Warehouse Dehumidifier Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440452 | Date : Jan, 2026 | Pages : 253 | Region : Global | Publisher : MRU

Warehouse Dehumidifier Market Size

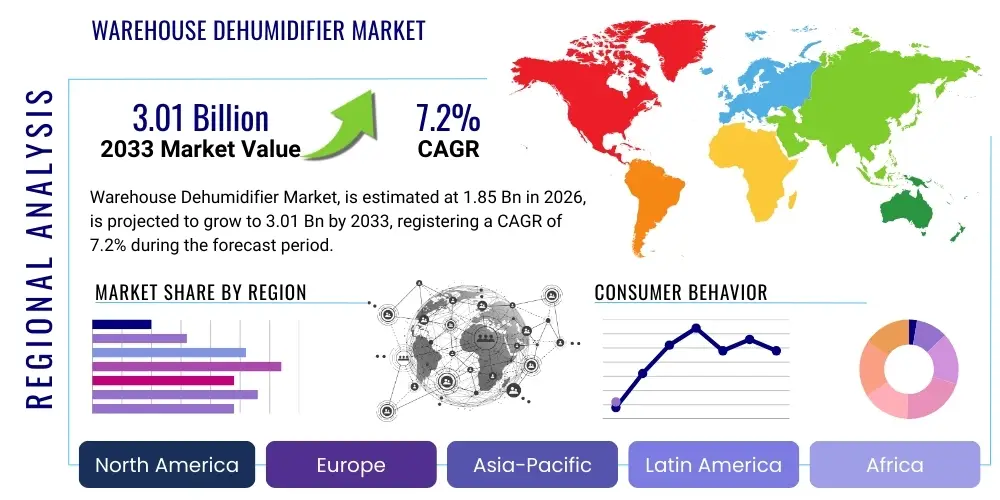

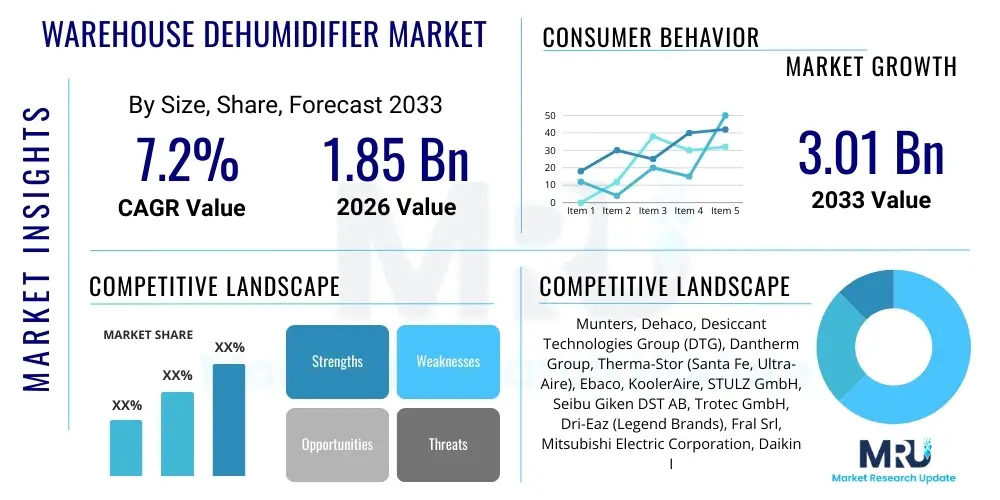

The Warehouse Dehumidifier Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.2% between 2026 and 2033. The market is estimated at USD 1.85 Billion in 2026 and is projected to reach USD 3.01 Billion by the end of the forecast period in 2033.

Warehouse Dehumidifier Market introduction

The Warehouse Dehumidifier Market encompasses a specialized segment within the broader HVAC and industrial equipment landscape, focused on managing ambient humidity levels within storage, logistics, and production facilities. Warehouse dehumidifiers are critical industrial appliances designed to extract excess moisture from the air, preventing a myriad of issues associated with high humidity, such as mold growth, corrosion, product degradation, and damage to structural integrity. These systems are essential for maintaining optimal environmental conditions, which directly impacts product quality, operational efficiency, and the longevity of stored goods, particularly in sensitive sectors like pharmaceuticals, food and beverage, electronics, and archival storage.

The core product offerings in this market typically include desiccant dehumidifiers and refrigerant (compressor-based) dehumidifiers, each suited for different temperature ranges, humidity levels, and operational requirements. Desiccant units excel in low-temperature and very low humidity applications, capable of achieving extremely dry conditions, while refrigerant dehumidifiers are generally more energy-efficient in warmer, moderately humid environments. Major applications span industrial warehouses, commercial storage facilities, cold storage units, logistics hubs, and specialized environments such as pharmaceutical manufacturing and food processing plants where precise humidity control is paramount to comply with stringent regulatory standards and maintain product efficacy or freshness.

The primary benefits derived from the deployment of warehouse dehumidifiers include enhanced product preservation, reduced risk of material damage, improved indoor air quality, prevention of rust and corrosion on machinery and infrastructure, and compliance with industry-specific storage guidelines. Key driving factors propelling market expansion include the increasing global demand for controlled storage environments, the proliferation of e-commerce necessitating extensive warehousing infrastructure, rising awareness regarding the adverse effects of humidity on various goods, and stringent regulatory requirements for product quality and safety across numerous industries. Furthermore, advancements in dehumidification technology, particularly towards energy efficiency and smart monitoring capabilities, are further stimulating market growth by offering more sophisticated and cost-effective solutions to end-users.

Warehouse Dehumidifier Market Executive Summary

The Warehouse Dehumidifier Market is experiencing robust growth driven by the escalating need for precise climate control in modern storage and logistics operations globally. Business trends indicate a strong focus on energy efficiency and the integration of smart technologies, such as IoT-enabled monitoring and automated control systems, to optimize operational costs and enhance dehumidification performance. Manufacturers are increasingly investing in research and development to produce more environmentally friendly refrigerants and desiccant materials, alongside modular and scalable solutions that can be tailored to diverse warehouse sizes and humidity challenges. The expansion of e-commerce and global supply chains is fueling the construction of new warehouses and distribution centers, each requiring sophisticated environmental management systems, thereby generating consistent demand for advanced dehumidification solutions.

Regionally, the market exhibits varied growth patterns, with Asia Pacific emerging as a dominant and rapidly expanding region due to accelerated industrialization, a booming manufacturing sector, and the rapid establishment of logistics and warehousing infrastructure in countries like China and India. North America and Europe continue to be significant markets, characterized by stringent quality control regulations in industries such as pharmaceuticals and food & beverage, which mandate effective humidity management. These developed regions also show a higher propensity for adopting advanced, energy-efficient, and digitally integrated dehumidifier systems. Latin America, the Middle East, and Africa are projected to demonstrate steady growth, influenced by industrial development projects and increasing foreign investments in manufacturing and logistics, driving the need for modern storage solutions.

Segmentation trends highlight a growing preference for desiccant dehumidifiers in applications requiring extremely low humidity levels, particularly in cold storage and pharmaceutical manufacturing, where conventional refrigerant units may struggle. Concurrently, the demand for high-capacity refrigerant dehumidifiers remains strong for large-scale general warehousing and distribution centers due to their cost-effectiveness in moderate humidity conditions. The increasing adoption of smart dehumidifiers, equipped with sensors and connectivity for remote monitoring and predictive maintenance, represents a significant segment trend. This technological integration not only enhances performance but also reduces manual intervention and operational downtime, appealing to businesses seeking optimized asset management and operational efficiency across their diverse storage facilities.

AI Impact Analysis on Warehouse Dehumidifier Market

The integration of Artificial Intelligence (AI) is poised to significantly transform the Warehouse Dehumidifier Market, moving beyond traditional reactive humidity control to proactive and predictive environmental management. Common user questions related to AI's impact often revolve around how AI can enhance energy efficiency, enable smarter operations, facilitate predictive maintenance, and contribute to overall cost savings. Users are keenly interested in understanding whether AI can optimize dehumidifier performance based on real-time environmental data and operational patterns, thereby reducing energy consumption and extending equipment lifespan. Concerns also include the ease of integrating AI systems with existing infrastructure, data security implications, and the potential for AI to autonomously adapt to varying storage conditions, ensuring optimal humidity levels without constant manual oversight.

AI's influence is anticipated to manifest through several key areas, primarily by enhancing the intelligence and autonomy of dehumidification systems. By analyzing vast datasets encompassing ambient temperature, humidity, external weather conditions, warehouse inventory types, and energy consumption patterns, AI algorithms can accurately predict future humidity fluctuations and modulate dehumidifier operation accordingly. This predictive capability allows systems to anticipate rather than merely react to changes, enabling highly precise and adaptive humidity control. For instance, AI can learn the specific humidity characteristics of a warehouse over time, understanding how different product loads or seasonal changes affect internal moisture levels, and then fine-tune settings to prevent deviations before they occur, ensuring consistent environmental conditions for sensitive goods.

Furthermore, AI-driven analytics can unlock substantial energy savings by optimizing operational cycles. Instead of running continuously or on fixed schedules, AI-powered dehumidifiers can operate only when necessary, adjusting fan speeds, compressor loads, and desiccant regeneration cycles based on actual needs and forecasted conditions, thereby minimizing energy waste. The technology also facilitates advanced fault detection and predictive maintenance. AI algorithms can detect subtle anomalies in equipment performance, such as unusual vibrations, temperature shifts in components, or changes in power draw, signaling potential issues before they lead to costly breakdowns. This shifts maintenance from a reactive to a proactive model, reducing downtime, extending the operational life of equipment, and lowering overall maintenance expenditures. Moreover, AI can integrate dehumidification processes with broader warehouse management systems, creating a holistic, smart environment where climate control interacts seamlessly with inventory management, energy grids, and security protocols, leading to unparalleled operational efficiency and data-driven decision-making for warehouse operators.

- Enhanced Energy Efficiency: AI algorithms optimize operational cycles and settings based on real-time data and predictive analytics, significantly reducing power consumption.

- Predictive Maintenance: AI analyzes performance data to identify potential equipment failures before they occur, enabling proactive maintenance and minimizing downtime.

- Automated Adaptive Control: Systems autonomously adjust dehumidifier settings in response to changing environmental conditions, cargo types, and external weather patterns.

- Data-Driven Optimization: AI provides insights into optimal humidity levels for specific goods, storage zones, and operational periods, improving preservation and reducing spoilage.

- Seamless Integration: Facilitates integration with broader Building Management Systems (BMS) and IoT platforms for centralized control and data synergy.

- Improved Air Quality & Safety: AI-monitored systems ensure consistent air quality, preventing mold and pathogen growth, which is crucial for health and regulatory compliance.

- Remote Monitoring & Diagnostics: Enables operators to monitor performance, diagnose issues, and control units remotely through AI-powered interfaces.

- Operational Cost Reduction: Leads to lower energy bills, reduced repair costs, and extended equipment lifespan, contributing to significant long-term savings.

DRO & Impact Forces Of Warehouse Dehumidifier Market

The Warehouse Dehumidifier Market is shaped by a complex interplay of Drivers, Restraints, and Opportunities, collectively forming its impact forces. A primary driver is the accelerating expansion of global e-commerce and logistics networks, which necessitates the construction and operation of vast warehousing infrastructures. These facilities, often storing diverse and sensitive goods ranging from electronics to pharmaceuticals, demand stringent humidity control to prevent damage, spoilage, and maintain product integrity, directly fueling the demand for specialized dehumidification solutions. Additionally, stringent regulatory standards and quality control protocols across industries like food & beverage, pharmaceuticals, and manufacturing mandate precise environmental conditions, making dehumidifiers an indispensable component of compliance strategies. Growing awareness among warehouse operators about the detrimental effects of uncontrolled humidity, such as mold growth, corrosion of machinery, and structural degradation, further propels market adoption as businesses seek to protect assets and investments.

Despite these robust drivers, several restraints temper market growth. The significant initial capital investment required for high-capacity industrial dehumidification systems can be a deterrent for small and medium-sized enterprises (SMEs) or facilities operating on tight budgets. Operating costs, particularly energy consumption, pose another challenge, as dehumidifiers can be energy-intensive, directly impacting profitability. Additionally, a lack of widespread awareness regarding the long-term benefits of humidity control, especially in developing regions, can hinder adoption rates. The complexity of selecting the appropriate dehumidification technology for specific warehouse conditions, coupled with potential challenges in integration with existing HVAC or building management systems, also presents hurdles for potential buyers, leading to delayed or suboptimal purchasing decisions.

Opportunities within the market largely stem from technological advancements and unmet needs. The continuous innovation in energy-efficient dehumidifier technologies, including more sophisticated desiccant materials and optimized refrigerant cycles, presents a significant avenue for growth, appealing to environmentally conscious and cost-sensitive operators. The integration of IoT, AI, and smart control systems offers immense potential for remote monitoring, predictive maintenance, and optimized performance, creating a new premium segment for intelligent dehumidification solutions. Furthermore, the burgeoning cold storage market, driven by global food trade and the pharmaceutical cold chain, represents a specialized niche where desiccant dehumidifiers are crucial, offering substantial growth prospects. Expansion into emerging economies, where industrialization and organized retail are on the rise, also provides fertile ground for market penetration, given increasing foreign investment and improving infrastructure that demands modern warehousing solutions and environmental controls.

Segmentation Analysis

The Warehouse Dehumidifier Market is meticulously segmented to provide a granular understanding of its diverse components, technologies, applications, and end-user industries. This segmentation is crucial for identifying specific market niches, understanding varying demand patterns, and tailoring product development and marketing strategies. The market is primarily bifurcated by the underlying technology of the dehumidifiers, their capacity to remove moisture, the specific applications they serve, and the end-use industries that deploy these solutions. Each segment exhibits distinct growth drivers and competitive landscapes, reflecting the varied requirements of industrial and commercial storage environments, from general logistics to highly specialized climate-controlled facilities.

- By Type

- Refrigerant Dehumidifiers: These units condense moisture out of the air using a refrigeration cycle. They are generally more efficient in warmer, moderately humid environments and are widely used in general warehousing.

- Desiccant Dehumidifiers: Utilizing a desiccant material (e.g., silica gel, lithium chloride) to absorb moisture, these units are highly effective in very cold environments or when extremely low humidity levels are required, crucial for cold storage and pharmaceutical applications.

- By Capacity (Pints/Day - PPD)

- Below 50 PPD: Typically used for smaller storage rooms or specific climate zones within larger warehouses.

- 50-150 PPD: Common for medium-sized warehouses and distribution centers with moderate humidity challenges.

- Above 150 PPD: High-capacity units designed for large industrial warehouses, cold storage facilities, and environments requiring extensive moisture removal.

- By Application

- Industrial Warehouses: General storage for manufacturing inputs and outputs.

- Commercial Warehouses: Storage for retail, wholesale goods, and consumer products.

- Cold Storage Facilities: Critical for food, beverage, and pharmaceutical storage where temperature and humidity control prevent frost and spoilage.

- Logistics & Distribution Centers: Hubs for inventory movement requiring stable conditions to protect goods during transit and storage.

- Pharmaceutical Storage: Highly regulated environments demanding precise humidity to preserve drug efficacy and comply with GMP standards.

- Food & Beverage Storage: Essential for preventing spoilage, mold, and maintaining freshness and shelf life of perishable goods.

- Archives & Museums: Protecting historical documents, artworks, and artifacts from moisture damage.

- Electronics & Semiconductor Storage: Preventing static discharge and corrosion of sensitive components.

- By End-Use Industry

- Manufacturing: Protecting raw materials, in-process goods, and finished products from moisture-related degradation.

- Food & Beverage: Ensuring food safety, preventing spoilage, and maintaining quality from production to distribution.

- Pharmaceutical: Adhering to strict environmental control standards for drug manufacturing, storage, and packaging.

- Logistics & Supply Chain: Maintaining optimal conditions across the entire supply chain to prevent damage during storage and transit.

- Retail & E-commerce: Protecting diverse consumer goods from humidity effects in vast storage facilities.

- Agriculture: Controlling humidity in agricultural product storage (e.g., grains, seeds, produce) to prevent spoilage and extend shelf life.

- Chemical & Petrochemical: Preventing moisture-induced reactions or degradation of sensitive chemicals.

- By Sales Channel

- Direct Sales: Manufacturers selling directly to large industrial clients and integrators.

- Indirect Sales: Through distributors, wholesalers, and online retailers, serving smaller businesses and replacement markets.

Value Chain Analysis For Warehouse Dehumidifier Market

The value chain for the Warehouse Dehumidifier Market is a comprehensive network of interconnected activities, beginning with the sourcing of raw materials and extending through manufacturing, distribution, and end-user deployment, ultimately supported by post-sales services. Upstream analysis involves the procurement of essential components and materials, including specialized metals for casings, compressors, coils, fans, desiccant rotors, electronic controls, and refrigerants. Key suppliers in this segment provide high-quality, durable, and often customized components that are critical for the performance and longevity of dehumidifier units. Relationships with these upstream suppliers are vital for ensuring consistent quality, managing costs, and enabling innovation in product design and efficiency. Manufacturers often rely on a global network of suppliers to achieve competitive pricing and access advanced technological components, emphasizing supply chain resilience and ethical sourcing practices.

The manufacturing stage involves the assembly, testing, and quality control of dehumidifier units. This includes sophisticated processes for integrating refrigeration circuits, desiccant wheels, air filtration systems, and electronic control boards into a robust and efficient final product. Manufacturers differentiate themselves through engineering expertise, adherence to international quality standards, energy efficiency ratings, and the incorporation of advanced features such as IoT connectivity, smart sensors, and user-friendly interfaces. Investment in automated production lines and skilled labor is crucial to meet growing demand while maintaining product consistency and reliability. Downstream analysis focuses on the distribution and sales channels, which vary significantly based on the target customer segment. For large industrial clients and complex integration projects, direct sales through a manufacturer’s own sales force or specialized project consultants are common, allowing for tailored solutions and extensive technical support.

Indirect distribution channels, encompassing wholesalers, distributors, industrial equipment suppliers, and online retail platforms, play a crucial role in reaching a broader customer base, including SMEs and replacement markets. These intermediaries provide localized inventory, logistics support, and often installation and basic maintenance services, extending the manufacturer's reach. The final stage of the value chain involves the end-users – the warehouses and storage facilities – where the dehumidifiers are installed and operated. Post-sales services, including installation assistance, warranty support, preventive maintenance contracts, and spare parts supply, are critical for customer satisfaction and long-term relationships. The efficiency and effectiveness of the entire value chain are dependent on seamless communication, efficient logistics, and a commitment to quality and service at every stage, from raw material extraction to the final operational support provided to the end-user.

Warehouse Dehumidifier Market Potential Customers

The Warehouse Dehumidifier Market caters to a diverse array of end-users and buyers, spanning various industries that share a fundamental need for controlled atmospheric conditions to protect assets, ensure product quality, and comply with regulatory mandates. One of the most significant customer segments comprises the expansive logistics and supply chain sector, including third-party logistics (3PL) providers, distribution centers, and freight forwarding companies. These entities manage vast inventories of goods, often highly sensitive to humidity, ranging from packaged consumer electronics and textiles to automotive parts and industrial machinery. Maintaining stable humidity levels within these facilities is paramount to preventing damage, rust, corrosion, and mold formation, which can lead to significant financial losses and reputational harm, making dehumidifiers an indispensable investment for preserving product integrity throughout the storage and transit lifecycle.

Another crucial customer base is found within the manufacturing and processing industries, particularly in sectors such as food and beverage, pharmaceuticals, chemicals, and electronics. Food and beverage manufacturers require precise humidity control in their storage facilities to prevent spoilage, inhibit microbial growth, and extend the shelf life of perishable ingredients and finished products. Pharmaceutical companies operate under strict Good Manufacturing Practice (GMP) guidelines, which mandate specific temperature and humidity parameters for raw material storage, active pharmaceutical ingredients (APIs), and finished drug products to maintain efficacy and stability. Similarly, electronics and semiconductor manufacturers need dry environments to prevent static electricity discharge and corrosion of sensitive components. These industries represent high-value customers dueing to their stringent requirements, often demanding advanced, high-capacity, and technologically integrated dehumidification solutions that can meet precise environmental specifications and regulatory compliance.

Furthermore, the market's potential customers extend to specialized storage facilities such as cold storage warehouses, archival institutions, museums, and even military storage depots. Cold storage facilities, which often experience issues like frost buildup and ice formation at low temperatures, require desiccant dehumidifiers to maintain dry conditions, crucial for preserving frozen goods and optimizing energy efficiency by reducing defrost cycles. Archival institutions and museums invest in dehumidifiers to protect invaluable historical documents, artworks, and artifacts from moisture-induced degradation, ensuring their preservation for future generations. Moreover, the expanding e-commerce landscape drives continuous demand for new, often automated, warehousing spaces that inherently require sophisticated environmental control systems to protect a wide variety of goods destined for direct consumer delivery. This broad spectrum of industries underscores the fundamental and pervasive need for effective humidity control, positioning warehouse dehumidifiers as essential infrastructure for modern storage and operational excellence.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 3.01 Billion |

| Growth Rate | 7.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Munters, Dehaco, Desiccant Technologies Group (DTG), Dantherm Group, Therma-Stor (Santa Fe, Ultra-Aire), Ebaco, KoolerAire, STULZ GmbH, Seibu Giken DST AB, Trotec GmbH, Dri-Eaz (Legend Brands), Fral Srl, Mitsubishi Electric Corporation, Daikin Industries, Ltd., Carrier Global Corporation, Johnson Controls International plc, Trane Technologies plc, LG Electronics Inc., Panasonic Corporation, Condair Group AG |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Warehouse Dehumidifier Market Key Technology Landscape

The technology landscape of the Warehouse Dehumidifier Market is dynamic, characterized by continuous innovation aimed at improving efficiency, performance, and operational intelligence. The core technologies primarily revolve around two distinct principles: refrigerant-based (condensation) dehumidification and desiccant-based (adsorption) dehumidification. Refrigerant dehumidifiers utilize a compressor to cool a coil below the dew point of the air, causing moisture to condense and collect, while dry air is then reheated and circulated. Recent advancements in this segment focus on optimizing compressor technology for higher energy efficiency, using environmentally friendly refrigerants with lower Global Warming Potential (GWP), and integrating variable-speed fans and smart controls to match performance with real-time humidity loads, thereby reducing power consumption and operational costs. These improvements make refrigerant units more adaptable and cost-effective for a wider range of moderate humidity applications in diverse warehouse environments.

Desiccant dehumidifiers, on the other hand, employ a desiccant material, typically embedded in a rotating wheel, to adsorb moisture from the air. A separate regeneration air stream is then heated to drive the moisture out of the desiccant, which is then exhausted outside. This technology is particularly favored for applications requiring very low humidity levels or operating in cold environments where condensation-based methods become inefficient, such as cold storage, pharmaceutical manufacturing, and sensitive electronics storage. Key technological advancements in desiccant systems include the development of new, more efficient desiccant materials with higher adsorption capacities, optimized wheel designs for better airflow and regeneration efficiency, and advanced heat recovery systems to minimize the energy required for regeneration. These innovations not only enhance dehumidification effectiveness but also improve the overall energy footprint of desiccant units, making them more attractive for critical applications.

Beyond the fundamental dehumidification methods, the market is witnessing a significant shift towards smart and integrated technologies. The advent of IoT (Internet of Things) connectivity is transforming dehumidifiers into intelligent devices capable of remote monitoring, data logging, and seamless integration with broader Building Management Systems (BMS) and warehouse automation platforms. This allows operators to monitor humidity levels, equipment status, and energy consumption in real-time from any location, enabling proactive adjustments and predictive maintenance. Artificial Intelligence (AI) and machine learning algorithms are being integrated to analyze environmental data, predict humidity trends, and autonomously optimize dehumidifier settings for peak efficiency and precise control, leading to substantial energy savings and extended equipment lifespan. Advanced sensor technologies, including sophisticated humidity, temperature, and dew point sensors, provide more accurate data inputs for these smart systems, further enhancing their precision and responsiveness. This convergence of core dehumidification principles with cutting-edge digital technologies is creating a new generation of high-performance, intelligent, and energy-efficient warehouse dehumidifiers.

Regional Highlights

- North America: A mature market characterized by robust industrial infrastructure, stringent quality control regulations in pharmaceutical and food & beverage sectors, and a high adoption rate of advanced, energy-efficient dehumidification solutions. The presence of major e-commerce players and sophisticated logistics networks drives continuous demand for precise humidity control in warehouses and distribution centers. Key countries include the United States and Canada, known for early technology adoption and a focus on operational efficiency and compliance.

- Europe: A significant market driven by strong manufacturing bases, particularly in Germany, the UK, and France, coupled with strict environmental and product safety standards. There's a growing emphasis on sustainable and energy-efficient dehumidifiers due to regulatory pressures and corporate sustainability goals. The region also boasts a well-developed cold chain logistics sector, further propelling the demand for specialized desiccant dehumidifiers.

- Asia Pacific (APAC): The fastest-growing market globally, propelled by rapid industrialization, burgeoning manufacturing sectors in China, India, and Southeast Asian countries, and explosive growth in e-commerce and logistics infrastructure. The expansion of cold storage facilities to support agricultural produce and pharmaceutical distribution further contributes to market growth. Increasing foreign investment and improving economic conditions are leading to greater adoption of modern warehousing solutions.

- Latin America: An emerging market showing steady growth, influenced by increasing industrial development, expanding trade activities, and growing awareness of the benefits of controlled storage environments. Countries like Brazil and Mexico are leading the adoption, driven by investments in manufacturing and logistics, although initial cost remains a significant factor in purchasing decisions.

- Middle East and Africa (MEA): This region is experiencing nascent but growing demand, primarily spurred by investments in infrastructure, diversification of economies away from oil, and the development of organized retail and logistics sectors. High ambient temperatures and humidity in certain areas make dehumidification essential for protecting goods. Investments in food security and pharmaceutical manufacturing are key drivers, particularly in GCC countries and South Africa.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Warehouse Dehumidifier Market.- Munters

- Dehaco

- Desiccant Technologies Group (DTG)

- Dantherm Group

- Therma-Stor (Santa Fe, Ultra-Aire)

- Ebaco

- KoolerAire

- STULZ GmbH

- Seibu Giken DST AB

- Trotec GmbH

- Dri-Eaz (Legend Brands)

- Fral Srl

- Mitsubishi Electric Corporation

- Daikin Industries, Ltd.

- Carrier Global Corporation

- Johnson Controls International plc

- Trane Technologies plc

- LG Electronics Inc.

- Panasonic Corporation

- Condair Group AG

Frequently Asked Questions

What is a warehouse dehumidifier and why is it essential?

A warehouse dehumidifier is an industrial-grade appliance designed to remove excess moisture from the air within large storage and logistics facilities. It is essential for preventing product damage (e.g., spoilage, corrosion), inhibiting mold growth, protecting machinery, ensuring structural integrity, and complying with industry-specific quality and safety regulations for various goods.

What are the main types of warehouse dehumidifiers available?

The two primary types are refrigerant (condensation) dehumidifiers, which are efficient in warmer, moderately humid conditions by cooling air to condense moisture, and desiccant (adsorption) dehumidifiers, which use a moisture-absorbing material and are ideal for very low humidity requirements or cold environments.

How does humidity affect goods stored in a warehouse?

High humidity can lead to numerous issues, including mold and mildew growth on perishable goods and packaging, rust and corrosion on metals, warping of wood products, reduced shelf life for food items, degradation of electronic components, and even structural damage to the warehouse itself, resulting in significant financial losses.

What role does AI play in modern warehouse dehumidification?

AI enhances dehumidification by enabling predictive maintenance, optimizing energy consumption through smart scheduling based on real-time and forecasted conditions, and providing autonomous, adaptive control. This leads to more precise humidity management, reduced operational costs, and extended equipment lifespan, integrating seamlessly with broader warehouse management systems.

Which industries are the primary end-users of warehouse dehumidifiers?

Key industries include logistics and supply chain (distribution centers, 3PLs), food & beverage, pharmaceuticals, manufacturing (electronics, chemicals), and specialized storage facilities such as cold storage, archives, and museums. These sectors require strict climate control to preserve product integrity, meet regulatory standards, and protect valuable assets.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager