Vibratory Pile Hammers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433885 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Vibratory Pile Hammers Market Size

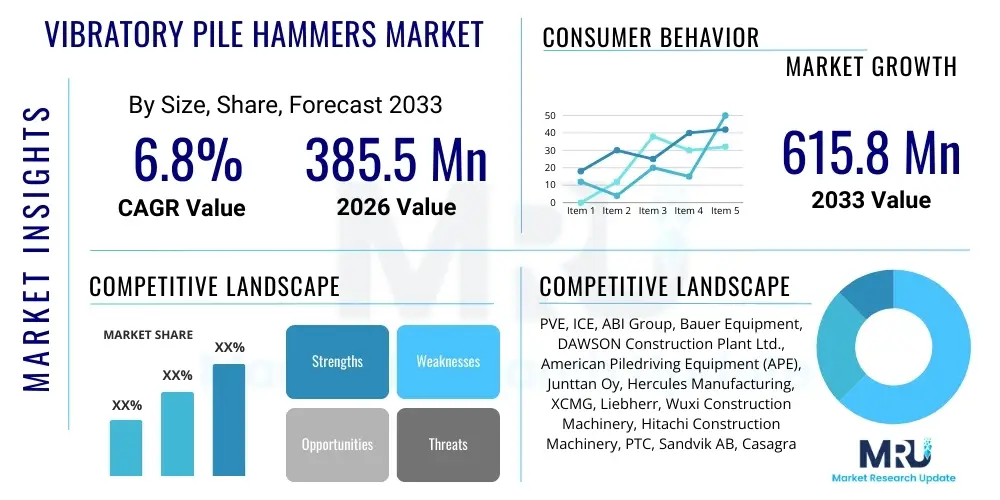

The Vibratory Pile Hammers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at $385.5 Million in 2026 and is projected to reach $615.8 Million by the end of the forecast period in 2033.

Vibratory Pile Hammers Market introduction

The Vibratory Pile Hammers Market encompasses the global trade and utilization of specialized construction equipment designed for driving or extracting piles, sheets, casings, and beams into or out of the ground using high-frequency vibration. These machines, vital for foundation engineering, operate on the principle of reducing soil friction and inertia through oscillating motion, allowing the piles to penetrate dense or cohesive soil strata more efficiently than traditional impact hammers. The increasing complexity and scale of modern infrastructure projects, particularly those involving marine construction, deep foundations, and civil engineering works in urban environments, necessitate the use of these advanced vibrating mechanisms due to their speed, reduced noise pollution compared to impact hammers, and enhanced versatility across various soil types.

Vibratory pile hammers are categorized primarily based on their mounting mechanism (excavator-mounted or crane-suspended) and their operational frequency (low or high). The high-frequency vibrators, in particular, are gaining traction due to regulations limiting noise in residential areas, as their operation minimizes ground disturbance and structural vibration issues. Major applications span residential and commercial construction, transportation infrastructure (bridges, railways, roads), port development, offshore wind farm installations, and critical pipeline laying in the oil and gas sector. The primary benefit of employing vibratory technology lies in the significant reduction of project timelines and the lower wear and tear on the pile materials themselves, making them an economically viable choice for large-scale foundation work.

Driving factors fueling this market include rapid global urbanization leading to extensive demand for new residential and commercial infrastructure, coupled with massive governmental investments in upgrading aging transportation networks, especially in the Asia Pacific and North American regions. Furthermore, the global push towards renewable energy infrastructure, specifically offshore wind power generation, requires robust marine foundation installations, where vibratory hammers are the preferred tool for driving monopiles and jacket foundations. Continuous innovation focused on increasing hydraulic power, improving noise attenuation, and developing specialized clamps and attachments for diverse piling materials further solidify the market’s positive growth trajectory over the forecast period.

Vibratory Pile Hammers Market Executive Summary

The Vibratory Pile Hammers Market is defined by consistent demand driven by robust global infrastructure spending and the persistent need for rapid, efficient foundation solutions in challenging geological conditions. Business trends indicate a strong move toward higher frequency, variable moment vibratory hammers that offer superior control, reduced environmental impact, and greater compatibility with standard construction machinery like excavators. Key market players are intensely focused on integrating telematics and IoT capabilities into their machinery, enabling remote monitoring, predictive maintenance, and optimized performance metrics for fleet management companies and rental businesses. Furthermore, the rental market segment is experiencing accelerated growth, particularly in emerging economies, as contractors prefer renting high-capital equipment to mitigate ownership risks and maintenance costs.

Regionally, Asia Pacific (APAC) holds the dominant market share due to unparalleled infrastructure development programs in China, India, and Southeast Asian nations. North America and Europe, while mature markets, show steady growth fueled by rehabilitation projects, strict environmental regulations favoring quiet operation, and burgeoning investment in offshore renewable energy projects. In terms of segments, the excavator-mounted segment is exhibiting the fastest growth due to its versatility and ease of mobilization on smaller and medium-sized construction sites. Concurrently, the application segment driven by infrastructure construction, including roads, bridges, and port expansion, remains the largest revenue generator, although the marine construction segment is expected to demonstrate the highest CAGR, particularly supporting the transition to offshore energy sources.

Overall, the market dynamic is characterized by the strategic consolidation of key manufacturers, rapid adoption of advanced hydraulic systems for improved efficiency, and intense competition based on machinery power, reliability, and service network strength. The shift towards electrification and hybrid power solutions is an emerging trend, addressing carbon reduction targets set by global construction firms. Successful market penetration hinges on manufacturers’ ability to provide machinery that balances high driving force with compliance with stringent global noise and vibration standards, ensuring project viability in sensitive urban and ecological zones.

AI Impact Analysis on Vibratory Pile Hammers Market

Common user questions regarding AI’s impact on the Vibratory Pile Hammers Market frequently center on predictive maintenance, operational efficiency improvements, and autonomous foundation laying processes. Users are keen to understand how AI-driven diagnostics can minimize downtime and reduce catastrophic failures associated with high-stress machinery. Furthermore, there is significant interest in how machine learning algorithms can analyze real-time soil resistance and geotechnical data to automatically adjust the hammer's frequency, amplitude, and eccentric moment for optimal driving performance, maximizing energy efficiency and ensuring structural integrity. Expectations are high for AI to streamline complex logistical challenges associated with large piling projects, including automated fleet management, scheduling, and optimizing the sequence of operations, leading to faster project completion times and reduced operational costs across the construction life cycle.

- Real-Time Operational Optimization: AI algorithms analyze soil conditions, pile material, and hammer telemetry data to automatically adjust vibratory parameters (frequency, amplitude) for maximum driving efficiency and minimal energy expenditure.

- Predictive Maintenance and Diagnostics: Machine learning models monitor vibration patterns, oil pressure, and temperature data to predict potential component failures (e.g., bearings, hydraulic pumps) weeks in advance, drastically reducing unplanned downtime and maintenance costs.

- Autonomous Piling Operations: Integration of AI with GPS, LiDAR, and specialized sensors to enable semi-autonomous or fully autonomous positioning and driving of piles, enhancing precision and operator safety.

- Geotechnical Data Integration: AI platforms process complex geotechnical reports and site surveys to recommend the most suitable vibratory hammer model and operational settings before construction begins.

- Enhanced Safety Protocols: AI systems monitor operator fatigue and ensure adherence to operational safety limits, automatically flagging or halting operations if instability or unsafe practices are detected.

DRO & Impact Forces Of Vibratory Pile Hammers Market

The Vibratory Pile Hammers Market is significantly influenced by a confluence of driving forces, major restraints, and emerging opportunities, all modulated by the critical impact forces of technological advancement and environmental regulation. The primary driver is robust government spending on infrastructure and renewable energy, particularly the global commitment to offshore wind farms which necessitate specialized marine piling equipment. Rapid urbanization, especially in emerging economies, further compounds the demand for efficient foundation equipment for high-rise buildings and transit systems. However, the market faces significant restraints, including the high initial capital investment required for these sophisticated machines and the stringent noise and vibration regulations in densely populated urban environments, which sometimes favor quieter, but slower, alternatives or require substantial noise mitigation measures.

Opportunities in the market are largely concentrated around technological innovation and geographic expansion. The development of advanced variable moment vibratory hammers, which allow operators to minimize ground resonance during start-up and shutdown, directly addresses noise complaints and regulatory constraints. Furthermore, the massive untapped potential in the specialized deep foundation and deep-sea infrastructure sectors presents lucrative avenues for manufacturers developing high-powered, durable machinery. The increasing prominence of the equipment rental market also provides an opportunity for manufacturers to gain wider market exposure without relying solely on large direct capital sales, catering to smaller and medium-sized contractors.

The impact forces shaping the market include competitive intensity driven by globalization, where key players from Europe and North America compete vigorously against fast-growing Asian manufacturers, particularly through aggressive pricing and expanding service networks. Economic volatility, particularly fluctuations in raw material prices (steel, specialized alloys) and hydraulic components, directly impacts manufacturing costs and equipment pricing. Crucially, the force of technological change, including the move towards electric and hybrid vibratory systems, is compelling manufacturers to invest heavily in R&D to maintain competitive parity and meet increasingly rigorous global environmental and efficiency standards, thereby accelerating product obsolescence cycles.

Segmentation Analysis

The Vibratory Pile Hammers Market segmentation provides a granular understanding of the diverse product offerings and application domains that constitute the industry. The market is primarily segmented based on Type (defining mounting method), Operating Frequency (influencing efficiency and noise), and End-Use Application (defining project type). This detailed breakdown reveals distinct demand patterns and market maturity levels across different product categories. For instance, the transition toward high-frequency and variable moment technology represents a maturation within the Type and Frequency segments, reflecting a market preference for environmentally compliant and high-performance solutions capable of handling complex geotechnical challenges efficiently.

The segmentation by Type, specifically distinguishing between Excavator-Mounted and Crane-Suspended units, highlights the differences in project scale and flexibility requirements. Excavator-mounted hammers offer superior maneuverability and are highly favored for confined or urban job sites, driving significant volume growth in residential and commercial construction. In contrast, crane-suspended systems provide the necessary power and reach for massive infrastructure projects, such as bridge construction and major port expansions. Analyzing these segments is crucial for manufacturers to tailor their production capabilities and marketing strategies, ensuring alignment with the specific logistical and power demands of various contractor types.

Furthermore, segmentation by Application is paramount, as the market is heavily cyclical and dependent on large government and private capital expenditure. The infrastructure sector (roads, bridges, railways) currently dominates revenue share, reflecting continuous global investment in connectivity. However, the Marine Construction segment is poised for the highest growth rate, driven explicitly by large-scale capital projects in offshore oil and gas decommissioning and, more significantly, the global transition to renewable offshore wind energy. Understanding these sectoral trends allows suppliers of vibratory pile hammers to forecast future demand accurately and prioritize R&D efforts towards specialized tools, such as those capable of handling the immense weight and dimensions of offshore monopiles and turbine foundations.

- By Type

- Excavator-Mounted Vibratory Pile Hammers

- Crane-Suspended Vibratory Pile Hammers

- Leader-Mounted Vibratory Pile Hammers

- By Frequency

- Low Frequency Hammers (Below 1000 RPM)

- High Frequency Hammers (Above 1000 RPM)

- Variable Moment Hammers

- By Application

- Construction (Residential, Commercial, Industrial)

- Infrastructure (Bridges, Roads, Railways)

- Marine Construction (Ports, Harbors, Offshore Wind)

- Oil and Gas (Pipeline Installation, Platforms)

- Environmental Projects (Cofferdams, Sheet Piling)

- By Power Source

- Hydraulic Vibratory Hammers

- Electric Vibratory Hammers (Emerging)

Value Chain Analysis For Vibratory Pile Hammers Market

The value chain for the Vibratory Pile Hammers Market begins with the Upstream segment, dominated by suppliers of critical raw materials and highly specialized components. This includes high-grade steel and alloys required for robust hammer casings and jaws, high-performance hydraulic systems (pumps, motors, valves), and advanced electronic controls and sensors. The quality and reliability of these upstream components are non-negotiable, directly influencing the final product's durability, power output, and operational lifespan under extreme stress conditions. Key relationships in this stage involve long-term procurement contracts with specialized hydraulic manufacturers and metal processors, where supply chain stability and quality control are primary concerns.

The Midstream phase involves the core manufacturing, assembly, and testing processes. Manufacturers leverage advanced CNC machining, precision welding, and intricate assembly lines to integrate hydraulic systems, eccentrics, gearboxes, and control units into the final hammer structure. This phase is characterized by high capital expenditure in production facilities and significant investment in R&D to optimize vibration damping, power-to-weight ratio, and noise reduction features. Once manufactured, the distribution channel plays a pivotal role in market penetration. Sales often occur through a dual strategy: Direct sales channels are utilized for large, custom orders placed by major global construction conglomerates and marine contractors, offering specialized technical support and long-term service agreements.

Conversely, Indirect distribution channels, primarily comprising independent heavy equipment distributors and dedicated equipment rental companies, handle the majority of standard machinery sales and rentals. Rental fleets are particularly crucial as they allow smaller contractors to access high-value equipment without major capital outlay, thereby expanding the market reach significantly. The Downstream phase encompasses after-sales services, including maintenance, repairs, spare parts provision, and operator training. Given the specialized nature of vibratory hammers, maintaining an extensive and responsive service network is a critical competitive differentiator, ensuring minimal operational downtime for end-users like civil engineering firms, specialized piling contractors, and port authorities.

Vibratory Pile Hammers Market Potential Customers

The potential customer base for vibratory pile hammers is diverse yet specialized, primarily comprising entities engaged in heavy civil engineering and large-scale foundation work. The End-Users/Buyers of this product are predominantly specialized piling contractors who own and operate the equipment for foundation projects. These contractors make purchasing decisions based on the hammer's maximum driving force (moment rating), compatibility with their existing carrier fleet (excavator size), reliability metrics, and local compliance with environmental regulations, particularly noise and vibration controls. Large global engineering, procurement, and construction (EPC) firms also represent significant buyers, often procuring hammers as part of comprehensive project equipment packages for massive infrastructure developments such as high-speed rail lines and cross-sea bridges.

Another crucial customer segment is the heavy equipment rental and leasing sector. These companies purchase large volumes of varied vibratory hammers to maintain a diverse fleet suitable for different project sizes and geological conditions. Their purchasing criteria focus heavily on the machine's durability, ease of maintenance, and high resale value. Furthermore, governmental and port authorities involved in maritime infrastructure expansion and maintenance (e.g., deepening navigation channels, constructing new berths) frequently act as direct buyers or heavily influence the equipment specifications utilized by their chosen contractors. The burgeoning offshore wind energy sector also generates a highly specialized set of customers, including dedicated marine foundation installation companies who require custom, high-capacity vibratory hammers for deep-sea operations.

Finally, the oil and gas industry remains a consistent, albeit fluctuating, customer base, utilizing vibratory hammers for the installation and decommissioning of offshore platforms and the laying of subsea pipelines. These buyers prioritize equipment robustness and specialized features capable of operating reliably in harsh marine environments. The diversity of these potential customers underscores the need for manufacturers to offer a wide product portfolio, ranging from compact, low-frequency hammers for urban construction to colossal, crane-suspended units required for major offshore infrastructure projects, backed by comprehensive global technical support.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $385.5 Million |

| Market Forecast in 2033 | $615.8 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | PVE, ICE, ABI Group, Bauer Equipment, DAWSON Construction Plant Ltd., American Piledriving Equipment (APE), Junttan Oy, Hercules Manufacturing, XCMG, Liebherr, Wuxi Construction Machinery, Hitachi Construction Machinery, PTC, Sandvik AB, Casagrande S.p.A., Foundation Equipment Corp., TGS Vibro Hammer, HPSI. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Vibratory Pile Hammers Market Key Technology Landscape

The technological landscape of the Vibratory Pile Hammers Market is rapidly evolving, driven primarily by the need for increased efficiency, greater control, and compliance with strict environmental mandates. The most significant technological advancement is the widespread adoption of Variable Moment (VM) technology. VM hammers utilize adjustable counterweights or eccentric masses, allowing the operator to dynamically adjust the moment and frequency during operation. Crucially, this technology enables the machine to start and stop without transmitting resonant low-frequency vibrations into the surrounding soil, thereby eliminating nuisance ground movement and significantly reducing the risk of structural damage to nearby buildings, making them ideal for urban projects.

Another major technological focus involves the refinement of hydraulic and power management systems. Modern vibratory hammers employ highly sophisticated, closed-loop hydraulic circuits that maximize the transfer of power from the carrier machine or power pack directly to the eccentric weights, ensuring higher overall energy efficiency. Telematics and integrated sensor technologies represent a rapidly growing area, enabling remote diagnostics, real-time performance monitoring, and geo-fencing capabilities. These smart systems transmit critical data on parameters such as oil temperature, pressure, and instantaneous vibration readings, which are vital for predictive maintenance scheduling and optimizing operational efficiency across large construction fleets, reducing overall operating costs for contractors.

The industry is also seeing pioneering efforts in electrification. While hydraulic systems dominate, the emergence of fully electric vibratory hammers signals a commitment to reducing emissions and noise further. Electric hammers, powered by onboard battery packs or high-voltage lines, offer unparalleled precision in controlling frequency and amplitude, minimizing localized emissions compared to traditional diesel power packs. This technology, though currently niche and high-cost, is expected to become standard, especially for projects mandating zero-emission equipment. Furthermore, advancements in clamp design, utilizing multi-jaw and self-centering systems, enhance safety and allow for the efficient handling of a wider variety of sheet piles, H-beams, and concrete elements, boosting the versatility of the equipment.

Regional Highlights

The global Vibratory Pile Hammers Market exhibits significant regional variations in growth drivers, technological adoption, and market maturity, heavily influenced by local infrastructure spending and environmental regulations. Asia Pacific (APAC) stands as the largest and fastest-growing market, primarily due to aggressive infrastructure development policies in China and India, focusing on massive railway networks, port expansions, and urbanization projects. The sheer scale of construction activity in Southeast Asia, particularly Vietnam and Indonesia, drives robust demand for both small excavator-mounted units and large crane-suspended hammers for marine projects. APAC manufacturers are also emerging as key global competitors, focusing on cost-effective and powerful equipment models.

North America and Europe represent mature markets characterized by stable demand for technologically advanced and environmentally compliant machinery. In North America, public-private partnerships supporting bridge repair, highway expansion, and pipeline installation maintain steady market momentum. The European market, guided by the strictest environmental standards (especially regarding noise and ground vibration), exhibits high demand for high-frequency and variable moment vibratory hammers. Europe’s regional growth is strongly underpinned by vast investments in offshore wind energy projects in the North and Baltic Seas, necessitating specialized, high-capacity marine vibratory equipment.

Latin America (LATAM) and the Middle East and Africa (MEA) are emerging regions offering high growth potential, though they are often characterized by project volatility. LATAM market growth is tied to mining infrastructure and limited urban development projects, relying heavily on equipment imports. The MEA region, particularly the Gulf Cooperation Council (GCC) states, sees intermittent high demand fueled by mega-projects in construction, such as new city developments and major port projects. Adoption in MEA is often focused on maximizing power and efficiency in challenging desert and marine environments, with equipment reliability and after-sales service being paramount purchasing considerations.

- Asia Pacific (APAC): Dominates the market share due to unprecedented urbanization rates and expansive government investment in transportation, port facilities, and residential infrastructure, particularly in China and India.

- North America: Stable market growth driven by the replacement cycle of aging infrastructure (bridges, roads) and a steady increase in commercial construction projects, favoring excavator-mounted models for efficiency.

- Europe: High adoption of advanced, high-frequency, Variable Moment (VM) hammers to comply with stringent noise and vibration regulations. Strongest growth linked to specialized marine construction for offshore wind farms.

- Middle East & Africa (MEA): Growth is project-specific, fueled by oil & gas infrastructure, and large urban development initiatives in Saudi Arabia and the UAE, demanding powerful, reliable equipment suitable for harsh conditions.

- Latin America (LATAM): Market expansion dependent on commodity prices and foreign investment in mining and energy infrastructure, with a growing reliance on the equipment rental segment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Vibratory Pile Hammers Market.- PVE Piling & Vibro Equipment

- International Construction Equipment (ICE)

- ABI Group (DELMAG)

- American Piledriving Equipment (APE)

- Bauer Equipment

- DAWSON Construction Plant Ltd.

- Junttan Oy

- Hercules Manufacturing

- XCMG Construction Machinery

- Liebherr Group

- Wuxi Construction Machinery

- Hitachi Construction Machinery

- PTC

- Sandvik AB (Through acquisition/distribution channels)

- Casagrande S.p.A.

- TGS Vibro Hammer

- HPSI Piling Equipment

- OZMA Piling

- Berminghammer Foundation Equipment

- Kowan Industry Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Vibratory Pile Hammers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What factors determine the selection of a vibratory pile hammer for a project?

Hammer selection is primarily determined by the pile type (sheet pile, H-beam, pipe), the pile size and weight, the required penetration depth, the soil characteristics (cohesive vs. granular), and local noise/vibration regulations. The hammer's eccentric moment and hydraulic power output must be matched to the project demands for optimal efficiency.

How do Variable Moment (VM) vibratory hammers differ from standard hammers?

VM vibratory hammers utilize counter-rotating eccentrics that can be dynamically synchronized to minimize the eccentric moment during start-up and shut-down phases. This crucial feature eliminates the detrimental low-frequency resonance associated with standard hammers, making VM units highly suitable for use near existing structures in urban environments.

Which application segment is expected to show the highest growth rate in the forecast period?

The Marine Construction segment, specifically driven by the rapid global expansion of offshore wind energy projects, is projected to register the highest Compound Annual Growth Rate (CAGR). These complex projects require specialized, high-capacity vibratory hammers for driving large monopiles and jacket foundations in deep-water environments.

What role does telematics play in the operation of modern vibratory pile hammers?

Telematics enables real-time remote monitoring of critical operational parameters, including oil pressure, temperature, fuel consumption, and vibration frequency. This data is essential for implementing predictive maintenance schedules, optimizing fleet utilization, ensuring safety compliance, and maximizing uptime for high-capital equipment.

Are noise regulations a significant restraint on the Vibratory Pile Hammers Market?

Yes, stringent noise and vibration regulations, particularly in highly urbanized areas of North America and Europe, serve as a major restraint. This factor is driving demand away from impact hammers toward quieter, high-frequency vibratory hammers and Variable Moment technology, necessitating continuous investment in noise reduction features by manufacturers.

What is the primary power source for vibratory pile hammers and what are the alternatives?

The primary power source remains the hydraulic power pack, often driven by diesel engines, which offers high power density and reliability. However, the market is gradually transitioning, with electric and hybrid power packs emerging as environmentally friendly alternatives, particularly for indoor or emission-sensitive construction sites.

How does the rental market affect the vibratory hammer industry?

The rental market significantly reduces the entry barrier for smaller contractors, allowing them access to high-cost machinery without massive capital outlay. This expansion of accessibility drives overall market volume and encourages manufacturers to focus on robust, easily maintainable, and versatile equipment suitable for diverse rental applications.

Which region currently holds the largest market share for vibratory pile hammers?

The Asia Pacific (APAC) region currently holds the largest market share, fueled by massive governmental expenditure on infrastructure, including port development, high-speed rail, and large-scale residential construction projects across countries like China, India, and Indonesia.

What is the typical lifespan of a professional-grade vibratory hammer?

A professional-grade vibratory pile hammer, with proper maintenance and operation, typically has an operational lifespan exceeding 10,000 to 15,000 working hours, though highly stressful marine applications might slightly reduce this, emphasizing the importance of robust build quality and preventative maintenance.

How is the demand for excavator-mounted hammers evolving?

Demand for excavator-mounted vibratory hammers is growing rapidly due to their exceptional mobility, quick setup time, and integration with common construction machinery. They are favored for smaller and medium-sized projects, urban construction, and utility work where large crane setups are impractical or costly.

What challenges do vibratory hammers face in cohesive soils?

In highly cohesive (clay) soils, vibratory action can sometimes be less effective than impact hammering because the soil tends to dampen vibrations, failing to significantly reduce skin friction. Specialized high-frequency hammers or supplementary jetting systems are often required to overcome this challenge effectively.

What are the key differences between low frequency and high frequency hammers?

Low-frequency hammers (below 1000 RPM) are generally older technology and transmit significant vibrations to surrounding structures. High-frequency hammers (above 1000 RPM) are preferred as they minimize the transmission of harmful low-frequency vibrations, offering smoother operation and better performance in granular soils, aligning better with modern urban construction requirements.

How does the increasing complexity of offshore wind foundations influence the market?

The transition to deeper water installations requires significantly larger and more powerful vibratory hammers capable of handling vast monopiles and jacket foundations. This drives innovation toward ultra-high moment hammers, specialized lifting mechanisms, and marine-hardened equipment designed for prolonged exposure to saltwater conditions.

What are the implications of raw material price volatility on the hammer manufacturing industry?

Fluctuations in the price of high-grade steel, specialized alloys for eccentric weights, and complex hydraulic components directly increase manufacturing costs. Manufacturers often absorb some costs but this volatility can lead to higher equipment prices for end-users and pressure profit margins across the value chain.

How is competition intensifying within the Vibratory Pile Hammers Market?

Competition is increasing, driven by established players focusing on technological leadership (Variable Moment, telematics) and Asian manufacturers offering competitive pricing and rapid product iterations. Success relies on balancing high-performance machinery with expanded service networks and favorable leasing options globally.

What specific safety features are being integrated into new vibratory hammer models?

Modern hammers incorporate advanced safety features such as automatic load monitoring, self-locking clamps, overload protection systems for the hydraulic circuit, and remote control capabilities, which minimize the need for personnel near the active piling zone, improving overall site safety.

How important is the after-sales service network for market participants?

The after-sales service network is critically important, particularly for highly specialized and expensive machinery. Reliable and rapid provision of spare parts, specialized technicians, and maintenance support minimizes expensive project downtime, serving as a key factor in contractor procurement decisions and vendor loyalty.

What defines the upstream segment of the Vibratory Pile Hammers value chain?

The upstream segment involves the sourcing and supply of highly technical components, including specialized high-tensile steel, precise gearbox components, high-flow hydraulic pumps, advanced rubber elastomers for vibration dampening, and sophisticated electronic control units necessary for hammer functionality and performance.

Is the construction sector the sole consumer of vibratory pile hammers?

No, while construction is the largest consumer, significant demand also comes from the Infrastructure sector (bridges, railways), Marine construction (ports, offshore platforms), Oil and Gas (pipeline laying), and Environmental remediation projects (cofferdams and temporary retaining walls).

How is the concept of efficiency measured in vibratory pile hammers?

Efficiency is measured by the energy transferred to the pile, often assessed through penetration rate (meters per minute) relative to the hydraulic power consumption. Modern efficiency improvements focus on optimized eccentric tuning and reduced energy loss within the hydraulic system, translating to faster job completion and lower fuel costs.

What impact does the drive towards carbon neutrality have on the market?

The push for carbon neutrality accelerates the development and adoption of electric and hybrid vibratory hammers, necessitating a move away from traditional diesel power packs. This trend requires manufacturers to invest heavily in battery technology and efficient power electronics to meet future emission standards and contractor sustainability goals.

Why are vibratory hammers often preferred over impact hammers in certain applications?

Vibratory hammers are preferred for their speed, especially in granular soils, and their ability to extract piles efficiently. Critically, they generate less percussive noise and ground vibration than impact hammers, making them the default choice for sensitive urban construction sites or projects near historic structures.

What are the key technical specifications potential buyers look for when comparing models?

Potential buyers focus on the eccentric moment (or driving force), maximum frequency (vibrations per minute), maximum line pull, required hydraulic flow and pressure, weight of the hammer head, and compatibility with specific carrier machines (excavator class or crane capacity).

How does geotechnical data influence the operational settings of a vibratory hammer?

Geotechnical data, such as soil density, water table level, and friction angle, determines the optimal frequency and eccentric moment setting for the hammer. In soft or submerged soils, lower frequency settings might be optimal, while dense, granular soils require high-frequency, high-moment settings to minimize skin friction effectively.

What are the current trends regarding automation in piling operations?

Current trends focus on semi-automation, utilizing GPS and high-precision sensors for automated pile alignment and positioning before driving. Full automation, including adaptive frequency adjustment based on real-time soil resistance feedback, is a key R&D area aimed at improving accuracy and reducing reliance on manual operator input.

Are Chinese manufacturers becoming dominant in the global vibratory hammer market?

Chinese manufacturers, driven by massive domestic infrastructure spending and strong governmental support, are rapidly increasing their market share globally. They often compete effectively on price and are closing the technology gap, particularly in producing robust, powerful hammers suitable for large-scale projects.

What is the role of the gearbox in the functionality of a vibratory pile hammer?

The gearbox transfers rotational power from the hydraulic motor to the eccentric weights. Its design is critical, as it must handle immense torque and vibration without failure, ensuring the consistent, high-frequency oscillatory motion necessary for efficient pile driving and extraction.

How do specialized clamps contribute to market growth?

Specialized clamps, such as sheet pile clamps, pipe clamps, or custom concrete pile clamps, enhance the versatility of the vibratory hammer. This allows contractors to utilize a single machine for a broader array of foundation materials, minimizing equipment inventory and boosting the overall utility of the investment.

What is the current estimated CAGR for the Vibratory Pile Hammers Market?

The market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033, driven by sustained global investment in infrastructure and the specialized demands of the marine energy sector.

How do excavator-mounted systems offer an advantage over crane-suspended systems?

Excavator-mounted systems offer a key advantage in terms of mobility and quick mobilization. They are self-contained units that use the carrier machine’s hydraulics, eliminating the need for separate cranes or power packs on smaller sites, significantly reducing setup time and logistical complexity.

What factors restrain the adoption of vibratory pile hammers in certain construction markets?

The primary restraints include the high initial purchase price, leading to a reliance on the rental market, and performance limitations in highly dense rock or stiff clay environments where powerful impact hammers may still be more effective, necessitating hybrid foundation solutions.

How does the concept of ground resonance relate to hammer operation?

Ground resonance occurs when the frequency of the vibratory hammer matches the natural frequency of the surrounding soil, leading to magnified ground movement and increased structural risk to nearby buildings. Variable Moment technology was specifically developed to counter this phenomenon during critical startup and shutdown phases.

What impact does the growth of smart cities have on demand for specialized piling equipment?

The development of smart cities requires deep foundations within highly confined and sensitive urban areas, dramatically increasing the demand for advanced, low-noise, low-vibration (Variable Moment) vibratory hammers that can operate without disrupting neighboring communities or complex utility networks.

What are the opportunities presented by the decommissioning of offshore oil and gas platforms?

Decommissioning efforts require specialized high-capacity vibratory hammers and extractors capable of removing large, deeply embedded steel piles used for aging platforms. This provides a lucrative, recurring opportunity for manufacturers focusing on marine extraction equipment.

How do manufacturers ensure the reliability of vibratory hammers under extreme stress?

Manufacturers ensure reliability through rigorous fatigue testing, utilizing high-specification materials (especially for eccentric shafts and gearboxes), integrating advanced vibration isolation systems, and employing complex cooling circuits to manage thermal stress in hydraulic components during continuous, high-load operation.

What is the forecast market size for the Vibratory Pile Hammers Market by 2033?

The Vibratory Pile Hammers Market is projected to reach an estimated value of $615.8 Million by the end of the forecast period in 2033, reflecting consistent demand across global infrastructure and energy sectors.

What are the primary target customers in the downstream segment of the value chain?

Primary target customers include specialized piling contractors, major EPC (Engineering, Procurement, and Construction) firms, heavy equipment rental companies, and governmental agencies involved in port and civil infrastructure maintenance and expansion projects globally.

How are environmental considerations driving innovation in vibratory hammer design?

Environmental considerations mandate innovation in noise attenuation, leading to the development of quieter high-frequency and Variable Moment systems, as well as the accelerating trend towards electric or hybrid power sources to reduce localized carbon and particulate emissions at construction sites.

What distinguishes the demand characteristics of North America from the Asia Pacific region?

North America’s demand is characterized by high replacement cycles and a preference for technologically compliant, efficient units for maintenance and urban infill projects. APAC demand is dominated by massive volume growth in new infrastructure construction, driving a need for powerful, cost-effective, high-output machinery.

In which segment do oil and gas applications primarily utilize vibratory hammers?

The oil and gas industry utilizes vibratory hammers for the installation of temporary platforms, cofferdams, and, most commonly, for driving the protective casings and sections used in the laying of subsea pipelines across various continental shelves.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Vibratory Pile Hammers Market Statistics 2025 Analysis By Application (Crane Suspended, Excavator Mounted), By Type (Electric Vibratory Pile Hammers, Hydraulic Vibratory Pile Hammers), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Vibratory Pile Hammers Market Statistics 2025 Analysis By Application (Crane Suspended, Excavator Mounted), By Type (Hydraulic Vibratory Pile Hammers, Electric Vibratory Pile Hammers), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager