Waste Oil Recycling Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431782 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Waste Oil Recycling Market Size

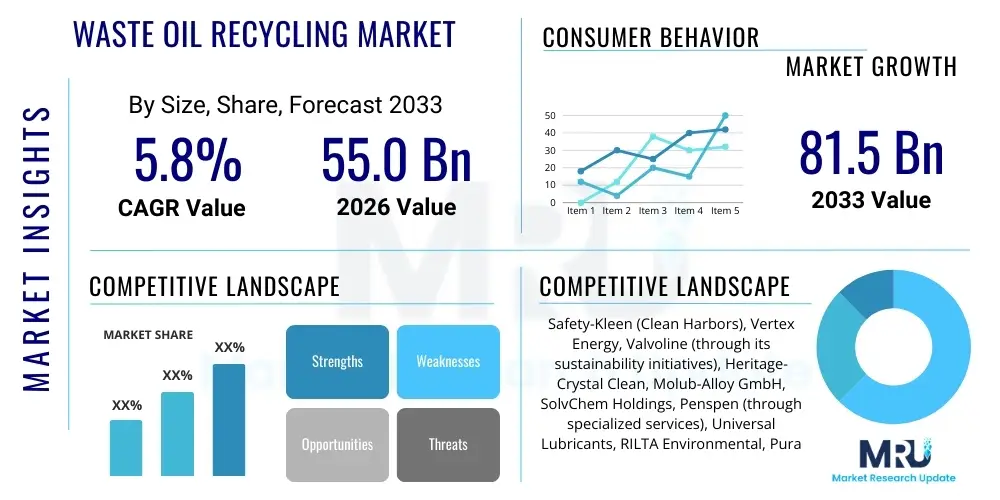

The Waste Oil Recycling Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $55.0 Billion in 2026 and is projected to reach $81.5 Billion by the end of the forecast period in 2033. This robust expansion is fundamentally driven by escalating environmental mandates and the increasing cost volatility associated with virgin base oils, compelling industries globally to seek sustainable and cost-effective alternatives. The mature regulatory environment in developed economies, coupled with rapidly adopting circular economy principles in emerging markets, significantly underpins this forecasted growth trajectory, making waste oil recycling an indispensable component of industrial sustainability strategies.

The valuation reflects not only the volume of used lubricant oil being collected and processed but also the premium associated with Group II and Group III base oils derived from advanced re-refining processes. Technological advancements, particularly in vacuum distillation and hydrotreating, have elevated the quality of recycled products, allowing them to compete directly with products derived from crude oil. Furthermore, governmental incentives, such as tax credits and mandated procurement of recycled content, are amplifying the economic viability of new and existing recycling facilities, attracting substantial private investment and fostering capacity expansion across key geographical regions, including North America and Asia Pacific.

Market size calculation incorporates revenue generated from various end-products, including re-refined base oils, asphalt extenders, and process fuels, segmented by the source of waste oil (automotive, industrial, marine). The consistent global production of waste lubricants, estimated in the tens of millions of metric tons annually, provides a stable feedstock supply, ensuring long-term market sustainability. Infrastructure development for efficient collection and transportation remains a critical factor influencing the overall achievable market size, especially in highly fragmented industrial sectors where centralized recycling hubs offer enhanced economies of scale and operational efficiencies.

Waste Oil Recycling Market introduction

The Waste Oil Recycling Market encompasses the collection, processing, and reuse of used lubricating oils, including engine oils, hydraulic fluids, transmission oils, and industrial process oils, which have degraded during service. This market addresses a significant environmental challenge by preventing the improper disposal of hazardous petroleum derivatives, which otherwise contaminate soil and water systems. The primary product generated through advanced recycling techniques is high-quality re-refined base oil (RRBO), often classified as API Group II or Group III, suitable for blending into new lubricants. The process transforms a waste stream into a valuable resource, aligning perfectly with global circular economy goals and resource efficiency mandates.

Major applications of recycled waste oil products span several sectors. The most high-value application is the production of new lubricating oils for automotive and industrial machinery, where RRBO offers performance characteristics comparable to virgin base oils, particularly when enhanced through hydrofinishing technologies. Other significant applications include using processed waste oil as fuel for industrial boilers, kilns, and power generation (subject to stringent pollutant standards), or as feedstocks in asphalt production. The inherent benefit of recycling lies in its significantly lower carbon footprint and reduced energy requirement compared to refining crude oil, making it an environmentally and economically advantageous practice.

The market is predominantly driven by stringent governmental regulations governing waste disposal and promoting sustainable resource management, particularly in the OECD nations. The rising awareness regarding environmental protection, coupled with increasing crude oil prices that make base oil production expensive, further catalyzes market growth. Furthermore, the development and deployment of advanced re-refining technologies, such as thin-film evaporation and catalytic hydrotreating, are crucial driving factors, as they improve the yield and purity of the final product, overcoming historical limitations related to recycled oil quality and consistency. These technical capabilities ensure that recycled products meet the demanding specifications of modern engine technologies.

Waste Oil Recycling Market Executive Summary

The Waste Oil Recycling Market is poised for substantial growth, driven by fundamental shifts in business models toward resource circularity and robust regulatory enforcement across major economies. Current business trends indicate a significant consolidation among collectors and re-refiners, aiming to establish larger, more integrated facilities capable of handling diverse waste oil streams efficiently and achieving higher quality output standards. Investment in advanced pretreatment processes, crucial for removing contaminants like water, solvents, and heavy metals before the main refining step, is a key strategic priority for leading market participants, minimizing operational bottlenecks and improving final product yield and purity. Strategic partnerships between base oil suppliers and waste oil collectors are becoming common, securing stable feedstock supply chains and integrating recycled products seamlessly into the mainstream lubricant market.

Regionally, Asia Pacific (APAC) is projected to exhibit the fastest growth rate, fueled by rapid industrialization, burgeoning vehicle populations, and the recent implementation of stricter environmental controls in key countries like China and India. North America and Europe, while representing mature markets, maintain high market shares due to well-established regulatory frameworks, advanced collection infrastructure, and high adoption rates of re-refined base oils, supported by consumer and industrial preference for sustainable products. Segment trends emphasize the dominance of the automotive sector as the largest source of waste oil, but the industrial oils segment (e.g., transformer oils, metalworking fluids) is showing increasing potential, driven by regulatory pressure to extend the lifecycle of specialized industrial lubricants. Group II and Group III base oil production via hydrotreating dominates the technology segment, reflecting the market’s pivot towards high-specification end products.

In summary, the market outlook is overwhelmingly positive, characterized by technological advancement, favorable macroeconomic conditions centered on sustainability, and a supportive regulatory environment. Key challenges include overcoming the capital-intensive nature of re-refining infrastructure and addressing the variability in waste oil feedstock quality, which necessitates sophisticated analytical and blending capabilities. Market leaders are focusing on optimizing logistics and improving collection ratios, particularly from smaller, dispersed sources, to maximize the economic and environmental benefits derived from this essential recycling industry. The push for higher base oil purity mandates continuous investment in hydroprocessing technology to ensure compliance with demanding lubricant specifications.

AI Impact Analysis on Waste Oil Recycling Market

Common user questions regarding AI's impact on the Waste Oil Recycling Market primarily revolve around optimizing logistics, predicting feedstock quality, enhancing process efficiency, and ensuring regulatory compliance. Users seek to understand how AI-driven predictive maintenance can reduce downtime in capital-intensive re-refining plants and how machine learning algorithms can analyze complex chemical signatures in incoming waste oil to optimize blending and processing recipes instantly. There is significant interest in AI's role in improving the traceability and accountability of collected oil volumes, addressing common concerns about "ghost leakage" and illegal disposal, and generating automated reports necessary for stringent environmental audits. The key themes summarized from user inquiries indicate high expectations for AI to automate quality control, reduce operating costs, and enhance the overall sustainability metrics of the recycling value chain.

AI technologies, including computer vision, predictive analytics, and deep learning, are strategically being applied across the waste oil recycling lifecycle. In the collection phase, AI optimizes routing and scheduling for collection trucks, drastically reducing fuel consumption and operational expenditure while improving pickup density in urban and industrial clusters. At the processing plant, AI models analyze real-time sensor data from distillation columns, fractionation units, and hydrotreating reactors, predicting optimal temperature and pressure settings to maximize yield of high-value Group II base oil while minimizing energy consumption and preventing equipment fouling. Furthermore, the application of sophisticated pattern recognition allows recyclers to identify and isolate specific contaminants (e.g., PCBs, heavy solvents) more quickly and accurately than traditional laboratory testing, accelerating the pre-treatment phase.

The implementation of AI also extends into market forecasting and supply chain risk management. Machine learning algorithms process external factors such as crude oil price volatility, regulatory changes, and regional industrial output statistics to provide highly accurate forecasts for re-refined base oil pricing and feedstock availability. This predictive capability enables refiners to optimize inventory management, hedge against commodity price risks, and strategically plan capital expenditure for facility expansion. The integration of robust AI-powered monitoring systems is fundamental to achieving high operational uptime, which is critical given the high fixed costs associated with advanced re-refining facilities, thus creating a tangible competitive advantage for early adopters.

- AI-driven optimization of waste oil collection routes, reducing transport costs and carbon emissions.

- Machine learning algorithms used for real-time feedstock analysis and quality prediction, optimizing blending ratios prior to distillation.

- Predictive maintenance implemented on distillation units and hydrotreaters to minimize costly unscheduled downtime.

- Automated compliance monitoring and reporting, ensuring adherence to strict environmental discharge and product quality standards (e.g., sulfur content, flash point).

- Enhanced process control through deep learning, maximizing Group II/III base oil yield from complex feedstocks.

DRO & Impact Forces Of Waste Oil Recycling Market

The dynamics of the Waste Oil Recycling Market are defined by a complex interplay of stringent environmental regulations (Drivers), the capital intensity and heterogeneity of feedstock (Restraints), and the sustained global push toward circular economies (Opportunities). The primary driving force is the global mandate for sustainable waste management, encapsulated by legislation forcing the safe collection and processing of hazardous waste oils, coupled with mandates or incentives favoring the use of re-refined base oils (RRBOs) in new lubricant formulations. The restraining forces include the high initial investment required for establishing advanced re-refining facilities (e.g., hydrotreating and vacuum distillation plants), which limits participation to large, capitalized entities, and the inherent variability in collected waste oil quality, necessitating expensive and complex pre-treatment processes before refining can commence.

Key opportunities within the market are centered around technological innovation and geographical expansion. Advancements in catalytic processes and membrane separation technologies offer pathways to produce ultra-pure Group III base oils from waste streams, opening up lucrative premium lubricant markets that were previously inaccessible to recycled products. Geographically, opportunities are abundant in emerging economies, particularly in Southeast Asia and Latin America, where current recycling infrastructure is rudimentary, and rapid motorization generates massive quantities of untapped waste oil feedstock. The development of modular, decentralized processing units also presents an opportunity to capture waste oil in regions where centralized collection logistics are currently prohibitively expensive or inefficient. These opportunities, if strategically leveraged, can significantly accelerate market growth beyond current projections.

The impact forces exert considerable pressure on market participants, forcing them to adopt higher operational and environmental standards. Regulatory pressure acts as a consistent force, driving technology adoption and market consolidation, ensuring only those capable of meeting stringent quality and environmental controls remain viable. Economic forces, driven by the fluctuating price differential between virgin crude base oils and RRBOs, heavily influence the profitability and competitive positioning of recycled products. Societal forces, particularly increasing corporate and consumer preference for sustainably sourced materials, amplify the demand pull for RRBOs, giving companies utilizing recycled content a crucial advantage in their marketing and corporate social responsibility reporting. These forces collectively dictate the strategic direction and competitive intensity within the global waste oil recycling sector.

Segmentation Analysis

The Waste Oil Recycling Market is comprehensively segmented based on the Technology utilized for processing, the Application of the recycled product, the Source of the waste oil, and the Type of Base Oil produced. Technology segmentation, including simple acid/clay treatment, thin-film evaporation, and advanced hydrotreating, determines the purity and market value of the end product, with hydrotreating dominating due to its ability to yield high-quality Group II and Group III base oils. Application analysis focuses on the end use of the processed oil, primarily encompassing automotive lubricants, industrial lubricants, and marine lubricants, alongside process fuels and asphalt production. Source segmentation differentiates between automotive engine oils (the largest volume contributor) and various industrial oils such as hydraulic, gear, and transformer oils, which often require specialized pre-treatment due to different contamination profiles.

The segmentation by base oil type is crucial as it reflects the quality and market premium achieved. Recycled oils are classified using the API system, ranging from Group I (conventional solvent-refined) to Group III (hydrocracked synthetic equivalents). The global trend shows a significant shift away from Group I derived from basic recycling processes towards Group II and Group III base oils, which meet the high-performance requirements of modern, complex internal combustion engines. This transition necessitates continuous investment in advanced technology like catalytic processes and specialized solvent extraction techniques, thereby shaping the competitive landscape and strategic direction of major re-refiners. Understanding these granular segment dynamics is essential for market players to tailor their investment strategies and optimize their product portfolios for maximum profitability.

Geographic segmentation further divides the market into major regions—North America, Europe, Asia Pacific, Latin America, and Middle East & Africa—reflecting regional differences in regulatory maturity, industrial activity, and infrastructure development. For instance, European markets are defined by strict environmental directives favoring circularity, while APAC markets are defined by high volume potential and increasing regulatory adoption. This multi-layered segmentation allows for precise market sizing, competitive analysis, and identification of high-growth niche opportunities within the complex global recycling landscape, ensuring market strategies are regionally and technologically appropriate for sustained growth.

- Technology:

- Acid/Clay Treatment (Declining)

- Thin-Film Evaporation

- Vacuum Distillation/Fractionation

- Catalytic Hydrotreating/Hydrofinishing (Leading Segment)

- Application:

- Automotive Lubricants

- Industrial Lubricants (Hydraulic, Gear, Transformer Oil)

- Marine Lubricants

- Process Fuels/Burner Fuel

- Asphalt Extenders

- Source:

- Automotive Waste Oil (Used Engine Oil, Transmission Fluid)

- Industrial Waste Oil (Metalworking Fluids, Hydraulic Oil, Sludges)

- Base Oil Type:

- Group I

- Group II

- Group III

Value Chain Analysis For Waste Oil Recycling Market

The Waste Oil Recycling value chain commences with the upstream analysis involving the generation and initial collection of used oil. Waste oil generators include garages, industrial plants, marine vessels, and large commercial fleets. The initial collection phase is critical and fragmented, relying on a dense network of certified collectors who must adhere to hazardous waste handling regulations. Efficiency at this stage is heavily dependent on logistical optimization and strong relationships between collectors and source generators. Upstream activities also involve preliminary testing to identify highly contaminated batches (e.g., those containing PCBs or excessive water) which require specialized pre-treatment, influencing the economic viability of subsequent refining steps.

Midstream activities constitute the core processing stages: pre-treatment, re-refining, and base oil finishing. Pre-treatment removes water, solids, and light solvents, typically through settling, filtration, and dehydration. The re-refining process is generally conducted using advanced technologies like thin-film evaporation coupled with vacuum distillation to separate lubricating oil fractions from asphaltic residue. The highest value addition occurs during downstream finishing processes, primarily hydrotreating (catalytic hydrogenation), which removes remaining sulfur, nitrogen, and unsaturated compounds, thereby improving color, oxidation stability, and overall quality to meet Group II/III specifications. This technological investment dictates the company's competitive position and ability to target premium end-markets.

Downstream analysis focuses on the distribution channel and end-user marketing. Re-refined base oils are primarily sold directly to lubricant blenders and additive manufacturers who formulate them into finished lubricant products. Direct sales offer greater control over pricing and specifications. Indirect distribution involves selling RRBOs through large chemical distributors or commodity trading houses, particularly for export markets. The acceptance and integration of RRBOs depend significantly on rigorous quality assurance and the establishment of long-term supply agreements with major lubricant companies. Strong branding and transparency regarding the environmental benefits of recycled products are essential for gaining market acceptance, often supported by regulatory incentives that mandate or encourage recycled content usage.

Waste Oil Recycling Market Potential Customers

The primary potential customers and end-users of products derived from the Waste Oil Recycling Market are large, globally operating lubricant blenders and oil marketers who require high-quality base oils as their primary raw material. These customers include major international oil companies (IOCs) and independent lubricant manufacturers who are increasingly integrating re-refined base oils (RRBOs) into their product portfolios to meet corporate sustainability goals and adhere to evolving environmental procurement mandates. The demand from this segment is driven by the need for consistent supply, high technical specifications (Group II/III purity), and cost competitiveness relative to virgin base oils, making long-term supply contracts critical for both the refiner and the blender.

A secondary, yet significant, customer base comprises industrial sectors requiring fuel substitutes or low-grade oils. This includes cement kiln operators, asphalt producers, utility companies utilizing industrial boilers, and certain maritime sectors where processed waste oil can be utilized as bunker fuel, provided it meets strict sulfur and ash content regulations. While these applications yield lower margins compared to high-purity base oil sales, they serve as crucial outlets for heavier fractions and residues generated during the recycling process, optimizing overall operational efficiency and minimizing disposal costs for the recycler. The preference of these customers is highly price-sensitive, balancing energy content against required emissions compliance.

Additionally, governments and public sector organizations are emerging as vital potential customers, driven by sustainable public procurement policies. Many municipalities and defense departments are mandated to preferentially purchase lubricants containing a minimum percentage of recycled content, particularly for fleet maintenance and public works machinery. This institutional demand segment provides a stable, long-term market for RRBO producers, reinforcing the market stability and supporting investment in new capacity. Successful engagement with this customer group requires adherence to rigorous tendering processes and demonstrably high ethical and environmental standards throughout the supply chain.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $55.0 Billion |

| Market Forecast in 2033 | $81.5 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Safety-Kleen (Clean Harbors), Vertex Energy, Valvoline (through its sustainability initiatives), Heritage-Crystal Clean, Molub-Alloy GmbH, SolvChem Holdings, Penspen (through specialized services), Universal Lubricants, RILTA Environmental, Puraglobe, Eco Lube Recovery, H&R Group, Veolia Environnement, Neste Corporation, Recyc Quebec, TFC Recycling, Petro-Canada Lubricants, AVISTA OIL AG, Kleen-Flo, Enva Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Waste Oil Recycling Market Key Technology Landscape

The technology landscape of the Waste Oil Recycling Market is dominated by sophisticated re-refining processes designed to maximize the yield and purity of base oils, enabling them to compete directly with virgin products. The shift away from rudimentary acid/clay treatment, which generated substantial hazardous waste sludge, has led to the widespread adoption of modern thermal and chemical processes. Key among these are Thin-Film Evaporation and Vacuum Distillation, which serve as the primary separation techniques. Thin-film evaporators efficiently remove lighter contaminants and separate the lubricating oil fraction from heavy asphaltic residues at lower temperatures under vacuum, thereby minimizing thermal degradation and maximizing the recovery rate of valuable base oil fractions suitable for further processing.

The most advanced and commercially significant technology is Catalytic Hydrotreating (or Hydrofinishing). Following initial distillation, the intermediate base oil stock is treated with hydrogen gas under high pressure and temperature in the presence of specialized catalysts. This process achieves deep saturation, removing residual sulfur, nitrogen, oxygen, and chlorine compounds, and improving the color and thermal stability of the oil. Hydrotreating is indispensable for producing API Group II and Group III base oils, which are necessary for modern, high-performance lubricants. Investment in hydrotreating capacity is the leading technological trend, directly impacting a company's ability to serve the high-specification automotive lubricant market, thereby dictating competitive advantage and profitability in mature recycling economies.

Other crucial technologies include advanced pre-treatment methods such as solvent extraction (e.g., using propane or N-methyl-2-pyrrolidone) for effective de-asphalting and contaminant removal prior to distillation, and membrane filtration systems. Membrane technology, while still niche, is gaining traction for polishing steps and removing trace particulates and water, offering lower energy consumption compared to thermal methods. Overall, the technological evolution is characterized by an increasing focus on integrated systems that combine chemical pre-treatment, advanced thermal separation, and high-pressure catalytic finishing, ensuring compliance with increasingly stringent environmental discharge limits while achieving base oil products of exceptional, consistent quality.

Regional Highlights

- North America: This region holds a significant share of the global waste oil recycling market, primarily due to well-established collection infrastructures, mature regulatory mandates (like those enforced by the EPA), and a high concentration of sophisticated re-refining facilities, particularly in the United States and Canada. The region benefits from strong corporate emphasis on sustainability, driving demand for high-quality Group II RRBOs. Key players are heavily investing in capacity expansion and optimization of logistics networks to capture feedstock efficiently from a highly dispersed source base.

- Europe: Europe is characterized by the most stringent environmental legislation, notably the Waste Framework Directive, which mandates priority treatment for waste oil recycling over burning or disposal. This regulatory environment fosters strong market growth and high recycling rates. Germany, France, and the UK are leaders in utilizing advanced hydrotreating technologies. The focus is increasingly on the circularity of resources, promoting the use of RRBOs in key industrial and automotive applications through legislative incentives and carbon taxation mechanisms.

- Asia Pacific (APAC): APAC is the fastest-growing market, propelled by rapid industrialization, burgeoning vehicle sales, and recent stringent environmental regulations adopted by countries like China, India, and Japan. While collection infrastructure is still developing in many parts of Southeast Asia, the sheer volume of waste oil generated presents immense untapped potential. Government initiatives promoting domestic recycling capacity and foreign direct investment in advanced re-refining technology are critical growth accelerators in this region.

- Latin America: This region presents a market with significant potential but varying levels of infrastructure maturity. Brazil and Mexico are leading the efforts, establishing formal collection systems and attracting international investment in basic processing plants. Regulatory enforcement is increasing, shifting practices away from informal disposal methods toward structured recycling, offering medium to long-term growth opportunities for established technology providers.

- Middle East and Africa (MEA): Growth in MEA is concentrated in industrialized zones, particularly the GCC countries, which possess established refining capabilities and are beginning to integrate waste oil streams into their energy and refining complexes. The market growth here is strongly tied to national energy transition strategies and investments aimed at reducing dependence on imported base oils through domestic recycling capabilities, focusing initially on burner fuel and asphalt applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Waste Oil Recycling Market.- Safety-Kleen (Clean Harbors)

- Vertex Energy

- AVISTA OIL AG

- Heritage-Crystal Clean

- Puraglobe

- Molub-Alloy GmbH

- Universal Lubricants

- Veolia Environnement

- Neste Corporation

- H&R Group

- RILTA Environmental

- Eco Lube Recovery

- TFC Recycling

- Valvoline

- Petro-Canada Lubricants

- Kleen-Flo

- SolvChem Holdings

- Penspen

- Recyc Quebec

- Enva Group

Frequently Asked Questions

Analyze common user questions about the Waste Oil Recycling market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary technologies used to recycle waste oil into high-quality base oil?

The primary advanced technologies are Vacuum Distillation, which separates oil fractions based on boiling points under low pressure, and Catalytic Hydrotreating, which chemically removes contaminants and impurities to produce high-purity Group II and Group III base oils suitable for modern lubricant manufacturing.

How does the quality of re-refined base oil compare to virgin base oil?

Modern re-refining processes, particularly those involving hydrotreating, produce base oils (RRBOs) that meet or exceed the performance specifications of virgin base oils, often achieving Group II and Group III classification, which are critical for high-performance automotive and industrial lubricants.

What is the main driver behind the growth of the Waste Oil Recycling Market?

The central driver is stringent governmental and environmental regulations, especially in developed economies, which mandate the responsible management of hazardous waste oil and actively promote the use of sustainable, recycled content to support the circular economy.

Which geographical region is expected to show the fastest growth in waste oil recycling?

The Asia Pacific (APAC) region is forecasted to exhibit the fastest growth, driven by rapid industrial expansion, escalating vehicle populations, and the recent introduction of stricter waste management and environmental protection laws in major economies like China and India.

What are the significant hurdles facing new entrants in the waste oil recycling industry?

New entrants face significant hurdles primarily related to the high initial capital investment required for establishing advanced re-refining facilities (hydrotreating plants) and securing a reliable, consistent supply of feedstock that meets acceptable quality standards, amidst a highly fragmented collection market.

The exhaustive analysis contained within this report underscores the robust future of the Waste Oil Recycling Market, positioning it not merely as a waste management necessity but as a critical sector for sustainable resource supply. The ongoing technological convergence towards high-purity Group II and Group III base oil production solidifies the industry's role in the global lubricant supply chain. Furthermore, the persistent pressure from environmental agencies and corporate sustainability mandates ensures that investment in efficient collection and advanced processing infrastructure will remain a strategic imperative for market leaders. Future growth will hinge on optimizing complex logistics across disparate industrial and automotive sources, necessitating advanced AI and digital tools to maintain economic viability against fluctuating crude oil prices. The shift in competitive dynamics is observable as traditional chemical companies and integrated oil majors increasingly acquire or partner with specialized re-refiners to internalize the sustainability benefits and secure a diversified base oil supply. This market’s success is a direct indicator of the global commitment to resource circularity and industrial decarbonization efforts.

In conclusion, the Waste Oil Recycling Market is fundamentally resilient, supported by non-discretionary feedstock generation and high-value end products. The high barriers to entry, driven by regulatory compliance and required capital expenditure, tend to favor large, established players with the capacity to manage heterogeneous waste streams and deploy cutting-edge hydroprocessing technology. Strategic attention must be given to developing effective collection infrastructure in emerging markets, as these regions represent the highest volume potential for feedstock. Overall profitability will be increasingly correlated with efficiency gains realized through automation and predictive analytics, ensuring the industry continues its evolution from a niche waste service into a core component of sustainable base oil manufacturing globally. The harmonization of international standards for RRBO quality is essential to unlocking further cross-border trade and investment, enabling the full realization of the projected market growth through 2033.

The sustained emphasis on reducing industrial waste and minimizing reliance on fossil fuels provides a powerful tailwind for market development. Companies that demonstrate transparent, verifiable environmental performance metrics and possess integrated collection-to-refinery operations are best positioned to capture market share. Regulatory risk, although a driver, necessitates continuous vigilance regarding evolving contamination standards and product specifications, demanding flexible operational strategies. The strategic significance of recycled lubricants in meeting the performance demands of next-generation electric and hybrid vehicle transmissions, while specialized, further diversifies the market's long-term application base. This market represents a compelling investment thesis anchored in environmental stewardship and economic efficiency.

The Waste Oil Recycling Market's resilience is further cemented by the fact that lubricating oils, irrespective of electrification trends in transportation, remain indispensable for industrial machinery, hydraulics, and power generation turbines. While the profile of automotive waste oil might evolve, the steady demand for industrial lubricants ensures a persistent feedstock source. Market participants are increasingly exploring chemical recycling methods alongside conventional re-refining to handle heavily contaminated or synthetic oil waste streams, further broadening the scope of what can be sustainably processed. This diversified technological approach mitigates risks associated with feedstock variability and ensures the continuous advancement of the industry's ability to maximize resource recovery.

The high capital expenditure associated with building and operating advanced re-refining facilities often necessitates strategic governmental support, either through direct subsidies, favorable loan terms, or mechanisms that stabilize the price differential between virgin and recycled base oils. Such support is crucial for accelerating infrastructure development, especially in regions struggling to establish efficient recycling economies. Furthermore, the skilled labor required to manage complex hydrotreating and quality control processes represents a key operational challenge. Companies must invest heavily in specialized training and automated process control systems to maintain consistent, high-specification output necessary to meet global lubricant standards, ensuring the credibility and reliability of RRBOs in the sophisticated end-user markets.

Finally, the growing scrutiny from consumers and institutional investors regarding ESG (Environmental, Social, and Governance) performance acts as an external accelerator for the market. Companies demonstrating superior recycling rates and lower emissions intensity in their operations attract preferential capital and gain reputational advantages. This focus on verifiable sustainability metrics encourages continuous improvement in processing efficiency and overall supply chain transparency, reinforcing the structural growth trajectory forecasted for the Waste Oil Recycling Market through 2033. The long-term success of the industry is therefore inextricably linked to its ability to deliver superior environmental outcomes alongside commercially viable, high-quality products.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager