Warp Knitting Machinery Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433727 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Warp Knitting Machinery Market Size

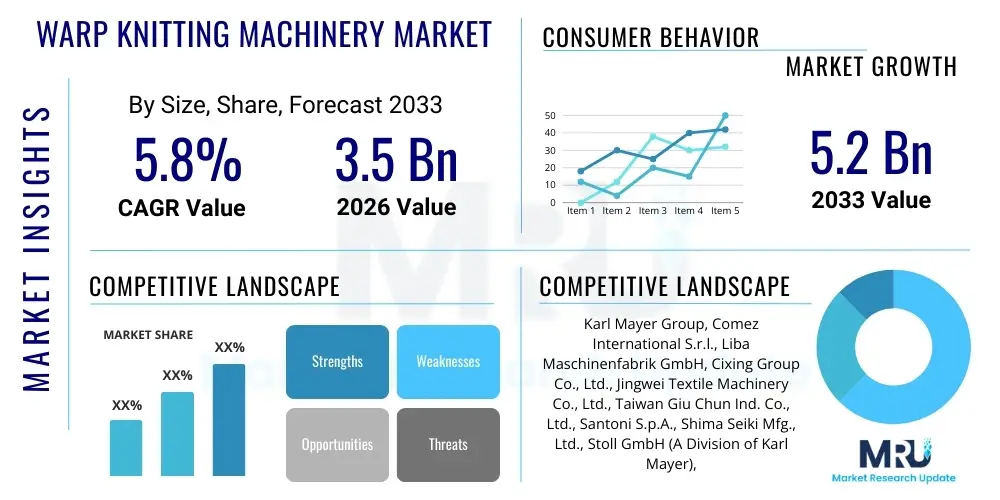

The Warp Knitting Machinery Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 3.5 Billion in 2026 and is projected to reach USD 5.2 Billion by the end of the forecast period in 2033. This consistent growth trajectory reflects the robust and sustained global demand for high-performance textiles, coupled with continuous technological advancements in knitting precision and speed. The necessity for textile manufacturers worldwide to upgrade their existing fleets with highly efficient, energy-saving models also underpins this projected market expansion throughout the forecast period.

Warp Knitting Machinery Market introduction

The Warp Knitting Machinery Market encompasses the global sale and distribution of specialized equipment used for producing warp knitted fabrics. Warp knitting is a process where the loops are formed vertically along the fabric length, utilizing multiple parallel yarns, leading to textiles that possess superior dimensional stability, exceptional stretch-resistance, and high production versatility compared to weft knitted or woven structures. These specialized machines, which fall predominantly into categories such as tricot, raschel, and crochet machines, form the bedrock of modern, high-speed textile manufacturing, enabling the efficient mass production of both simple plain fabrics and complex technical textiles tailored for demanding applications.

Key product categories within this highly technical domain include high-performance tricot machines, primarily utilized for apparel, intimate wear, and certain types of technical textiles requiring a very smooth surface and controlled elasticity. Raschel machines, which offer greater versatility in pattern and complexity, are employed extensively for producing structural fabrics like lace, industrial netting, safety gear, and heavy-duty industrial fabrics such as geotextiles and crucial components for the automotive industry. The ability of warp knitting technology to integrate varied yarn types, including synthetics, natural fibers, and composite materials, across a wide range of gauges, secures its position as an indispensable technology in the modern materials industry.

The primary applications driving the robust demand span across technical textiles—the fastest-growing segment—fashion apparel, high-end home furnishings, and specialized medical textiles. The market expansion is significantly bolstered by the growing global adoption of performance textiles, especially in the automotive sector (for upholstery and lightweight components), construction (for reinforcement materials), and the medical field (for sophisticated implants and advanced wound care). Furthermore, technological advancements focusing on digitization, enhancing energy efficiency, increasing operational speed, and pushing the boundaries of machine gauge capabilities are continually incentivizing manufacturers across mature and emerging markets to upgrade their machinery fleets, ensuring sustained momentum and high-quality output.

Warp Knitting Machinery Market Executive Summary

The Warp Knitting Machinery Market is undergoing significant evolution, defined by key business trends that prioritize automation, digital integration, and sustainability. The industry trend is moving decisively towards highly automated, resource-efficient machinery equipped with sophisticated electronic control systems, which not only minimize human intervention but also optimize material usage and pattern change flexibility. Leading machinery manufacturers are intensely focused on integrating IIoT sensors and advanced software to provide textile producers with real-time operational diagnostics and performance benchmarking, positioning the market at the forefront of the global Industry 4.0 revolution in textile manufacturing.

From a regional perspective, the dynamism of the market remains centered in the Asia Pacific (APAC) region, which commands the largest volume share due to the sheer scale of textile production in major economies like China, India, Vietnam, and Bangladesh. These nations act as the world’s primary sourcing hubs, fueling massive procurement of both mid-range and high-speed machinery. Conversely, established markets in Europe and North America, while lower in volume, represent the key growth segments for high-value, specialized machinery. Investment in these Western markets is heavily directed towards highly specialized, fine-gauge machines tailored for producing performance-critical technical textiles and customized, sustainable fashion textiles that adhere to strict environmental standards and high-quality specifications.

Segment analysis reveals that machine types capable of handling specialized technical yarns and complex three-dimensional structures, primarily Raschel machines, are forecast to achieve the highest Compound Annual Growth Rate (CAGR). The fastest accelerating application is technical textiles, driven by its essential role in achieving regulatory compliance and performance enhancements across diverse industries, from aerospace to sports apparel. Concurrently, the increasing integration of electronic drive systems (E-drives) for precision control over yarn feed and needle movement is a pervasive technological trend across all machine types, enhancing synchronization, reducing maintenance burdens, and ultimately enabling textile manufacturers to handle a wider array of fibers and complex knitting structures with unparalleled operational reliability and precision, thereby boosting overall market value.

AI Impact Analysis on Warp Knitting Machinery Market

User inquiries concerning Artificial Intelligence (AI) and Machine Learning (ML) integration in warp knitting machinery overwhelmingly focus on optimizing operational uptime, ensuring superior fabric quality at high speeds, and streamlining the complexity of design translation. Key concerns revolve around the transition costs associated with adopting AI-enabled diagnostics systems and ensuring data security for proprietary knitting patterns and operational efficiency metrics. Users expect AI algorithms to revolutionize maintenance schedules by accurately predicting mechanical stress points and component wear using sophisticated sensor data analysis, thereby transforming reactive maintenance into highly precise, proactive scheduling. Another significant expectation is the use of AI-powered vision systems to maintain perfect fabric consistency across kilometers of material, eliminating minor imperfections that are often missed by human inspectors or traditional mechanical monitoring tools.

The deployment of AI and Machine Learning models is ushering in a new era of intelligence within warp knitting operations, moving far beyond basic automation. These systems are strategically utilized to analyze the immense volumes of continuous data streamed from machine sensors—monitoring variables such as guide bar temperature, yarn input tension, knitting needle vibration profiles, and atmospheric conditions—to dynamically adjust control parameters in milliseconds. This sophisticated real-time optimization capability allows machinery to consistently operate at its peak efficiency envelope, ensuring maximum throughput and superior fabric homogeneity while simultaneously minimizing material waste and mitigating the thermal and mechanical stresses that lead to premature component degradation. The net result is a significant improvement in Overall Equipment Effectiveness (OEE) and a palpable reduction in the energy footprint associated with high-speed manufacturing.

Beyond the immediate machine floor, AI is proving transformative in the broader scope of production planning and material logistics. By integrating external data streams, including real-time market order flow, historical production bottlenecks, and complex inventory movement data, AI-driven algorithms can generate highly accurate and adaptable production schedules. This intelligent scheduling capability reduces inventory holding costs, shortens production lead times dramatically, and significantly enhances the textile manufacturer's agility in responding to dynamic fashion cycles or unexpected changes in demand for technical textiles. This transition toward predictive, data-driven manufacturing, central to the Industry 4.0 ethos, effectively elevates warp knitting from a highly skilled mechanical craft to a precision engineering process managed and optimized by intelligent systems, ensuring manufacturers remain competitive in a rapidly evolving global market landscape.

- AI-Powered Predictive Maintenance: Reduces unplanned machine downtime by utilizing sensor data (vibration, temperature, current load) to forecast component failure probabilities with high accuracy, enabling scheduled replacements.

- Automated Quality Control (AQC) with Machine Vision: Employs high-speed cameras and sophisticated ML models to detect subtle fabric defects (e.g., dropped stitches, pattern inaccuracies, color deviations) in real-time, drastically reducing the necessity for manual inspection.

- Optimized Pattern Design and Translation: AI algorithms expedite the complex process of translating customer specifications or CAD patterns into highly efficient electronic guide bar control sequences, cutting development time and minimizing programming errors.

- Resource and Energy Consumption Optimization: ML models continuously refine knitting parameters, including machine speed and internal cooling systems, based on the specific material and environmental conditions to achieve optimal performance per unit of energy consumed.

- Intelligent Supply Chain Synchronization: AI integrates production capacity data with raw material logistics and inventory levels to optimize procurement and minimize material shortages or excessive stock holding.

DRO & Impact Forces Of Warp Knitting Machinery Market

The Warp Knitting Machinery Market operates under a distinct set of Drivers, Restraints, and Opportunities (DRO) that define its current growth trajectory and future potential. The market’s primary expansion is fueled by the relentless global push for high-performance and innovative technical textiles, alongside the necessary modernization of textile infrastructure in developing economies. Conversely, the market faces significant restraints related to the intensely high capital expenditure required for advanced, digitally integrated machinery, coupled with persistent fluctuations in global raw material prices which impact the profitability and investment capacity of textile mills worldwide. These opposing forces—innovation demand versus cost barriers—create a complex, yet dynamic, investment environment for machinery manufacturers.

Drivers: A paramount driver is the explosive growth and diversification of the technical textiles sector. Warp knitted fabrics are indispensable in the manufacturing of critical materials for safety, environmental protection, and structural reinforcement, including automotive composites, geo-grids for civil engineering, and fire-retardant materials. The superior tensile strength, stability, and light weight of warp knitted structures make them preferable to woven alternatives in high-stress applications, guaranteeing sustained investment in high-end machinery. Furthermore, intense global competition compels textile manufacturers to continuously seek greater operational efficiency, favoring the newest generation of high-speed, electronically controlled machines that deliver substantial improvements in throughput and labor productivity over older mechanical models.

Restraints: The most substantial restraint remains the inherently high initial cost associated with purchasing state-of-the-art, large-format warp knitting machines, especially those equipped with advanced electronic guide bars and full Industry 4.0 integration. This elevated cost base often excludes Small and Medium-sized Enterprises (SMEs) and manufacturers in developing regions from accessing the latest technology, leading to market fragmentation based on technological access. Moreover, the cyclical nature of the global textile and apparel industry means that capital investment in machinery is highly susceptible to global economic downturns and geopolitical instability, which can dramatically pause or reduce procurement volumes on short notice, creating demand volatility for machinery suppliers.

Opportunities: Significant opportunities are emerging from the nexus of environmental sustainability and digitalization. There is a burgeoning demand for warp knitting machines specifically engineered to efficiently process recycled, biodegradable, and sustainable synthetic fibers, helping textile manufacturers meet stringent regulatory and consumer-driven eco-standards. Furthermore, the robust adoption of cyber-physical systems, IIoT, and AI offers a chance for machinery providers to transition into solution providers, offering integrated software and service packages (e.g., predictive maintenance subscriptions, remote diagnostics) alongside hardware sales, thereby creating new, high-margin recurring revenue streams and deepening customer lock-in through technology dependency.

Segmentation Analysis

The Warp Knitting Machinery Market segmentation provides a granular view of market dynamics based on machine type, application, and end-use, reflecting the highly specialized nature of the equipment and its diverse end-uses. The machine type segmentation (Tricot, Raschel, Crochet) fundamentally dictates the scope of fabric production capabilities, influencing investment decisions based on desired output volume and fabric complexity. Raschel machines, due to their flexibility in producing structural and high-performance technical textiles, are attracting disproportionate investment compared to the high-volume, standard output of tricot machines. The rapid expansion of specialized functional textiles is fundamentally shifting market dynamics within these categories, demanding greater versatility from machine builders.

The segmentation by application is crucial, highlighting the massive financial pivot towards the technical textiles category, encompassing high-value sectors such as automotive safety, civil engineering geotextiles, and specialized medical implants. These applications necessitate machines capable of extremely high precision, consistency, and the handling of challenging, technical yarns like carbon fiber, glass fiber, or specific high-tenacity polyesters. In contrast, the apparel segment requires speed and rapid pattern change capabilities to keep pace with fast-fashion cycles. Understanding the varying demands across these application areas allows manufacturers to optimize product portfolios and target market-specific feature sets, such as fine-gauge capability for luxury apparel or robust construction for industrial fabrics.

Segmentation by Gauge Type—Coarse, Medium, and Fine—further refines the market map, correlating directly to fabric density and intended use. Fine-gauge machines (E28 and above) are vital for premium, lightweight, high-density fabrics used in high-end sportswear, lingerie, and delicate medical textiles, representing a high-margin segment. Coarse-gauge machines (E6–E12) are essential for durable industrial products like netting, mesh, and heavy geotextiles. This granular segmentation aids both machinery producers and potential buyers in correctly matching machinery investment to specific market niches and technical requirements, ensuring capital efficiency and maximized return on investment in a competitive environment.

- By Machine Type:

- Tricot Machines (High-speed production of smooth, basic fabrics)

- Raschel Machines (Versatile, used for lace, nets, and technical/industrial fabrics)

- Crochet Machines (Specialized for narrow fabrics, trims, and elaborate patterns)

- Others (e.g., Double-bar Raschel Machines, Compound Needle Machines)

- By Application:

- Apparel and Clothing (Lingerie, Sportswear, Outerwear)

- Home Furnishings (Curtains, Bedding, Upholstery backing)

- Technical Textiles (Automotive Interiors, Geotextiles, Filtration Media, Construction Reinforcement)

- Medical Textiles (Bandages, Prosthetic Socks, Implants, Gowns)

- Industrial & Protective Textiles (Nets, Ropes, Safety Vests)

- By Gauge Type:

- Coarse Gauge (E6 – E12): Primarily for industrial, heavy-duty applications.

- Medium Gauge (E14 – E24): Balanced use across apparel, home, and standard technical textiles.

- Fine Gauge (E28 and Above): Used for premium, lightweight, high-density apparel and specialized medical fabrics.

Value Chain Analysis For Warp Knitting Machinery Market

The value chain for the Warp Knitting Machinery Market is characterized by highly specialized upstream component sourcing and technologically intensive assembly processes. The upstream phase involves the meticulous selection and procurement of high-precision components, notably advanced electronic control units (ECUs), high-speed servo motors, specialized high-grade steel for precision knitting elements (needles, sinkers, guide bars), and custom industrial software. Suppliers in this segment, often European or Japanese precision engineering firms, dictate the technological ceiling of the final machine, as the reliability, speed, and overall electronic sophistication are directly dependent on these input components. Leading machinery manufacturers invest significantly in proprietary control software and mechanical design to optimize the integration of these sophisticated elements, forming their primary technological competitive barrier.

The core manufacturing stage involves complex assembly, extensive calibration, and rigorous quality assurance (QA) protocols. Modern warp knitting machine assembly is less about manual labor and more about precision robotics and controlled environments to ensure the perfect alignment of thousands of knitting elements operating at extremely high speeds. After assembly, extensive testing and software integration occur, preparing the machine for market release. This phase demands deep engineering expertise, particularly in fluid dynamics, thermal management, and vibration control, to ensure the machine can maintain consistency and longevity when operating at high production speeds.

The downstream distribution network utilizes a hybrid model. For major, multi-million dollar deals with global textile conglomerates, direct sales teams and dedicated field engineers manage the process, from initial consultation and site preparation to installation, commissioning, and long-term service contracts. For smaller accounts or penetration into geographically remote markets, machinery manufacturers rely heavily on authorized regional agents and distributors. These intermediaries are vital for localized inventory of common spare parts, offering first-line technical support in the native language, and providing essential application training. Effective post-sales service, including remote diagnostics and rapid spare parts fulfillment facilitated by digital platforms, is a crucial element that determines customer loyalty and influences future purchasing decisions, making service revenue an increasingly important component of the value chain.

Warp Knitting Machinery Market Potential Customers

The primary customers for warp knitting machinery are large-scale, vertically integrated textile mills that operate high-volume production lines for mass-market apparel and home textiles. These companies prioritize speed, reliability, and low operational costs (TCO). A secondary, but increasingly important, customer base consists of specialized technical textile manufacturers. These producers require high-precision, versatile machinery to create highly engineered products like composite reinforcements, automotive airbags, filtration media, and sophisticated medical textiles, emphasizing quality, precision, and customization over sheer volume output.

Furthermore, SMEs operating in niche markets, such as lace production, specialized netting, or smart textile prototyping, represent a growing customer segment, often seeking medium-sized or specialized crochet machines that offer flexibility and quick changeover capabilities. In emerging economies, textile manufacturers focused on modernizing outdated equipment are significant buyers, targeting entry-level to mid-range machines that offer improved automation and energy efficiency compared to their legacy systems. Governmental and educational research institutes also constitute a small but vital customer base, utilizing advanced machinery for materials research and workforce training and contributing to the development of next-generation textile applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.5 Billion |

| Market Forecast in 2033 | USD 5.2 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Karl Mayer Group, Comez International S.r.l., Liba Maschinenfabrik GmbH, Cixing Group Co., Ltd., Jingwei Textile Machinery Co., Ltd., Taiwan Giu Chun Ind. Co., Ltd., Santoni S.p.A., Shima Seiki Mfg., Ltd., Stoll GmbH (A Division of Karl Mayer), Pailung Machinery Mill Co., Ltd., Terrot GmbH, Fukuhara Industrial & Trading Co., Ltd., Lonati S.p.A., Monarch Knitting Machinery Corporation, Qunsheng Machinery, Runyuan Knitting Machinery Co., Ltd., Dazhou Knitting Machinery Co., Ltd., Huixing Knitting Machinery, Yongde Knitting Machinery, Zhejiang Jingyi Machinery. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Warp Knitting Machinery Market Key Technology Landscape

The technological evolution of the Warp Knitting Machinery Market is fundamentally driven by the shift from mechanical reliance to integrated electronic and software-based control systems, epitomizing the textile sector's transition to Industry 4.0. The most critical technological advancement is the widespread adoption of sophisticated Electronic Guide Bar (EGB) control systems, which have entirely replaced cumbersome mechanical pattern chains. EGB technology utilizes precise linear motors and complex software algorithms to control the lateral movement of guide bars, offering near-limitless pattern flexibility and facilitating changeovers in minutes rather than hours. This capability is paramount for meeting the demands of high-mix, low-volume production characteristic of the technical textile and fast-fashion markets, significantly reducing non-productive time and enhancing machine utilization rates.

Further defining the competitive landscape is the pervasive integration of the Industrial Internet of Things (IIoT) and advanced sensing technologies. Contemporary machines are equipped with hundreds of sensors monitoring critical parameters such as bearing temperature, machine vibration harmonics, yarn tension uniformity, and minute energy consumption fluctuations. This extensive sensor network generates vast streams of Big Data, which, when analyzed through centralized manufacturing execution systems (MES), facilitates real-time performance monitoring and sophisticated condition-based monitoring (CBM). The data enables highly accurate predictive maintenance scheduling, significantly boosting Mean Time Between Failures (MTBF) and ensuring consistent, high-quality output by immediately flagging and correcting performance drift.

Material science innovation also plays a vital role, particularly in designing lighter, faster, and more robust mechanical components. Manufacturers are increasingly utilizing advanced lightweight materials, such as specialized carbon fiber composites and high-strength aluminum alloys, in high-speed reciprocating parts like needle bars and sinker mechanisms. This reduction in mass inertia allows machines to operate reliably at significantly higher revolutions per minute (RPM) while consuming less energy and reducing mechanical wear. Concurrently, software innovation focuses on developing advanced simulation tools that allow textile engineers to digitally prototype new fabric structures and optimize machine settings before physical production begins, drastically compressing the product development lifecycle and enhancing first-time-right manufacturing efficiency, solidifying technology as the core driver of market value.

Regional Highlights

The global distribution and growth profile of the Warp Knitting Machinery Market are highly asymmetrical, reflecting diverse regional economic drivers, labor costs, and technological adoption rates.

- Asia Pacific (APAC): APAC is the unequivocally dominant market, driven by its status as the world’s primary textile and apparel production base. Countries like China, which leads in both production capacity and domestic technical textile consumption, alongside Vietnam, Indonesia, and India, fuel the largest volume demand for warp knitting machinery. Regional growth is supported by government policies promoting textile industry modernization, particularly the shift toward high-value synthetics and automated manufacturing.

- Europe: This region is characterized by high technological sophistication and a focus on specialized, fine-gauge production. While volume procurement is lower than APAC, Europe leads in the innovation and manufacturing of premium, technologically complex warp knitting machines. Key demand is concentrated in the production of high-performance technical textiles for medical, filtration, and automotive industries, prioritizing energy efficiency, precision, and adherence to stringent EU environmental standards.

- North America: The market here is a high-value niche, primarily driven by strong domestic defense and automotive sectors. North American manufacturers demand highly automated, intelligent machinery (IIoT and AI-enabled) capable of minimizing reliance on high-cost labor and meeting stringent performance specifications for specialized industrial fabrics, favoring quality and durability over low cost.

- Latin America (LAMEA): Showing consistent, moderate growth, LAMEA countries, particularly Brazil, Mexico, and Argentina, are investing in machinery upgrades to enhance domestic manufacturing capabilities and capture regional market share. The focus is mainly on mid-range, versatile tricot and raschel machines suitable for general apparel and emerging infrastructure projects.

- Middle East & Africa (MEA): This region is an emerging market with growth largely influenced by foreign investment and strategic government initiatives in countries like Turkey (a major regional hub) and parts of North Africa aiming to establish modern, localized textile supply chains. Procurement often involves new, entry-level to mid-range machinery that offers excellent return on investment and high energy efficiency.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Warp Knitting Machinery Market.- Karl Mayer Group (Germany)

- Comez International S.r.l. (Italy)

- Liba Maschinenfabrik GmbH (Germany)

- Cixing Group Co., Ltd. (China)

- Jingwei Textile Machinery Co., Ltd. (China)

- Taiwan Giu Chun Ind. Co., Ltd. (Taiwan)

- Santoni S.p.A. (Italy, part of Lonati Group)

- Shima Seiki Mfg., Ltd. (Japan)

- Stoll GmbH (Germany, now part of Karl Mayer)

- Pailung Machinery Mill Co., Ltd. (Taiwan)

- Terrot GmbH (Germany)

- Fukuhara Industrial & Trading Co., Ltd. (Japan)

- Lonati S.p.A. (Italy)

- Monarch Knitting Machinery Corporation (USA/UK)

- Qunsheng Machinery (China)

- Runyuan Knitting Machinery Co., Ltd. (China)

- Dazhou Knitting Machinery Co., Ltd. (China)

- Huixing Knitting Machinery (China)

- Yongde Knitting Machinery (China)

- Zhejiang Jingyi Machinery (China)

Frequently Asked Questions

Analyze common user questions about the Warp Knitting Machinery market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the projected Compound Annual Growth Rate (CAGR) for the Warp Knitting Machinery Market?

The Warp Knitting Machinery Market is projected to exhibit a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. This consistent growth is primarily driven by surging global demand for technical textiles and essential modernization investments by manufacturers in emerging economies.

Which segment holds the largest share in the Warp Knitting Machinery Market by application?

While the Apparel segment accounts for massive unit volume, the Technical Textiles application segment, encompassing automotive, medical, and construction fabrics, is projected to demonstrate the fastest revenue growth due to high per-unit machinery value and mandatory performance requirements.

How does Industry 4.0 influence the purchase of new warp knitting machines?

Industry 4.0 significantly influences procurement by mandating features such as IIoT connectivity, AI-driven predictive maintenance, and electronic pattern generation (EGB systems). Buyers prioritize digital integration to optimize Overall Equipment Effectiveness (OEE) and achieve high automation levels.

Which geographical region is the primary driver of market growth and volume demand?

Asia Pacific (APAC), led by countries like China and India, is the primary driver of market volume and consumption. The region benefits from lower operating costs, vast production capacity, and strategic government backing for textile sector expansion and modernization programs.

What are the primary restraints affecting investment in warp knitting machinery?

The main restraints are the substantial initial capital investment required for high-tech, electronically controlled machines, which poses a significant barrier to entry, and the market’s sensitivity to global economic downturns and fluctuations in yarn commodity prices.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager