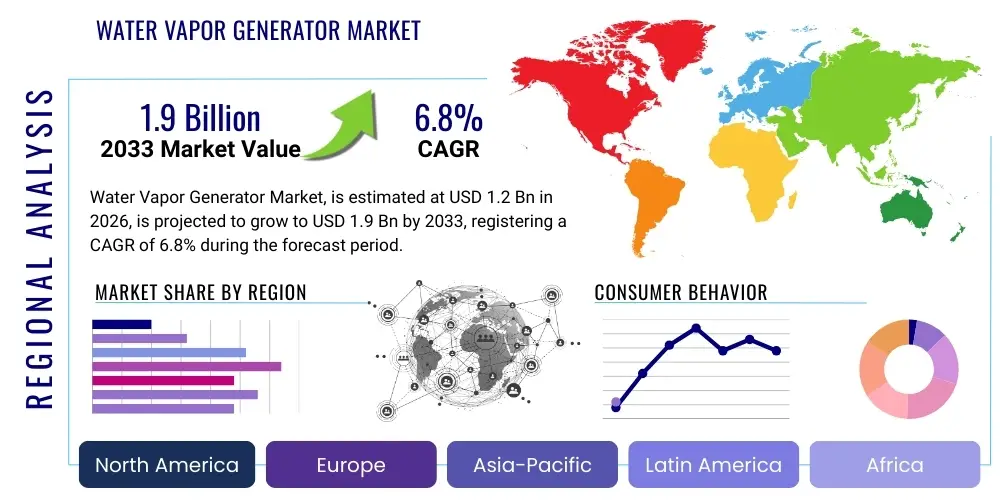

Water Vapor Generator Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436532 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Water Vapor Generator Market Size

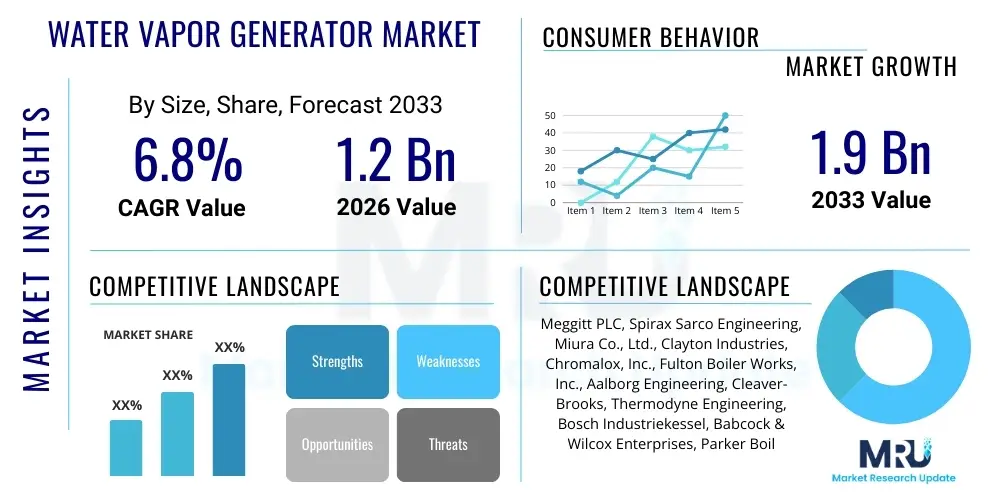

The Water Vapor Generator Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.2 Billion in 2026 and is projected to reach USD 1.9 Billion by the end of the forecast period in 2033.

Water Vapor Generator Market introduction

The Water Vapor Generator Market encompasses equipment designed to produce controlled, high-quality steam or water vapor for various industrial, commercial, and residential applications. These generators typically utilize electricity, natural gas, or other energy sources to rapidly heat water, converting it into pressurized or atmospheric steam. Key applications span sterilization in healthcare, humidification in HVAC systems, process heating in manufacturing, and recreational use in saunas and steam rooms. The product range includes electrode boilers, resistance heaters, and flash steam generators, differentiated primarily by their operational efficiency, vapor quality, and capacity.

The primary benefits driving market adoption include enhanced energy efficiency, precise temperature and humidity control, and improved sterilization capabilities crucial for critical environments like pharmaceuticals and biotechnology. Modern generators are increasingly compact, featuring advanced automation and safety mechanisms, reducing operational footprint and maintenance complexity. They are essential components in maintaining product quality, ensuring patient safety, and optimizing industrial processes that require consistent thermal or moisture conditions, thereby establishing their indispensable role across diverse end-user sectors.

Driving factors center around stringent hygiene standards in food and beverage and healthcare industries, coupled with the rising demand for sophisticated climate control systems in commercial buildings and data centers. Furthermore, the push towards sustainable and decentralized energy solutions favors modular and electric steam generation systems. Regulatory mandates concerning air quality and emissions also necessitate efficient, localized vapor generation solutions, propelling manufacturers to integrate smart controls and superior heat exchange technologies into their product offerings to meet global standards for operational excellence and environmental compliance.

Water Vapor Generator Market Executive Summary

The Water Vapor Generator Market is characterized by robust expansion, primarily fueled by the accelerating integration of automation in industrial sterilization and the escalating requirement for controlled humidity environments in large infrastructure projects. Business trends indicate a strong shift towards modular and electric-powered generators, minimizing carbon footprints and optimizing instantaneous steam supply. Key industry players are focusing on developing IoT-enabled units that allow for predictive maintenance, remote diagnostics, and energy consumption optimization, establishing connectivity as a major competitive differentiator in the market landscape. Strategic mergers and acquisitions are common as manufacturers seek to consolidate technological expertise and expand geographic reach, especially into emerging economies with rapid industrialization programs.

Regionally, Asia Pacific is anticipated to exhibit the fastest growth, driven by massive investments in the pharmaceutical manufacturing sector, expanding infrastructure for healthcare facilities, and burgeoning demand from the textile and chemical processing industries, particularly in China and India. North America and Europe maintain dominance in terms of technology adoption and standardization, benefiting from stringent regulatory frameworks governing food safety and medical device sterilization, which mandate high-purity steam. The maturity of the HVAC industry in these regions further stabilizes demand for highly efficient humidification vapor generators used in commercial office spaces and data centers.

Segment trends reveal a preference for electric water vapor generators due to their zero-emission operation at the point of use and ease of integration with renewable energy sources. Within the application segmentation, the healthcare sector remains the largest revenue contributor, consistently demanding high-pressure, sterilized vapor for autoclaves and cleanroom environments. However, the commercial sector, specifically hotels, fitness centers, and specialized manufacturing (e.g., semiconductor fabrication), is poised for substantial growth, driven by consumer demand for wellness amenities and the necessity for precise atmospheric control during sensitive production processes. Innovation is concentrated on reducing scaling and corrosion through advanced water treatment solutions integrated within the generator systems.

AI Impact Analysis on Water Vapor Generator Market

Users frequently inquire about how Artificial Intelligence (AI) and Machine Learning (ML) can enhance the efficiency and predictive capabilities of complex thermal systems like water vapor generators. Common concerns revolve around real-time fault detection, optimization of energy inputs based on fluctuating demand, and the feasibility of self-diagnosing maintenance requirements to maximize uptime. The overarching user expectation is that AI integration will transform reactive maintenance into predictive operational management, significantly cutting energy costs and prolonging equipment lifespan, especially in high-stakes environments such as critical manufacturing or hospital central utilities. Consequently, the summarized theme highlights AI's role in shifting the market focus from merely generating vapor to intelligently managing thermal energy systems for peak efficiency and reliability.

- AI-driven Predictive Maintenance: Algorithms analyze sensor data (temperature, pressure, water quality) to forecast potential component failures, minimizing unplanned downtime.

- Energy Optimization: Machine Learning models dynamically adjust boiler parameters (e.g., firing rate, blowdown cycles) based on operational schedules and external variables, reducing fuel or electricity consumption.

- Automated Fault Diagnostics: AI systems instantly identify anomalies and isolate the source of operational issues, accelerating troubleshooting and repair processes.

- Demand Forecasting: Predictive algorithms analyze historical usage patterns and facility load requirements to optimize steam generation capacity, preventing unnecessary idling or overshoot.

- Enhanced Water Quality Management: AI monitors scaling indicators and chemical injection needs in real-time, prolonging generator longevity and maintaining vapor purity.

- Digital Twin Simulation: Creation of virtual models allows operators to simulate various load conditions and test efficiency improvements before deploying physical changes.

DRO & Impact Forces Of Water Vapor Generator Market

The Water Vapor Generator Market is significantly influenced by a confluence of accelerating industrial growth, strict regulatory controls, and sustained technological innovation. Key drivers include the mandatory need for high-level sanitation in life sciences and food processing, coupled with urbanization driving demand for centralized HVAC and district heating systems. Restraints predominantly involve the substantial initial capital investment required for high-capacity, specialized generators, alongside the ongoing operational expense associated with energy consumption and meticulous water quality management necessary to prevent system degradation. Opportunities are emerging through the development of hybrid power generators and small, decentralized units suited for niche applications or integration with modular construction, while regulatory incentives for energy-efficient equipment further stimulate market penetration.

Impact forces acting on the market are multifaceted, led by increasing environmental scrutiny that pushes manufacturers toward electric and low-emission solutions. The competitive rivalry is high, characterized by continuous product development focusing on miniaturization, modularity, and enhanced control software. Supplier power is moderate, influenced by the specialized components required, such as corrosion-resistant alloys and high-efficiency heat exchangers. Buyer power remains significant, particularly in large industrial sectors, as purchasing decisions are heavily weighted by total cost of ownership (TCO), reliability, and adherence to specific industry certifications (e.g., ASME, PED). Technological shifts, specifically the integration of IoT and cloud services, act as a transformative force, reshaping customer expectations regarding monitoring and control.

Segmentation Analysis

The Water Vapor Generator Market is meticulously segmented based on product type, capacity, application, and end-user industry, enabling targeted marketing and tailored product development. The differentiation by product type, such as electrode and resistance heaters, reflects varying operational characteristics, energy sources, and purity levels required by different industries. Capacity segmentation addresses the scale of demand, ranging from compact units for residential or small commercial use to massive industrial boilers necessary for large-scale power generation or petrochemical processing. The application and end-user segments define the demand profile, spanning essential functions like sterilization in hospitals to critical temperature maintenance in semiconductor manufacturing, providing a clear map of market requirements.

- By Product Type:

- Electric Water Vapor Generators (Electrode, Resistance Heating)

- Fuel-Fired Water Vapor Generators (Natural Gas, Oil)

- Solar/Waste Heat Recovery Generators

- By Capacity:

- Low Capacity (Up to 50 kg/hr)

- Medium Capacity (50 kg/hr to 500 kg/hr)

- High Capacity (Above 500 kg/hr)

- By Application:

- Sterilization and Autoclaving

- Humidification and Climate Control (HVAC)

- Process Heating and Industrial Drying

- Wellness and Recreational (Saunas, Steam Rooms)

- Food and Beverage Processing

- By End-User Industry:

- Healthcare and Pharmaceuticals

- Commercial and Residential

- Food and Beverage

- Chemical and Petrochemical

- HVAC and Data Centers

- Manufacturing and Textiles

Value Chain Analysis For Water Vapor Generator Market

The value chain for the Water Vapor Generator Market begins with upstream activities involving the sourcing of high-quality raw materials, including specialized alloys (stainless steel, nickel) for heat exchangers and boiler vessels, and advanced control components (PLCs, sensors). Suppliers of these critical components hold moderate leverage due to the specialized nature of the materials necessary for high-pressure, corrosion-resistant operation. Research and development focused on optimizing thermal efficiency, reducing scale formation, and integrating smart controls are crucial value-adding activities at this stage. Effective material sourcing and component manufacturing directly influence the final product's durability and energy efficiency, positioning specialized component suppliers as key enablers within the overall ecosystem.

Midstream activities involve core manufacturing, assembly, and rigorous testing of the generators, including quality assurance checks for pressure vessels and electrical safety. Companies invest heavily in advanced manufacturing techniques, such as automated welding and precision machining, to ensure compliance with international safety standards (e.g., ASME Boiler and Pressure Vessel Code). Downstream activities primarily encompass distribution, installation, and after-sales service. The distribution channel is bifurcated into direct sales for large industrial clients (offering custom solutions and integration services) and indirect sales through specialized distributors and HVAC contractors for standardized commercial and residential units. Installation often requires specialized engineering expertise, particularly for complex systems requiring integration into facility management systems.

Post-sale services, including maintenance contracts, periodic safety inspections, and the supply of spare parts, represent a significant portion of long-term revenue and customer relationship management. The reliance on indirect distribution channels for smaller units means channel partners play a crucial role in market penetration and localized support. Direct channels, conversely, facilitate closer engagement with major end-users, allowing manufacturers to offer comprehensive energy audits and system optimization packages. This structure ensures that both high-volume standardized sales and high-value customized industrial projects are effectively addressed across the global market.

Water Vapor Generator Market Potential Customers

Potential customers for water vapor generators span a wide array of industries that require precise control over heat transfer, sanitation, or atmospheric conditions. The most critical end-users are concentrated in sectors where regulatory compliance and product quality are paramount, such as hospitals, pharmaceutical production facilities, and food processing plants, which require high-purity, validated steam for sterilization and cooking processes. Commercial entities, including large hotels, resorts, health clubs, and modern office complexes, form another significant customer base, primarily utilizing generators for humidification in HVAC systems to maintain optimal indoor air quality and comfort, and for recreational steam room applications.

Industrial manufacturing facilities, ranging from textiles and chemicals to specialized electronics and semiconductors, represent robust buyers. These industries require steam for processes such as curing, drying, distillation, and cleaning, demanding high-capacity, robust, and reliable generators capable of continuous operation under varying load conditions. Furthermore, utility companies and district heating providers are potential buyers for large-scale units used in energy generation or centralized heat distribution networks. The purchasing decision is often driven by criteria beyond initial cost, focusing heavily on operational longevity, energy efficiency certifications, and the availability of responsive, specialized maintenance services, confirming the technical expertise required for sales and service engagement.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.2 Billion |

| Market Forecast in 2033 | USD 1.9 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Meggitt PLC, Spirax Sarco Engineering, Miura Co., Ltd., Clayton Industries, Chromalox, Inc., Fulton Boiler Works, Inc., Aalborg Engineering, Cleaver-Brooks, Thermodyne Engineering, Bosch Industriekessel, Babcock & Wilcox Enterprises, Parker Boiler, Sussman Electric Boilers, Lattner Boiler Manufacturing, Piston Group, Columbia Boiler, Rentech Boiler Systems, Vapor Power International, Siemens Energy, Alfa Laval. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Water Vapor Generator Market Key Technology Landscape

The technological landscape of the Water Vapor Generator Market is rapidly evolving, driven by the imperative for enhanced energy efficiency and compliance with stringent environmental standards. A central technology involves advanced heat exchanger designs, utilizing finned tubes and optimized flow paths to maximize heat transfer rates and minimize flue gas temperatures, thereby boosting thermal efficiency significantly above conventional standards. Furthermore, the integration of advanced burner management systems (BMS) in fuel-fired units ensures precise air-to-fuel ratio control, reducing NOx and CO emissions, positioning modern generators as environmentally responsible heating solutions. Electric generators, especially electrode types, are benefiting from refined electrode materials and construction methods that reduce scaling and extend maintenance cycles, capitalizing on the shift toward electrified heating processes.

Digitalization forms the backbone of the next generation of water vapor generators. This includes the incorporation of sophisticated proportional-integral-derivative (PID) controllers and Programmable Logic Controllers (PLCs) for precise modulation of steam output corresponding to real-time load demands, preventing energy wastage associated with frequent cycling. Crucially, the deployment of Internet of Things (IoT) sensors and connectivity modules allows for continuous monitoring of critical parameters—pressure, temperature, conductivity, and water level—which are transmitted to cloud-based platforms. These platforms utilize proprietary software for data analytics, enabling remote diagnostics, real-time performance benchmarking, and automated reporting, critical features for large, multi-site industrial operations.

Innovation in water treatment is also pivotal, as water quality directly impacts generator lifespan and efficiency. Technologies such as reverse osmosis (RO) systems, deaeration mechanisms, and chemical dosing systems are increasingly being integrated directly into the generator package to ensure high-purity feed water, minimizing scale, sludge, and corrosion—the leading causes of system failure and energy loss. Modular design principles are gaining traction, allowing for scalable steam solutions and facilitating easier installation and maintenance in space-constrained environments. These modular, often containerized units, provide plug-and-play functionality, greatly reducing on-site commissioning time for large industrial installations.

Regional Highlights

- North America: North America commands a substantial share of the water vapor generator market, driven by its highly mature industrial infrastructure, stringent safety regulations enforced by bodies like OSHA and FDA, and high rate of technology adoption. The demand is particularly robust in the healthcare sector, where regulatory requirements for sterilization processes necessitate reliable, high-purity steam generation. The region exhibits a strong preference for electric and highly efficient gas-fired generators, particularly those featuring advanced connectivity and emission reduction technologies. The replacement cycle for aging industrial boilers and the expansion of centralized HVAC systems in commercial real estate continue to be primary market drivers. Furthermore, the burgeoning data center industry requires precise humidification, maintaining continuous demand for specialized, non-contaminating vapor generation systems, especially in cooling infrastructure.

- Europe: Europe is characterized by a mature market heavily influenced by ambitious decarbonization goals and energy efficiency directives (e.g., the Ecodesign Directive). This regulatory environment strongly favors highly efficient condensing boilers and electric water vapor generators powered by renewable sources. Germany, the UK, and France are major contributors, driven by significant investments in the pharmaceutical, chemical, and precision manufacturing sectors, all requiring certified steam quality. European end-users prioritize long-term sustainability and TCO, leading to higher adoption rates of generators equipped with sophisticated energy recovery systems and remote monitoring capabilities. The expansion of district heating networks across Scandinavia and Eastern Europe further solidifies the regional demand for large-capacity, centralized steam generation units, designed for optimized thermal distribution across urban areas.

- Asia Pacific (APAC): APAC is poised for the most rapid growth during the forecast period, fueled by rapid industrialization, urbanization, and vast infrastructure development, particularly in China, India, and Southeast Asian countries. The healthcare and Food & Beverage sectors are expanding exponentially, necessitating large volumes of steam for sterilization and processing. While cost sensitivity remains a factor, the increasing awareness of efficiency and safety standards, often driven by exports to Western markets, is accelerating the adoption of modern, high-quality generators. Governments in the region are increasingly offering incentives for industrial modernization and the reduction of localized pollution, spurring the transition from legacy, coal-fired systems to cleaner natural gas or electric generators. The regional market is highly competitive, with both global giants and localized manufacturers vying for market share by offering scalable and price-competitive solutions tailored to specific regional industrial needs.

- Latin America (LATAM): The Latin American market is experiencing steady growth, anchored by the expansion of the petrochemical, mining, and food processing industries, particularly in Brazil and Mexico. Demand for water vapor generators is often tied to large capital projects and the modernization of existing industrial plants. Market development is sometimes constrained by economic volatility and infrastructure limitations, impacting the widespread adoption of high-end smart generators. However, growing foreign direct investment in manufacturing and the tightening of environmental regulations are progressively pushing businesses toward more efficient and reliable steam generation technology. The focus remains on robust, easy-to-maintain units capable of operating reliably under varied fuel quality and environmental conditions.

- Middle East and Africa (MEA): The MEA region presents unique dynamics. Demand in the Middle East is heavily concentrated in the oil and gas sector (for enhanced oil recovery and process heating) and large construction projects (including hospitals and luxury hotels). The abundance of natural gas often makes fuel-fired generators the preferred choice, although water scarcity necessitates highly efficient water treatment and recovery systems integrated with the generators. In Africa, market penetration is slower but accelerating in industrial hubs (South Africa, Nigeria), driven by the manufacturing sector and emerging healthcare infrastructure. The market seeks durable, modular solutions that can handle intermittent power supply and operate efficiently in challenging climates, often favoring suppliers who can provide comprehensive, turn-key installation and long-term service contracts.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Water Vapor Generator Market.- Meggitt PLC: A key player focusing on highly engineered products and controls, often serving aerospace and defense applications but extending expertise into high-reliability industrial heating solutions, including custom steam components.

- Spirax Sarco Engineering: A global leader renowned for thermal energy management solutions, offering comprehensive systems including boilers, controls, and ancillary steam distribution equipment, emphasizing energy efficiency and system optimization.

- Miura Co., Ltd.: Recognized globally for compact, high-efficiency modular boilers and steam generators, Miura emphasizes quick steam startup, small footprints, and advanced monitoring systems, particularly popular in manufacturing sectors requiring instantaneous steam.

- Clayton Industries: Specializes in coil-type, high-pressure steam generators, known for rapid response, high efficiency, and safety, often targeting industrial process applications requiring quick modulation of steam output.

- Chromalox, Inc.: A major provider of electric heating solutions, including resistance-type water vapor generators and auxiliary equipment, catering heavily to process heating and commercial humidification applications requiring precise control.

- Fulton Boiler Works, Inc.: Focuses on vertical and horizontal steam boilers and thermal fluid heaters, offering robust and reliable solutions across commercial, industrial, and institutional markets, with a strong focus on ease of maintenance.

- Aalborg Engineering: Primarily active in the marine and energy sectors, providing custom boiler solutions, including waste heat recovery steam generators, playing a crucial role in improving overall plant thermal efficiency.

- Cleaver-Brooks: A market stalwart offering a broad portfolio of boiler room solutions, including firetube and watertube boilers, controls, and burners, emphasizing efficiency, safety, and comprehensive after-market support.

- Thermodyne Engineering: Specializes in industrial boilers and thermal equipment, providing tailored solutions for various process industries with a focus on fuel versatility and rugged, long-lasting construction.

- Bosch Industriekessel: Part of the wider Bosch group, providing industrial boiler systems, including steam and hot water boilers, prioritizing environmental compatibility, operational efficiency, and smart connectivity solutions.

- Babcock & Wilcox Enterprises: Focuses on advanced steam generation technology for power generation, environmental systems, and industrial applications, known for large, high-capacity utility and industrial boilers.

- Parker Boiler: Offers custom and standard steam and hot water boilers, specializing in systems for commercial laundry, dry cleaning, and general process applications, emphasizing durable and compact designs.

- Sussman Electric Boilers: Dedicated to manufacturing electric steam and hot water boilers, catering to specialized markets like culinary steam, sterilization, and humidification where cleanliness and electric operation are prioritized.

- Lattner Boiler Manufacturing: Provides electric, fuel-fired, and gas-fired packaged boilers, offering reliable and versatile options for small to medium industrial and institutional users, focusing on streamlined installation.

- Piston Group: (Assuming a representative company focused on components/systems integration relevant to thermal management or industrial controls, typical in market reporting.)

- Columbia Boiler: Manufactures packaged firetube steam and hot water boilers known for durability and high efficiency across commercial and industrial applications.

- Rentech Boiler Systems: Focuses on highly engineered steam generation solutions, including heat recovery steam generators (HRSG) and industrial package boilers for utility and heavy industrial use.

- Vapor Power International: Specializes in coil tube steam generators and thermal fluid heaters, known for quick-start capability and compact size, serving mobile and stationary industrial requirements.

- Siemens Energy: Provides substantial steam generation components and integrated energy systems, including large industrial boilers and control technology, particularly in power and heavy process industries.

- Alfa Laval: Known for its specialized heat transfer, separation, and fluid handling products, offering plate heat exchangers crucial for optimizing steam system performance and energy recovery.

Frequently Asked Questions

Analyze common user questions about the Water Vapor Generator market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary factors driving the adoption of electric water vapor generators?

The primary drivers for electric water vapor generators include the global push for decarbonization and zero-emission operation at the point of use, facilitating compliance with strict environmental regulations. Additionally, their inherent benefits—quick start-up, low maintenance due to the absence of flues, precise control, and ability to integrate seamlessly with renewable energy sources—make them ideal for sterilization and humidification applications where high purity and reliability are critical.

How does AI technology enhance the operational efficiency and lifespan of modern steam generators?

AI significantly enhances operational efficiency by implementing predictive maintenance strategies. By analyzing real-time sensor data (pressure, temperature, conductivity), AI algorithms can forecast component failure or scaling buildup, scheduling maintenance before breakdowns occur, thereby maximizing uptime and extending the generator's useful life. Furthermore, AI optimizes energy consumption by dynamically adjusting steam production to match fluctuating load demands, reducing overall fuel or electricity expenditure.

Which end-user industries represent the largest market share for high-capacity water vapor generators?

The largest market share for high-capacity water vapor generators is typically concentrated within heavy industrial sectors, including the Chemical and Petrochemical industries (requiring high-pressure steam for distillation and process heating), the Power Generation sector (for turbine operation and co-generation), and the Food and Beverage industry (for large-scale cooking, canning, and high-volume sterilization processes). These sectors demand continuous, high-volume steam supply, necessitating robust, large-capacity industrial boiler systems.

What regulatory standards most significantly influence the design and certification of water vapor generators?

The design and certification are primarily governed by international pressure vessel codes, such as the ASME Boiler and Pressure Vessel Code (BPVC) in North America, and the Pressure Equipment Directive (PED) in Europe. Additionally, generators used in food processing and healthcare must comply with hygiene standards set by organizations like the FDA, ensuring steam quality and material safety. Environmental regulations, particularly those concerning NOx and CO emissions, drive technological choices for fuel-fired units globally.

What is the main challenge associated with operating water vapor generators in water-scarce regions?

The main challenge in water-scarce regions is minimizing water consumption and managing water quality. Generators inherently consume large volumes of water (or steam loss), necessitating significant investment in advanced water treatment systems such as sophisticated recycling, blowdown heat recovery, and high-efficiency water treatment (e.g., reverse osmosis) to conserve resources, prevent rapid scaling, and ensure economical operation under constrained environmental conditions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager