Volumetric Feeder Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434704 | Date : Dec, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Volumetric Feeder Market Size

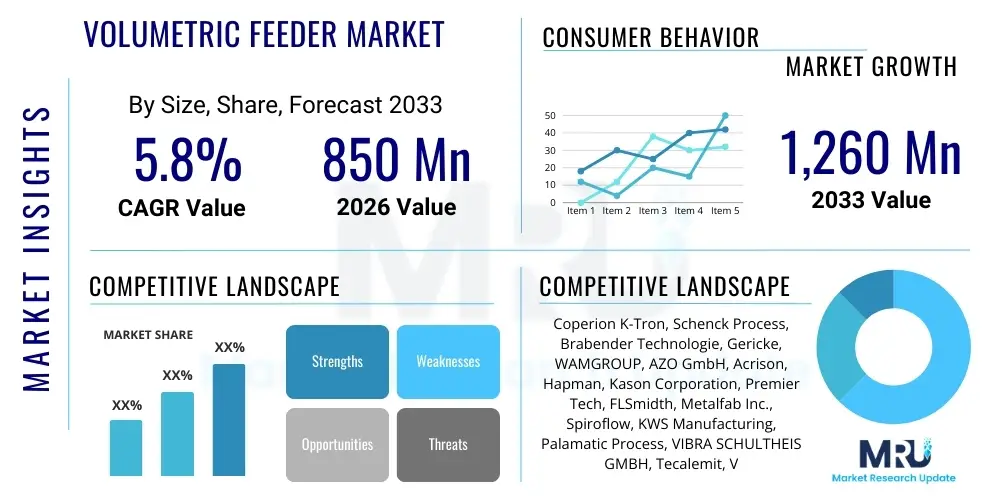

The Volumetric Feeder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 850 Million in 2026 and is projected to reach USD 1,260 Million by the end of the forecast period in 2033.

Volumetric Feeder Market introduction

The Volumetric Feeder Market encompasses the supply and demand of equipment designed to accurately dispense dry bulk materials or powders based on volume rather than weight. These systems are crucial components in various industrial processes requiring the controlled introduction of ingredients, additives, or raw materials. Volumetric feeders operate by displacing a constant volume of material over a set period, offering a cost-effective and relatively simple solution for many feeding applications where moderate accuracy is sufficient, or where material properties make gravimetric (loss-in-weight) feeding overly complex or expensive.

Major applications for volumetric feeders span highly diverse industries, including food and beverage processing, pharmaceuticals, plastics compounding, chemical manufacturing, and construction materials production. In the food sector, they ensure precise blending of minor ingredients like flavorings, spices, and vitamins. For the plastics industry, volumetric feeders are essential for introducing color concentrates, stabilizers, and fillers during the extrusion or molding processes. The inherent benefits of these devices include their robust construction, ease of maintenance, and compatibility with a wide range of material flow characteristics, from free-flowing granules to cohesive powders.

The market growth is primarily driven by increasing automation across manufacturing sectors globally, the continuous demand for high-quality, consistently formulated end products, and the expansion of processing capabilities in emerging economies. Furthermore, the development of enhanced feeder designs, incorporating improved material handling components, sophisticated controls, and modular architectures, contributes significantly to their versatility and adoption. The push for operational efficiency and reduced material waste in high-volume production environments solidifies the position of volumetric feeders as indispensable components in modern industrial infrastructure.

Volumetric Feeder Market Executive Summary

The global Volumetric Feeder Market demonstrates robust growth, propelled by strong business trends focusing on industrial automation and the necessity for precise, high-throughput material handling in production lines. Key business trends include the shift towards modular equipment designs that allow for easy integration and scalability, and the integration of advanced sensors for improved real-time performance monitoring. While gravimetric feeders offer superior accuracy, the volumetric segment remains highly attractive due to its lower capital expenditure requirement and suitability for materials that exhibit consistent bulk density. Investments in sustainable manufacturing practices are also driving the need for reliable feeding systems to handle recycled or alternative raw materials effectively.

Regionally, Asia Pacific (APAC) stands as the dominant market, driven by rapid industrialization, massive investments in infrastructure, and the expansion of manufacturing bases in countries like China, India, and Southeast Asia. North America and Europe maintain significant market shares, characterized by stringent quality control standards, high levels of automation maturity, and a strong presence of pharmaceutical and specialized chemical industries demanding reliable dosing technology. These mature markets are experiencing replacement cycles and upgrades to feeders featuring advanced digital interfaces and connectivity capabilities, aligning with Industry 4.0 paradigms. Latin America and the Middle East & Africa (MEA) represent high-growth potential markets, fueled by diversification efforts in petrochemical and food processing sectors.

Segment trends highlight the continued dominance of the plastics and chemical industries in terms of application, specifically due to the large volumes of materials handled, such as resins, fillers, and additives. Among product types, single-screw volumetric feeders currently hold the largest market share due to their simplicity and cost-effectiveness, suitable for free-flowing materials. However, the twin-screw segment is experiencing the fastest growth rate, increasingly adopted for difficult-to-handle, cohesive, or sticky powders, offering better material conditioning and reduced bridging issues, especially within pharmaceutical and advanced materials processing where flow assurance is critical.

AI Impact Analysis on Volumetric Feeder Market

User queries regarding AI in the Volumetric Feeder Market frequently revolve around predictive maintenance capabilities, optimization of material flow settings, and integrating feeders into larger, autonomously controlled smart factory ecosystems. Users are primarily concerned with how AI algorithms can leverage continuous operational data (such as motor torque, vibration, and material throughput variations) to anticipate mechanical failures, thereby minimizing unplanned downtime. Furthermore, there is significant interest in using machine learning to dynamically adjust feed rates based on upstream process variables or real-time quality control feedback, ensuring optimal material dosing despite minor inconsistencies in raw material bulk density or environmental factors. The underlying expectation is that AI will transform volumetric feeders from passive dosing devices into active, self-optimizing components of an intelligent production line.

While volumetric feeders inherently offer less measurement feedback than gravimetric types, AI enhances their performance by modeling their behavior. Machine learning models can analyze historical performance data across different materials and environmental conditions, learning the optimal parameters (like screw speed, agitation rate) required to maintain a consistent volumetric output. This modeling allows for highly accurate, predictive tuning, compensating for factors that might otherwise lead to drift or inconsistency, effectively bridging the gap between simple volumetric feeding and more complex gravimetric accuracy in certain applications. This capability is vital for industries prioritizing consistency, such as specialty chemical and pharmaceutical manufacturing.

Moreover, AI facilitates advanced anomaly detection, moving beyond simple sensor thresholds to identify complex patterns indicative of early material build-up, screw wear, or impending motor failure. This shift from reactive or scheduled maintenance to predictive maintenance significantly boosts Overall Equipment Effectiveness (OEE). The integration of AI-powered control systems also contributes to resource optimization by minimizing material giveaway or under-dosing, which is critical in managing expensive additives or potent ingredients in the final product formulation. The overarching impact is the transformation of volumetric feeder operations into highly reliable, digitally managed processes.

- AI enables predictive maintenance scheduling by analyzing vibration, temperature, and current draw anomalies.

- Machine learning algorithms optimize screw speed and agitation dynamically based on historical material flow characteristics.

- Improved flow assurance through AI modeling of complex, non-free-flowing material behavior.

- Integration into smart factory networks for centralized, autonomous control and remote diagnostics.

- Enhanced calibration accuracy and reduced drift over long operational periods through continuous feedback loop refinement.

- Optimization of energy consumption by adjusting motor operation based on required throughput and material load.

DRO & Impact Forces Of Volumetric Feeder Market

The Volumetric Feeder Market is influenced by a dynamic interplay of Drivers, Restraints, and Opportunities (DRO), which collectively shape the competitive landscape and technological trajectory. A primary driver is the pervasive trend toward industrial automation, compelling manufacturers across all sectors to invest in reliable, automated dosing solutions to reduce manual labor dependency and human error. Simultaneously, the inherent cost-effectiveness of volumetric feeders, particularly when compared to highly accurate but significantly more expensive gravimetric alternatives, makes them the preferred choice for high-volume, less critical bulk material applications. These drivers are amplified by increasing production capacities globally, especially in emerging economies seeking efficiency upgrades.

However, the market faces significant restraints, primarily centered around the fundamental limitation of volumetric technology: its reliance on consistent bulk density. Fluctuations in raw material properties (such as moisture content, particle size distribution, or compaction) directly impact the actual mass delivered, leading to dosing inaccuracies that are unacceptable in certain quality-critical processes, particularly in high-potency drug manufacturing or highly sensitive chemical reactions. Furthermore, the rising regulatory scrutiny in pharmaceutical and food industries often mandates the use of gravimetric (loss-in-weight) systems for enhanced traceability and precision, thereby limiting the scope of high-value applications for volumetric feeders. Technological complexity related to handling very difficult materials, such as extremely cohesive or fragile products, also poses a constraint.

Opportunities for market expansion are abundant, particularly through technological enhancements and market diversification. The development of hybrid or smart volumetric feeders that incorporate advanced sensors and control algorithms to partially compensate for bulk density variations represents a significant growth pathway. Furthermore, the untapped potential in the recycling and waste-to-energy sectors requires robust, cost-effective feeding solutions for heterogeneous and often difficult bulk materials, areas where volumetric feeders are well-suited. The expansion into niche applications requiring highly specialized material handling, such as advanced ceramics and specialized battery materials, also offers substantial market potential.

Segmentation Analysis

The Volumetric Feeder Market is comprehensively segmented based on product type, application, operating principle, and end-use industry. This segmentation provides a granular view of market dynamics, revealing varying growth rates and adoption patterns across different industrial requirements. The type segmentation, including single-screw, twin-screw, and vibratory feeders, reflects the suitability of the equipment for materials with diverse flow characteristics, ranging from free-flowing pellets to cohesive powders. The application analysis provides crucial insights into the volume demand generated by major processing sectors like plastics, food, and chemicals, which are the primary consumers of high-throughput feeding technology.

Analysis by the operating principle distinguishes between continuous and batch feeding mechanisms. Continuous feeders are integral to high-volume manufacturing processes like extrusion and continuous blending, where steady material flow is paramount. Batch feeders, conversely, are utilized for predetermined, discrete quantities, often found in smaller mixing operations or formulation processes requiring specific recipe adherence. Understanding these segmentation nuances is crucial for manufacturers to tailor their product offerings and marketing strategies to meet specific operational needs and regulatory compliance standards across different industrial domains.

- By Type:

- Single Screw Feeders

- Twin Screw Feeders

- Vibratory Feeders

- Belt Feeders

- Rotary Valve Feeders

- By Application:

- Dosing/Metering

- Blending/Mixing

- Extrusion

- Filling

- By End-Use Industry:

- Plastics and Rubber

- Food and Beverage (F&B)

- Chemical and Petrochemical

- Pharmaceuticals and Cosmetics

- Construction Materials (Cement, Aggregates)

- Mining and Metallurgy

- By Operation:

- Continuous Feeders

- Batch Feeders

Value Chain Analysis For Volumetric Feeder Market

The value chain for the Volumetric Feeder Market begins with raw material suppliers, predominantly providing specialized stainless steel, engineering plastics, and complex electronic components necessary for manufacturing the robust feeder hardware and control systems. The upstream analysis focuses on managing the procurement risk associated with specialized materials, ensuring high quality (especially food-grade or pharmaceutical-grade steel), and maintaining stable costs. Original Equipment Manufacturers (OEMs) then undertake design, fabrication, assembly, and rigorous testing, focusing on maximizing feeder accuracy, reliability, and ease of cleaning, which are critical factors for end-user adoption. Competitive differentiation at this stage often relies on proprietary screw geometry, specialized agitation mechanisms, and advanced motor control technology.

The distribution channel plays a pivotal role in market reach. Direct sales channels are often employed for large, complex projects or customized systems, particularly those sold to major petrochemical or pharmaceutical corporations, allowing for direct technical support and system integration consultation. Indirect channels, involving distributors, local representatives, and system integrators, are crucial for reaching small and medium enterprises (SMEs) and for accessing international markets, where local presence and quick service response are essential. System integrators often bundle feeders with other processing equipment, such as mixers, extruders, and conveyors, offering turnkey solutions to end-users.

Downstream analysis focuses on the end-users—the various manufacturing industries that integrate these feeders into their production lines. Effective post-sales support, including spare parts availability, maintenance contracts, and technical training, is essential for ensuring long operational lifecycles and customer satisfaction. The efficiency and reliability of the volumetric feeder directly impact the quality and consistency of the end-product, making the downstream relationship critical for repeat business and market reputation. Technological advancement and localized service capabilities are key determinants of success in the highly competitive downstream environment.

Volumetric Feeder Market Potential Customers

The primary customers for volumetric feeders are large industrial manufacturing facilities and processing plants that require consistent and controlled introduction of bulk solids or powders into a continuous stream or batch process. These customers span capital-intensive sectors suchuding plastics compounding operations that rely on precise dosing of colorants and stabilizers; major food processors requiring accurate mixing of flavorings, preservatives, and flour additives; and basic and specialty chemical producers utilizing feeders for catalysts, fillers, and reaction ingredients. The necessity for reliable, high-volume material handling positions these heavy industries as the core consumer base.

Secondary, yet rapidly growing, customer segments include the pharmaceutical industry, particularly for initial blending stages of non-critical excipients and granulating processes, although highly active pharmaceutical ingredients (APIs) often demand gravimetric precision. Additionally, the construction industry (cement and dry mortar mixing plants) and the environmental sector (water treatment and waste management requiring precise chemical dosing) represent expanding opportunities. Customers are increasingly prioritizing suppliers who can offer feeders with superior material contact parts, minimizing cross-contamination risk, and providing simplified disassembly features for quick cleaning and changeover times, directly impacting their operational throughput and compliance.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 Million |

| Market Forecast in 2033 | USD 1,260 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Coperion K-Tron, Schenck Process, Brabender Technologie, Gericke, WAMGROUP, AZO GmbH, Acrison, Hapman, Kason Corporation, Premier Tech, FLSmidth, Metalfab Inc., Spiroflow, KWS Manufacturing, Palamatic Process, VIBRA SCHULTHEIS GMBH, Tecalemit, Vibra Screw, Eriez Manufacturing Co., Magnum Systems. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Volumetric Feeder Market Key Technology Landscape

The technology landscape within the Volumetric Feeder Market is characterized by incremental innovations focusing on improving material flow reliability and enhancing control sophistication. A core technological aspect involves optimized screw design, including specialized geometries (e.g., steep-walled, concave, or spiral screws) tailored to prevent bridging, rat-holing, and material segregation, especially when handling fine, cohesive, or highly fluidizable powders. The shift toward modular, quick-change tooling designs is also prevalent, facilitating faster product changeovers and simplifying sanitation procedures, which is critical in regulated environments like food and pharma.

Modern volumetric feeders increasingly incorporate advanced materials of construction, such as highly polished stainless steel (304 or 316L) and specialized polymers, to meet stringent hygiene and corrosion resistance requirements. Technological advancements are also evident in the drive systems, where high-precision servo motors and advanced gearboxes are replacing traditional drive mechanisms. These new drive systems offer enhanced torque control, wider speed turndown ratios, and higher volumetric accuracy, even at very low feed rates, addressing the need for micro-dosing applications in specialty chemical and pharmaceutical research.

Furthermore, digitalization is heavily influencing the control architecture. Although fundamentally volumetric, modern units are equipped with sophisticated Human-Machine Interfaces (HMIs), integrated control panels, and the ability to communicate via standard industrial protocols (e.g., EtherNet/IP, PROFINET). Sensor technology improvements, particularly in material level monitoring and feeder shaft rotation sensing, ensure smoother operation and quicker detection of material flow interruptions. The integration of proprietary software allows for logging operational parameters, aiding in process validation and compliance efforts, bridging the gap between hardware functionality and Industry 4.0 data requirements.

Regional Highlights

Regional analysis reveals distinct market maturity levels and growth trajectories across the globe, heavily influenced by industrial infrastructure and regulatory frameworks.

- Asia Pacific (APAC): Dominates the global volumetric feeder market, driven by massive manufacturing output in China, India, and Southeast Asia across plastics, construction, and basic chemicals. Rapid urbanization and subsequent infrastructure development necessitate high-throughput, cost-effective material dosing solutions.

- North America: Characterized by high technological adoption and stringent quality demands, particularly in the pharmaceutical, advanced food processing, and specialized chemical sectors. Growth here is steady, fueled by the replacement of older equipment and the adoption of feeders with enhanced digital connectivity and quick-cleaning features.

- Europe: A mature market focused on advanced manufacturing, regulatory compliance (especially ATEX and hygienic design standards), and high-precision applications. Western European countries are early adopters of automation and prefer modular systems that integrate seamlessly with existing sophisticated factory setups.

- Latin America (LATAM): Exhibits significant potential, driven by expansions in the commodity chemical, mining, and regional food and beverage sectors. Market penetration is accelerating as local manufacturers seek to upgrade outdated infrastructure to improve competitiveness and efficiency.

- Middle East & Africa (MEA): A growth market primarily concentrated around petrochemical refining, large-scale construction projects, and increasing investment in local food production facilities, particularly in the Gulf Cooperation Council (GCC) nations. Demand is focused on robust, low-maintenance equipment suitable for harsh operating environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Volumetric Feeder Market.- Coperion K-Tron

- Schenck Process

- Brabender Technologie

- Gericke

- WAMGROUP

- AZO GmbH

- Acrison

- Hapman

- Kason Corporation

- Premier Tech

- FLSmidth

- Metalfab Inc.

- Spiroflow

- KWS Manufacturing

- Palamatic Process

- VIBRA SCHULTHEIS GMBH

- Tecalemit

- Vibra Screw

- Eriez Manufacturing Co.

- Magnum Systems

Frequently Asked Questions

Analyze common user questions about the Volumetric Feeder market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between volumetric and gravimetric feeders?

Volumetric feeders dispense material based on volume (constant displacement) and are favored for their lower cost and simplicity, provided the material has consistent bulk density. Gravimetric (loss-in-weight) feeders measure and dispense material based on mass, offering significantly higher accuracy and compensating automatically for bulk density fluctuations, making them essential for high-precision, critical applications.

Which industries are the largest users of volumetric feeders?

The largest consumer industries include Plastics and Rubber Manufacturing, which require high-volume dosing of resins and additives; the Basic Chemical Industry for catalysts and fillers; and the Food and Beverage sector for ingredient blending where precision requirements are moderate and material consistency is high.

How is industrial automation impacting the volumetric feeder market?

Increased industrial automation drives demand for volumetric feeders as essential components in automated production lines, ensuring continuous, controlled material flow and reducing reliance on manual operations. Modern feeders integrate advanced controls and connectivity features compliant with Industry 4.0 standards for remote monitoring and centralized system management.

What types of materials are best suited for single-screw volumetric feeders?

Single-screw volumetric feeders are optimally designed for free-flowing, non-cohesive materials such as pellets, granules, flakes, and powders with good flow characteristics. These feeders offer a cost-effective solution for high-throughput applications where bridging or material adhesion is not a significant concern.

What technological trends are enhancing volumetric feeder accuracy?

Accuracy enhancements are driven by optimized screw geometries tailored to specific material properties, the implementation of high-resolution servo drive systems for precise speed control, and the incorporation of smart sensor technology for monitoring material level and detecting flow inconsistencies, often coupled with AI for predictive adjustments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager