Co., Ltd., Tongtai Machine & Tool Co., Ltd., Accuway Machinery Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Vertical Turning Machines Market Key Technology Landscape

The Vertical Turning Machines market is undergoing significant technological evolution, primarily driven by the overarching trends of Industry 4.0 and the increasing demand for higher precision, efficiency, and automation. Central to this landscape are advanced Computer Numerical Control (CNC) systems, which provide sophisticated multi-axis control, enabling complex machining operations with extreme accuracy and repeatability. These modern CNCs integrate advanced algorithms for tool path optimization, collision avoidance, and real-time process monitoring, enhancing both productivity and safety. The development of more powerful and user-friendly human-machine interfaces (HMIs) further simplifies complex programming and operation, making advanced VTM capabilities accessible to a wider range of skilled personnel, while reducing setup times and potential for human error.

Another crucial technological development is the integration of Internet of Things (IoT) sensors and connectivity into VTMs. These sensors collect vast amounts of data on machine performance, spindle load, vibration, temperature, and tool wear, transmitting it to cloud-based platforms for analysis. This data forms the backbone for predictive maintenance strategies, allowing manufacturers to anticipate equipment failures, schedule maintenance proactively, and minimize unscheduled downtime. Furthermore, IoT integration facilitates remote monitoring and diagnostics, enabling machine manufacturers to offer enhanced support and services, improving overall equipment effectiveness (OEE) for end-users. The ability to connect VTMs into a broader digital manufacturing ecosystem is transforming factory floors into smart, interconnected production environments.

Beyond control systems and connectivity, advancements in tooling technology, such as specialized inserts and high-performance cutting tools designed for advanced materials like superalloys and composites, are vital for enhancing VTM capabilities. Multi-tasking VTMs that integrate turning with milling, drilling, and grinding capabilities in a single machine are gaining prominence, reducing part handling and improving overall manufacturing efficiency. Robotic integration for automated workpiece loading/unloading and tool changes is also becoming standard in high-volume production environments, contributing to lights-out manufacturing. Furthermore, the burgeoning field of Artificial Intelligence (AI) is being applied to VTMs for adaptive process control, quality inspection, and intelligent automation, promising further leaps in productivity, precision, and autonomous operation. These technological advancements collectively contribute to making VTMs more intelligent, efficient, and versatile.

Regional Highlights

- Asia Pacific (APAC): Dominates the market due to robust manufacturing growth, particularly in China, India, Japan, and South Korea. Rapid industrialization, significant investments in automotive, electronics, and heavy machinery sectors, and government support for local manufacturing drive high demand for VTMs. The region is a key hub for both production and consumption of these machines.

- Europe: A mature market characterized by technological innovation and high-value manufacturing, especially in Germany, Italy, and France. Strong demand from the automotive, aerospace, and general engineering industries for high-precision, automated VTMs. Focus on Industry 4.0 adoption and advanced manufacturing techniques drives continuous upgrades and new installations.

- North America: Significant market share, with the United States leading in adoption, particularly in aerospace & defense, heavy equipment, and energy sectors. Emphasis on high-performance, multi-axis VTMs for complex parts, coupled with growing investments in automation and smart factory initiatives to maintain global competitiveness.

- Latin America: Emerging market with growing industrialization, especially in Brazil and Mexico. Demand for VTMs is spurred by expanding automotive manufacturing and infrastructure development, though economic volatility and reliance on imports can influence market growth.

- Middle East & Africa (MEA): Gradually developing market, driven by diversification efforts away from oil and gas, leading to investments in manufacturing, infrastructure, and defense. Opportunities for VTM adoption are present in countries like Saudi Arabia and UAE, supported by government visions for industrial growth and technological advancement.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Vertical Turning Machines Market.- DMG MORI AKTIENGESELLSCHAFT

- Okuma Corporation

- Mazak Corporation

- EMAG GmbH & Co. KG

- Schiess GmbH

- WFL Millturn Technologies GmbH & Co. KG

- Starrag Group

- Doosan Machine Tools Co., Ltd.

- Hyundai WIA Corporation

- JTEKT Corporation

- Haas Automation, Inc.

- Gleason Corporation

- Pietro Carnaghi S.p.A.

- You Ji Machine Industrial Co., Ltd.

- Chevalier Machinery Inc.

- Kent CNC

- Goodway Machine Corp.

- Hwacheon Machinery Works Co., Ltd.

- Tongtai Machine & Tool Co., Ltd.

- Accuway Machinery Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Vertical Turning Machines market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are Vertical Turning Machines?

Vertical Turning Machines (VTMs) are advanced industrial machine tools designed for precision machining of large, heavy, and often irregularly shaped workpieces. They feature a vertical spindle with a rotating chuck or table, allowing gravity to assist in stabilizing the workpiece during operations like turning, boring, facing, and milling, ensuring high accuracy and rigidity. Modern VTMs are typically CNC-controlled for automated, complex manufacturing.

What industries commonly use Vertical Turning Machines?

VTMs are indispensable across various heavy industries. Key sectors include automotive (for brake discs, flywheels), aerospace & defense (for turbine disks, landing gear), heavy machinery (for large gears, shafts), power generation (for wind turbine hubs, valve bodies), and general manufacturing for high-precision, large-diameter components. Their capacity for high accuracy on substantial parts makes them critical in these applications.

How does AI impact the Vertical Turning Machines market?

AI significantly impacts VTMs by enabling predictive maintenance to minimize downtime, optimizing cutting parameters for enhanced precision and tool life, improving quality control through intelligent vision systems, and assisting in automated program generation. This leads to increased operational efficiency, reduced waste, and the potential for more autonomous manufacturing processes, driving smarter and more adaptive VTM operations.

What are the primary benefits of using Vertical Turning Machines?

The main benefits of VTMs include superior precision and rigidity for large and heavy workpieces, efficient space utilization due to their vertical design, improved chip evacuation for better surface finishes and tool longevity, and enhanced automation capabilities with CNC controls. They also facilitate easier loading and unloading of cumbersome parts, contributing to higher productivity and reduced manual labor.

What is the future outlook for the Vertical Turning Machines market?

The future outlook for the Vertical Turning Machines market is positive, driven by continuous industrial growth, increasing demand for automation, and the integration of advanced technologies like Industry 4.0, IoT, and AI. Expect further innovations in multi-tasking capabilities, energy efficiency, and predictive analytics. Emerging markets will contribute significantly to growth, alongside ongoing demand from mature industrial sectors for sophisticated, high-performance machining solutions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager