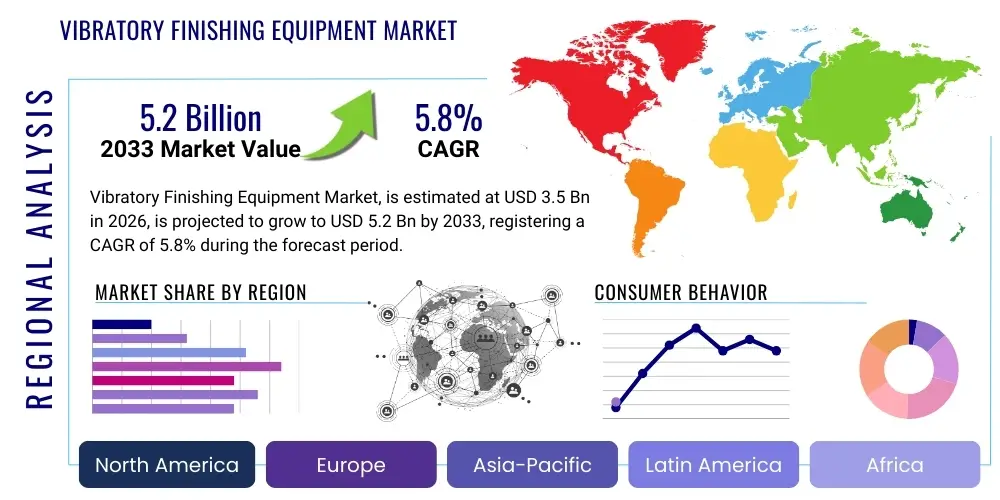

Vibratory Finishing Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436872 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Vibratory Finishing Equipment Market Size

The Vibratory Finishing Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 3.5 Billion in 2026 and is projected to reach USD 5.2 Billion by the end of the forecast period in 2033.

Vibratory Finishing Equipment Market introduction

The Vibratory Finishing Equipment Market encompasses machinery utilized for mass finishing operations, primarily focused on deburring, descaling, radiusing, polishing, and cleaning small to medium-sized components using abrasive media and liquid compounds. These finishing processes are essential across various industrial sectors to improve surface quality, enhance aesthetic appeal, and prepare parts for subsequent treatments like plating or coating. The equipment, available primarily as tub or bowl systems, utilizes controlled vibration to create friction between the components and the media, achieving uniform surface refinement efficiently. Major applications span the highly demanding automotive, aerospace, medical devices, and precision engineering industries, where high-quality surface integrity is non-negotiable. The market is significantly driven by the accelerating demand for high-precision components, strict regulatory standards for product finish, and the continuous industrial transition towards fully automated manufacturing processes that require consistent, repeatable surface preparation methods.

Vibratory Finishing Equipment Market Executive Summary

The Vibratory Finishing Equipment Market is currently characterized by robust business trends focusing on high-efficiency, noise-reduction technologies, and increased integration of automation features to meet Industry 4.0 requirements. Segment trends indicate a strong shift towards fully automatic vibratory bowl finishers, particularly in high-volume production environments, driven by the necessity for reduced labor costs and maximized throughput. Geographically, the Asia Pacific (APAC) region dominates the market share due to its massive and rapidly expanding automotive, electronics, and general manufacturing base, benefiting from significant foreign direct investment and localized technological adoption. Conversely, mature markets in North America and Europe are driving innovation through the integration of advanced monitoring systems and sustainable finishing media, prioritizing environmental compliance and energy efficiency. Overall market growth is underpinned by the consistent need for superior component surface quality across all high-precision manufacturing verticals.

AI Impact Analysis on Vibratory Finishing Equipment Market

User inquiries frequently revolve around how AI and Machine Learning (ML) can transition vibratory finishing from a traditionally empirical process to a data-driven, precise operation. Key themes center on achieving zero-defect finishing, optimizing media consumption, and reducing cycle times. Specifically, users are keen on predictive algorithms that anticipate media wear, identify process anomalies, and recommend optimal finishing recipes based on material and geometry complexity. The manufacturing sector views AI integration as a direct solution to inconsistencies arising from manual process adjustment and media degradation, aiming for unparalleled process repeatability and reduced scrap rates, especially in critical applications like aerospace turbine blades and orthopedic implants.

The integration of AI involves deploying sophisticated sensor technology, including acoustic, vibration, and temperature monitoring, coupled with cloud-based analytics platforms. This integration allows manufacturers to monitor operational parameters in real-time, thereby enabling continuous process adjustment and optimization without human intervention. This digital feedback loop ensures consistency across batches, a critical requirement in high-precision sectors. Furthermore, AI systems facilitate rapid calibration when switching between different component types or materials, drastically minimizing downtime and mitigating common manual setup errors, accelerating the deployment of complex finishing tasks across varied production lines.

The long-term strategic value of AI lies in creating self-optimizing finishing cells, fully aligning with the vision of smart factories. Manufacturers expect AI to manage complex variables such as compound ratios, water flow rates, vibration frequency, and load capacity autonomously. This sophisticated level of automation not only addresses persistent skilled labor shortages within the mass finishing sector but also unlocks new levels of operational efficiency and energy optimization. Consequently, the incorporation of AI-enabled controls is rapidly positioning high-end vibratory finishing equipment as a critical, high-value component for enterprises committed to maintaining Industry 4.0 standards globally and maximizing lifecycle value of their capital investments.

- Enhanced Predictive Maintenance: AI algorithms analyze vibration and acoustic signatures to predict equipment failure and schedule preventative maintenance, minimizing unplanned downtime.

- Optimized Process Parameters: Machine learning models determine the ideal combination of media type, compound ratio, and cycle time for specific component geometries, ensuring consistent surface finish.

- Automated Quality Control: Integrated vision systems and AI analyze component images post-finish to detect defects (e.g., incomplete deburring or polishing flaws) automatically, reducing reliance on manual inspection.

- Media Lifecycle Management: AI tracks the wear rate of finishing media and recommends timely replenishment or replacement, ensuring optimal process performance and reduced material waste.

- Energy Efficiency Optimization: Algorithms adjust equipment operation modes (e.g., amplitude and frequency) based on load size and desired finish, reducing energy consumption per batch.

DRO & Impact Forces Of Vibratory Finishing Equipment Market

The Vibratory Finishing Equipment Market dynamics are characterized by several compelling Drivers (D), significant Restraints (R), and substantial Opportunities (O), which collectively shape the competitive landscape and technological development. Key drivers include the escalating global demand for high-quality, precise surface finishes in complex components across the automotive and aerospace industries, coupled with the increasing adoption of automated manufacturing processes seeking repeatable results. Restraints primarily involve the high initial capital investment required for advanced machinery, persistent issues related to operational noise, and the environmental disposal concerns associated with spent media and wastewater from wet finishing processes. However, promising opportunities emerge from the development of advanced, eco-friendly finishing media and compounds, the integration of remote monitoring capabilities (IoT), and the expansion into emerging manufacturing hubs in Southeast Asia and Latin America. These forces collectively dictate technological advancement, focusing on noise reduction, sustainability, and enhanced automation features.

Segmentation Analysis

The Vibratory Finishing Equipment market is extensively segmented based on machine type, operational modality, automation level, and end-user application, reflecting the diverse requirements of the manufacturing sector. Analysis by machine type reveals the dominance of vibratory bowl finishers due to their high throughput and ease of integration into automated lines, while vibratory tub finishers remain crucial for processing larger or longer components that require specialized handling. The distinction between wet and dry processes drives equipment features, with dry finishing gaining traction in applications requiring a fine polish or minimal waste water. Understanding these segments is crucial for strategic market entry and product development, enabling manufacturers to tailor solutions to specific industry needs, whether addressing high-volume automotive parts or high-specification aerospace components.

- By Type:

- Vibratory Bowl Finishers

- Vibratory Tub Finishers (Rectangular Machines)

- Centrifugal Disc Finishers

- Centrifugal Barrel Finishers

- By Operation:

- Wet Finishing (Wet Process Equipment)

- Dry Finishing (Dry Process Equipment)

- By Automation Level:

- Manual/Batch Systems

- Semi-Automatic Systems

- Fully Automatic (Continuous Flow) Systems

- By Application/End-User Industry:

- Automotive (Engine components, transmission parts)

- Aerospace and Defense (Turbine blades, structural components)

- Medical Devices (Implants, surgical tools)

- Jewelry and Consumer Goods

- Heavy Machinery and Construction

- Precision Engineering (Electronics, fasteners)

- By Media Type:

- Ceramic Media

- Plastic Media

- Steel Media

- Natural Media (e.g., Walnut Shells, Corn Cobs)

Value Chain Analysis For Vibratory Finishing Equipment Market

The value chain for vibratory finishing equipment begins upstream with the procurement of essential raw materials, primarily specialized steels and high-density polymers for machine construction, alongside the sourcing of abrasive media (ceramic, plastic, steel) and chemical compounds. Upstream activities are heavily reliant on stable supply chains for high-quality components, including motors, control panels, and specialized liners (polyurethane) that withstand intense vibrational stresses. The manufacturing stage involves complex fabrication and assembly, demanding high engineering precision to ensure the equipment operates reliably under industrial conditions and minimizes noise output, representing a significant value addition point.

Moving downstream, the distribution channel is bifurcated into direct sales channels, favored for highly customized or large-scale automatic systems requiring direct technical support and installation expertise, and indirect channels utilizing regional distributors or third-party integrators. These indirect partners play a crucial role in providing localized inventory, maintenance services, and application consulting, particularly in fragmented geographical markets. The effectiveness of the downstream channel is intrinsically linked to the distributor's technical competency regarding mass finishing applications, ensuring that end-users receive the optimal media and compound recommendations tailored to their specific material and finish requirements.

The ultimate value realization occurs at the end-user stage, where the equipment improves component quality, reduces manual labor, and enhances overall production efficiency. Feedback from end-users, especially those in high-compliance sectors like medical and aerospace, is critical for continuous product improvement, driving manufacturers to invest in R&D focusing on process monitoring, waste management, and sustainable media development. The entire chain is now seeing increased digitization, with remote diagnostics and IoT integration adding significant post-sale value, improving equipment uptime, and securing long-term service contracts.

Vibratory Finishing Equipment Market Potential Customers

The primary customers for vibratory finishing equipment are organizations engaged in precision component manufacturing that require consistent, high-quality surface preparation for large volumes of parts. This includes Tier 1 and Tier 2 suppliers within the global automotive industry, which rely on mass finishing for critical engine, transmission, and braking components to ensure functional integrity and longevity. The aerospace sector is a high-value customer segment, utilizing vibratory equipment for deburring and polishing components such as turbine blades, structural brackets, and landing gear parts, where stringent regulatory standards and zero-defect tolerance are paramount, often necessitating highly sophisticated, automated systems.

Beyond traditional heavy industries, the medical device manufacturing sector represents a rapidly growing customer base. Manufacturers of surgical instruments, orthopedic implants (e.g., knee and hip replacements), and dental prosthetics require finishing processes that achieve extremely smooth, sterilized surfaces free of microscopic burrs. This demand drives the market for highly controlled, specialized finishing systems, often utilizing gentle media and specialized compounds to maintain material properties while achieving biocompatibility standards. These customers prioritize process validation, repeatability, and documentation capabilities above all else, often opting for premium equipment with integrated data logging features.

Furthermore, general precision engineering firms, including those manufacturing fasteners, tools, consumer electronics housings, and specialized hydraulic components, constitute a foundational customer segment. These diverse buyers seek cost-effective solutions to improve component appearance and functionality, often favoring versatile vibratory bowl finishers for general-purpose applications. The increasing shift towards micro-manufacturing and complex 3D-printed parts is also generating a niche demand for fine finishing equipment capable of handling delicate and geometrically intricate structures, expanding the customer base toward advanced manufacturing research labs and specialized contract finishing service providers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.5 Billion |

| Market Forecast in 2033 | USD 5.2 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Rosler Oberflächentechnik GmbH, Mass Finishing, Inc., Walther Trowal GmbH & Co. KG, Vibra Finish Co., Bel Air Finishing Supply Corp., Sweco, Inc., C&M Topline, Acme Finishing Systems, OTEC Präzisionsfinish GmbH, PDJ Vibro, LLC, Washington Mills, Kemet International, BV Products, Finishing Systems, Inc., Precision Finishing, Inc., Metal Finishing Supply Inc., Ken-Tool, Norstone, Inc., Vibra Finish (Hong Kong) Limited, and Vibe Tech. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Vibratory Finishing Equipment Market Key Technology Landscape

The technological evolution of the Vibratory Finishing Equipment Market is primarily driven by the need for enhanced operational efficiency, superior surface finish predictability, and reduced environmental impact. Contemporary equipment incorporates advanced digital control systems that allow precise regulation of key parameters, including vibration frequency, amplitude, and process cycle time, moving away from purely mechanical adjustments. A key area of innovation is in the development of noise suppression technologies, utilizing specialized dampening materials, acoustic enclosures, and optimized equipment designs to comply with increasingly strict occupational safety and health regulations, making the equipment suitable for integration into diverse factory environments.

Another significant technological advancement lies in the formulation and optimization of finishing media and compounds. Manufacturers are continuously developing high-performance, long-lasting abrasive media (e.g., specialized ceramic or plastic media with controlled wear rates) and environmentally friendly liquid compounds that minimize hazardous waste generation. Furthermore, the integration of auxiliary technologies, such as sophisticated filtration and wastewater recycling systems, is becoming standard for wet finishing applications, addressing the market restraint related to environmental compliance and promoting sustainable manufacturing practices across the sector.

Crucially, the rise of Industry 4.0 principles is driving the adoption of smart finishing technologies, including IoT sensors for real-time process monitoring, cloud connectivity for remote diagnostics, and integrated automation systems for automated loading and unloading. These technological enhancements enable predictive maintenance, immediate fault detection, and seamless integration with broader Manufacturing Execution Systems (MES). This smart manufacturing focus is transforming the vibratory finishing process into a data-rich operation, providing manufacturers with unprecedented control over surface quality metrics and total cost of ownership, thereby solidifying the equipment's role as a critical component in the modern, connected factory ecosystem.

Regional Highlights

- Asia Pacific (APAC): APAC represents the largest and fastest-growing regional market, driven by the massive expansion of the automotive and consumer electronics manufacturing base in countries like China, India, and South Korea. Rapid industrialization, favorable government policies promoting foreign investment, and the increasing consumer demand for manufactured goods necessitating high-quality finishing are central to this regional dominance. Investments are primarily directed towards high-throughput, fully automated vibratory bowl systems.

- North America: This region is characterized by high demand for sophisticated and high-precision finishing equipment, particularly within the aerospace and medical device sectors. The market here prioritizes advanced automation, AI integration for quality control, and compliance with stringent environmental regulations. While volume growth is steady, the focus is on value addition through technological innovation and customized finishing solutions.

- Europe: Europe, particularly Germany, Italy, and the UK, exhibits a mature market defined by rigorous quality standards and a strong emphasis on sustainability. European manufacturers are leaders in developing quiet, energy-efficient equipment and eco-friendly media. The automotive and general engineering sectors remain primary consumers, driving demand for high-performance equipment that aligns with circular economy principles.

- Latin America (LATAM): The LATAM market, led by Brazil and Mexico, shows significant growth potential, fueled by expanding local automotive assembly operations and infrastructure development projects. The market is increasingly adopting semi-automatic and automatic systems, moving away from manual processes, reflecting an ongoing industrial modernization trend requiring basic, reliable, and cost-effective finishing solutions.

- Middle East and Africa (MEA): This region is an emerging market with growing demand linked to investments in defense manufacturing and heavy industries, particularly in Saudi Arabia and the UAE. Market penetration is accelerating, focusing initially on standard, robust vibratory tub finishers for general deburring tasks, with future growth anticipated in specialized applications as industrial diversification progresses.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Vibratory Finishing Equipment Market.- Rosler Oberflächentechnik GmbH

- Walther Trowal GmbH & Co. KG

- Mass Finishing, Inc.

- Sweco, Inc.

- Bel Air Finishing Supply Corp.

- OTEC Präzisionsfinish GmbH

- Vibra Finish Co.

- C&M Topline

- PDJ Vibro, LLC

- Kemet International Ltd.

- Washington Mills

- BV Products

- Finishing Systems, Inc.

- Acme Finishing Systems

- Precision Finishing, Inc.

- Metal Finishing Supply Inc.

- Ken-Tool

- Norstone, Inc.

- Rollwasch Italiana S.p.A.

- Vibe Tech

Frequently Asked Questions

Analyze common user questions about the Vibratory Finishing Equipment market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of vibratory finishing equipment in manufacturing?

The primary function of vibratory finishing equipment is to execute mass finishing processes such as deburring, descaling, radiusing, and polishing of component surfaces. It ensures consistency, improves surface quality, and prepares parts for subsequent surface treatments like plating or coating in high-volume production.

Which industrial application accounts for the largest demand in the vibratory finishing equipment market?

The automotive industry accounts for the largest demand, utilizing the equipment extensively for critical engine, chassis, and transmission components. Strict requirements for part performance and lifecycle durability necessitate consistent, high-quality surface integrity achieved through mass finishing processes.

What are the key technological advancements driving innovation in the market?

Key advancements include the integration of IoT and AI for predictive maintenance and process optimization, development of noise reduction technologies, and the introduction of sustainable, high-performance finishing media and environmentally friendly compounds to minimize industrial waste.

How do vibratory bowl finishers differ from vibratory tub finishers?

Vibratory bowl finishers are ideal for high-volume, continuous processing of small to medium-sized parts, utilizing centrifugal action for efficient media movement. Tub finishers, characterized by their rectangular design, are typically used for processing larger, longer, or more delicate components that require specialized separation and handling.

Which geographical region exhibits the strongest growth potential for vibratory finishing equipment?

The Asia Pacific (APAC) region, driven by rapid industrialization, massive investments in automotive and electronics manufacturing, and expanding production capacities in countries like China and India, is projected to exhibit the strongest growth potential through 2033.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager