Vibrating Sifter Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433413 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Vibrating Sifter Machine Market Size

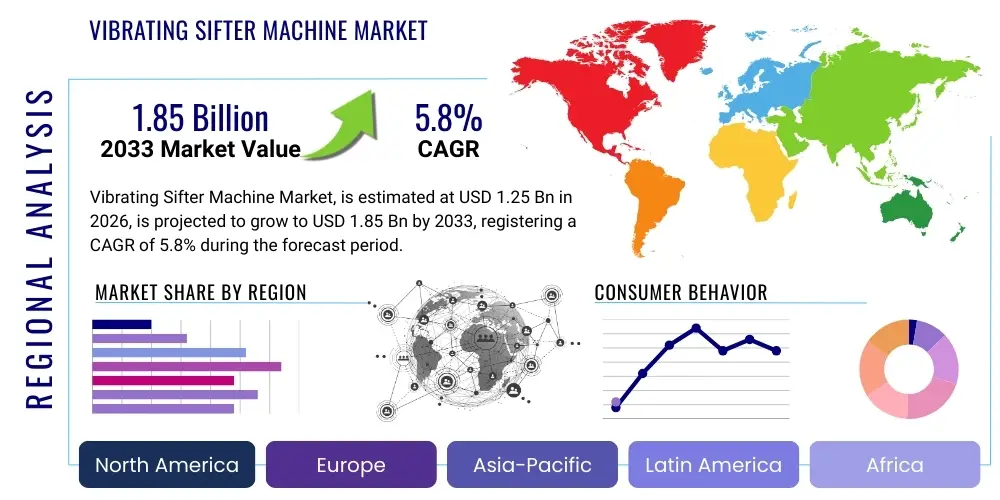

The Vibrating Sifter Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 1.85 Billion by the end of the forecast period in 2033.

Vibrating Sifter Machine Market introduction

The Vibrating Sifter Machine Market encompasses equipment essential for particle size separation, classification, and grading across numerous industrial sectors globally. These machines, also known as vibro sifters, screeners, or separators, utilize controlled mechanical vibration to facilitate the movement of material across screens of specified mesh sizes. The primary function is to remove oversized or undersized contaminants, ensuring product purity, consistency, and compliance with stringent quality standards. This equipment is indispensable in sectors where precise powder and granular handling is paramount, including pharmaceuticals, where strict regulatory compliance dictates particle distribution, and the food and beverage industry, where foreign object detection and ingredient uniformity are critical for consumer safety and product quality.

The product range within this market is extensive, covering equipment differentiated by motion mechanics—such as circular vibratory sifters, linear vibratory screens, gyratory separators, and tumbler screening machines. Major applications span from raw material inspection and pre-processing stages to final quality control before packaging. Key benefits derived from adopting modern vibrating sifter technology include enhanced operational efficiency, reduced labor costs due to automation, improved sanitation characteristics (especially models designed for easy clean-in-place, or CIP), and superior separation accuracy. These machines are increasingly being integrated into fully automated production lines, leading to higher throughput rates and reliable performance metrics, which is crucial for large-scale manufacturing environments.

The market is predominantly driven by the rapid expansion of the pharmaceutical and nutraceutical industries, which demand high-capacity, validated screening solutions for active pharmaceutical ingredients (APIs) and excipients. Furthermore, increasing global regulatory scrutiny regarding food safety and product contamination mandates the use of highly efficient sifting and screening equipment. Technological advancements, such as the incorporation of ultrasonic deblinding systems and robust stainless-steel construction for hygienic applications, further bolster market growth. The escalating demand for processed foods, refined chemicals, and high-quality construction materials worldwide acts as a fundamental catalyst, compelling manufacturers to invest in reliable separation technology to maintain competitive edge and meet escalating consumer expectations.

Vibrating Sifter Machine Market Executive Summary

The Vibrating Sifter Machine Market is experiencing robust growth driven by stringent quality control regulations and the increasing global trend towards industrial automation and process efficiency. Business trends indicate a strong shift towards highly customized and sanitary design equipment, particularly in the Asia Pacific region, which is rapidly expanding its manufacturing base in pharmaceuticals and food processing. Key manufacturers are focusing on integrating advanced materials, such as specialized alloys and polymers, to enhance durability and reduce downtime associated with corrosion or wear. Furthermore, digital integration, including IoT sensors for real-time performance monitoring and predictive maintenance, is becoming a standard offering, enabling proactive operational adjustments and optimizing overall equipment effectiveness (OEE). This focus on smart manufacturing principles is redefining competitive dynamics within the industry.

Regional trends highlight that North America and Europe remain key revenue generators due to their mature industrial infrastructure and significant investments in advanced manufacturing technologies, especially for high-value APIs and specialized chemicals. However, the Asia Pacific (APAC) region is projected to register the highest Compound Annual Growth Rate (CAGR), fueled by massive infrastructural investments in China, India, and Southeast Asian countries aimed at modernizing food processing and establishing robust pharmaceutical supply chains. Latin America and the Middle East & Africa (MEA) are emerging markets, characterized by growing urbanization and industrialization, leading to increased demand for basic separation technology in mining and construction materials, gradually transitioning toward more sophisticated applications.

Segment trends reveal that the pharmaceutical and food & beverage segments dominate the application landscape, driven by non-negotiable requirements for hygiene, validation, and preventing cross-contamination. Segmentation by motion type indicates that Circular Vibratory Screeners hold the largest market share due to their versatility and cost-effectiveness, widely adopted for general industrial sifting tasks. Conversely, Tumbler Screening Machines, offering high precision and gentle handling, are showing accelerated growth, particularly favored in sensitive applications such as metallurgy powders and fine chemical processing where product integrity cannot be compromised. The aftermarket services segment, including spare parts, screen mesh replacement, and maintenance contracts, is also growing rapidly, ensuring continued machine uptime and contributing significantly to overall market revenue stability.

AI Impact Analysis on Vibrating Sifter Machine Market

User queries regarding AI’s influence on the Vibrating Sifter Machine Market primarily revolve around operational optimization, predictive maintenance capabilities, and enhancing sieving precision. Users frequently ask if AI can eliminate manual screen inspection, how machine learning algorithms optimize vibration frequencies based on material characteristics (moisture, density), and the feasibility of real-time particle analysis for quality assurance. Concerns often center on the cost-effectiveness of retrofitting older equipment with AI-enabled sensors and the cybersecurity risks associated with networked, smart sifting systems. There is a strong expectation that AI will lead to minimal downtime, superior consistency, and automated regulatory compliance reporting, drastically reducing human error and improving overall yield in highly regulated industries.

The integration of Artificial Intelligence and Machine Learning (ML) transforms traditional sifting operations from reactive maintenance schedules to proactive, performance-driven systems. AI algorithms analyze continuous data streams collected from vibration sensors, pressure gauges, temperature probes, and output quality monitors. By correlating these variables, AI can predict mechanical failure—such as impending bearing wear or screen blockage—hours or days before a critical failure occurs, allowing maintenance teams to intervene during planned downtime, thereby maximizing operational throughput and minimizing expensive, unplanned interruptions. Furthermore, ML models can be trained on specific material properties and desired output specifications to dynamically adjust sifting parameters, including amplitude and frequency, ensuring optimal separation efficiency regardless of minor variations in feed material consistency.

Beyond predictive maintenance, AI is significantly impacting quality control and process optimization. Advanced AI-powered vision systems are being integrated above the screens to analyze particle flow, distribution, and identify foreign materials or agglomerates in real time, surpassing the speed and consistency of human inspection. This allows for immediate, automated process adjustments, ensuring every batch meets the required specifications. The optimization capability extends to energy consumption; AI monitors motor load and power usage, adjusting operational parameters to achieve the required separation quality with the minimum possible energy input, contributing to sustainability goals and reducing operational costs. This shift elevates the vibrating sifter machine from a simple mechanical device to an intelligent, integrated component of the smart factory ecosystem.

- AI-powered Predictive Maintenance: Forecasting mechanical failures based on vibration anomaly detection.

- Dynamic Parameter Adjustment: ML optimization of vibration frequency and amplitude based on material rheology.

- Automated Quality Control: Real-time particle analysis and foreign material detection using integrated vision systems.

- Enhanced Throughput Consistency: Maintaining optimal sifting performance despite variations in feed material characteristics.

- Energy Consumption Optimization: ML algorithms adjusting motor usage for minimum power draw while maintaining separation quality.

- Automated Regulatory Reporting: Generating audit trails and validation documentation seamlessly through system integration.

DRO & Impact Forces Of Vibrating Sifter Machine Market

The market trajectory for Vibrating Sifter Machines is fundamentally shaped by a confluence of powerful drivers, structural restraints, and evolving opportunities, which collectively define the impact forces acting upon the industry. A primary driver is the global escalation of quality and safety standards, particularly within the pharmaceutical and food sectors, which necessitates highly reliable, validated separation equipment to comply with regulations set by bodies like the FDA and EMEA. Simultaneously, the inherent challenge of material blinding and screen maintenance acts as a structural restraint, demanding significant research investment into self-cleaning mechanisms like ultrasonic systems and specialized mesh coatings. Opportunities are heavily concentrated in emerging markets and the increasing adoption of highly precise screening technology for advanced materials, such as metal powders for additive manufacturing (3D printing), opening high-margin niches.

Key drivers include the global expansion of manufacturing industries that require powder processing, rapid technological advancements leading to machines with higher capacity and finer separation capabilities, and the overwhelming industry shift towards automation to reduce manual labor dependency and enhance process repeatability. However, the market faces significant restraints, notably the high initial capital investment required for specialized, sanitary-design equipment, which can be prohibitive for small and medium-sized enterprises (SMEs). Additionally, the operational constraint of machine vibration and noise generation in certain older models still poses challenges in densely populated or acoustically sensitive manufacturing environments, although newer designs address these issues effectively.

Opportunities for sustained market growth are found in customizing equipment for unique material properties (e.g., highly sticky, abrasive, or temperature-sensitive powders) and developing fully integrated, IoT-enabled sifting solutions that communicate seamlessly with enterprise resource planning (ERP) and manufacturing execution systems (MES). The impact forces, therefore, lean towards accelerated growth, fueled by regulatory push and technological pull, compelling manufacturers to innovate constantly in terms of efficiency and hygiene. The ability to overcome restraints related to maintenance complexity and initial cost via offering robust service contracts and flexible financing models will be crucial for sustained competitive advantage, ensuring the market maintains its upward trajectory throughout the forecast period.

Segmentation Analysis

The Vibrating Sifter Machine Market is comprehensively segmented based on machine type, motion mechanics, end-use application, and operation capacity, reflecting the diverse industrial requirements globally. The segmentation by machine type (Circular, Rectangular, Gyratory, Tumbler) is critical as each configuration offers distinct advantages regarding throughput, required separation precision, and efficiency for different material types. The most substantial revenue is generated through the end-use application segment, where pharmaceutical and food & beverage processing represent the largest demand centers due to their critical need for absolute product purity and validated processes. Understanding these segments is paramount for manufacturers to tailor their design specifications—such as material construction (304 vs. 316L stainless steel) and finish requirements—to meet specific industry mandates.

Detailed analysis of the market segments reveals robust demand growth in the higher-precision segments, specifically Gyratory and Tumbler screeners. While circular sifters are ubiquitous due to their high throughput and ease of cleaning, the increasing complexity of powders in specialty chemicals and additive manufacturing requires the gentler, longer-retention-time motion characteristic of tumbler screeners, minimizing particle attrition. Capacity segmentation (Small, Medium, High) directly correlates with the scale of the customer's manufacturing operation, with high-capacity machines being predominantly adopted by large chemical and mining conglomerates, while medium-capacity machines form the backbone of the consumer packaged goods (CPG) sector.

Furthermore, segmentation by operation type (Wet vs. Dry) is crucial, particularly for mining and wastewater treatment applications where slurries and liquids must be processed. Dry screening remains the largest segment, catering to powders and granules in food, pharma, and chemical industries. This intricate segmentation framework allows for targeted marketing and product development strategies, ensuring that manufacturers address the niche requirements of specialized materials while capitalizing on the broad demand from high-volume industrial sectors. The overall market dynamics are increasingly governed by the move towards specialized segmentation required by technologically advanced end-users.

- By Type:

- Circular Vibratory Screeners

- Rectangular Vibratory Screeners

- Gyratory Screeners

- Tumbler Screeners

- Linear Vibratory Screeners

- By End-Use Application:

- Pharmaceutical and Nutraceutical

- Food and Beverage Processing

- Chemical and Petrochemical

- Mining and Metallurgy

- Plastics and Polymers

- Ceramics and Glass

- Water and Wastewater Treatment

- By Operation Type:

- Dry Screening

- Wet Screening (Dewatering)

- By Capacity:

- Small Capacity (Up to 100 kg/hr)

- Medium Capacity (100 kg/hr – 500 kg/hr)

- High Capacity (Above 500 kg/hr)

Value Chain Analysis For Vibrating Sifter Machine Market

The value chain for the Vibrating Sifter Machine Market begins with upstream activities involving the sourcing of high-grade raw materials, primarily stainless steel (304 and 316L for sanitary applications), specialized motors, vibration isolation components (springs and elastomers), and high-quality mesh screen materials (woven wire, perforated plate, or synthetic). Key success factors in the upstream stage involve maintaining stable supply chains, negotiating favorable long-term contracts for steel alloys, and ensuring material traceability, especially for machinery destined for regulated environments like pharmaceuticals. Manufacturers must also invest heavily in precision engineering capabilities to ensure the dynamic balance and durability of the vibrating elements, which are critical for optimal machine performance and longevity. Supplier risk mitigation and quality control are paramount in this phase.

Midstream activities involve the core manufacturing processes: component fabrication, assembly, integration of control systems (including HMI/PLC interfaces), surface finishing (polishing for sanitary standards), and rigorous quality assurance and testing (such as Factory Acceptance Tests or FATs). Distribution channels are bifurcated into direct sales and indirect representation. Direct sales are typically favored for high-value, highly customized, or complex integrated systems purchased by large multinational corporations, allowing the manufacturer to maintain greater control over technical consultation and installation. Indirect channels, utilizing regional distributors, value-added resellers (VARs), and engineering firms, are crucial for reaching SMEs and geographically diverse markets, leveraging local expertise for sales and initial support.

The downstream segment focuses on installation, commissioning, after-sales service, and the supply of consumable spare parts, such as replacement screen meshes and seals. Profitability in the downstream segment is highly reliant on providing excellent technical support, offering prompt maintenance services, and securing long-term service contracts. Potential customers prioritize suppliers who offer extensive validation documentation (IQ/OQ/PQ protocols), swift response times, and easily accessible inventories of essential wear parts. The sustainability of the product depends heavily on these downstream services, transforming the initial capital expenditure into a long-term operational relationship and securing recurring revenue streams through the sales of specialized consumables and maintenance packages.

Vibrating Sifter Machine Market Potential Customers

Potential customers for Vibrating Sifter Machines are diverse, spanning virtually every industrial sector that handles dry powders, granules, or liquid slurries requiring separation, classification, or filtration. The primary end-users are large-scale manufacturers and processors in highly regulated industries where product purity is non-negotiable. This includes global pharmaceutical companies requiring sifters for processing APIs, excipients, and tablet coatings; these entities prioritize machines compliant with GMP (Good Manufacturing Practices) and featuring polished, crevice-free surfaces for easy sterilization and validation documentation. Similarly, major food and beverage corporations utilize this equipment extensively for flour sifting, sugar grading, dairy powder classification, and contamination removal to ensure consumer safety and product texture consistency.

Beyond the core regulated sectors, significant purchasing power comes from the chemical industry, which uses sifters for separating catalysts, resins, and fine chemicals, demanding equipment resistant to corrosive or explosive atmospheres (ATEX compliance). Mining and metallurgy operations represent another substantial customer segment, relying on high-capacity, robust sifters (often linear or rectangular types) for screening aggregates, metal powders, and ore concentrates. These customers require high mechanical durability and resistance to abrasive materials, often prioritizing throughput over fine-mesh precision. Construction materials producers, including cement and gypsum manufacturers, also utilize large-scale sifters for quality control and material classification.

Emerging buyers include contract manufacturing organizations (CMOs) and contract development and manufacturing organizations (CDMOs) across pharma and food sectors, who require versatile machinery capable of handling various materials and batch sizes. Furthermore, the burgeoning additive manufacturing (3D printing) industry is becoming a specialized buyer, demanding ultra-precise tumbler screening technology to recover and classify expensive, fine metal and polymer powders (e.g., titanium, stainless steel, nylon) to maintain the quality and consistency required for high-performance 3D-printed parts. The purchasing decisions of these potential customers are heavily influenced by regulatory compliance, ease of cleaning/validation, machine reliability (uptime), and energy efficiency.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.85 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Russell Finex, Sweco (A Duravant Company), Kason Corporation, Gericke Group, GKM Siebtechnik, Retsch GmbH, Derrick Corporation, Midwestern Industries, Vibra-Pro, Inc., Pennwalt Process Technologies, Star Trace Private Limited, Sodeva Process, VIBROSCREEN, Inc., Gough Engineering (Process Technology) Ltd., Xinxiang Dayong Vibration Equipment Co., Ltd., J. Engelsmann AG, Cleveland Vibrator Company, A.S.P. Sealing Solutions, Changzhou Jinggong Machinery Co., Ltd., Henan Shuangli Machinery Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Vibrating Sifter Machine Market Key Technology Landscape

The technological landscape of the Vibrating Sifter Machine Market is currently defined by innovations focused on enhancing efficiency, minimizing downtime, ensuring hygiene, and improving integration into smart factory ecosystems. One of the most significant advancements is the proliferation of ultrasonic sieving technology, which utilizes high-frequency sound waves to prevent the clogging or "blinding" of fine mesh screens when processing lightweight, sticky, or electrostatically charged powders. This technology dramatically increases throughput, especially for meshes below 100 microns, by eliminating the need for mechanical screen cleaning methods which can degrade the mesh integrity or contaminate the product. The use of advanced materials, particularly corrosion-resistant 316L stainless steel with ultra-smooth surface finishes, is standardizing machine design for critical sanitary applications, aligning the equipment with stringent FDA and GMP requirements globally.

Another crucial technological development involves sophisticated motion control and automation systems. Modern sifters are equipped with Variable Frequency Drives (VFDs) and specialized balancing mechanisms that allow operators to precisely tune the vibration pattern (amplitude, frequency, and phase angle) based on the specific rheological properties of the material being processed. This customization ensures optimal separation efficiency and minimizes material degradation (attrition). Furthermore, integration of Internet of Things (IoT) sensors and Industrial Control Systems (ICS) enables real-time monitoring of machine health, including bearing temperature, motor load, and vibration spectrum analysis. This digitalization facilitates predictive maintenance scheduling and remote diagnostics, moving the industry towards Industry 4.0 standards.

Innovation is also evident in the modular design and ease-of-cleaning capabilities, particularly in the food and pharmaceutical sectors. Quick-release clamping systems, tool-free mesh exchange mechanisms, and clean-in-place (CIP) compatibility are now highly sought-after features that reduce labor time for changeovers and enhance operational safety. Specialized systems are also being developed for inert gas handling (e.g., nitrogen purging) when sifting highly sensitive or explosive materials like metal powders or specialty chemicals, ensuring process safety and preventing material oxidation. The convergence of these technological innovations is driving the market towards highly efficient, digitally controlled, and exceptionally hygienic sifting solutions, redefining operational benchmarks for purity and productivity.

Regional Highlights

North America maintains a dominant position in terms of market value, driven by a highly mature pharmaceutical industry and significant investment in advanced manufacturing processes. The region’s stringent regulatory environment, particularly concerning food safety and drug purity enforced by the FDA, mandates the constant replacement and upgrading of older equipment with highly automated, stainless-steel sanitary sifters. The United States is the central market hub, characterized by strong demand for high-capacity and precision gyratory screeners for large-scale production of specialized chemicals and bulk pharmaceuticals. Furthermore, the rapid growth of the nutraceutical and medical device sectors further fuels demand for reliable classification equipment. Manufacturers in this region focus heavily on providing detailed validation packages and superior after-sales technical support to meet customer compliance requirements.

Europe represents another key region, particularly Germany, France, and the UK, due to their strong presence in the chemical, food processing, and automotive industries. European manufacturers are leaders in developing highly specialized sifting technologies, focusing heavily on sustainability and energy efficiency in their machine designs. The region demonstrates high demand for tumbler screeners and ultrasonic systems for processing fine chemical powders and high-value materials used in specialized battery technology and aerospace applications. Regulatory frameworks such as ATEX directives are critical here, driving the market toward explosion-proof and intrinsically safe sifting solutions. The European market emphasizes precision engineering and longevity, prioritizing capital equipment that offers high OEE and low operational lifetime costs.

Asia Pacific (APAC) is projected to be the fastest-growing region during the forecast period. This rapid expansion is primarily attributable to massive government and private sector investments aimed at expanding and modernizing the domestic pharmaceutical, food processing, and chemical industries in countries like China, India, and South Korea. China, as the world's manufacturing powerhouse, exhibits immense demand for both basic and advanced sifting machines across a wide range of industries, from mining to electronics. India’s burgeoning generic drug manufacturing sector necessitates continuous investment in validated process equipment. While the initial demand often focuses on cost-effective, high-throughput circular sifters, the increasing regulatory alignment with global standards is rapidly driving demand for sophisticated, sanitary-design equipment. This shift represents a significant opportunity for international vendors specializing in hygienic and automated systems.

- North America: Market dominance due to stringent FDA regulations, mature pharmaceutical and chemical industries, and high adoption of automated, validated sanitary equipment.

- Europe: Strong demand for precision sifting technology, driven by specialization in fine chemicals, high focus on ATEX compliance, and robust R&D in energy-efficient designs.

- Asia Pacific (APAC): Highest growth rate globally, spurred by infrastructural development, massive expansion of the pharmaceutical and food processing sectors in China and India, and increasing demand for modern, reliable machinery.

- Latin America (LATAM): Growth concentrated in mining, construction, and basic food processing sectors, focusing on robust, high-capacity sifters for bulk materials.

- Middle East & Africa (MEA): Emerging market potential driven by investments in petrochemicals, infrastructure projects, and localized food manufacturing, leading to foundational demand for standard vibrating screeners.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Vibrating Sifter Machine Market.- Russell Finex

- Sweco (A Duravant Company)

- Kason Corporation

- Gericke Group

- GKM Siebtechnik

- Retsch GmbH

- Derrick Corporation

- Midwestern Industries

- Vibra-Pro, Inc.

- Pennwalt Process Technologies

- Star Trace Private Limited

- Sodeva Process

- VIBROSCREEN, Inc.

- Gough Engineering (Process Technology) Ltd.

- Xinxiang Dayong Vibration Equipment Co., Ltd.

- J. Engelsmann AG

- Cleveland Vibrator Company

- A.S.P. Sealing Solutions

- Changzhou Jinggong Machinery Co., Ltd.

- Henan Shuangli Machinery Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Vibrating Sifter Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a Vibrating Sifter Machine in the pharmaceutical industry?

In the pharmaceutical industry, the primary function is to ensure product purity and particle size uniformity by accurately classifying Active Pharmaceutical Ingredients (APIs) and excipients, removing oversized contaminants, and validating material readiness according to strict GMP standards.

How does ultrasonic technology improve the performance of vibrating sifters?

Ultrasonic technology prevents screen blinding, which occurs when fine particles clog the mesh openings. By vibrating the screen mesh at high frequency, it keeps the apertures clear, significantly increasing throughput and efficiency, especially when handling fine, sticky, or electrostatically charged powders.

What are the key differences between a Circular Vibratory Sifter and a Tumbler Screener?

Circular vibratory sifters use high frequency, low amplitude vibration for high throughput separation. Tumbler screeners utilize a three-dimensional gyratory motion (similar to manual sifting) with low frequency and long retention time, providing extremely high separation accuracy and gentle handling, suitable for sensitive or friable materials.

Which region currently dominates the Vibrating Sifter Machine Market in terms of revenue?

North America currently dominates the market revenue, driven by robust investments in advanced manufacturing technologies, high demand from the pharmaceutical and specialized chemical sectors, and stringent regulatory requirements mandating validated, hygienic equipment.

What is the projected Compound Annual Growth Rate (CAGR) for the market between 2026 and 2033?

The Vibrating Sifter Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033, fueled by global regulatory compliance and industrial automation trends.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager