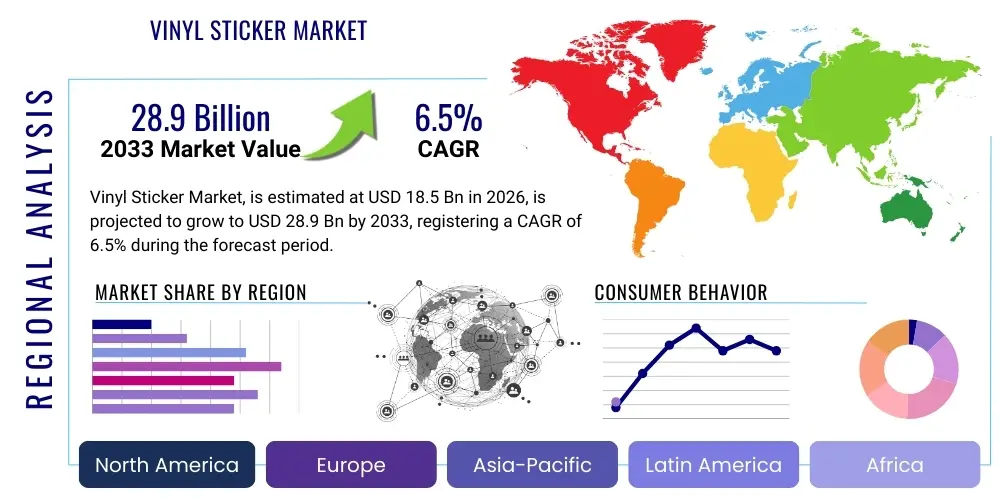

Vinyl Sticker Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436807 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Vinyl Sticker Market Size

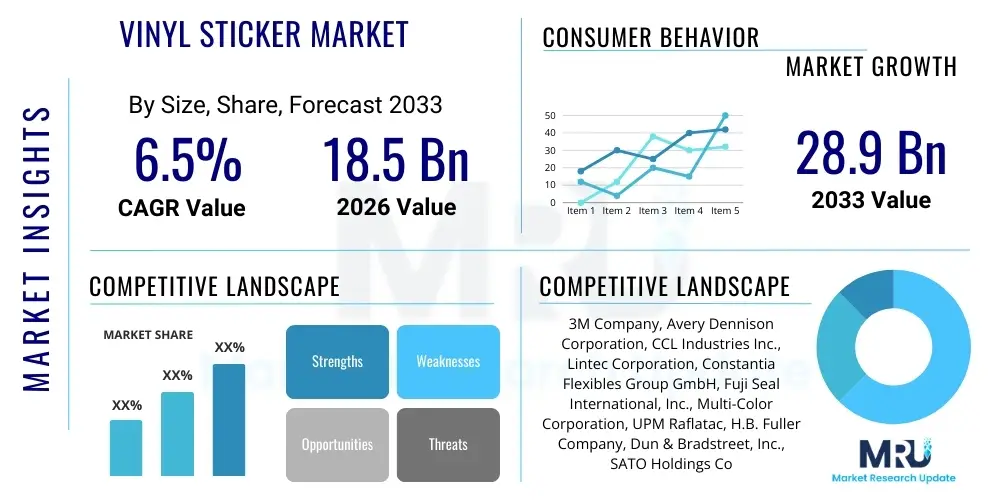

The Vinyl Sticker Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 18.5 billion in 2026 and is projected to reach USD 28.9 billion by the end of the forecast period in 2033. This robust expansion is primarily attributed to the soaring demand for personalized branding solutions, the rapid expansion of the e-commerce sector requiring specialized packaging labels, and technological advancements in printing and material science that enhance durability and aesthetic quality. The shift toward high-definition digital printing further allows for cost-effective, small-batch customization, fueling growth across diverse end-use industries, particularly retail and automotive sectors.

Vinyl Sticker Market introduction

The Vinyl Sticker Market encompasses the production and distribution of adhesive labels and decals primarily manufactured from Polyvinyl Chloride (PVC) films or other synthetic polymer materials. These products are favored due to their inherent properties, including exceptional durability, resistance to water, moisture, UV radiation, and abrasion, making them ideal for both indoor and demanding outdoor applications. Vinyl stickers serve crucial functional and aesthetic roles across a myriad of industries, ranging from product identification and safety labeling to large-format architectural signage and vehicle wraps, acting as a highly visible and versatile marketing tool.

Major applications of vinyl stickers span several high-growth sectors. In the automotive industry, they are extensively used for detailing, protective wraps, and aftermarket customization. The packaging sector utilizes them for high-quality, durable labeling for consumer goods, particularly those exposed to harsh environments or refrigeration. Furthermore, the rise of personalized consumerism has dramatically boosted demand in the home décor and DIY markets, where customized vinyl decals offer temporary and cost-effective decorative solutions. The flexibility in sizing, shape, and printing technology—including digital, screen, and flexographic methods—ensures market adaptability to highly specific client requirements globally.

The market is predominantly driven by increasing disposable income leading to higher demand for aesthetic personalization, combined with the low cost and high impact of vinyl stickers as a promotional medium. Key benefits include superior longevity compared to paper-based alternatives, enhanced visual appeal through vivid color reproduction, and relative ease of application and removal. However, the industry is increasingly focused on innovation to address environmental concerns associated with traditional PVC, fostering the development and integration of bio-based or easily recyclable vinyl alternatives to maintain sustainable market growth.

Vinyl Sticker Market Executive Summary

The Vinyl Sticker Market is undergoing significant evolution driven by disruptive business trends focused on customization and sustainability. The shift towards small-batch, on-demand printing, facilitated by advanced digital printing technologies, is redefining the traditional manufacturing landscape, allowing small enterprises and individual designers to access high-quality production previously limited to large corporations. Key business trends include the vertical integration of digital printing services within major packaging companies to offer bundled solutions and the aggressive marketing of eco-friendly vinyl alternatives, such as Polypropylene (PP) and Polyethylene (PE) films, to capture environmentally conscious consumer segments and comply with tightening regulatory standards, particularly in Europe and North America.

Regionally, the Asia Pacific (APAC) continues its dominance, primarily due to its massive manufacturing base, low labor costs, and rapidly expanding automotive and consumer electronics sectors, which are major consumers of technical and decorative vinyl products. However, North America and Europe demonstrate the highest per capita spending on customized and specialty vinyl applications, such particularly high-performance outdoor decals and automotive wraps. European growth is heavily influenced by strict mandates on material safety and recyclability, pushing innovations toward bio-degradable adhesives and non-PVC materials. Meanwhile, emerging markets in Latin America and the Middle East and Africa (MEA) are showing promising growth trajectories, stimulated by infrastructure development and rising organized retail activity, requiring extensive commercial signage and promotional materials.

Segment trends highlight the burgeoning growth of the digital printing segment, which offers unmatched flexibility and variable data printing capabilities crucial for promotional campaigns and complex inventory labeling. By application, the packaging and labeling segment remains the largest volume driver, though the automotive aftermarket segment, focused on vehicle wrapping and protective films (PPF), is projected to exhibit the highest CAGR due to increased consumer interest in vehicle personalization and preservation. Furthermore, material segmentation shows a gradual, yet noticeable, transition from conventional monomeric PVC towards specialized cast and polymeric vinyl films offering superior long-term performance and dimensional stability required for premium applications.

AI Impact Analysis on Vinyl Sticker Market

User queries regarding the impact of Artificial Intelligence (AI) on the Vinyl Sticker Market primarily revolve around operational efficiency, customization possibilities, and supply chain optimization. Common user concerns include how AI can streamline the complex design-to-print workflow, reduce material waste through predictive quality control, and enhance the speed and accuracy of order fulfillment for highly personalized sticker runs. Users are keenly interested in AI-driven design tools that allow non-professional users to generate high-quality, print-ready designs automatically, and how predictive analytics can forecast demand for specific materials (e.g., matte vs. gloss vinyl) in localized markets, thus minimizing inventory costs and improving response times.

AI's primary influence is expected in automating pre-press operations and optimizing the entire manufacturing pipeline. Generative AI tools are simplifying the creative process by instantly modifying colors, adjusting resolutions, and ensuring design compatibility with specific printing methods (e.g., UV, screen), significantly reducing the time required from customer concept to final proof. Furthermore, machine learning algorithms are being integrated into large-format digital printers to monitor machine health, predict potential component failures, and dynamically adjust ink deposition rates based on environmental factors like temperature and humidity, ensuring consistent color accuracy and minimizing expensive material spoilage inherent in high-volume production.

In the customer-facing realm, AI enhances personalized commerce. Recommendation engines analyze past purchase data, browsing behavior, and demographic information to suggest highly relevant sticker designs, materials, or bundle offers to individual users, significantly boosting conversion rates for e-commerce platforms specializing in custom decals. This hyper-personalization, coupled with AI-optimized logistics routes and inventory placement, fundamentally changes the speed and efficiency of the custom vinyl sticker market, making it more responsive and less prone to human error throughout the order lifecycle. The long-term impact points towards a fully automated, adaptive manufacturing ecosystem capable of handling mass customization at speed.

- AI-driven design automation simplifies complex graphic creation and pre-press setup, accelerating time-to-market.

- Machine learning algorithms optimize cutting path efficiency, minimizing material waste (vinyl substrate utilization).

- Predictive maintenance for industrial printing equipment reduces downtime and lowers operational expenditure (OPEX).

- AI recommendation engines enhance e-commerce personalization, boosting sales of custom and niche sticker designs.

- Automated quality inspection systems using computer vision ensure flawless output consistency, crucial for high-tolerance applications like vehicle wraps.

DRO & Impact Forces Of Vinyl Sticker Market

The Vinyl Sticker Market is significantly shaped by a dynamic interplay of Drivers, Restraints, and Opportunities (DRO). A primary driver is the pervasive trend of branding and advertising across physical and digital platforms, where vinyl stickers offer a durable, cost-effective, and highly impactful means of offline promotion, especially popular among small and medium-sized enterprises (SMEs). This is amplified by the exponential growth of e-commerce packaging, where attractive, tamper-evident, and informative vinyl labels are essential. Opportunities are opening up in specialized, high-performance applications, such as reflective safety markings, medical device labeling, and advanced automotive protective films, requiring materials with superior chemical and thermal resistance and offering higher profit margins.

However, the market faces significant restraints, most notably the escalating environmental concerns surrounding the disposal of traditional PVC vinyl, a non-biodegradable material, which puts intense pressure on manufacturers to adopt costly, though sustainable, alternatives. Furthermore, the market is highly fragmented and competitive, leading to severe pricing pressure, particularly in the commodity decal segment, which can depress profitability. Regulatory hurdles, such as the restrictions on certain chemical components (e.g., phthalates) in vinyl production in regions like the European Union, necessitate costly reformulation and compliance measures, acting as temporary barriers to market expansion for traditional players.

The combined impact forces—Market Attractiveness, Buyer Power, Supplier Power, and Intensity of Rivalry—dictate the market structure. Market Attractiveness remains high due to the versatility and low capital entry barrier for custom printing services. Buyer Power is moderate to high, as end-users (especially large retailers and automotive companies) have numerous suppliers and can negotiate favorable terms, particularly in standardized label procurement. Supplier Power is moderate; while raw material suppliers (polymers, specialized inks) provide essential components, the abundance of vinyl suppliers keeps input price increases manageable. Crucially, the Intensity of Rivalry is extremely high, driven by the presence of numerous small digital print shops and aggressive competition from large-scale printing conglomerates, ensuring innovation and efficiency remain critical competitive differentiators.

Segmentation Analysis

Segmentation analysis provides a crucial framework for understanding the diverse dynamics within the Vinyl Sticker Market, allowing suppliers to tailor their offerings to specific end-user needs and technological requirements. The market is primarily segmented based on material type, printing technology, application, and end-use industry, each exhibiting unique growth trajectories and profitability profiles. The dominance of PVC as a material type is slowly being challenged by more environmentally conscious alternatives, though PVC remains the benchmark for durability and cost-effectiveness in high-volume applications. The granularity of segmentation reflects the high degree of specialization required in modern printing and finishing processes.

The segmentation by printing technology is particularly pivotal, separating traditional methods like screen and flexographic printing—suitable for massive, long-run production—from modern digital and wide-format inkjet printing, which cater to the surging demand for small-run, high-variability customization. Digital printing is projected to capture a progressively larger share due to its efficiency in variable data printing and rapid turnaround times. Furthermore, segmentation by application highlights the shift in volume drivers; while promotional and safety labeling remain foundational, the rapid expansion in functional applications, such as anti-microbial coatings on vinyl films used in healthcare and reflective vinyl for transportation, indicates diversification beyond purely decorative use.

Understanding the interplay between these segments is vital for strategic investment. For instance, manufacturers targeting the high-growth automotive industry must focus on durable, cast vinyl materials produced using UV-cured digital printing technology to meet the stringent longevity and performance requirements of vehicle wraps. Conversely, companies serving the rapidly growing e-commerce packaging sector prioritize cost-effective monomeric vinyl produced via high-speed flexography for standardized logistical labels. This detailed segmentation allows market players to identify underserved niches, such as specialized holographic or security vinyl stickers, offering higher margins compared to generic promotional decals.

- By Material Type:

- PVC (Polyvinyl Chloride)

- PP (Polypropylene)

- PE (Polyethylene)

- Other Polymers (e.g., PET, specialty films)

- By Printing Technology:

- Digital Printing (Inkjet, UV Cured)

- Screen Printing

- Flexographic Printing

- Lithography/Offset Printing

- By Application:

- Packaging and Labeling

- Automotive Decals and Wraps

- Promotional and Advertising Signage

- Home Decor and Wall Art

- Safety and Identification Labels

- By End-Use Industry:

- Retail and FMCG

- Automotive and Transportation

- Manufacturing and Logistics

- Healthcare and Pharmaceuticals

- Architecture and Construction

Value Chain Analysis For Vinyl Sticker Market

The Value Chain for the Vinyl Sticker Market begins with the Upstream segment, dominated by the procurement and processing of raw materials. This includes major chemical manufacturers supplying base polymers (PVC resin, PP, PE pellets), specialized adhesive manufacturers providing acrylic or rubber-based formulations, and ink producers developing solvent, eco-solvent, and UV-curable inks. Quality control at this initial stage is critical, as the consistency and durability of the final sticker product are directly dependent on the film and adhesive characteristics. High supplier power exists for specialized components, such as premium cast vinyl films or sophisticated proprietary ink formulations, making strategic sourcing and long-term contracts essential for midstream converters.

The Midstream segment involves the core manufacturing process: conversion and printing. This stage includes coating the film with adhesives, lining it with release liners (usually silicone-coated paper or film), and the actual printing and finishing processes (die-cutting, lamination, weeding). Investment in state-of-the-art wide-format digital printers, precision cutting plotters, and automated roll-to-roll machinery defines competitive advantage in this stage. Companies that excel in utilizing Variable Data Printing (VDP) and managing complex, short-run customization orders demonstrate superior value capture, shifting the market dynamics away from pure volume manufacturing towards specialized, high-value service provision.

The Downstream distribution channel is highly diversified, involving both Direct and Indirect sales methods. Direct sales are common for large volume corporate clients (e.g., automotive manufacturers purchasing thousands of identical safety labels) or for highly specialized custom wrap shops dealing directly with consumers. Indirect channels include wholesale distributors who supply smaller print shops, stationery retailers, and increasingly, large e-commerce marketplaces (Amazon, Etsy). The proliferation of online custom sticker platforms has revolutionized indirect sales, allowing manufacturers to reach a global consumer base without traditional retail intermediaries. Efficiency in logistics and inventory management is paramount in the downstream segment to handle the vast array of customized orders.

Vinyl Sticker Market Potential Customers

The Vinyl Sticker Market serves a vast and heterogeneous clientele, where potential customers span major industrial conglomerates down to individual consumers engaged in DIY projects. Key end-users often fall into three broad categories: corporate entities requiring large volumes of functional or safety labels (e.g., logistics, healthcare), businesses focused on promotional branding and aesthetic modification (e.g., retail, automotive aftermarket), and direct consumers seeking personalization (e.g., hobbyists, home decorators). The versatility of vinyl allows manufacturers to target these disparate groups with highly differentiated product lines, from industrial-grade asset tags to high-gloss vehicle wraps.

Small and Medium-sized Enterprises (SMEs) represent a significant and rapidly growing customer base. For SMEs, vinyl stickers provide an affordable and effective marketing tool for packaging, product labeling, and creating unique brand identities without the need for extensive capital investment in complex signage. The rise of pop-up shops, local craft breweries, and artisanal food producers necessitates visually appealing, durable labels that communicate brand quality, making them heavy consumers of custom-printed, short-run vinyl stickers. This segment values quick turnaround times, design flexibility, and competitive pricing, typically preferring local or online custom printing services.

Large corporate buyers, particularly those in the Automotive, Logistics, and FMCG sectors, demand technical specifications such as chemical resistance, prolonged outdoor durability, and adherence to regulatory standards (e.g., UL recognized components). These buyers focus on bulk purchasing, consistency, and traceability. The procurement cycles are often long-term contracts, rewarding manufacturers who demonstrate exceptional quality control and the capability to integrate variable data printing for tracking and inventory management. Consequently, the ideal customer portfolio for a vinyl sticker manufacturer often balances the high volume and stability offered by large corporations with the higher margin, customized work generated by the expansive SME and consumer segments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 18.5 Billion |

| Market Forecast in 2033 | USD 28.9 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M Company, Avery Dennison Corporation, CCL Industries Inc., Lintec Corporation, Constantia Flexibles Group GmbH, Fuji Seal International, Inc., Multi-Color Corporation, UPM Raflatac, H.B. Fuller Company, Dun & Bradstreet, Inc., SATO Holdings Corporation, R.R. Donnelley & Sons Company, Toray Industries, Inc., Arconvert S.p.A., Saint-Gobain S.A., Mactac LLC, Spandex Group, Hexis S.A., Orafol Europe GmbH, Kay Premium Marking Films (KPMF) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Vinyl Sticker Market Key Technology Landscape

The Vinyl Sticker Market's technological landscape is continuously evolving, driven primarily by the need for faster production speeds, higher resolution output, superior material durability, and environmental compliance. A cornerstone technology is Wide-Format Digital Printing, particularly utilizing UV-curable and Latex inks. UV-curing technology offers instant drying and superior resistance to scratching, chemicals, and fading, making it essential for high-performance outdoor vinyl applications like vehicle graphics and industrial labeling. Latex printing, on the other hand, provides a non-solvent-based alternative that is increasingly favored for indoor applications and ecologically sensitive projects due to its minimal odor and immediate readiness for lamination or application, bridging the gap between quality and sustainability.

Advancements in adhesive and film technology are equally crucial. Innovations include repositionable and low-tack adhesives that simplify application and removal processes without damaging underlying surfaces, addressing the high demand for temporary promotional graphics. Furthermore, the development of specialty vinyl films, such as reflective, holographic, and metallic finishes, expands the aesthetic possibilities and functional applications of stickers in sectors like safety signage and premium branding. The continuous improvement in the structural integrity of cast vinyl films, which resist shrinkage and conform better to complex curves, remains vital for the profitable and high-quality vehicle wrap segment, demonstrating technological leadership through material science.

In the finishing stages, sophisticated computer-aided cutting systems and automated die-cutting machines are paramount. These systems utilize advanced optical sensors and software to precisely follow complex contours (contour cutting), dramatically reducing production time and human error associated with intricate designs. The integration of Variable Data Printing (VDP) capabilities across digital printing platforms allows manufacturers to change text, graphics, and barcodes on the fly within a single print run without stopping the press, a capability highly valued by logistics and pharmaceutical companies for serialization and track-and-trace requirements. This technological convergence ensures that vinyl sticker production remains highly efficient, adaptable, and capable of meeting diverse customization demands.

Regional Highlights

Regional dynamics within the Vinyl Sticker Market are characterized by differentiated demand profiles, regulatory environments, and manufacturing capabilities, with significant strategic importance placed on Asia Pacific (APAC) and mature markets like North America and Europe. APAC holds the largest market share, predominantly driven by China and India, which serve as global manufacturing hubs for raw vinyl films and finished decals. The rapid urbanization, infrastructure projects, and burgeoning automotive industry in these countries generate massive demand for promotional signage, protective films, and mass-market product labels, positioning the region as the volume leader.

North America is characterized by high average selling prices and a strong focus on high-performance, branded vinyl solutions. The region exhibits high demand for custom vehicle wrapping, architectural graphics, and specialized industrial labeling (e.g., aerospace and electronics). Consumers and businesses in the U.S. and Canada emphasize durability, aesthetic quality, and technological innovation, driving the adoption of premium materials like cast vinyl and advanced digital printing techniques. Growth here is primarily driven by the robust aftermarket automotive sector and specialized marketing services seeking impactful, temporary advertising solutions.

Europe stands out due to stringent environmental regulations, particularly the European Union's directives regarding PVC waste and chemical content. This regulatory environment is compelling the market towards sustainable alternatives (non-PVC films, biodegradable adhesives) and pushing the adoption of eco-solvent and water-based printing inks. While facing moderate growth due to saturation, Europe leads in the innovation of sustainable and highly functional vinyl products, such as those used in renewable energy systems and sensitive healthcare applications. Latin America and MEA, though smaller, are emerging as high-growth regions fueled by increasing foreign direct investment, expansion of organized retail, and rising advertising expenditure, creating new avenues for promotional and retail signage.

- Asia Pacific (APAC): Dominates manufacturing volume; driven by automotive, packaging, and infrastructure development, particularly in China and India.

- North America: High-value market focused on customization, premium vehicle wraps, and rapid adoption of digital printing technologies.

- Europe: Growth influenced by stringent environmental mandates; leading innovation in sustainable, non-PVC materials and eco-friendly inks.

- Latin America (LATAM): Emerging market characterized by increasing organized retail and rising demand for consumer product labeling and promotional graphics.

- Middle East & Africa (MEA): Growth tied to urbanization, construction booms, and rising advertising spend, especially in the GCC countries.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Vinyl Sticker Market.- 3M Company

- Avery Dennison Corporation

- CCL Industries Inc.

- Lintec Corporation

- Constantia Flexibles Group GmbH

- Fuji Seal International, Inc.

- Multi-Color Corporation

- UPM Raflatac

- H.B. Fuller Company

- Dun & Bradstreet, Inc.

- SATO Holdings Corporation

- R.R. Donnelley & Sons Company

- Toray Industries, Inc.

- Arconvert S.p.A.

- Saint-Gobain S.A.

- Mactac LLC

- Spandex Group

- Hexis S.A.

- Orafol Europe GmbH

- Kay Premium Marking Films (KPMF)

Frequently Asked Questions

Analyze common user questions about the Vinyl Sticker market and generate a concise list of summarized FAQs reflecting key topics and concerns.What primary factors are driving the current growth of the Vinyl Sticker Market?

The market growth is primarily driven by the escalating demand for highly personalized branding and promotional materials, coupled with the exponential expansion of the e-commerce sector requiring specialized, durable packaging labels and low-volume custom graphics.

What are the most significant material restraints affecting vinyl sticker manufacturers?

The most significant restraint is the increasing environmental scrutiny and regulatory pressure surrounding traditional Polyvinyl Chloride (PVC) usage and disposal, necessitating costly transitions toward sustainable, non-PVC polymeric and bio-based film alternatives.

How is digital printing technology influencing the vinyl sticker production landscape?

Digital printing, particularly UV-cured inkjet, enables highly efficient, short-run customization, rapid prototyping, and Variable Data Printing (VDP), fundamentally shifting the market towards on-demand production and higher-resolution output quality.

Which geographical region holds the largest market share and why?

Asia Pacific (APAC), led by countries like China and India, holds the largest market share due to its vast, cost-effective manufacturing base and immense domestic consumption driven by burgeoning automotive, retail, and construction industries.

What is the role of vinyl stickers in the rapidly growing automotive aftermarket sector?

In the automotive aftermarket, vinyl stickers are crucial for vehicle personalization (car wraps), brand promotion, and preservation, with high-performance cast vinyl and Paint Protection Films (PPF) driving substantial revenue growth in this specialized segment.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager