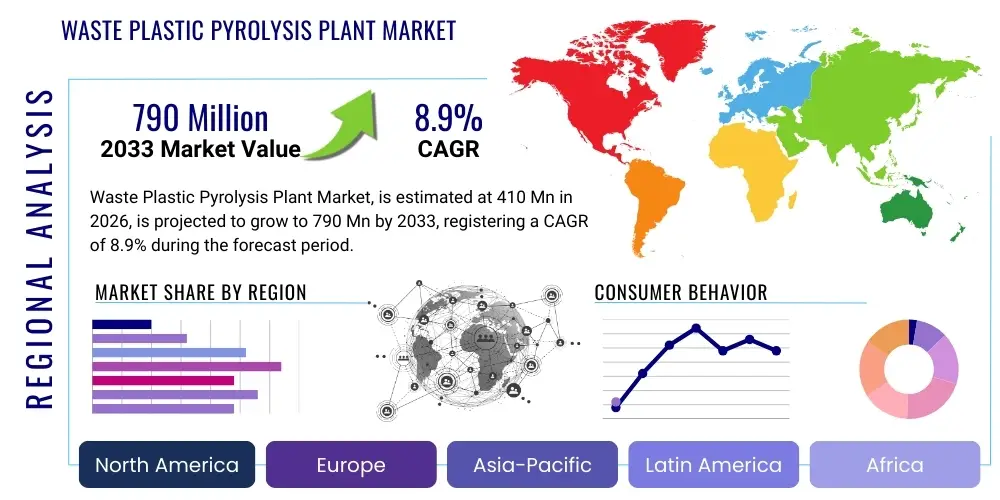

Waste Plastic Pyrolysis Plant Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439698 | Date : Jan, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Waste Plastic Pyrolysis Plant Market Size

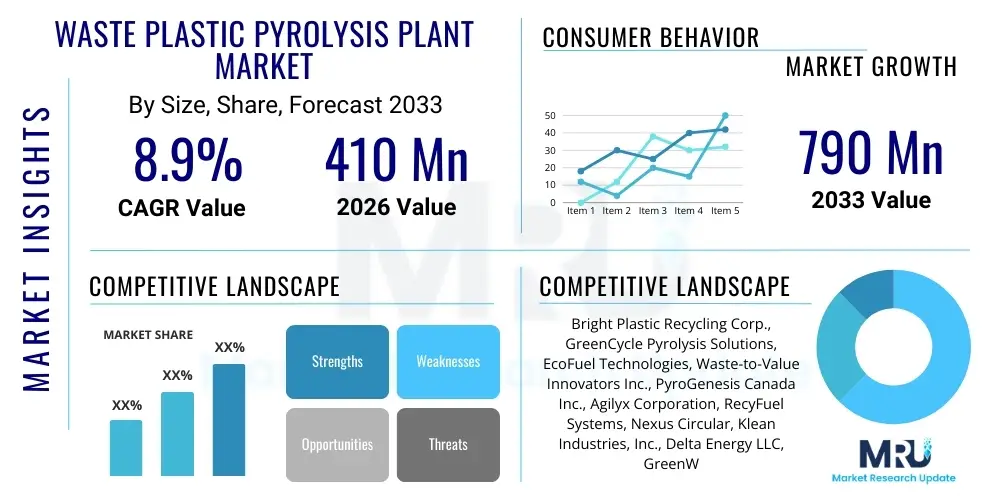

The Waste Plastic Pyrolysis Plant Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.9% between 2026 and 2033. The market is estimated at USD 410 Million in 2026 and is projected to reach USD 790 Million by the end of the forecast period in 2033.

Waste Plastic Pyrolysis Plant Market introduction

The Waste Plastic Pyrolysis Plant Market encompasses the development, manufacturing, and deployment of industrial systems designed to convert plastic waste into valuable resources through a thermochemical process called pyrolysis. This technology addresses the escalating global plastic waste crisis by breaking down complex polymer chains in an oxygen-free environment, yielding products such as pyrolysis oil (often used as fuel or chemical feedstock), syngas, carbon black, and wax. Major applications include energy generation, chemical production, and the manufacturing of new plastic materials, fostering a circular economy model. The primary benefits include waste volume reduction, resource recovery, and a significant decrease in landfill dependency and associated environmental pollution. Driving factors for market expansion include stringent environmental regulations, growing demand for sustainable waste management solutions, increasing awareness about plastic pollution, and the economic viability of converting waste into valuable commodities, especially in regions with high plastic consumption and inadequate recycling infrastructure. The market also benefits from technological advancements that enhance efficiency and reduce operational costs.

Waste Plastic Pyrolysis Plant Market Executive Summary

The Waste Plastic Pyrolysis Plant Market is experiencing robust growth, driven by an urgent need for sustainable plastic waste management and the push towards a circular economy. Business trends highlight increasing investments in research and development to enhance plant efficiency, optimize product yields, and minimize environmental footprints. There's a notable shift towards modular and scalable pyrolysis solutions, enabling deployment in diverse geographic and operational contexts, alongside growing collaborations between technology providers, waste management companies, and end-product consumers. Regional trends indicate significant market expansion in Asia Pacific, particularly in countries like China and India, owing to their vast plastic waste generation and evolving environmental policies, while Europe and North America demonstrate growth through regulatory support, technological innovation, and a strong emphasis on resource recovery and decarbonization efforts. Segment trends reveal a strong demand for continuous pyrolysis technology due to its higher throughput and automation capabilities, with pyrolysis oil being the most sought-after end-product, increasingly utilized as a fuel alternative or feedstock for virgin plastic production, thus underscoring the market's role in industrial decarbonization and resource conservation.

AI Impact Analysis on Waste Plastic Pyrolysis Plant Market

User queries regarding the impact of AI on the Waste Plastic Pyrolysis Plant Market frequently center on how artificial intelligence can optimize plant operations, improve efficiency, enhance product quality, and contribute to predictive maintenance. Common concerns include the complexity of integrating AI, data security, and the initial investment required, alongside expectations for AI to address feedstock variability, automate complex decision-making processes, and provide real-time performance analytics. Users anticipate AI playing a transformative role in making pyrolysis plants more sustainable, cost-effective, and resilient, ultimately accelerating the shift towards a more circular economy by improving the conversion of plastic waste into valuable resources.

- AI-driven optimization of reaction parameters (temperature, pressure, catalyst dosage) for maximum yield and quality of pyrolysis products.

- Predictive maintenance for plant machinery, reducing downtime and operational costs by forecasting equipment failures.

- Real-time feedstock analysis and sorting using machine learning to handle heterogeneous plastic waste streams efficiently.

- Automated process control systems enhancing operational stability and safety, minimizing human error.

- Supply chain optimization for plastic waste collection and end-product distribution, improving logistics and reducing carbon footprint.

- Enhanced data analytics for performance monitoring, identifying trends, and facilitating continuous improvement in plant operations.

DRO & Impact Forces Of Waste Plastic Pyrolysis Plant Market

The Waste Plastic Pyrolysis Plant Market is significantly shaped by a confluence of drivers, restraints, opportunities, and broader impact forces. Key drivers include the escalating global plastic waste crisis, which necessitates innovative disposal and recycling methods, coupled with increasing governmental regulations and policies promoting circular economy principles and sustainable waste management practices. Furthermore, the rising demand for alternative fuels and chemical feedstocks, driven by energy security concerns and decarbonization goals, fuels market growth. However, significant restraints impede faster adoption, primarily the high initial capital investment required for plant setup, the technological complexities associated with processing diverse plastic types, and potential environmental concerns regarding emissions and by-product management. Opportunities for market expansion are abundant, particularly in developing advanced pyrolysis technologies, exploring decentralized plant models, and valorizing all pyrolysis byproducts (oil, syngas, carbon black) into higher-value applications. The market is also influenced by broader impact forces such as fluctuating crude oil prices, which affect the competitiveness of pyrolysis oil, evolving global environmental treaties, and continuous innovation in material science and waste-to-energy technologies, all of which collectively determine the market's trajectory and potential for sustainable growth.

Segmentation Analysis

The Waste Plastic Pyrolysis Plant Market is broadly segmented based on various factors, including the type of technology employed, the feedstock processed, the end-products generated, the capacity of the plant, and the primary application of the derived materials. This detailed segmentation allows for a comprehensive understanding of market dynamics, identifies specific niches, and helps stakeholders tailor their strategies to address distinct market demands and technological preferences. Each segment reflects unique operational characteristics, investment requirements, and market potential, contributing to the overall diversity and growth of the pyrolysis industry.

- Technology:

- Batch Pyrolysis

- Continuous Pyrolysis

- Catalytic Pyrolysis

- Non-Catalytic Pyrolysis

- Microwave-assisted Pyrolysis

- Feedstock Type:

- Polyethylene (PE)

- Polypropylene (PP)

- Polystyrene (PS)

- Polyethylene Terephthalate (PET)

- Mixed Plastic Waste

- PVC

- Other Plastics

- End-Product:

- Pyrolysis Oil (Fuel Oil)

- Carbon Black

- Syngas

- Wax

- Other Chemical Feedstocks

- Capacity:

- Small Scale (<10 TPD)

- Medium Scale (10-50 TPD)

- Large Scale (>50 TPD)

- Application:

- Fuel Production

- Chemical Feedstock

- Energy Generation

- Carbon Black Manufacturing

- Electricity Generation

- Heating Applications

Value Chain Analysis For Waste Plastic Pyrolysis Plant Market

The value chain for the Waste Plastic Pyrolysis Plant Market begins with the upstream activities involving the collection, sorting, and pre-processing of plastic waste, which includes municipal solid waste management entities, industrial plastic waste generators, and specialized waste collection companies. These entities play a crucial role in providing segregated and relatively clean feedstock essential for efficient pyrolysis. The core of the value chain involves the technology providers and plant manufacturers who design, build, and install the pyrolysis plants, incorporating various technologies from batch to continuous and catalytic systems. Downstream activities focus on the processing and distribution of the end-products, such as pyrolysis oil, carbon black, and syngas, to various industries including fuel blending companies, chemical manufacturers, and energy producers. Distribution channels can be direct, where plant operators sell directly to large industrial buyers, or indirect, involving intermediaries and trading companies that facilitate the sale of pyrolysis products to a broader market, ensuring efficient resource recovery and integration into industrial supply chains while optimizing the economic viability of the entire process.

Waste Plastic Pyrolysis Plant Market Potential Customers

Potential customers and end-users of the Waste Plastic Pyrolysis Plant Market span a diverse range of industries and governmental bodies, all seeking sustainable solutions for plastic waste management and alternative energy or chemical feedstocks. Municipal solid waste management agencies are key buyers, looking to reduce landfill volume and convert waste into valuable resources, aligning with urban sustainability goals. Industrial plastic waste generators, such as packaging companies, automotive manufacturers, and electronics producers, represent a significant customer segment aiming to manage their own waste streams and comply with extended producer responsibility (EPR) regulations. Furthermore, petrochemical companies and refineries are interested in pyrolysis oil as a supplementary feedstock to reduce reliance on virgin fossil resources and enhance their sustainability profiles. Power generation companies and industrial facilities seeking alternative fuel sources for boilers or energy production also constitute a crucial customer base. Additionally, manufacturers of carbon black for tires, plastics, and paints are direct purchasers of this pyrolysis byproduct, making them integral to the market's downstream segments. The growing emphasis on circular economy principles and decarbonization initiatives across various sectors continues to broaden the potential customer base for waste plastic pyrolysis solutions globally.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 410 Million |

| Market Forecast in 2033 | USD 790 Million |

| Growth Rate | 8.9% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces | >|

| Segments Covered | >|

| Key Companies Covered | Bright Plastic Recycling Corp., GreenCycle Pyrolysis Solutions, EcoFuel Technologies, Waste-to-Value Innovators Inc., PyroGenesis Canada Inc., Agilyx Corporation, RecyFuel Systems, Nexus Circular, Klean Industries, Inc., Delta Energy LLC, GreenWPC Pyrolysis Pvt. Ltd., Envipure Private Limited, Beston Group, ReOil AG, Plastic Energy, Pyrox GmbH, Radian Oil & Gas Ltd., Sino-Eco Pyrolysis Tech, EarthFirst Technologies, Biogen Systems |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Waste Plastic Pyrolysis Plant Market Key Technology Landscape

The Waste Plastic Pyrolysis Plant market is characterized by a dynamic and evolving technology landscape, primarily driven by the need for increased efficiency, higher product yields, and minimized environmental impact. Key technologies employed include batch pyrolysis, which processes plastic waste in discrete batches, suitable for smaller scale operations and varied feedstock. Continuous pyrolysis systems offer higher throughput and are ideal for large-scale industrial applications, providing consistent production. Catalytic pyrolysis utilizes various catalysts (e.g., zeolites, metal oxides) to lower reaction temperatures, enhance product selectivity, and improve the quality of pyrolysis oil, making it more suitable for direct use or as chemical feedstock. Non-catalytic pyrolysis relies solely on thermal decomposition, often at higher temperatures. Emerging technologies such as microwave-assisted pyrolysis offer rapid heating and improved energy efficiency, potentially leading to better control over reaction products. Further advancements include integrating gasification for syngas purification, advanced separation techniques for refined pyrolysis oil, and robust control systems to handle heterogeneous plastic waste streams. The development of modular and scalable plant designs, alongside innovative methods for managing carbon black and other solid residues, are also crucial aspects of the technology landscape, driving the market towards more robust and economically viable waste-to-resource solutions.

Regional Highlights

- North America: Driven by stringent environmental regulations, advanced waste management infrastructure, and a focus on circular economy initiatives, leading to increased adoption of pyrolysis technologies, particularly in the US and Canada.

- Europe: Supported by ambitious decarbonization targets, strong emphasis on resource recovery, and significant investments in innovative waste-to-energy solutions across countries like Germany, the UK, and the Netherlands.

- Asia Pacific (APAC): Represents the largest and fastest-growing market due to massive plastic waste generation, rapid industrialization, and evolving environmental policies in China, India, and Southeast Asian nations.

- Latin America: Characterized by a growing awareness of plastic pollution and developing waste management infrastructure, creating nascent but promising opportunities for pyrolysis plant deployment in countries such as Brazil and Mexico.

- Middle East and Africa (MEA): Emerging market with increasing industrial development and initiatives to address plastic waste, particularly in the Gulf Cooperation Council (GCC) countries focusing on diversifying energy sources and sustainable development.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Waste Plastic Pyrolysis Plant Market.- Bright Plastic Recycling Corp.

- GreenCycle Pyrolysis Solutions

- EcoFuel Technologies

- Waste-to-Value Innovators Inc.

- PyroGenesis Canada Inc.

- Agilyx Corporation

- RecyFuel Systems

- Nexus Circular

- Klean Industries, Inc.

- Delta Energy LLC

- GreenWPC Pyrolysis Pvt. Ltd.

- Envipure Private Limited

- Beston Group

- ReOil AG

- Plastic Energy

- Pyrox GmbH

- Radian Oil & Gas Ltd.

- Sino-Eco Pyrolysis Tech

- EarthFirst Technologies

- Biogen Systems

Frequently Asked Questions

Analyze common user questions about the Waste Plastic Pyrolysis Plant market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a Waste Plastic Pyrolysis Plant?

A Waste Plastic Pyrolysis Plant is an industrial facility that thermally breaks down plastic waste in an oxygen-free environment, converting it into valuable products like pyrolysis oil, syngas, and carbon black, thus diverting waste from landfills.

What are the main products obtained from plastic pyrolysis?

The primary products derived from plastic pyrolysis are pyrolysis oil (a substitute for fuel oil or chemical feedstock), syngas (a combustible gas), and carbon black (used in various industries).

Is plastic pyrolysis environmentally friendly?

Plastic pyrolysis offers significant environmental benefits by reducing plastic waste, lowering landfill dependence, and recovering valuable resources. Modern plants are designed with emission controls to minimize their ecological footprint.

What are the key drivers for the Waste Plastic Pyrolysis Plant Market?

Key drivers include the global plastic waste crisis, increasing governmental regulations promoting circular economy models, rising demand for alternative fuels, and the economic viability of converting waste into valuable commodities.

What is the typical initial investment for a pyrolysis plant?

Initial investment costs for a pyrolysis plant can vary significantly based on capacity, technology, and location, ranging from hundreds of thousands to several millions of US dollars, encompassing equipment, infrastructure, and operational setup.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager