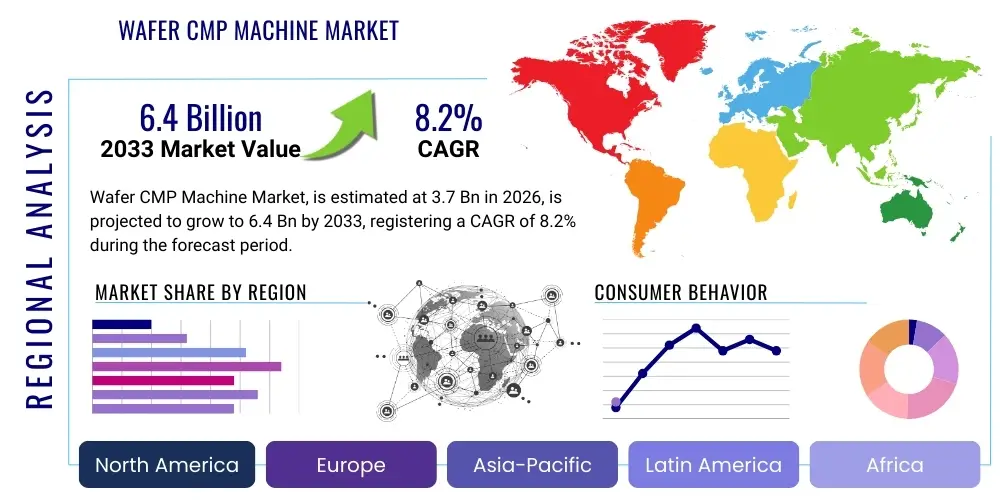

Wafer CMP Machine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440492 | Date : Jan, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Wafer CMP Machine Market Size

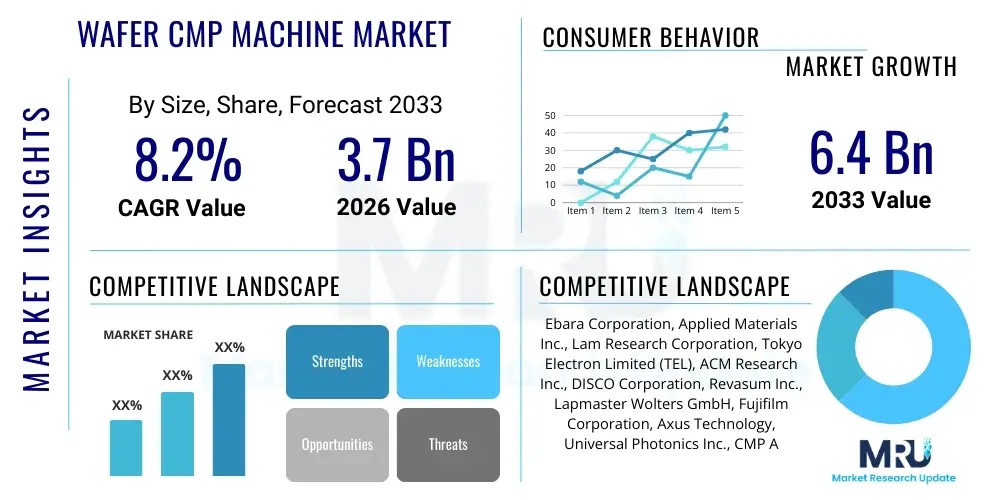

The Wafer CMP Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.2% between 2026 and 2033. The market is estimated at USD 3.7 Billion in 2026 and is projected to reach USD 6.4 Billion by the end of the forecast period in 2033.

Wafer CMP Machine Market introduction

The Wafer Chemical Mechanical Planarization (CMP) Machine Market is a cornerstone of advanced semiconductor manufacturing, providing the essential technology to achieve ultra-flat surfaces on silicon and other semiconductor wafers. This critical process combines mechanical abrasion with chemical reactions to precisely remove material, ensuring global planarity across the wafer. Wafer CMP machines are highly sophisticated systems designed for unparalleled precision and control, crucial for the fabrication of multi-layered integrated circuits where even nanoscale variations can lead to significant performance degradation or device failure. These machines utilize a combination of specialized polishing pads, abrasive slurries containing nanoparticles, and a rotating platen to achieve the desired surface quality and thickness uniformity, which are paramount for subsequent photolithography and deposition steps.

The primary applications of Wafer CMP machines span across various segments of the semiconductor industry, including logic devices, memory chips (DRAM and NAND flash), advanced packaging, MEMS, and power semiconductors. In logic and memory fabrication, CMP is indispensable for creating multiple interconnect layers and achieving the complex 3D structures found in modern chips like 3D NAND. The benefits derived from these machines are profound, encompassing improved device yield, enhanced electrical performance due to better interconnect integrity, reduction in critical dimension variations, and the enablement of advanced manufacturing nodes. The ability to precisely control film thickness and reduce defects at the atomic level directly translates to higher quality and more reliable semiconductor products.

Driving factors for the robust growth of the Wafer CMP Machine Market are deeply intertwined with the relentless advancement of the broader semiconductor industry. The accelerating demand for smaller, faster, and more powerful electronic devices, fueled by trends such as artificial intelligence, 5G connectivity, the Internet of Things (IoT), and high-performance computing, necessitates increasingly complex chip architectures. These advancements, including the transition to FinFET and Gate-All-Around (GAA) transistor structures, require more critical planarization steps. Furthermore, the expansion of advanced packaging technologies like 3D ICs and chiplets, which rely heavily on precise vertical interconnects, further amplifies the need for highly efficient and accurate CMP processes. The constant drive for higher yields and lower manufacturing costs also pushes innovation in CMP technology, making it an indispensable tool for semiconductor fabrication facilities worldwide.

Wafer CMP Machine Market Executive Summary

The Wafer CMP Machine Market is currently experiencing dynamic shifts driven by aggressive semiconductor technology roadmaps and increasing global demand for advanced electronics. Business trends indicate a strong focus on automation, integrating smart manufacturing principles, and expanding research and development into novel slurries, pads, and process control systems. Key players are investing heavily in improving throughput, reducing cost of ownership, and enhancing defectivity control, particularly for emerging materials and ultra-thin films. Strategic partnerships and mergers among equipment manufacturers and material suppliers are also becoming more common, aiming to offer integrated solutions and streamline the complex CMP ecosystem, thereby creating more resilient and efficient supply chains. The drive towards more sustainable manufacturing practices is also influencing equipment design, with an emphasis on reducing chemical waste and energy consumption.

Regionally, the market exhibits significant concentration and growth, primarily led by the Asia Pacific (APAC) region. Countries like Taiwan, South Korea, China, and Japan house the largest semiconductor foundries and IDMs, making them the epicenters of CMP machine demand and technological adoption. China, in particular, is witnessing substantial investment in domestic semiconductor manufacturing, driving a surge in demand for CMP equipment. North America and Europe, while having fewer fabrication facilities, remain crucial hubs for advanced R&D, pilot production, and the development of next-generation CMP technologies, often focusing on specialty applications and high-performance computing. Geopolitical considerations and the push for greater domestic chip production in various regions are also influencing regional investment patterns and contributing to localized market expansion.

In terms of segment trends, the market is seeing accelerated demand for CMP machines capable of handling 300mm wafers, with continuous innovation for future 450mm capabilities, although the latter's widespread adoption remains further out. The logic and memory segments continue to be the primary drivers, with particular emphasis on planarization for advanced FinFET, Gate-All-Around (GAA) structures, and 3D NAND stacking. There is also a growing segment focused on emerging materials like Silicon Carbide (SiC) and Gallium Nitride (GaN) for power electronics and RF applications, which present unique CMP challenges requiring specialized equipment and processes. The increasing complexity of interconnects and the integration of diverse materials within a single chip necessitate multi-step CMP processes, thereby increasing the overall market opportunity for these specialized machines and consumables.

AI Impact Analysis on Wafer CMP Machine Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the Wafer CMP Machine Market frequently revolve around how AI can enhance process precision, improve operational efficiency, and mitigate the inherent complexities of CMP. Users are keen to understand if AI can predict and prevent defects, optimize polishing recipes in real-time, and significantly reduce human intervention, leading to higher yields and lower costs. Concerns often include the robustness of AI models in dynamic manufacturing environments, data security implications for sensitive process data, and the skill gap required to implement and manage AI-driven systems. The overarching expectation is that AI will transform CMP from a largely empirical process into a highly data-driven and autonomous operation, pushing the boundaries of what is achievable in terms of planarization quality and throughput for next-generation semiconductor devices.

The integration of AI into Wafer CMP machines is rapidly evolving, moving beyond simple automation to intelligent process optimization. AI-powered algorithms can analyze vast datasets from various sensors embedded within CMP equipment, including real-time polishing rate monitors, defect detection systems, and metrology tools. This advanced analytical capability allows for immediate identification of subtle deviations from optimal conditions, enabling proactive adjustments to parameters such as platen speed, downforce, slurry flow rate, and pad conditioning. By constantly learning from historical data and current process conditions, AI can generate predictive models that anticipate potential issues like dishing or erosion before they impact wafer quality, thereby significantly enhancing process control and reducing material waste. This shift towards a more predictive and adaptive manufacturing paradigm is crucial for achieving the stringent requirements of sub-10nm technology nodes and beyond.

Furthermore, AI plays a pivotal role in improving the overall equipment effectiveness (OEE) of Wafer CMP machines through sophisticated predictive maintenance programs. By analyzing machine operational data, including vibration patterns, motor currents, and lubricant levels, AI algorithms can accurately forecast component failures or maintenance needs, allowing for scheduled interventions rather than reactive repairs. This minimizes unplanned downtime, a critical factor in high-volume manufacturing environments where every minute of machine idleness represents significant lost revenue. AI also contributes to yield management by correlating CMP process parameters with final device performance, providing actionable insights for continuous improvement. The ability of AI to automate recipe generation, adapt to variations in incoming wafer quality, and optimize consumable usage underscores its transformative potential, leading to more robust, efficient, and cost-effective CMP operations in the demanding semiconductor industry.

- Enhanced process control and parameter optimization through real-time data analysis.

- Predictive maintenance for critical components, minimizing unplanned downtime and improving machine availability.

- Real-time defect detection and classification using computer vision and machine learning algorithms.

- Improved yield management by identifying correlations between CMP processes and final device performance.

- Automated recipe generation and adaptive process adjustments based on wafer-to-wafer variations.

- Optimization of slurry consumption and polishing pad lifetime through intelligent usage patterns.

- Reduced human intervention and operator error, leading to increased consistency and operational cost savings.

- Facilitation of advanced metrology integration for precise in-situ monitoring and feedback loops.

DRO & Impact Forces Of Wafer CMP Machine Market

The Wafer CMP Machine Market is significantly influenced by a complex interplay of drivers, restraints, and opportunities, alongside powerful impact forces that shape its trajectory. Among the primary drivers is the escalating demand for smaller, more powerful, and energy-efficient semiconductor devices across diverse applications, ranging from consumer electronics to enterprise-grade data centers. The relentless miniaturization of transistors and the increasing complexity of integrated circuit designs, particularly the proliferation of multi-layered structures and 3D device architectures like FinFETs and 3D NAND, necessitate an ever-greater number of precise planarization steps. This fundamental requirement directly fuels the demand for advanced CMP machines capable of achieving sub-nanometer scale control. Furthermore, the burgeoning markets for Artificial Intelligence, 5G technology, IoT devices, and automotive electronics are creating unprecedented demand for high-performance chips, thereby accelerating investment in advanced fabrication capabilities that heavily rely on CMP.

Despite the robust growth drivers, the market faces several significant restraints. The exceptionally high capital investment required for purchasing and maintaining Wafer CMP machines is a major barrier, particularly for new entrants or smaller fabrication facilities. These machines are complex pieces of engineering, integrating precision mechanics, advanced chemical delivery systems, and sophisticated software, which translates into substantial upfront costs. Moreover, the technological complexity involved in developing and operating cutting-edge CMP processes, especially for new materials and highly advanced nodes, demands highly specialized expertise and continuous R&D expenditure. Environmental concerns pertaining to the disposal of chemical slurries and the consumption of ultrapure water also pose challenges, pushing manufacturers to invest in more sustainable and eco-friendly solutions, which can add to operational costs. Geopolitical tensions and trade restrictions can disrupt global supply chains for critical components and materials, impacting production and market stability.

Opportunities within the Wafer CMP Machine Market are largely driven by technological advancements and the emergence of new applications. The development of novel materials beyond traditional silicon, such as Silicon Carbide (SiC) and Gallium Nitride (GaN), for power electronics, electric vehicles, and high-frequency communication devices, presents a lucrative niche for specialized CMP solutions. These materials have distinct chemical and mechanical properties that require tailored planarization processes and equipment. The ongoing innovation in advanced packaging technologies, including 2.5D and 3D integration, chiplets, and wafer-level packaging, creates new CMP requirements for inter-layer dielectric and through-silicon via (TSV) planarization. Additionally, continuous research into next-generation slurries, polishing pads, and advanced process control systems, often leveraging AI and machine learning, offers avenues for market expansion and competitive differentiation. The underlying impact forces, primarily the insatiable demand for miniaturization and the increasing density of chip layers, will continue to dictate the strategic direction and technological evolution of the Wafer CMP machine market, emphasizing the need for ultra-flat surfaces and defect-free fabrication.

Segmentation Analysis

The Wafer CMP Machine Market is segmented to provide a granular understanding of its diverse components and dynamics, offering valuable insights into key market drivers, technological preferences, and application-specific demands. This segmentation allows for a detailed analysis of various machine types, their specific applications within the semiconductor manufacturing process, the levels of automation they incorporate, and the wafer sizes they are designed to handle. Each segment reflects unique technological requirements, market characteristics, and competitive landscapes, providing a comprehensive overview for stakeholders. Understanding these distinct categories is crucial for identifying growth opportunities, developing targeted strategies, and adapting to the evolving needs of the global semiconductor industry, which constantly pushes for greater precision, efficiency, and scalability in its manufacturing processes.

- By Type

- Rotary CMP Machines: Characterized by a rotating wafer and polishing pad, offering high throughput and versatility for various applications.

- Orbital CMP Machines: Feature an orbital motion of the polishing head, often preferred for specific material removal uniformity and advanced applications.

- Linear CMP Machines: Utilize a linear motion for polishing, offering precise control for specific processes and emerging materials, though less common for mass production.

- By Application

- Logic: Planarization for advanced microprocessors, GPUs, and other logic devices critical for computing and AI.

- Memory (DRAM & NAND): Essential for creating multi-layered structures in dynamic random-access memory and 3D NAND flash storage.

- MEMS (Micro-Electro-Mechanical Systems): Used for polishing and planarizing wafers for sensors, actuators, and other micro-devices.

- Power Devices: CMP for Silicon Carbide (SiC) and Gallium Nitride (GaN) wafers used in power electronics for electric vehicles and industrial applications.

- Others: Includes applications in optoelectronics, analog ICs, and specialty semiconductor fabrication.

- By Automation Level

- Fully Automatic CMP Machines: Integrated with robotic wafer handling, automated recipe management, and sophisticated process control systems, ideal for high-volume manufacturing.

- Semi-Automatic CMP Machines: Offer some level of automation for specific steps but may require manual intervention for wafer loading/unloading or parameter adjustments, suitable for R&D or lower-volume production.

- By Wafer Size

- 200mm Wafer CMP Machines: Predominantly used for legacy processes, specialty devices, and MEMS manufacturing.

- 300mm Wafer CMP Machines: The current industry standard for high-volume manufacturing of logic and memory chips.

- 450mm Wafer CMP Machines: Under development and research, representing the future scale for ultra-high-volume semiconductor production.

Value Chain Analysis For Wafer CMP Machine Market

The value chain for the Wafer CMP Machine Market is intricate, spanning from the specialized suppliers of raw materials and sophisticated components to the end-users in advanced semiconductor manufacturing facilities. Upstream activities involve a diverse ecosystem of suppliers providing essential ingredients for CMP processes. This includes manufacturers of high-purity abrasive particles (e.g., silica, ceria, alumina), chemical suppliers for specialized slurries and cleaning agents, and producers of advanced polishing pads made from proprietary polymers. Additionally, component manufacturers contribute precision robotics for wafer handling, advanced sensors for real-time monitoring, high-precision pumps for slurry delivery, and sophisticated control systems, all of which are integrated into the final CMP machine. The quality and innovation at this upstream level directly influence the performance and capabilities of the CMP equipment itself, highlighting the importance of robust supplier relationships and supply chain resilience.

Midstream in the value chain are the Wafer CMP machine manufacturers, who assemble these complex components and integrate proprietary technologies to produce the final planarization systems. These manufacturers invest heavily in research and development to enhance machine precision, throughput, automation, and defectivity control. Their core competencies lie in mechanical engineering, chemical engineering, materials science, and software development, enabling them to design machines capable of meeting the stringent requirements of current and future semiconductor nodes. The manufacturing process often involves extensive testing and calibration to ensure the machines deliver consistent and reliable performance under high-volume production conditions. Aftermarket services, including installation, maintenance, parts supply, and technical support, also form a critical part of the value proposition offered by these machine manufacturers, ensuring the longevity and optimal operation of their equipment in customer fabs.

Downstream, the primary customers are semiconductor foundries, integrated device manufacturers (IDMs), and specialized semiconductor producers who utilize CMP machines as a crucial step in their wafer fabrication lines. These end-users are responsible for the actual manufacturing of integrated circuits, memory chips, and other semiconductor devices. The distribution channel for Wafer CMP machines is predominantly direct, given the high capital expenditure, technical complexity, and the need for close collaboration between the manufacturer and the customer for customization, installation, and ongoing support. However, for consumables like slurries and pads, a mix of direct sales and specialized distributors is common. Indirect channels may also exist for spare parts and certain services. The strong direct relationship ensures that manufacturers can provide tailored solutions and integrate feedback from high-volume production environments directly into their R&D, fostering continuous innovation that addresses real-world manufacturing challenges and supports the relentless advancement of semiconductor technology.

Wafer CMP Machine Market Potential Customers

The potential customers for Wafer CMP machines are predominantly at the forefront of semiconductor manufacturing, representing entities that engage in the intricate process of fabricating integrated circuits and other advanced electronic components. These end-users are typically large-scale organizations with significant capital investments in cleanroom facilities and state-of-the-art production lines. The most prominent buyers include global semiconductor foundries, which specialize in manufacturing chips for fabless design companies. These foundries, such as TSMC, Samsung Foundry, and Intel Foundry Services, operate at the leading edge of technology, requiring the most advanced and high-throughput CMP solutions to meet the demanding specifications of their diverse clientele. Their continuous expansion and upgrades to new process nodes drive a substantial portion of the demand for the latest Wafer CMP machine technologies, emphasizing precision, uniformity, and defectivity control.

Integrated Device Manufacturers (IDMs) also represent a significant segment of potential customers. Companies like Intel, Micron Technology, SK Hynix, and Texas Instruments design, manufacture, and sell their own semiconductor products. These IDMs maintain their own fabrication facilities (fabs) and thus require a full suite of semiconductor manufacturing equipment, including Wafer CMP machines, to produce their proprietary logic, memory, and analog devices. For IDMs, the ability of CMP machines to support their unique device architectures and proprietary processes is crucial, often leading to close collaborative development with equipment suppliers. The internal demand for their own products, coupled with the strategic importance of controlling their manufacturing capabilities, makes IDMs consistent and substantial buyers in the Wafer CMP machine market, particularly as they push for technological self-sufficiency and innovation in their respective domains.

Beyond these major players, the customer base extends to specialty semiconductor manufacturers focusing on niche markets such as power electronics (e.g., manufacturers of SiC and GaN devices), optoelectronics, and MEMS. These companies, while potentially operating at lower volumes than the largest foundries, still require highly specialized CMP solutions tailored to the unique material properties and process requirements of their specific products. Furthermore, academic research institutions and government-funded laboratories involved in advanced materials science and nanotechnology research also acquire Wafer CMP machines for R&D purposes, pushing the boundaries of future semiconductor and micro-device fabrication. The increasing global investment in domestic semiconductor production, driven by geopolitical concerns and supply chain resilience, is also expanding the potential customer base to new regions and emerging players aiming to establish advanced manufacturing capabilities, further diversifying the market landscape for Wafer CMP machine suppliers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.7 Billion |

| Market Forecast in 2033 | USD 6.4 Billion |

| Growth Rate | 8.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ebara Corporation, Applied Materials Inc., Lam Research Corporation, Tokyo Electron Limited (TEL), ACM Research Inc., DISCO Corporation, Revasum Inc., Lapmaster Wolters GmbH, Fujifilm Corporation, Axus Technology, Universal Photonics Inc., CMP Advanced Technologies, Versum Materials, CMC Materials Inc. (now Entegris), SKC Inc., STRABAG SE, S&S Tech Co. Ltd., CETC, Hubei Dinglong Co. Ltd., Novellus Systems (part of Lam Research) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Wafer CMP Machine Market Key Technology Landscape

The technological landscape of the Wafer CMP Machine Market is characterized by continuous innovation aimed at achieving ever-higher levels of precision, uniformity, and throughput to meet the stringent demands of advanced semiconductor manufacturing. Central to this landscape are advanced process control (APC) systems, which leverage sophisticated sensors and algorithms to monitor and adjust polishing parameters in real-time. These systems integrate various metrology techniques, such as optical interferometry and eddy current sensors, for in-situ measurement of film thickness, topography, and defectivity, providing immediate feedback loops that optimize material removal rates and ensure global planarization. The drive towards data-driven manufacturing has led to the adoption of advanced analytics and machine learning, enabling predictive modeling for equipment performance and process optimization, moving beyond traditional statistical process control.

Endpoint detection systems represent another critical technological area, ensuring that the polishing process stops precisely when the target film thickness or surface condition is achieved. These systems employ diverse methods, including optical spectroscopy, electrical resistance monitoring, and acoustic emission detection, to accurately identify the end of the polishing cycle, preventing over-polishing or under-polishing which can severely impact device yield. Multi-zone polishing technology, featuring independently controllable pressure zones across the polishing platen, allows for precise tailoring of material removal rates across different areas of the wafer, addressing inherent non-uniformities and significantly improving within-wafer and wafer-to-wafer uniformity. Dual-platen systems, which enable sequential polishing steps on two different platens, are also gaining traction for complex multi-layer planarization requirements, enhancing throughput and process flexibility.

Beyond the core polishing mechanics, auxiliary technologies play a vital role in the overall performance of Wafer CMP machines. Robotic wafer handling systems ensure automated, contamination-free transfer of wafers between modules, minimizing human intervention and particulate contamination. Sophisticated slurry management systems are crucial for maintaining the precise chemical composition and particle dispersion of abrasive slurries, which are critical for consistent polishing performance. Furthermore, advanced cleaning technologies, often integrated post-CMP, utilize various chemical and mechanical methods to remove residual particles and chemical residues from the wafer surface, preventing defects in subsequent fabrication steps. As semiconductor technology progresses, the integration of these diverse technologies, often orchestrated by advanced software platforms and AI, will continue to define the forefront of Wafer CMP machine innovation, enabling the production of future generations of high-performance and reliable integrated circuits.

Regional Highlights

The global Wafer CMP Machine Market exhibits distinct regional dynamics driven by varying levels of semiconductor manufacturing investment, technological leadership, and geopolitical influences. Each region contributes uniquely to the market's overall growth and innovation landscape.

- Asia Pacific (APAC): Dominates the Wafer CMP machine market, primarily due to the concentration of major semiconductor manufacturing hubs in Taiwan, South Korea, China, and Japan. These countries host leading foundries and IDMs that are at the forefront of advanced logic and memory chip production, driving significant demand for state-of-the-art CMP equipment. China's ambitious goals for semiconductor self-sufficiency are leading to massive investments in new fabrication facilities, further solidifying APAC's market leadership. The region also benefits from a robust ecosystem of material and component suppliers, fostering continuous innovation and competitive pricing. This region is expected to maintain its leadership position due to ongoing expansion and technological upgrades in its extensive manufacturing infrastructure.

- North America: A significant market characterized by strong R&D capabilities, a focus on leading-edge technology development, and a growing emphasis on re-shoring semiconductor manufacturing. The United States, in particular, is home to major IDMs and equipment suppliers, driving innovation in CMP process control, metrology, and advanced materials. Government incentives and strategic initiatives aimed at bolstering domestic chip production contribute to steady investment in Wafer CMP machines, especially for advanced nodes and specialized applications like high-performance computing and defense. While not as high in volume production as APAC, North America's contribution to technological advancement and premium equipment sales remains crucial.

- Europe: Represents a focused market with strengths in specific semiconductor segments such as automotive, industrial, and power electronics. Countries like Germany and France have notable fabrication facilities and R&D centers that require advanced CMP solutions for their specialized products, particularly for Silicon Carbide (SiC) and Gallium Nitride (GaN) wafers. European companies often lead in equipment reliability and environmental sustainability, influencing global trends in CMP technology. The region also benefits from strong academic research and collaborative industry initiatives aimed at advancing semiconductor manufacturing capabilities, ensuring a steady, albeit niche, demand for Wafer CMP machines.

- Latin America & Middle East and Africa (MEA): These regions currently hold smaller shares of the Wafer CMP Machine market compared to other major geographical areas. However, there is emerging potential driven by increasing governmental focus on developing local technology infrastructure and diversifying economies. While large-scale semiconductor manufacturing is nascent, investments in packaging, assembly, and testing (OSAT) facilities, as well as specialized R&D initiatives, could lead to future growth in demand for CMP machines. The Middle East, for instance, is exploring opportunities in high-tech manufacturing, which may eventually include semiconductor fabrication, indicating future market expansion possibilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Wafer CMP Machine Market.- Ebara Corporation

- Applied Materials Inc.

- Lam Research Corporation

- Tokyo Electron Limited (TEL)

- ACM Research Inc.

- DISCO Corporation

- Revasum Inc.

- Lapmaster Wolters GmbH

- Fujifilm Corporation

- Axus Technology

- Universal Photonics Inc.

- CMP Advanced Technologies

- Versum Materials

- CMC Materials Inc. (now Entegris)

- SKC Inc.

- STRABAG SE

- S&S Tech Co. Ltd.

- CETC

- Hubei Dinglong Co. Ltd.

- Novellus Systems (part of Lam Research)

Frequently Asked Questions

What is Wafer CMP and why is it crucial in semiconductor manufacturing?

Wafer Chemical Mechanical Planarization (CMP) is a critical process in semiconductor fabrication that combines mechanical abrasion with chemical reactions to achieve ultra-flat surfaces on semiconductor wafers. This precise planarization is crucial for enabling the deposition of multiple, increasingly thin layers without defects, which is essential for manufacturing advanced integrated circuits and enhancing device performance and yield.

What are the main drivers for the Wafer CMP Machine market growth?

The primary drivers include the relentless demand for miniaturized and powerful electronic devices, the increasing complexity of chip architectures (like 3D NAND and FinFETs), the growth of emerging technologies such as AI, 5G, and IoT, and the continuous need for higher yields and improved device performance in semiconductor manufacturing. Advanced packaging trends also significantly contribute to market expansion.

How is AI impacting Wafer CMP technology?

AI is transforming Wafer CMP by enabling advanced process control and parameter optimization through real-time data analysis, enhancing predictive maintenance for reduced downtime, facilitating real-time defect detection and classification, and improving yield management. It also supports automated recipe generation and adaptive process adjustments, making CMP operations more efficient, precise, and cost-effective.

Which regions dominate the Wafer CMP Machine market?

The Asia Pacific (APAC) region, particularly Taiwan, South Korea, China, and Japan, currently dominates the Wafer CMP machine market. This dominance is attributed to the concentration of major semiconductor foundries and integrated device manufacturers (IDMs) in these countries, driving substantial investment in advanced fabrication capabilities and a robust demand for CMP equipment.

What are the key technological advancements in Wafer CMP machines?

Key technological advancements include sophisticated advanced process control (APC) systems, highly accurate endpoint detection mechanisms, multi-zone polishing for enhanced uniformity, and dual-platen systems for complex multi-step processes. Integration of AI and machine learning for predictive maintenance and process optimization, robotic wafer handling, and advanced slurry management systems are also crucial for next-generation CMP performance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager